Self-insulation composite wall body structure, installation mode, performance testing method and application of self-insulation composite wall body structure

A composite wall and installation technology, applied in the testing of machine/structural components, vibration testing, testing of mechanical components, etc., can solve the problems of easy aging, poor thermal insulation performance of external walls, falling off, etc., and achieve interface bonding ability. Lifting, combined performance and improved seismic performance, superior thermal insulation and combined performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

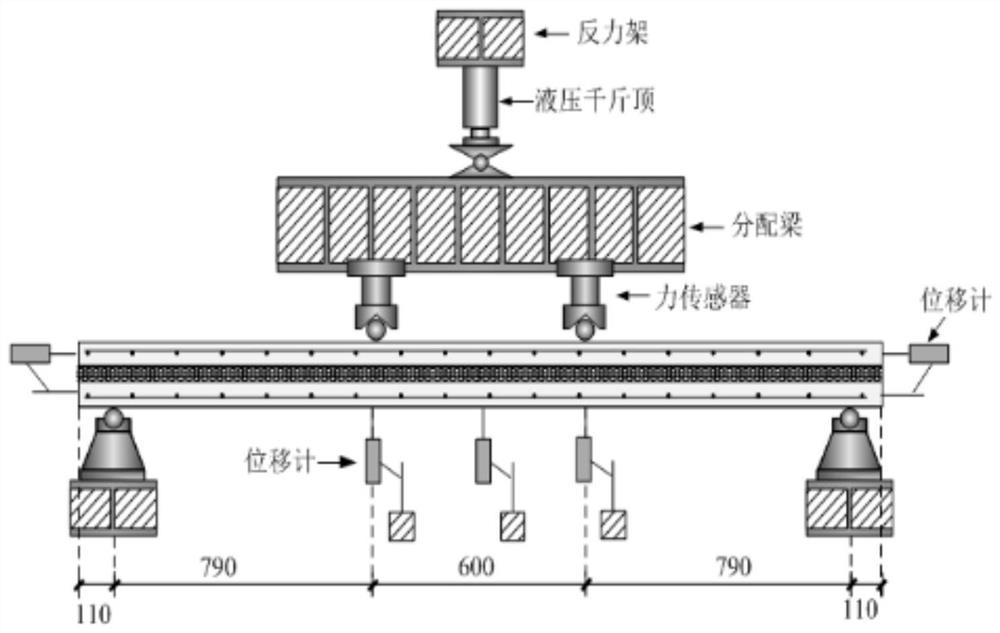

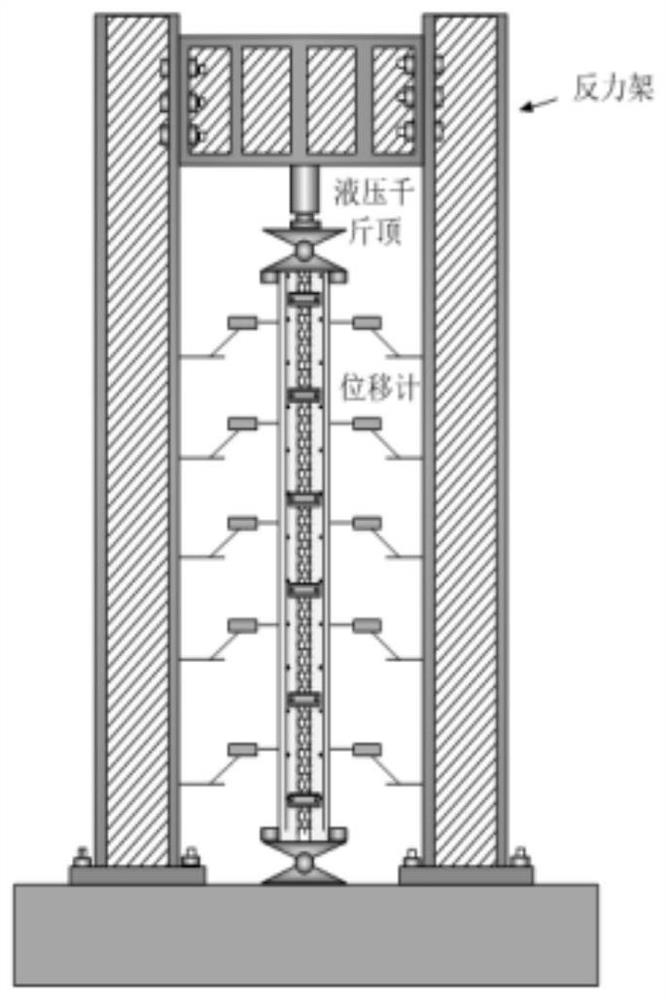

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

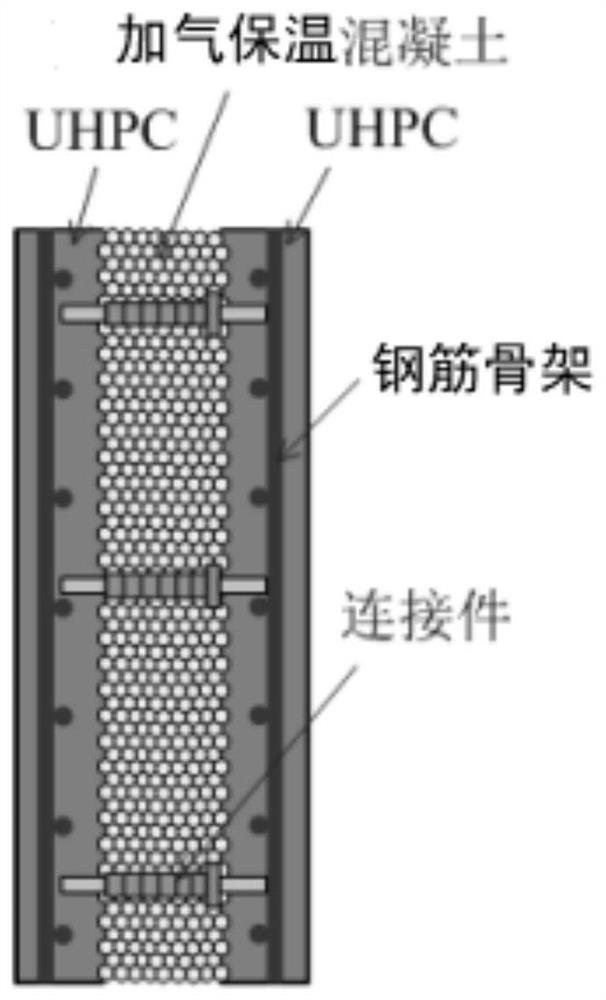

[0030] A self-insulating composite wall structure proposed by the present invention includes two layers of ultra-high-performance concrete inside and outside and aerated heat-retaining concrete in the middle layer. The aerated heat-retaining concrete is provided with a connecting piece that penetrates the two layers of the connecting piece. The ends respectively extend into the inner and outer layers of ultra-high performance concrete;

[0031] The ultra-high-performance concrete layer is provided with steel cages, and the inner layer of ultra-high-performance concrete, the aerated thermal insulation concrete layer and the outer layer of ultra-high-performance concret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com