Anti-dried fire-controlling gas combustion range

A gas stove and anti-dry burning technology, applied in the field of gas stoves, can solve the problems of high cost, control, temperature rise of kitchen utensils, etc., and achieve the effects of low cost and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

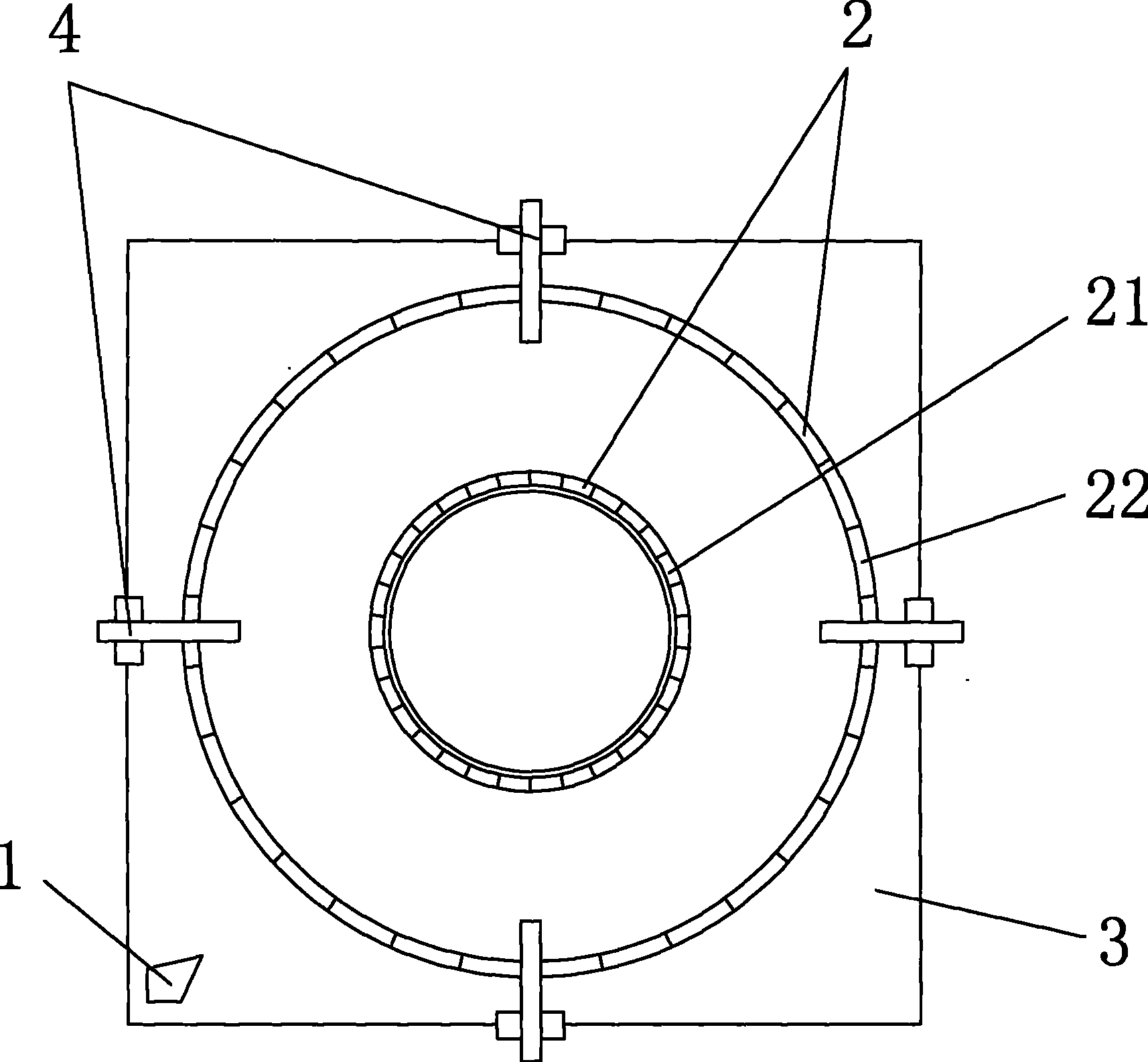

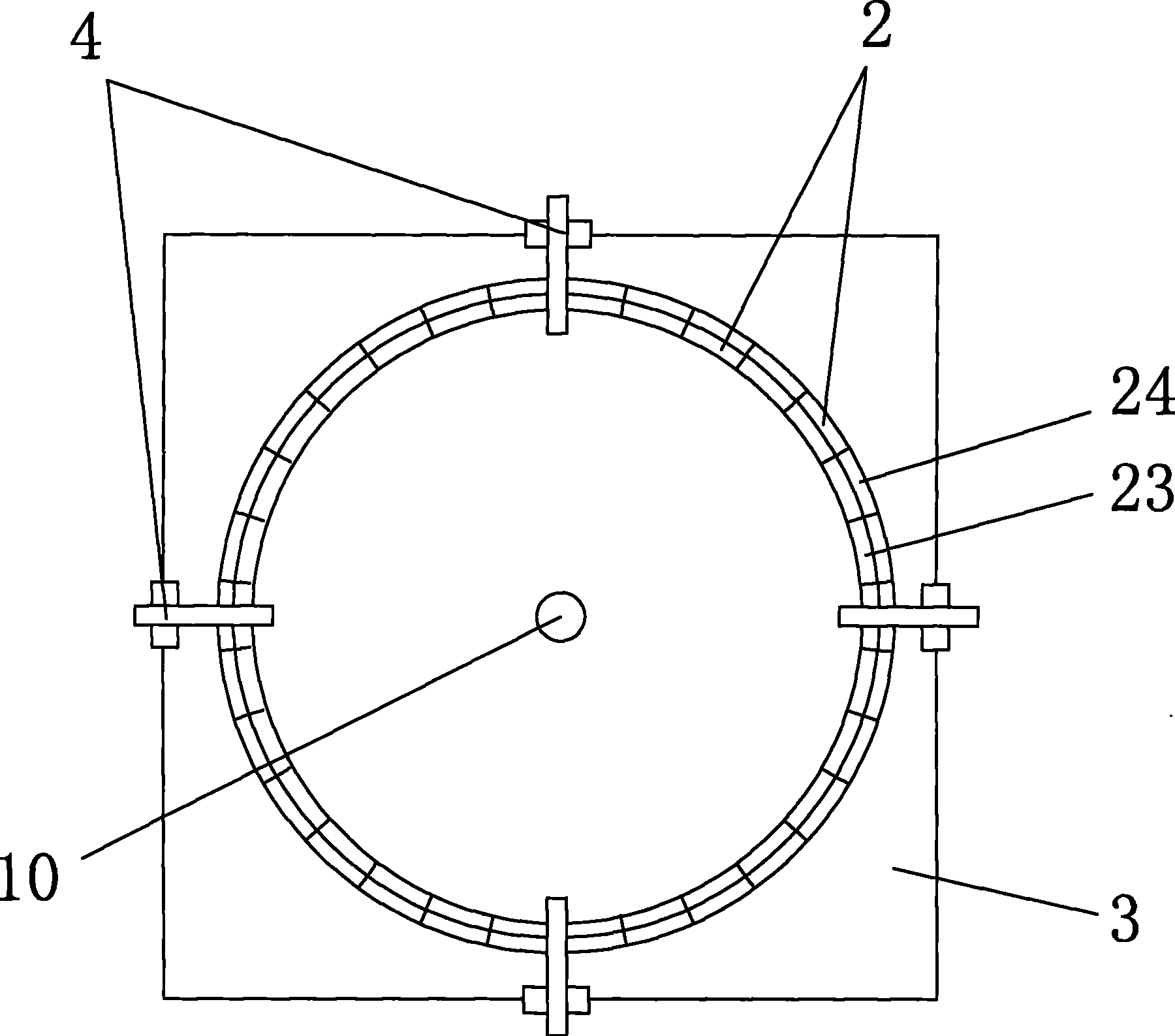

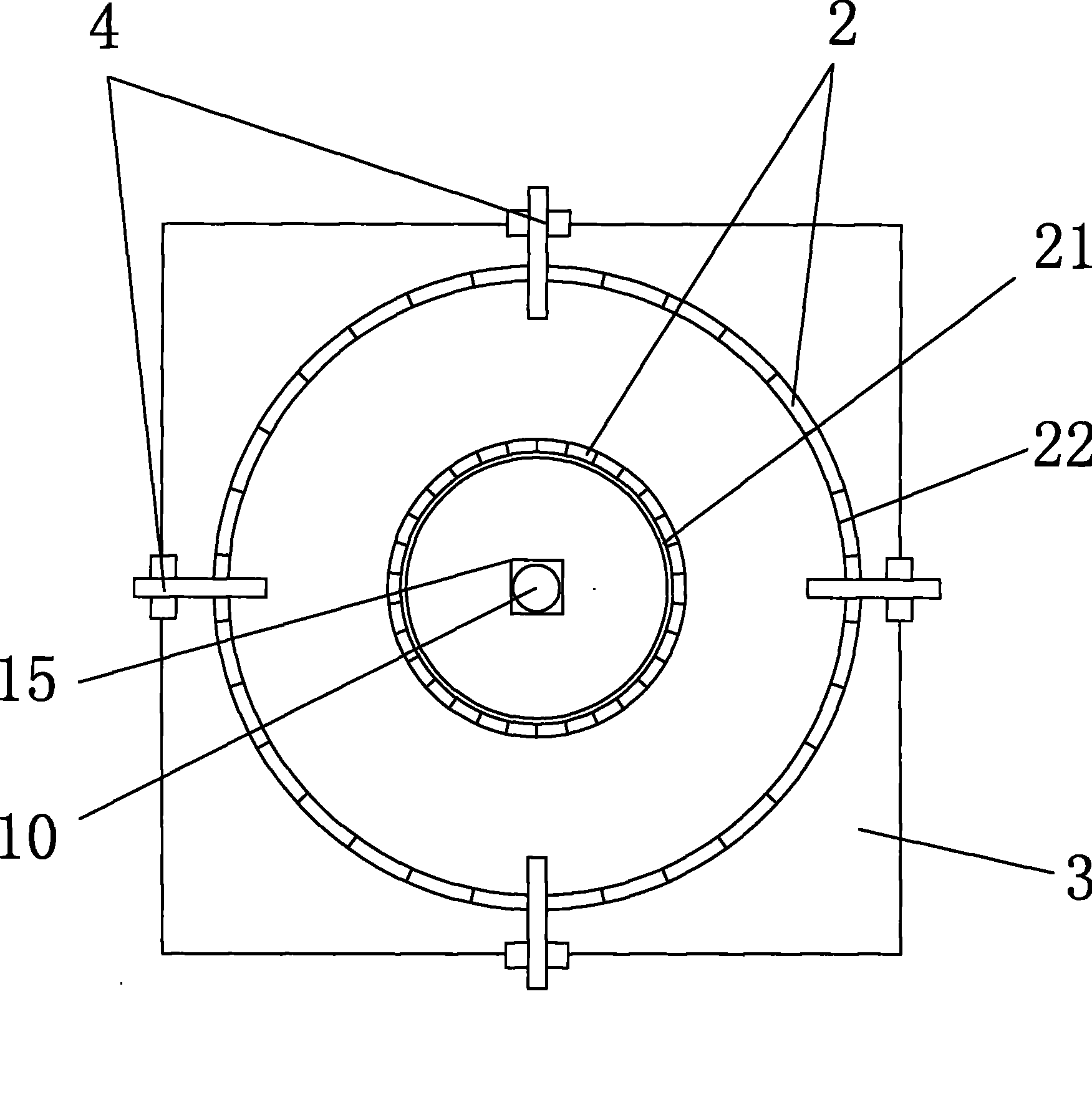

[0029] Such as figure 1 Shown in the figure is the top view diagram of the existing double-ring single-circle fire hole stove head. The burner combustion ring 2 on the gas stove shown in the figure has two inner and outer combustion rings 21, 22, and a circle of fire holes is arranged on each ring. This is also the composition of the combustion ring of the most common burner stove head in the gas stove currently in use. Of course, there are single-ring or multi-ring burner stove heads, which will not be explained here. Usually, each combustion ring 2 There is only a circle of fire holes. At the same time, in order to avoid damage to the kitchen utensils 5 due to operation or negligence, the kitchen utensils 5 are dry-burned for too long, so in the prior art, a temperature detection device 1 is arranged on the appropriate position of the gas cooktop 3, and the temperature The detection device 1 is usually a short-distance temperature sensing device such as an infrared transcei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com