Thin-oil-sealing gas holder

A technology of gas cabinets and thin oil, which is applied in the direction of adjustable capacity gas storage tanks, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problem of uneven heating of sealing oil, inability to seal the best performance temperature of oil, thin oil Problems such as the inability of the sealed gas cabinet to operate efficiently and stably, to achieve the effect of evenly heating the sealing oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

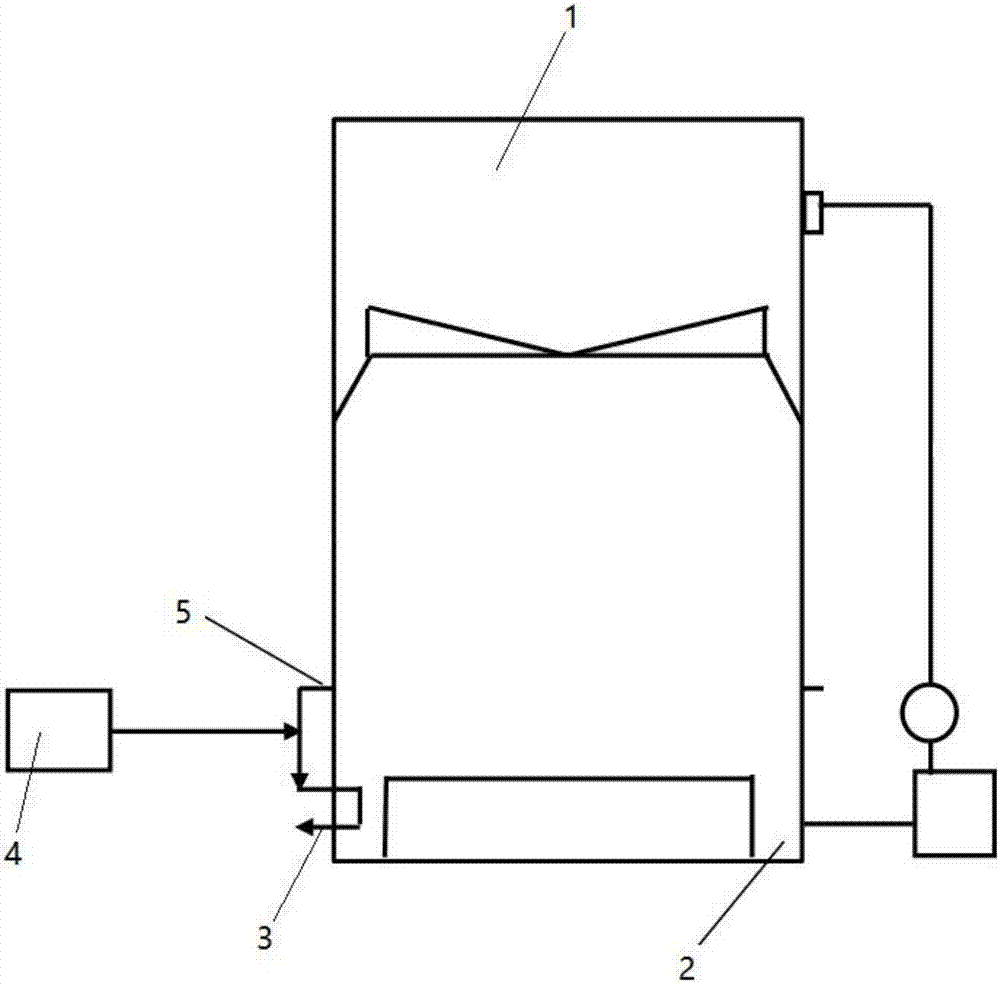

[0034] The embodiment of the present invention provides a thin oil sealed gas cabinet, please refer to figure 1 , figure 2 , the gas cabinet includes:

[0035] Gas cabinet body 1.

[0036] Specifically, the gas main cabinet 1 is a thin oil sealed gas cabinet.

[0037] Oil groove at the bottom of the cabinet 2.

[0038] Specifically, the tank bottom oil groove 2 is located at the lower end of the gas tank body 1 for storing thin oil.

[0039] Bottom heating water pipe 3.

[0040] Specifically, the bottom heating water pipe 3 is located in the oil ditch 2 at the bottom of the cabinet, and hot water flows through the bottom hot water pipe 3 for heating the thin oil in the oil ditch 2 at the bottom of the cabinet. The bottom heating water pipes 3 can be arranged in multiple groups, which are evenly distributed in the oil ditch 2 at the bottom of the cabinet, so as to achieve the technical effect of evenly heating the thin oil in the oil ditch 2 at the bottom of the cabinet.

...

Embodiment 2

[0060] The embodiment of the present invention provides a heating device for a thin oil sealed gas tank, please refer to figure 1 , figure 2 , wherein the thin oil-sealed gas cabinet includes:

[0061] Gas cabinet body 1.

[0062] Specifically, the gas main cabinet 1 is a thin oil sealed gas cabinet.

[0063] Oil groove at the bottom of the cabinet 2.

[0064] Specifically, the tank bottom oil groove 2 is located at the lower end of the gas tank body 1 for storing thin oil.

[0065] The heating device includes:

[0066] A bottom heating water pipe 3, the bottom heating water pipe 3 is located in the oil ditch 2 at the bottom of the cabinet; a heat source 4, the heat source 4 communicates with the bottom heating water pipe 3; wherein, the heat source 4 inputs hot water to make the The bottom heating water pipe 3 has a first predetermined temperature, so that the thin oil in the oil ditch 3 at the bottom of the cabinet has a second predetermined temperature.

[0067] Bott...

Embodiment 3

[0088] The embodiment of the present invention provides a specific implementation of a heating device for a thin oil-sealed gas tank, please refer to figure 1 , figure 2 .

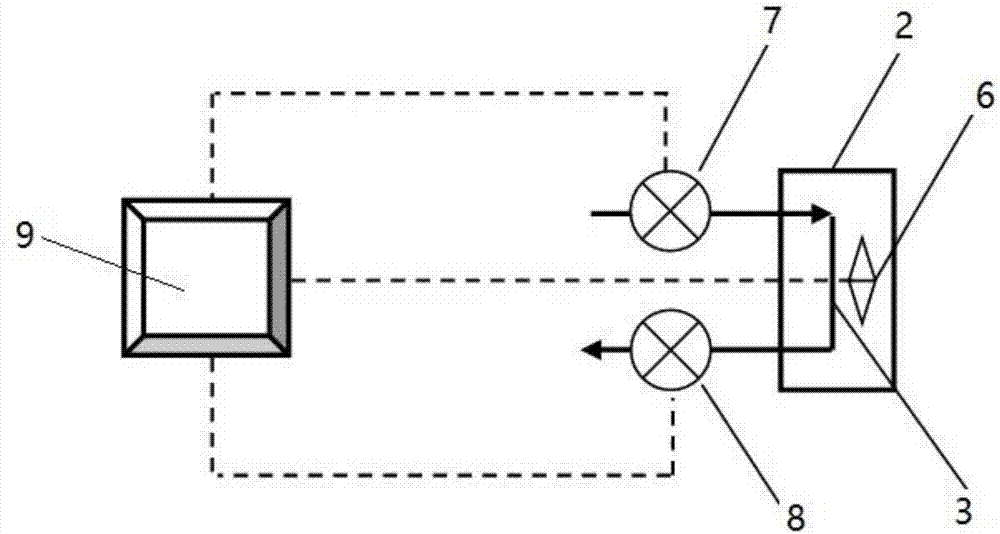

[0089] The heat source 4 is hot water with a temperature of 80-90°C provided by the factory, and the gas cabinet 1 is provided with an external heat exchange ring pipe 5, and one end of the external heat exchange ring pipe 5 is connected to the heat source 4 connected, the other end leads to six bottom heating water pipes 3, and the six bottom heating water pipes 3 are evenly distributed inside the oil ditch 2 at the bottom of the cabinet. An oil temperature sensor 6 is arranged near each bottom heating water pipe 3 for sensing the oil temperature near the bottom heating water pipe 3 . The six oil temperature sensors 6 are connected to the controller 9 respectively, and send the sensed oil temperature information to the controller 9 .

[0090] Each of the bottom heating water pipes 3 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com