Covalent triazine organic framework material as well as preparation method and application thereof

A technology of organic framework and covalent triazine, which is applied in the field of chemical materials, can solve the problems of high requirements for equipment conditions and inability to produce mass production well, and achieve the effects of low requirements for reaction conditions, easy batch synthesis, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

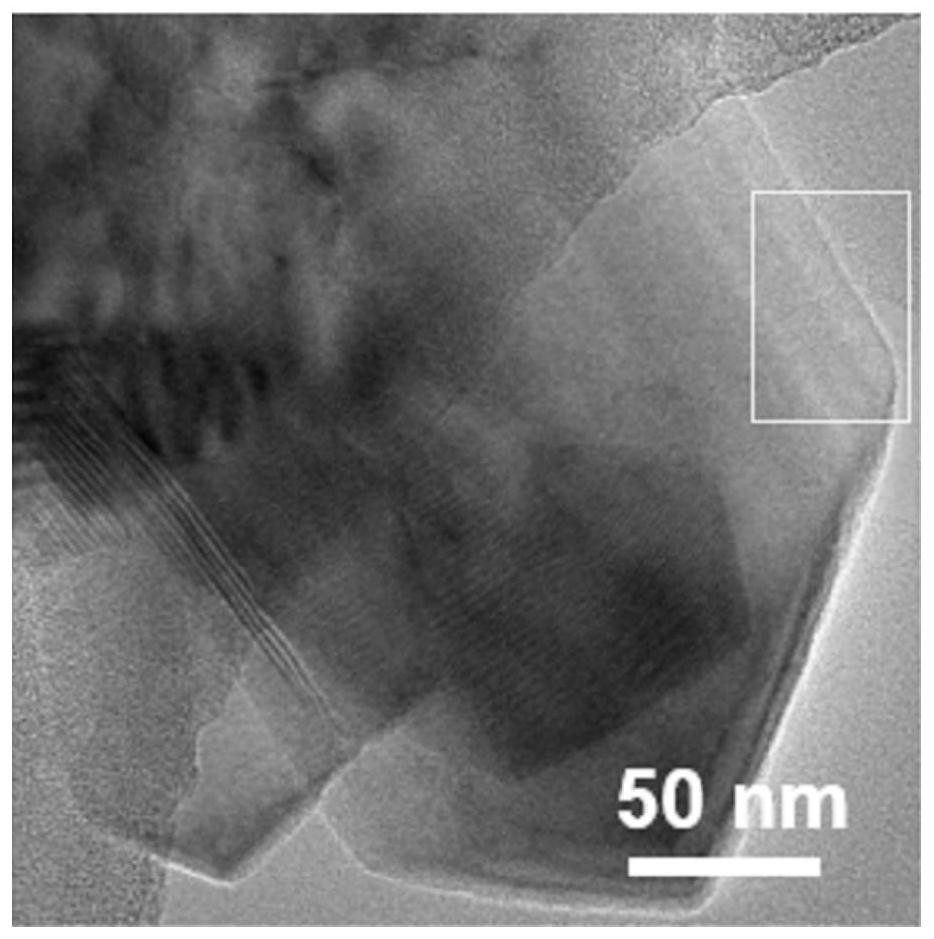

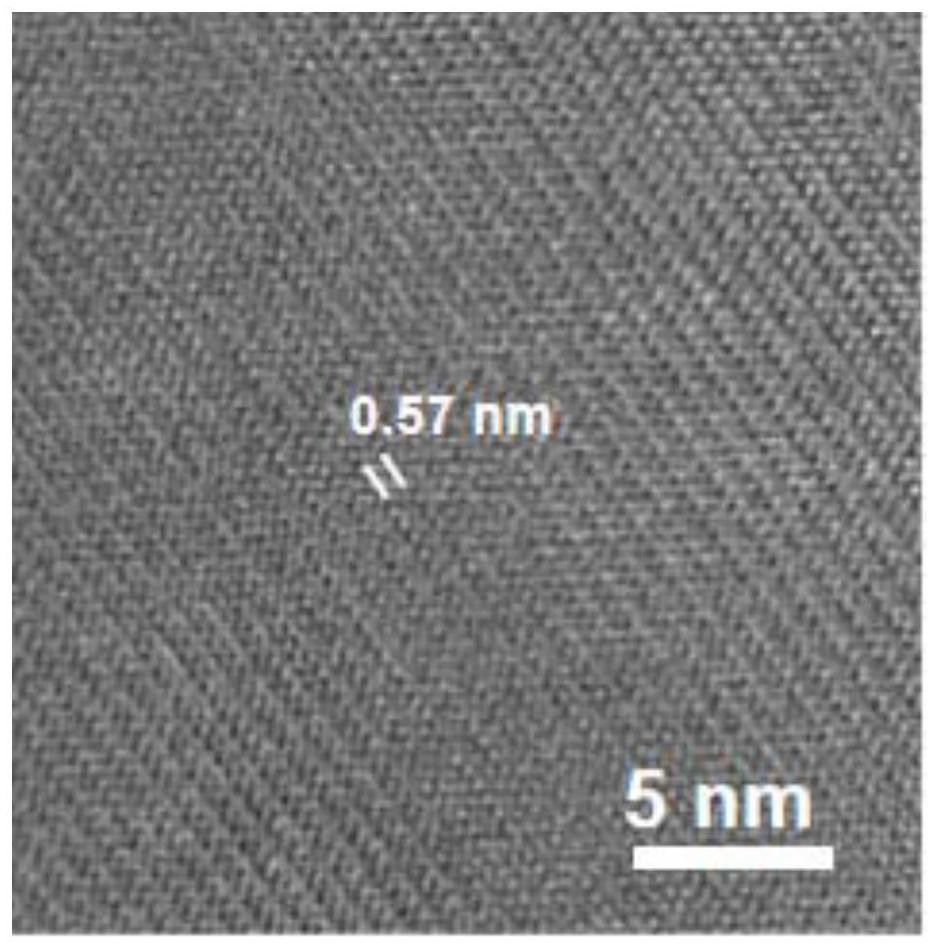

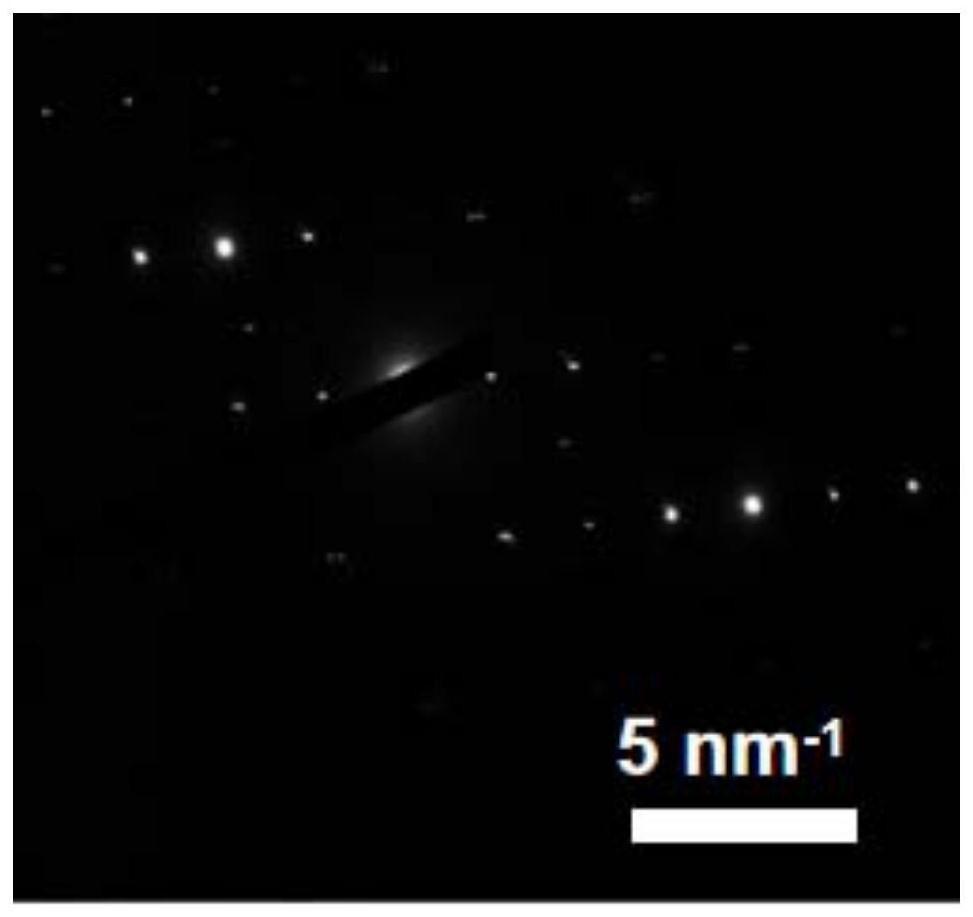

Image

Examples

preparation example Construction

[0058] The invention provides a method for preparing a covalent triazine organic framework (CTF) material, comprising:

[0059] Mixing and reacting raw materials including a covalent triazine organic framework (CTF) material precursor, a first solvent and a catalyst;

[0060] The reacted mixture was subjected to solid-liquid separation.

[0061] The above-mentioned first solvent includes at least one of dichloromethane (DCM), benzene and toluene; preferably, the amount of the first solvent is 4-10 times the total mass of the covalent triazine organic framework material precursor.

[0062] The above covalent triazine organic framework (CTF) material precursors include terephthalonitrile, methyl terephthalonitrile, isophthalonitrile, 1,3,5-benzenetrinitrile and 2,5-dicyanothiophene at least one of the

[0063] The above-mentioned catalyst includes trifluoromethanesulfonic acid (TFMS); the dosage of the catalyst is 1.4-2.4 times of the total mass of the precursor of the covalen...

Embodiment 1

[0080] (1) Place a clean reagent bottle (10mL) on the balance tray, add 1g of trifluoromethanesulfonic acid (TFMS) with a glass dropper, then add 2g of dichloromethane (DCM), and then add 0.5g of CTF For the precursor terephthalonitrile (DCB), after tightening the cap, shake and vibrate in the ultrasonic pool for about 2 minutes until the CTF precursor is completely dissolved. Then put the reagent bottle into a constant temperature oven, set the temperature at 50°C, and react for 24h.

[0081] (2) After the reaction in step (1), take out the reagent bottle, add about 10mL of DCM after cooling to room temperature, and then slowly add a small amount of N,N-dimethylformamide (DMF) dropwise to avoid a large amount of heat release Add the mixed solvent (1 / 1, v / v) of DCM / DMF subsequently, ultrasonic and stir, then with the centrifugal 20min of the rotating speed of 6000rpm; Add the mixed solvent (1 / 1 , v / v), sonicated and stirred, and centrifuged at 6000rpm for 20min. After repeati...

Embodiment 2

[0083] The difference between this example and Example 1 is that the amount of trifluoromethanesulfonic acid (TFMS) 1g is replaced by 0.8g, and the others are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com