Modified bamboo fiber reinforced asphalt mixture and preparation method thereof

A technology of asphalt mixture and bamboo fiber, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation of modified bamboo fiber reinforced asphalt mixture, concrete steps are:

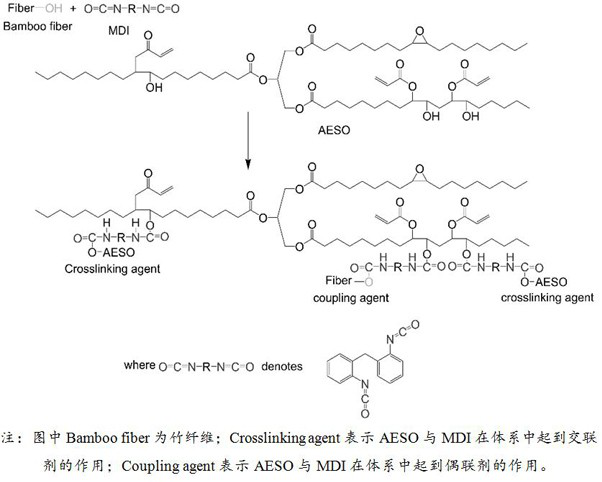

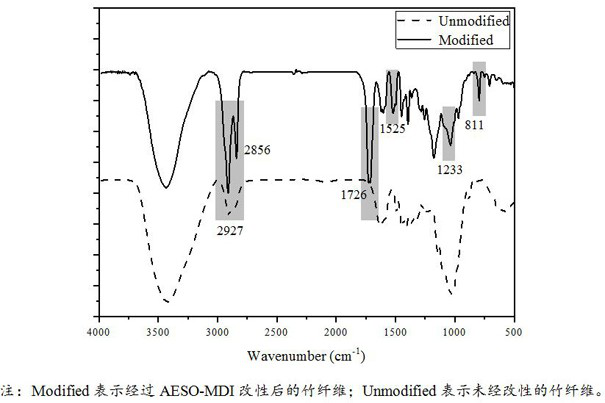

[0041] 1) Bamboo fiber modification process: Weigh 50g of dried bamboo fiber and 5g of AESO resin (the amount of AESO accounts for 10% of the mass of bamboo fiber), mix AESO and acetone in a weight ratio of 1:2 to form a solution, and spray it evenly on the Bamboo fiber surface, and then placed in an oven at 50 ° C for 30 minutes to make the acetone completely volatilize. Weigh 5.5g of MDI (its mass accounts for 10% of the total mass of AESO and bamboo fiber), add 0.55g of dibutyltin dilaurate (DBT, its mass accounts for 10% of the mass of MDI) to spray the surface of the fiber, mix well and put it in the oven Dry at 103°C for 10 minutes to obtain the modified bamboo fiber.

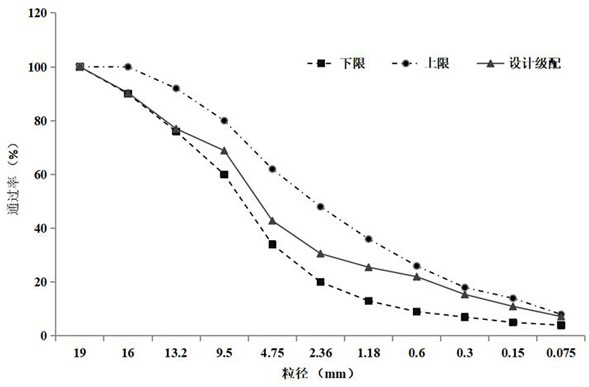

[0042] 2) Marshall sample preparation of modified bamboo fiber asphalt mixture: basalt aggregates are divided into three grades of 10-20mm, 5-10mm, and 0-3mm according to particle size, and the basalt aggreg...

Embodiment 2

[0044] The preparation of modified bamboo fiber reinforced asphalt mixture composite material, the specific steps are:

[0045] 1) Bamboo fiber modification process: Weigh 50g of dried bamboo fiber, 7.5g of AESO resin (the amount of AESO accounts for 15% of the mass of bamboo fiber), mix AESO and acetone in a weight ratio of 1:2 to form a solution, and spray evenly with a watering can Put it on the surface of bamboo fiber, then put it in an oven and dry it at 50°C for 30 minutes to make the acetone completely volatilize. Weigh 5.75g of MDI (its mass accounts for 10% of the total mass of AESO and bamboo fiber), add 0.575g of dibutyltin dilaurate (DBT, its mass accounts for 10% of the mass of MDI) to spray the surface of the fiber, mix well and put it in the oven Dry at 103°C for 10 minutes to obtain modified bamboo fiber.

[0046] 2) Marshall sample preparation of modified bamboo fiber asphalt mixture: basalt aggregates are divided into three grades of 10-20mm, 5-10mm, and 0-3...

Embodiment 3

[0048] The preparation of modified bamboo fiber reinforced asphalt mixture, concrete steps are:

[0049] 1) Bamboo fiber modification process: Weigh 50g of dried bamboo fiber and 10g of AESO resin (the amount of AESO accounts for 20% of the mass of bamboo fiber), mix AESO and acetone in a weight ratio of 1:2 to form a solution, and spray it evenly on the Bamboo fiber surface, and then placed in an oven at 50 ° C for 30 minutes to make the acetone completely volatilize. Weigh 6g of MDI (its mass accounts for 10% of the total mass of AESO and bamboo fiber), add 0.6g of dibutyltin dilaurate (DBT, its mass accounts for 10% of the mass of MDI) to spray the surface of the fiber, mix well and put it into the oven 103 Dry at ℃ for 10 minutes to obtain modified bamboo fiber.

[0050] 2) Marshall sample preparation of modified bamboo fiber asphalt mixture: basalt aggregates are divided into three grades of 10-20mm, 5-10mm, and 0-3mm according to particle size, and the basalt aggregates...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Marshall stability | aaaaa | aaaaa |

| Destruction strength | aaaaa | aaaaa |

| Destruction strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com