Antifatigue basic magnesium sulfate cement and preparation method thereof

A magnesium sulfate, anti-fatigue technology, applied in the field of cement, can solve the problems of strong basic magnesium sulfate cement preparation method, lack of fatigue resistance, etc., and achieve the effects of improving toughness, increasing strength, and high-pressure folding ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

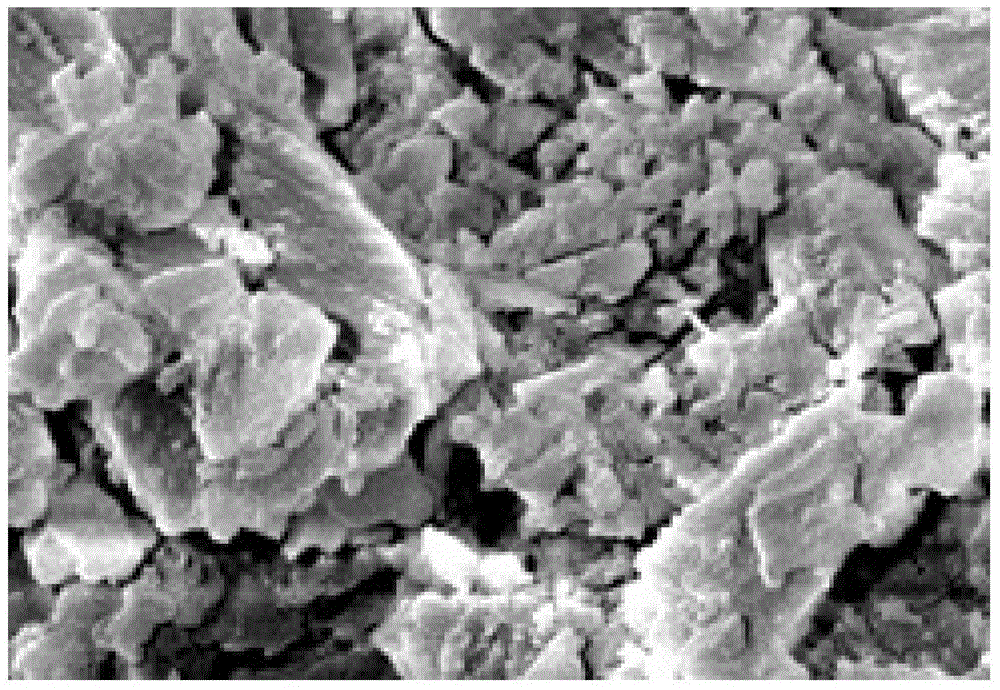

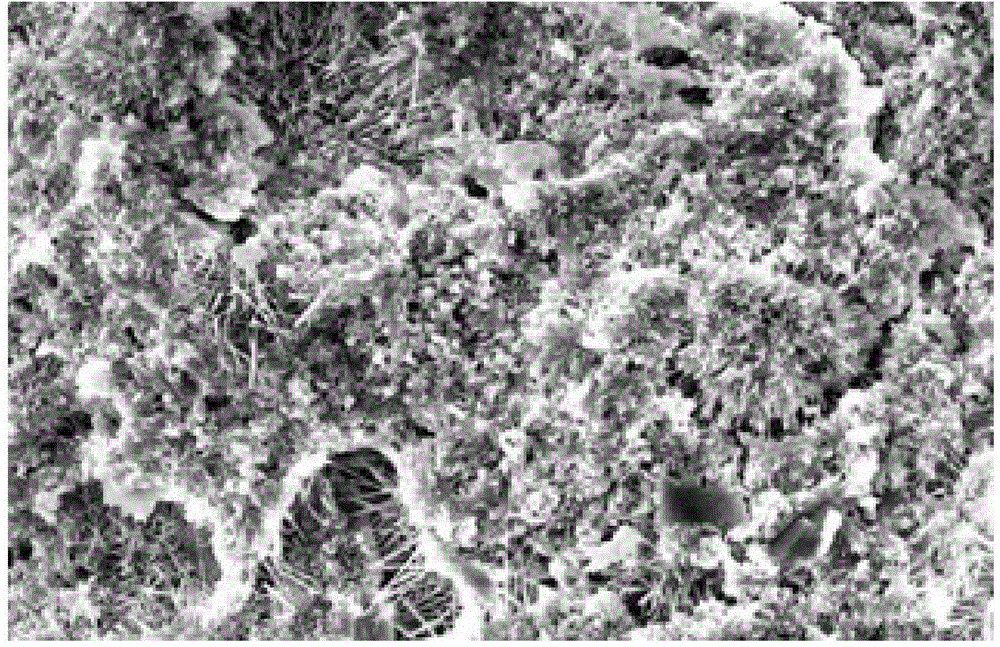

[0029] Such as figure 1 with figure 2 as shown, figure 1 It is the SEM topography of the microstructure of traditional magnesium oxysulfide cement after 30 days of hydration; figure 2 It is the SEM image of the anti-fatigue basic magnesium sulfate cement 30d of the present invention; the anti-fatigue basic magnesium sulfate cement prepared by industrial raw materials, the hydration product is 5.1.7 whiskers.

[0030] It can be seen that the hydration structure of traditional magnesium oxysulfide cement is mainly composed of a large number of flaky Mg(OH)2 crystals, and the structure is loose and the pores are more. The microstructure of anti-fatigue basic magnesium sulfate cement after hydration is composed of a large number of needle-like 5·1·7 whiskers with relatively uniform spatial distribution, the structure is dense, and there are both Mg(OH)2 gel phase and needles. The rod-shaped 5.1.7 whisker crystals are interwoven into a continuous three-dimensional space struct...

Embodiment 2

[0042] The difference between embodiment 2 and embodiment 1 is:

[0043] A kind of anti-fatigue basic magnesium sulfate cement of the present invention, described anti-fatigue basic magnesium sulfate cement is made up of the component of following mass percentage:

[0044]

[0045] The magnesium oxide is lightly burned dolomite powder. The straw is in powder form, and the powder fineness is 200 mesh.

[0046] Described magnesium oxide is made up of the component of following mass percentage:

[0047]

[0048] The preparation method of the anti-fatigue basic magnesium sulfate cement of the present invention, comprises the steps: (1) take by weighing each component of above-mentioned ratio by proportioning, magnesium oxide 45%, magnesium sulfate heptahydrate 20%, industrial waste slag powder 12%, white slag 9%, mineral admixture 4%, straw 5%, desulfurization gypsum 3%, fly ash 4%, coagulant 1.6%;

[0049] (2) Magnesium sulfate heptahydrate is configured into solution; ...

Embodiment 3

[0052] The difference between embodiment 3 and embodiment 2 is: a kind of anti-fatigue basic magnesium sulfate cement of the present invention, described anti-fatigue basic magnesium sulfate cement is made up of the component of following mass percentage:

[0053]

[0054] The magnesium oxide is a combination of lightly burned magnesite powder and lightly burned dolomite powder. The straw is in powder form, and the powder fineness is 300 mesh.

[0055] Described magnesium oxide is made up of the component of following mass percentage:

[0056]

[0057] The preparation method of the anti-fatigue basic magnesium sulfate cement of the present invention, comprises the steps: (1) take by weighing each component of above-mentioned ratio by proportioning, magnesium oxide 58%, magnesium sulfate heptahydrate 25%, industrial waste slag powder 15%, white slag 13%, mineral admixture 3-5%, straw 6%, desulfurization gypsum 4%, fly ash 5%, coagulant 2%;

[0058] (2) Magnesium sulfate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com