Quantitative packaging scale and quantitative packaging method capable of precisely controlling supply quantity

A quantitative packaging and precise control technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items, can solve the problems that the accuracy of weighing cannot be well controlled, the efficiency of manual work is low, and automatic production cannot be realized. , to achieve the effect of convenient blanking and loading, convenient transportation and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

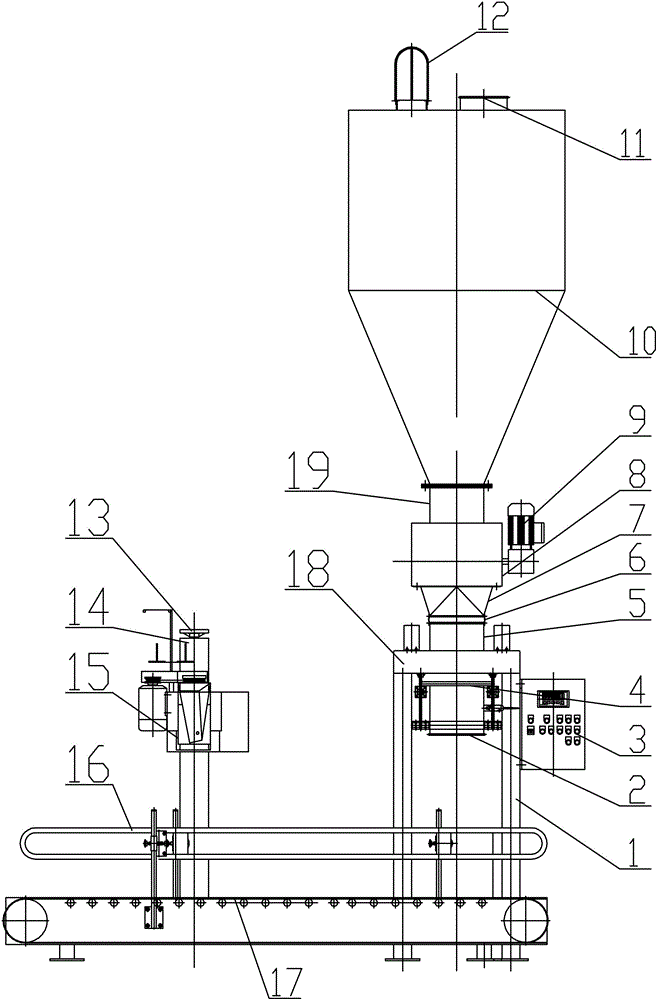

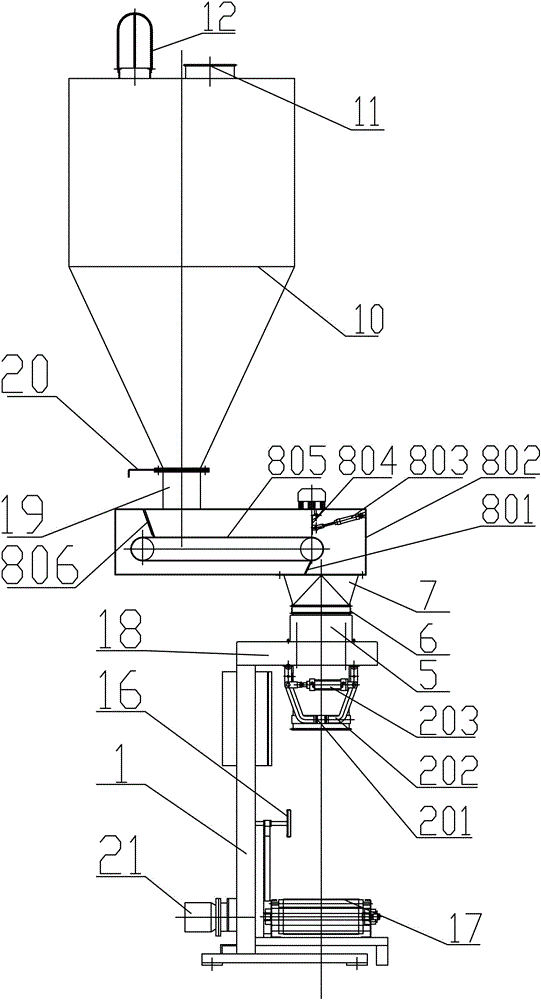

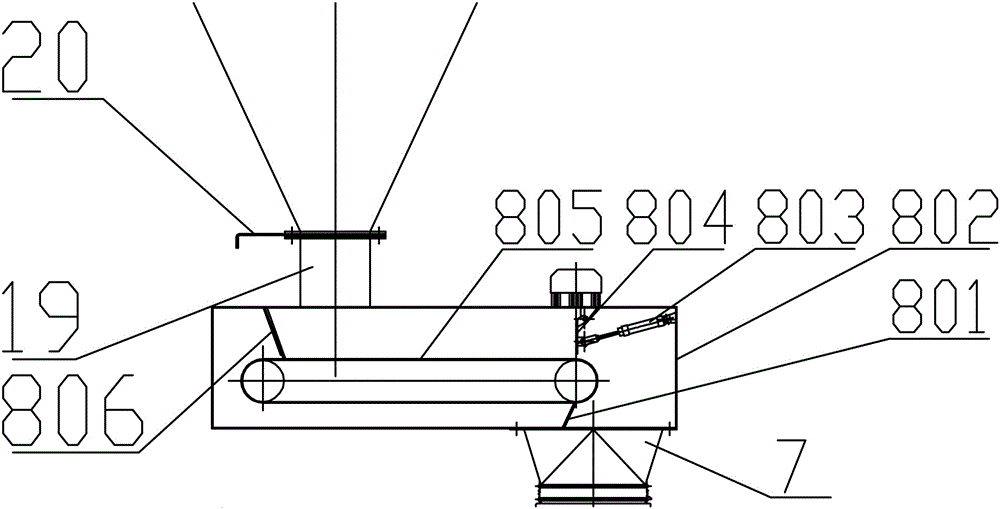

[0035] Such as Figure 1-4 , a quantitative packaging scale that can precisely control the amount of supply, it includes a frame 1, an automatic weighing device 4 is installed on the bottom end surface of the top working platform 18 of the frame 1, and an automatic weighing device 4 is installed on the automatic weighing device 4 Pneumatic entrainer 2, the top end surface of the top working platform 18 is equipped with a material receiving funnel 5, the material receiving funnel 5 is connected to the bottom feeding funnel 7 through a flexible connecting cylinder 6, and the bottom feeding funnel 7 is arranged at a quantitative The feeding end of the feeding device 8, the feeding end of the quantitative feeding device 8 is connected to the top feeding funnel 19, and the top feeding funnel 19 is arranged on the bottom of the storage hopper 10, and the bottom of the frame 1 Carrying conveyer belt 17 is installed, guard plate 16 is installed along the conveying direction of carryin...

Embodiment 2

[0045] The method for carrying out quantitative packaging by any quantitative packaging scale comprises the following steps:

[0046] S1: Set the weight of the material to be packaged through the packaging weighing display controller 3, clamp a packaging bag through the pneumatic clamper 2, start the storage hopper 10 to discharge the material, and the material enters the closed chassis 802 through the discharge hopper 19 and is conveyed The belt 805 drives the material forward, enters the flexible connecting cylinder 6 through the bottom feeding funnel 7, and finally enters the packaging bag through the feeding hole 201;

[0047] S2: During the continuous feeding process, the weighing sensor of the automatic weighing device 4 constantly feeds back the weight of the material. When the weight inside the bag is guaranteed to be close to the set value, the stopper cylinder 803 of the quantitative feeding device 8 is activated to pass the stopper. The material cylinder 803 drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com