All-in-one integrated commercial vehicle electric drive axle

An integrated technology for commercial vehicles, applied in the direction of motors, axles, wheels, etc., can solve the problems of the transmission shaft occupying layout space, low transmission efficiency, and large volume, achieve good heat dissipation effect, improve the use environment, and increase the heat dissipation area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the embodiments.

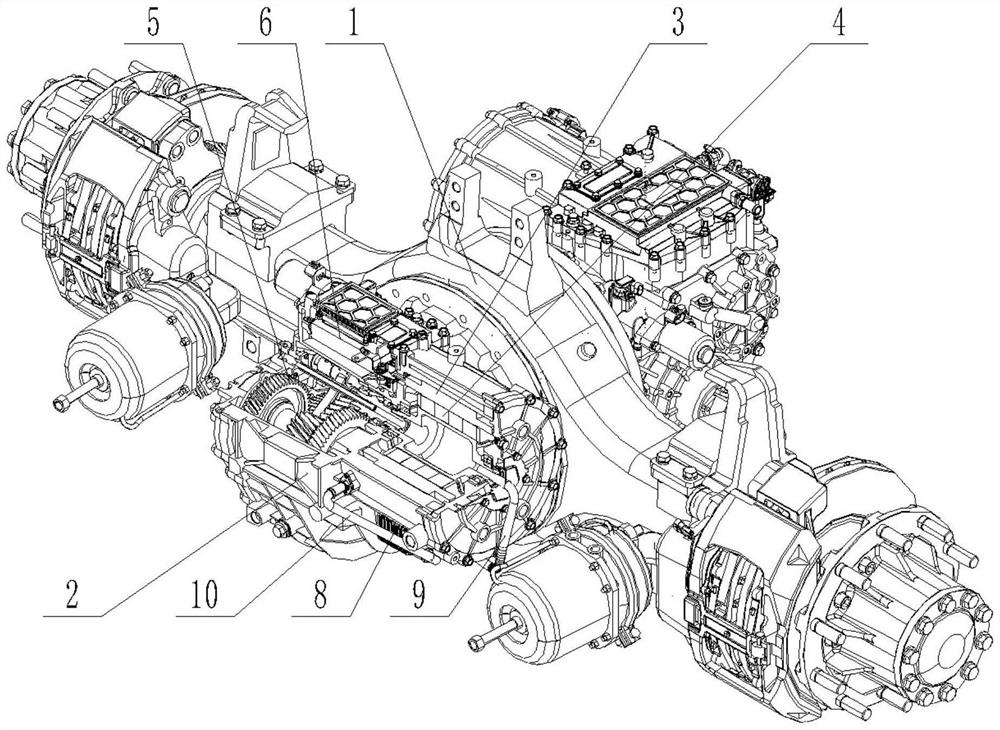

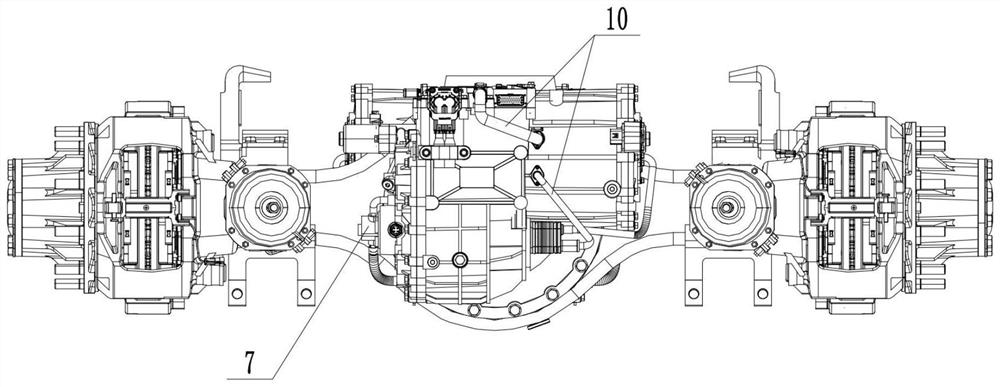

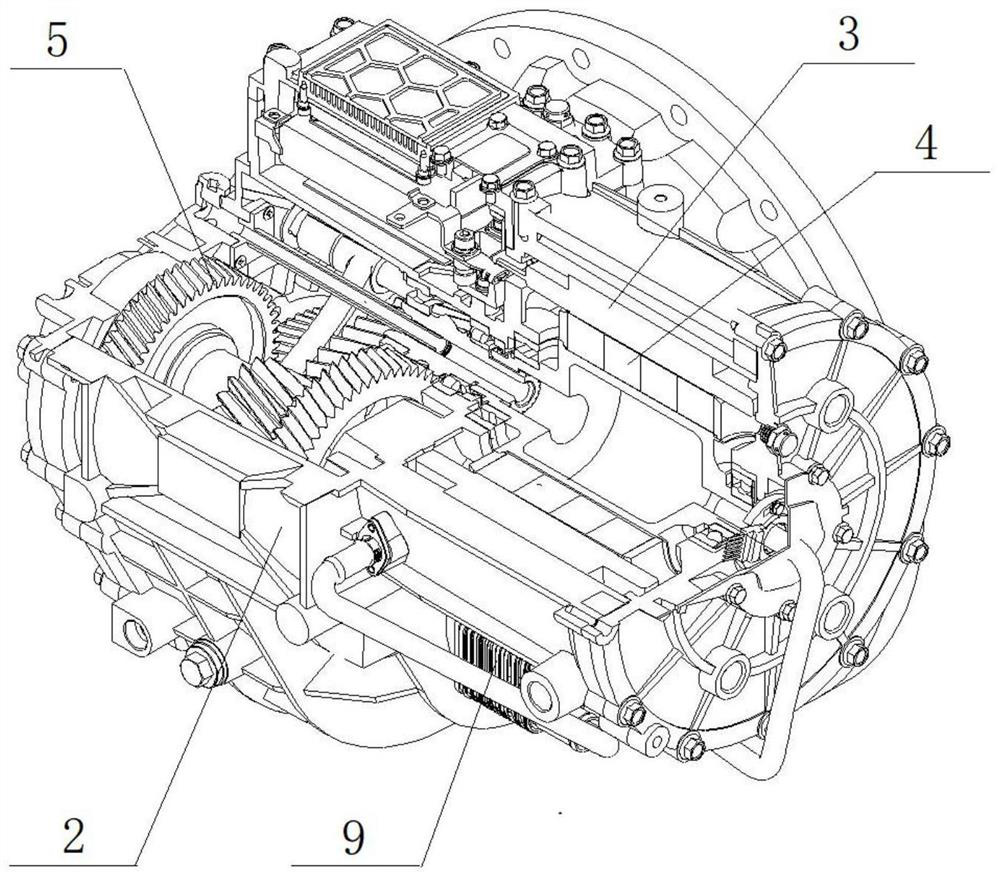

[0033] like figure 1 , figure 2 , image 3 The shown all-in-one integrated commercial vehicle electric drive axle includes an axle 1 and two sets of powertrains installed on the front and rear sides of the axle 1 in a central symmetry, each set of powertrains includes a housing 2, a motor, Gearbox, motor controller 6. The motor stator 3 is fixed on the housing 2 by means of interference fitting, the motor rotor 4 is fixed on the housing 2 by the shafting 5, the shafting 5 is fixed on the housing 2 by bearings, and the motor controller 6 is fixed on the housing 2 by bolts. On the casing 2, the oil pump 7 is fixed on the casing 2 by bolts, the heat exchanger 8 is fixed on the casing 2 by bolts, the oil pump 7 and the oil delivery hole of the shafting 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com