Memory and method of forming the same

A memory, wet etching technology, applied in semiconductor devices, electrical solid devices, electrical components, etc., can solve problems affecting memory performance, changes in electrical parameters such as resistance, achieve uniform thickness, improve yield, and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

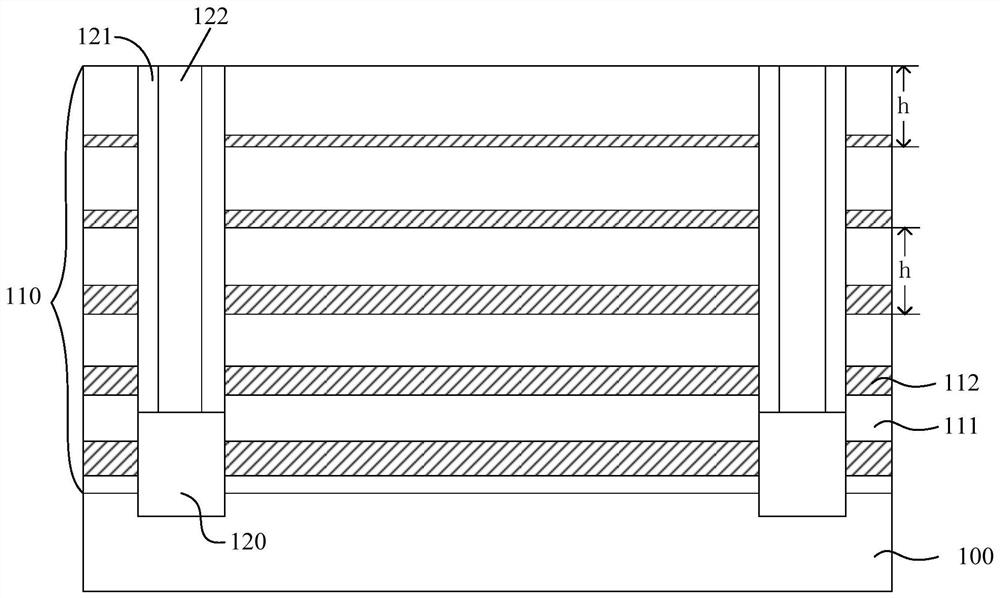

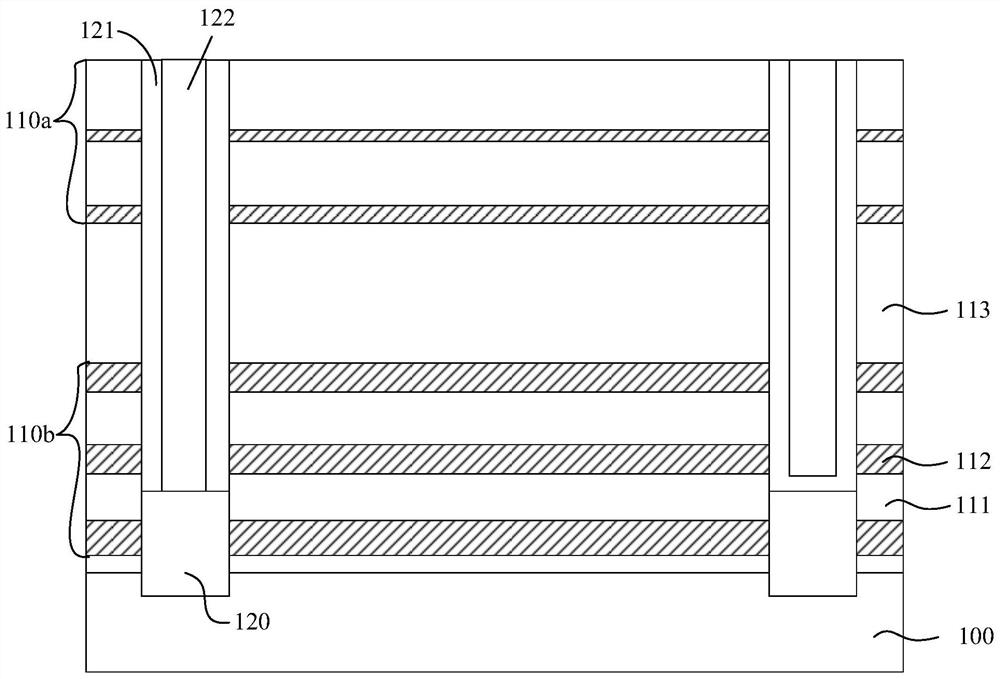

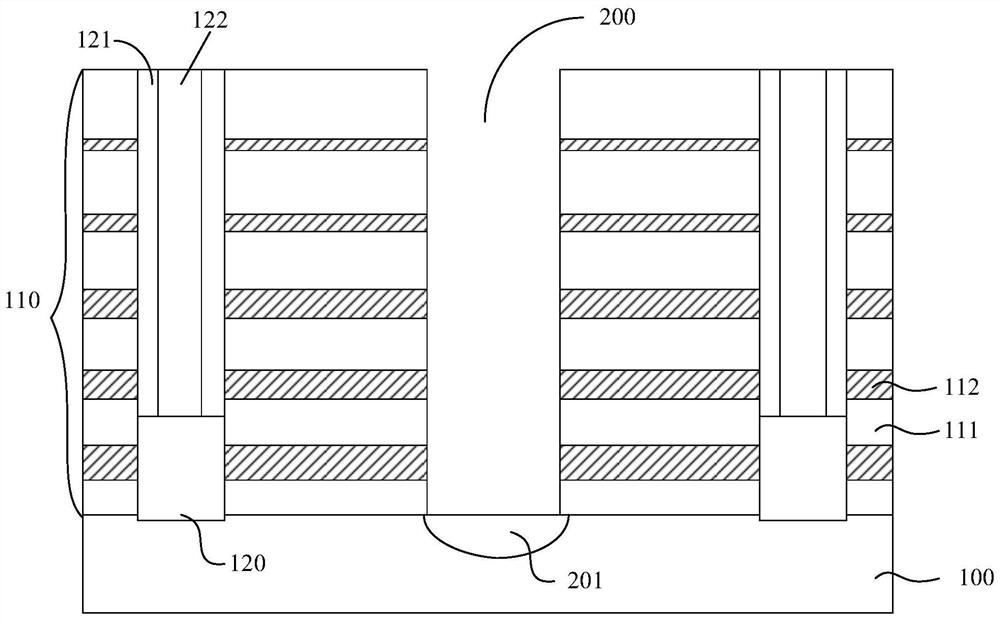

[0026] As mentioned in the background art, after removing the sacrificial layer in the prior art, the problem of non-uniform thickness of the insulating layer tends to occur.

[0027] The study found that, due to the large thickness of the stacked structure on the substrate surface, the depth of the gate line spacer groove formed before removing the sacrificial layer is relatively large. Although the etching solution has a high etching selectivity for the sacrificial layer during the wet etching process, it also causes etching to a certain extent for the insulating layer. During the wet etching process, the exchange rate of the etching solution near the top of the grid line spacer is greater than the exchange rate of the etching solution near the bottom of the grid line spacer, resulting in the grid line The concentration of silicon in the etching solution in the spacer gradually increases from the top of the stack structure downward, so that the etching rate of the insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com