Automatically-controlled constant-temperature circulating and lubricating device

A cyclic lubrication, self-controlled constant temperature technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as shortening unit life, inconvenient lubrication operation, and lack of good control of lubricating oil temperature value. , to achieve the desired effect of prolonging life and lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

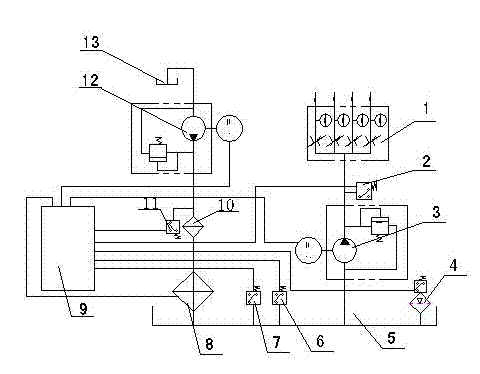

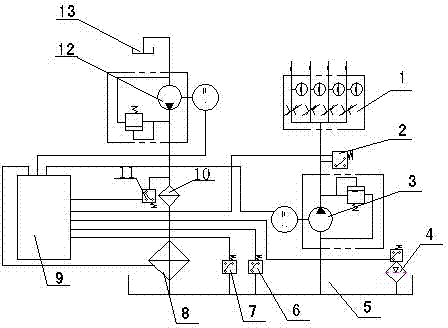

[0013] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] As shown in the drawings, a self-controlled constant temperature circulation lubrication device includes a control system 9, an oil storage tank 5, an oil supply pump 3 controlled by the control system 9 and connected to the oil storage tank 5, and a plurality of pumps for supplying oil to corresponding lubrication points. Oil and lubricating branch 1 connected with oil supply pump 3, oil return pump 12 connected with oil pool 13 of machine tool controlled by control system 9 and oil filter 10 connected with oil return pump 12, it also includes refrigeration system 8, said The refrigeration system 8 is arranged between the oil return pump 12 and the oil storage tank 5, and the refrigeration system 8 is electrically connected with the control system 9. In this specific embodiment, the refrigeration system 8 is a heat exchanger.

[0015] The contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com