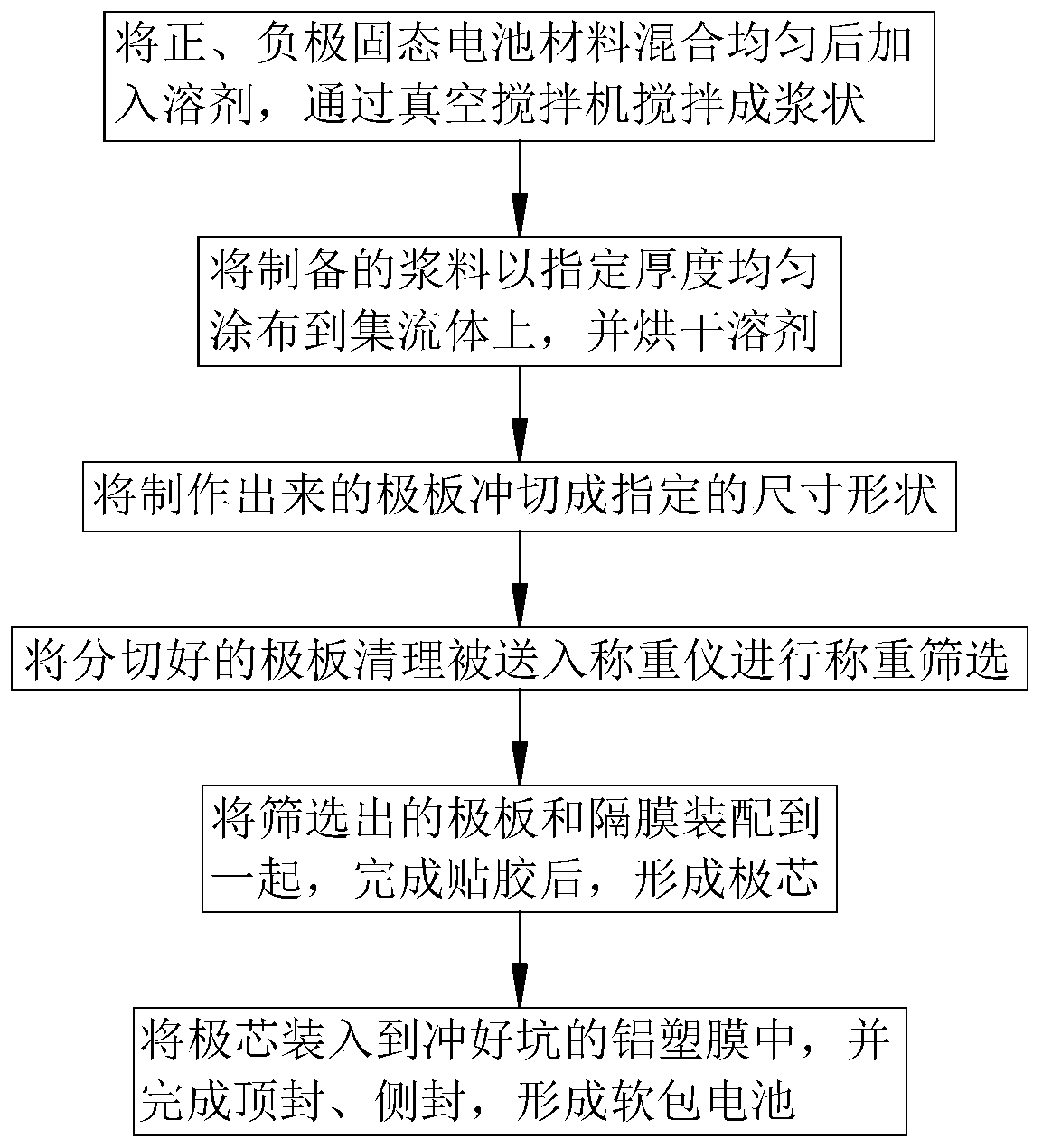

A lithium battery production process

A production process and technology of lithium batteries, which are applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, and final product manufacturing, etc., can solve the problems of low production efficiency, lack of screening function, and inability to automatically clean dust, so as to improve the cleaning efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

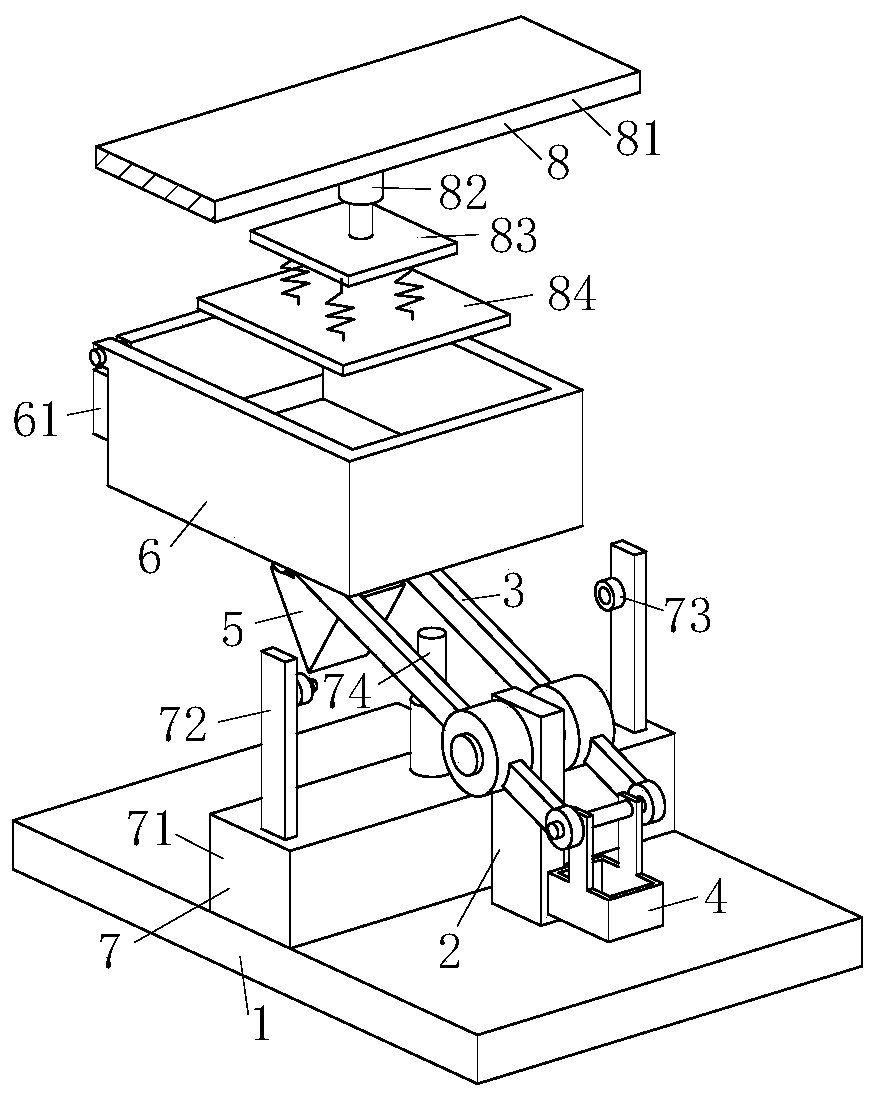

Examples

Embodiment approach

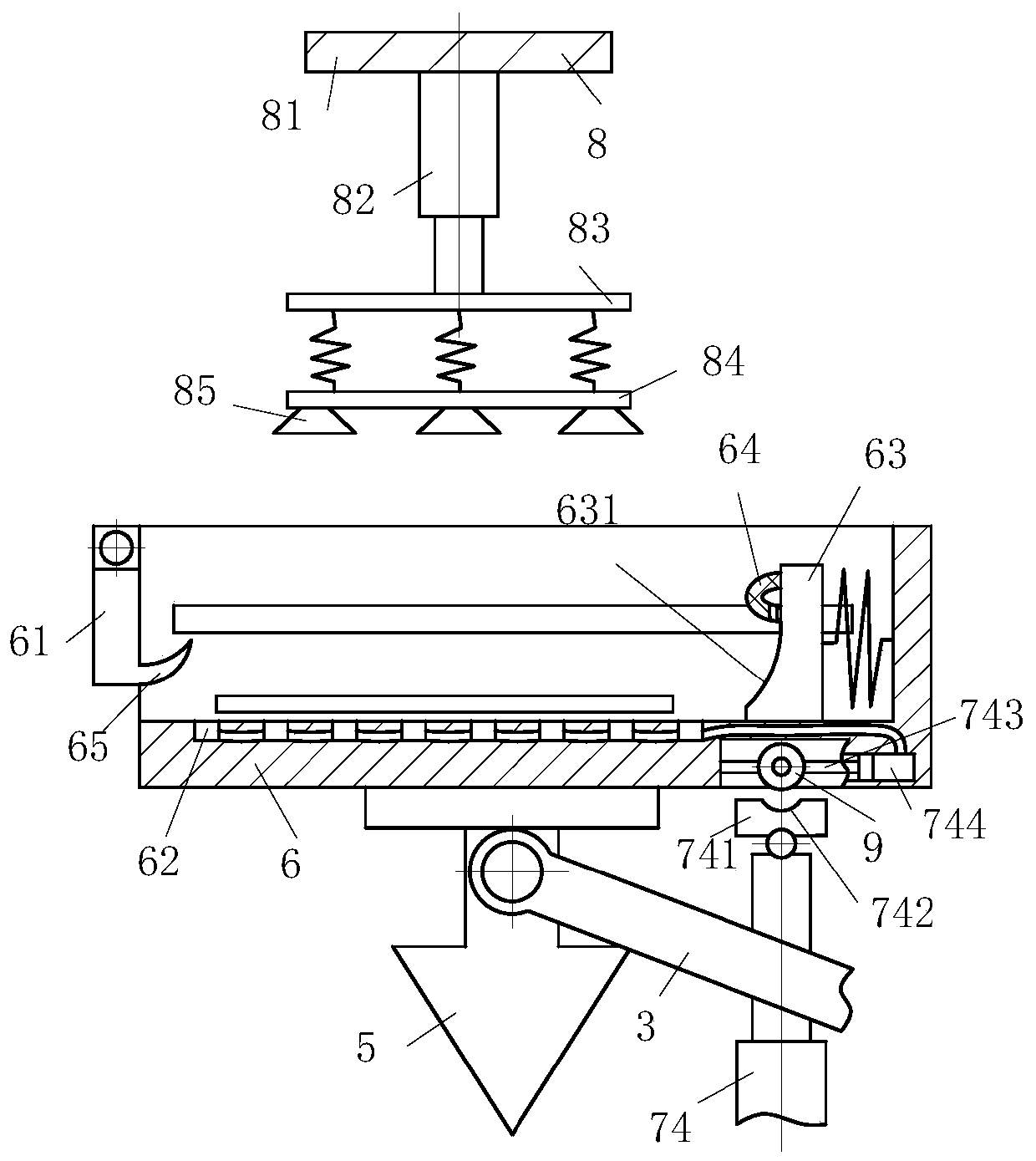

[0042] As an embodiment of the present invention, the end of the electric push rod 74 is rotatably mounted with a supporting plate 741; the rotating shaft of the supporting plate 741 is provided with a torsion spring, and the bottom of the weighing box 6 is slidingly installed with a roller 9 , the roller 9 is slidably installed on the bottom of the weighing box 6, and the middle part of the supporting plate 741 is provided with an arc groove 742, and the arc groove 742 is used to block the roller 9. When removing unqualified plates, The electric push rod 74 pushes the weighing box 6 upwards. By setting the roller 9 slidably installed in the weighing box 6, the supporting plate 741 pushes the roller 9 upward while rotating around the roller 9, reducing the electric push rod 74. End wear.

[0043] As an embodiment of the present invention, the end of the rotating shaft of the roller 9 is provided with a connecting rod 743, and the end of the connecting rod 743 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com