Super-high-temperature prefabricated directly-buried heat-preservation pipe fitting tee and production and usage method

A pipe fitting tee, prefabricated direct burial technology, applied in the direction of heat preservation, heat insulation protection of pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of high energy loss rate, high thermal conductivity, short life of the insulation layer, etc., to achieve Reduced thermal conductivity, low refractive index, strong waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

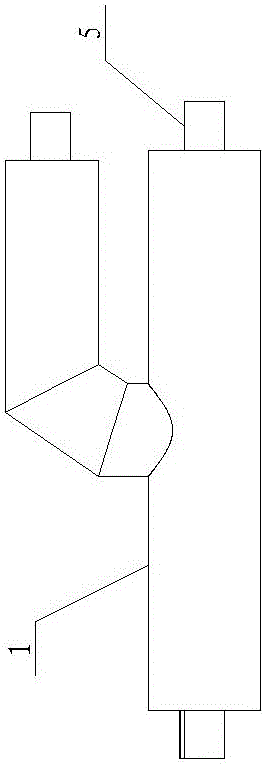

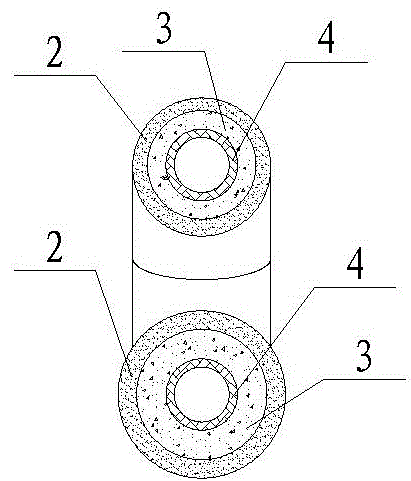

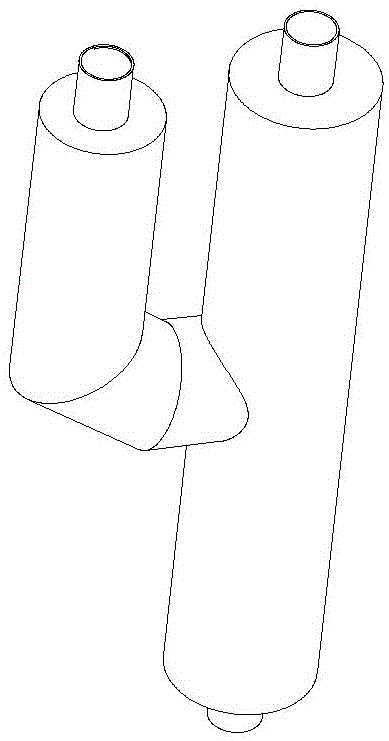

[0034] An ultra-high temperature prefabricated direct-buried thermal insulation pipe tee, which consists of: a steel pipe tee, the steel pipe tee 5 is wrapped with a rock wool heat insulation layer 4, and the rock wool heat insulation layer is coated with an air The gel layer 3, the airgel layer is coated with a polyurethane insulation layer 2, and the polyurethane insulation layer is coated with a metal outer protective tube 1 outside.

Embodiment 2

[0036] According to the ultra-high temperature prefabricated directly buried thermal insulation pipe fitting tee described in Example 1, the steel pipe tee can also be wrapped with an airgel felt layer, and the airgel felt layer is coated with a polyurethane insulation layer, so The outer side of the polyurethane insulation layer is covered with a metal outer protective tube.

Embodiment 3

[0038] According to the ultra-high temperature prefabricated direct-buried thermal insulation pipe fitting tee described in Example 2, the metal outer protective pipe can also be covered with a metal outer protective layer after using a polyurethane composite protective layer or a silicate composite protective layer according to temperature requirements. protective tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com