Test device of axial directional displacement of pipeline considering tension action of steel catenary riser

A technology of steel catenary and test device, which is applied in the direction of measuring device, testing of machine/structural components, instruments, etc., can solve the problems of difficult leveling of soil surface, excessive stress and large test size, etc.

Inactive Publication Date: 2017-12-12

TIANJIN UNIV

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The actual measurement data of the submarine pipeline reveals that every kilometer of the submarine pipeline can move tens of centimeters in the axial direction during a heating and cooling process, and the axial movement of the submarine pipeline can reach several meters during the entire service period of the submarine pipeline. Excessive stress in the tee / cross or jumper pipeline, loss of tension in the catenary riser and other adverse effects

Therefore, the axial directional movement caused by the tension of the steel catenary riser under the action of temperature and pressure is a problem that must be considered in the design of deep sea pipelines

At present, due to factors such as difficult control of the oil temperature in the test, large test size, and difficult leveling of the soil surface, most scholars remain at the stage of theoretical or numerical analysis on the law of axial directional movement of pipelines.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

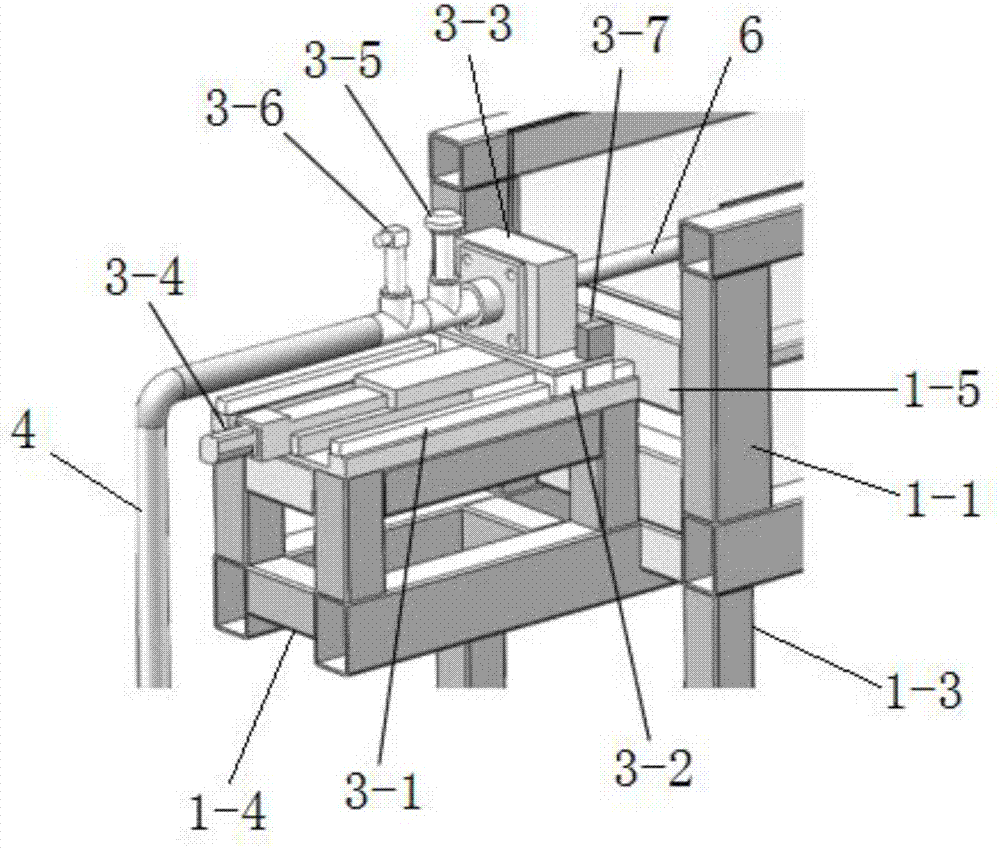

[0041] This test intends to study the axial directional displacement law of the pipeline under the effect of 50N tension on one side of the pipeline and continuous and rapid introduction of heat transfer oil at 80℃.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Login to View More

Abstract

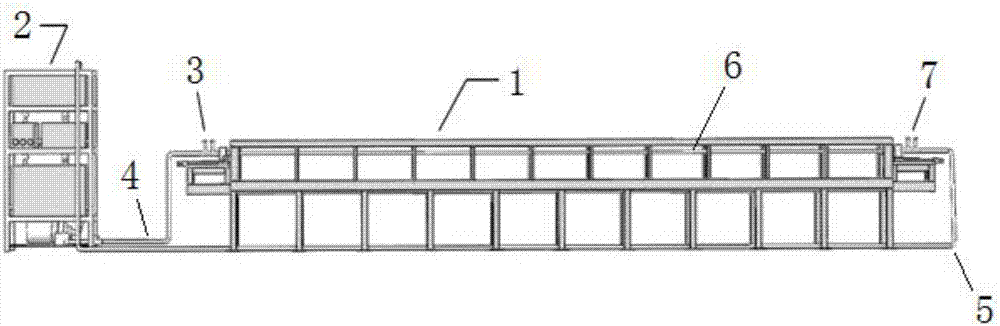

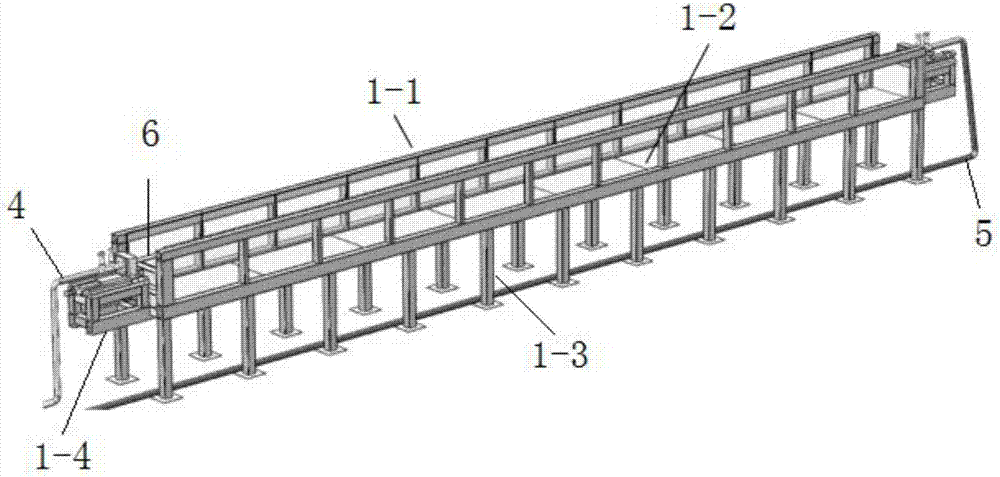

The invention discloses a test device of axial directional displacement of a pipeline considering the tension action of a steel catenary riser. The test device comprises a test groove, oil transportation equipment, an oil outlet pipeline, an oil return pipeline, an outlet collection device, an outlet collection device and a test oil transportation pipe. Innovatively, according to the device, hot oil can be circulated in the pipelines, at the same time, the tensile force is exerted on the pipelines, and the magnitude of the tensile force can be adjusted, so that the situation a submarine pipeline can cause the axial direction displacement under the tension action of the steel catenary riser. Therefore, the influence of different magnitudes of tensile force on the rule of axial movement of the submarine pipeline is researched. Moreover, the speed and temperature of oil entering into the submarine pipeline can be accurately controlled by the device, so that a corresponding temperature variation curve of the submarine pipeline is obtained. Therefore, the influence of different temperature variation conditions on the axial directional displacement of the submarine pipeline.

Description

Technical field [0001] The invention belongs to the field of offshore oil and gas transportation engineering, and in particular relates to a test device considering the axial directional displacement of a pipeline under the tension of a steel catenary standpipe. Background technique [0002] With the further development of my country's offshore oil and gas resources, offshore oil and gas transportation is also facing greater challenges. As the main means of oil and gas transportation, submarine oil pipelines can be as long as hundreds of kilometers, and due to water depth limitations, pipeline maintenance is difficult. Once an accident occurs, it will cause economic, environmental, and ecological losses and cause irreversible consequences. Therefore, in the design stage, the pipeline should be systematically studied to analyze potential safety hazards to ensure the smooth progress of production. The axial directional movement of pipelines is a new problem in deep-sea pipeline en...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M99/00

CPCG01M99/00G01M99/002

Inventor 刘润陆罗观李贝贝彭碧瑶

Owner TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com