Plastic particle loading machine capable of automatically weighing and discharging

A technology for automatic weighing of plastic granules, applied in the field of automatic weighing and discharging plastic granule feeders, can solve the problems of large feeding speed errors and inability to accurately control production quality parameters, and achieve feeding speed control and accurate Controlling the effect of production quality parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

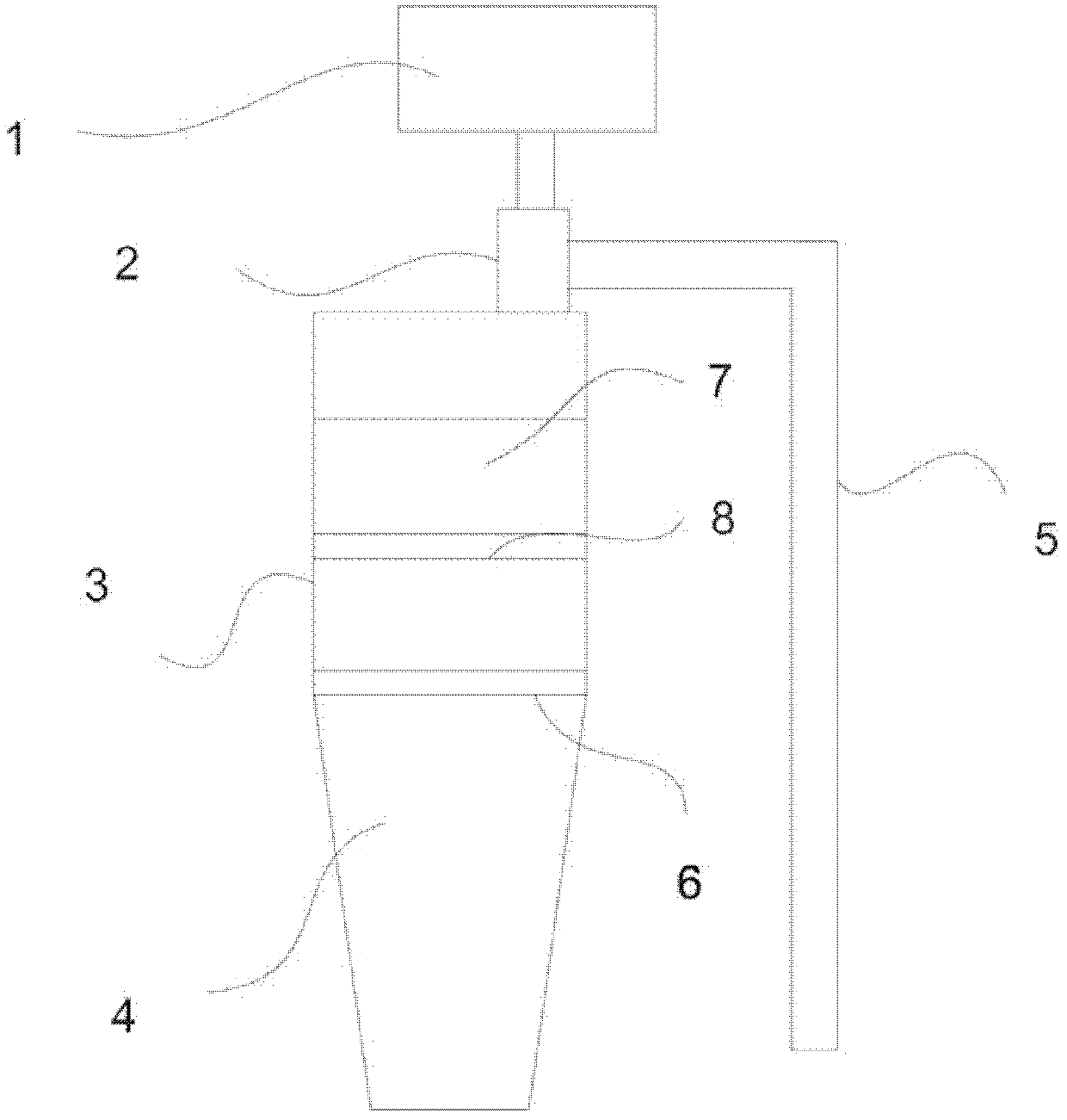

[0013] Such as figure 1 As shown, the present invention includes a conical feeder body 4 with an open lower end, the top of the conical feeder body is provided with a material introduction device for introducing external materials into the feeder body, and the outlet of the material introduction device is provided with a dryer 2. A material retention bin 7 and a weighing retention bin 3 are sequentially arranged in the feeder body from top to bottom. The upper end of the material retention bin communicates with the feeder body, and the bottom of the material retention bin is provided with The material discharge valve 8 is opened by monitoring the material height control valve in the weighing retention bin, and the weighi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com