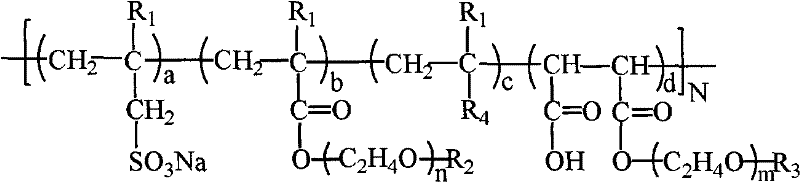

Preparation method for polycarboxylic acid series comb-shaped surface active agent

A surfactant and polycarboxylic acid technology, applied in chemical instruments and methods, transportation and packaging, dissolution, etc., can solve problems that are not conducive to marketization, industrialization and environmental protection, consume large solvents and energy, and prolong production cycles. , to achieve the effects of shortening the preparation time, reducing the preparation cost and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of poly(methyl methacrylate-co-vinyl acetate)-g-(polyethylene glycol monomethyl ether): weigh 15.0g methyl methacrylate, 8.6g vinyl acetate, 0.118g azobis For isobutyronitrile, measure 70mL of N,N-dimethylformamide, put each raw material into the reaction kettle at one time, heat and blow nitrogen to make it react at 100°C for 6h. After the reaction is complete, weigh 56.9g of polyethylene glycol monomethyl ether (molecular weight: 2000), 1.610g of sodium ethoxide, and measure 30mL of N,N-dimethylformamide. Reaction 4h. After the reaction, 60% of the solvent in the reaction system was removed under reduced pressure, and then the product was precipitated with cold n-heptane. After filtration under reduced pressure, the filter cake was dissolved with N,N-dimethylformamide, and the dissolved solution was washed with cold n-heptane Reprecipitation was carried out, and the dissolution and reprecipitation were repeated 5 times, and finally the product was dried u...

Embodiment 2

[0035]Preparation of poly(vinyl acetate-co-maleic anhydride)-g-(n-butanol): Weigh 12.9g vinyl acetate, 9.8g maleic anhydride, 0.908g azobisisoheptanonitrile, 0.114g dodeca Alkyl mercaptan, measure 52mL of N,N-dimethylformamide, put each raw material into the reaction kettle at one time, heat and blow nitrogen to make it react at 100°C for 8h. After the reaction is complete, weigh 5.6g of n-butanol, 2.264g of p-toluenesulfonic acid, and 58mL of N,N-dimethylformamide, and add them directly into the reaction kettle, allowing them to react at 100°C for 12h. After the reaction was completed, 60% of the solvent in the reaction system was removed under reduced pressure, and then the product was precipitated with cold ether. After filtration under reduced pressure, the filter cake was dissolved with N,N-dimethylformamide, and the dissolved solution was reprecipitated with cold ether. Dissolution and reprecipitation were repeated four times in this way, and finally the product was drie...

Embodiment 3

[0037] Preparation of poly(maleic anhydride-co-acrylic acid)-g-(polyethylene glycol monomethyl ether+n-butanol): Weigh 19.6g maleic anhydride, 7.2g acrylic acid, 1.340g dibenzoyl peroxide, 1.072g of dodecyl mercaptan, measure 219mL of dimethyl sulfoxide, put each raw material into the reaction kettle at one time, heat and blow nitrogen to make it react at 120°C for 6h. After the reaction is completed, take by weighing 24.3g polyethylene glycol monomethyl ether (molecular weight is 550), 5.6g n-butanol, 0.567g p-toluenesulfonic acid, measure 21mL dimethyl sulfoxide, directly add in the reaction kettle, make it Reaction at 120°C for 4h. After the reaction is completed, remove 80% of the solvent in the reaction system under reduced pressure, and then precipitate the product with cold n-hexane. After filtration under reduced pressure, the filter cake is dissolved with dimethyl sulfoxide, and the dissolved solution is reprecipitated with cold n-hexane, and so on. Dissolution and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com