Method for processing fruit and vegetable beverage by efficiently carrying out enzyme-killing color protection

A fruit and vegetable beverage and enzyme inactivation technology, which is applied in the field of high-efficiency enzyme inactivation and color protection processing fruit and vegetable beverages, can solve the problems of loss of soluble solids, poor enzyme inactivation effect, loss of flavor of fruits and vegetables, etc., so as to solve the problem of large loss of soluble solid content in fruits. , good crushing effect, short operation time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0030] 1. The first embodiment: the method for processing fruit and vegetable beverages with high efficiency inactivating enzymes and protecting color

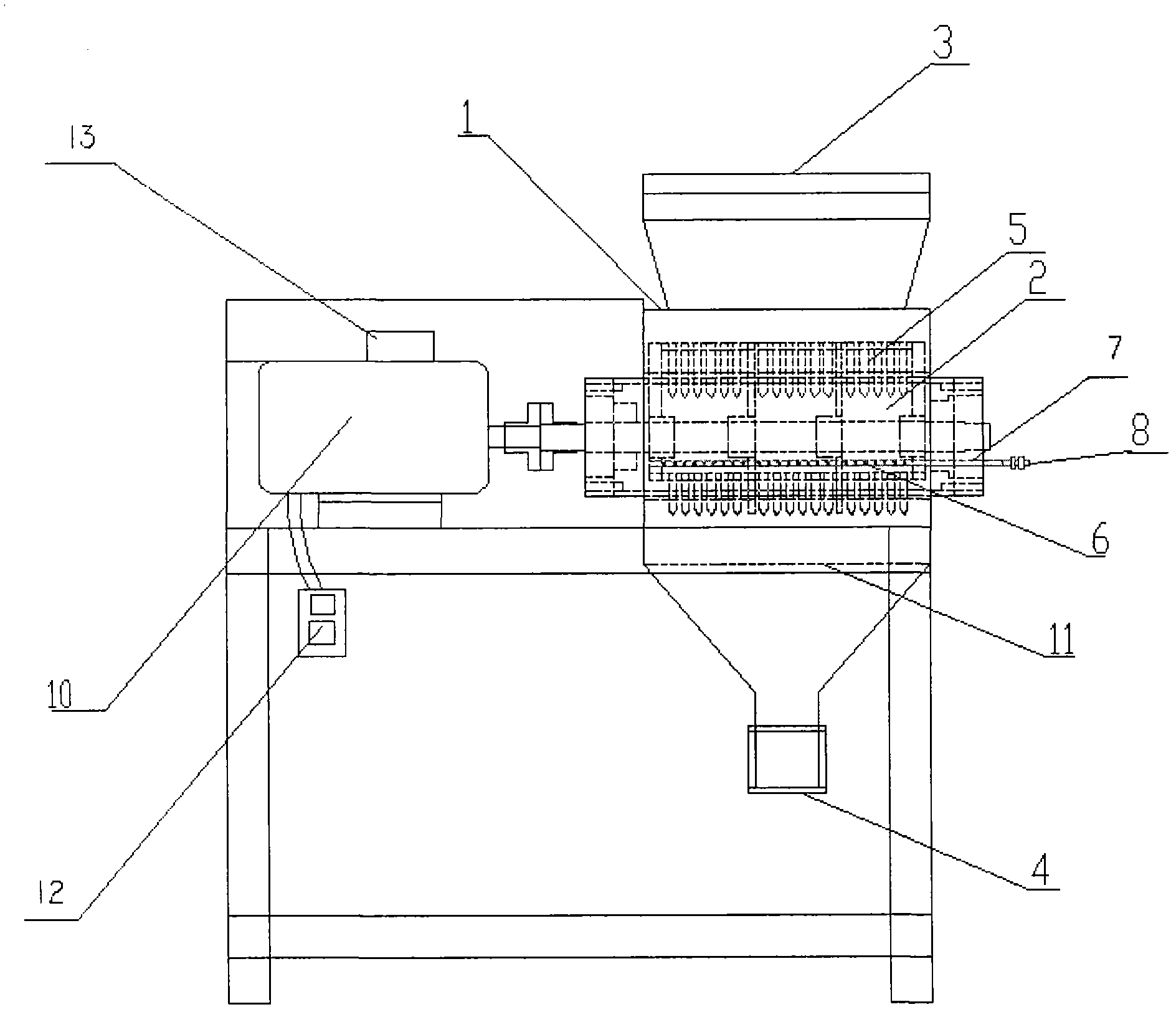

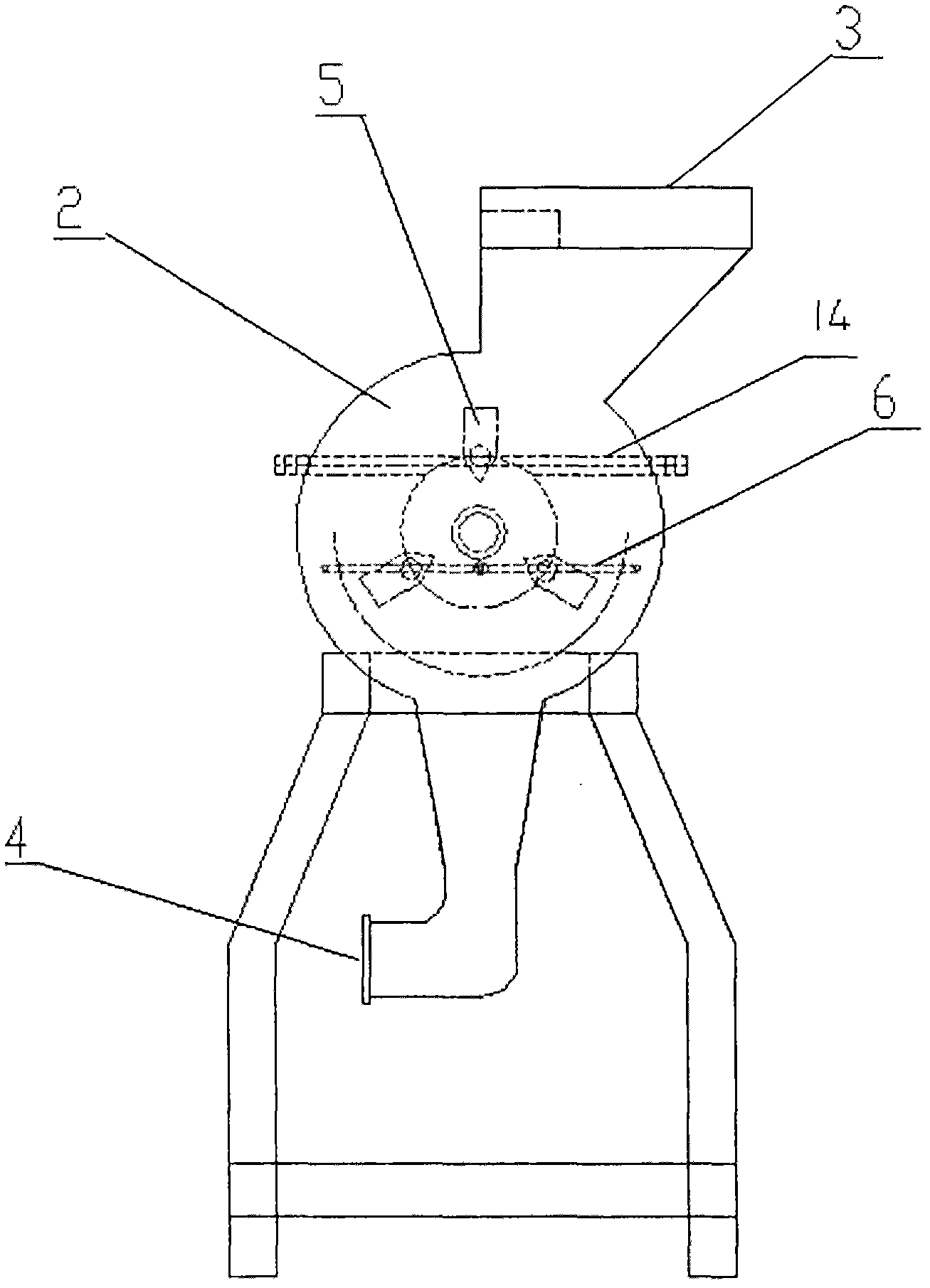

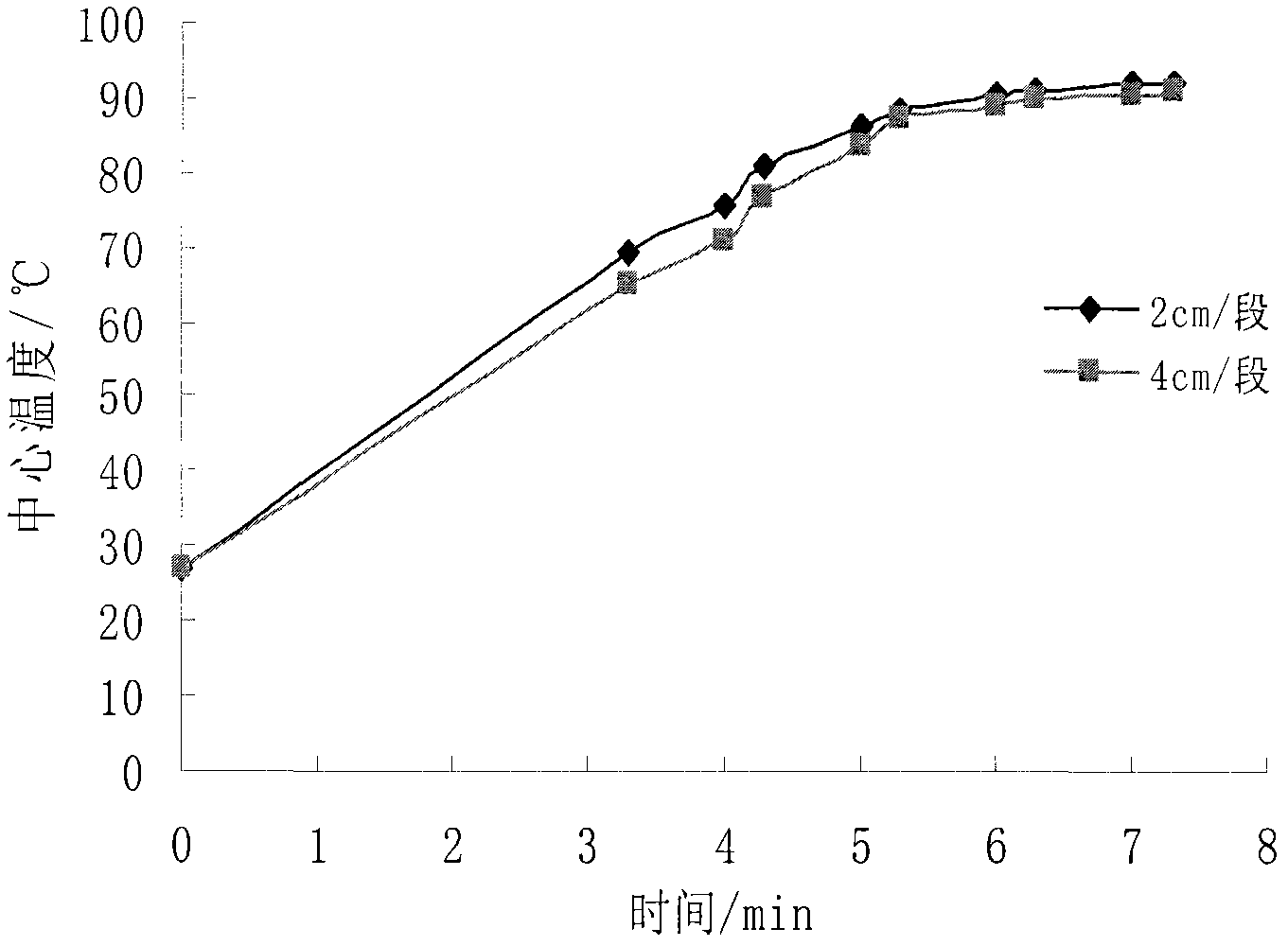

[0031] The method for efficiently killing enzymes and protecting color of the present invention to process fruit and vegetable beverages can be as follows: figure 1 The shown fruit and vegetable enzyme crushing device. figure 2 yes figure 1 left view of . as the picture shows. The main body 1 of the whole device can be made of stainless steel to meet the requirements of food safety. The material enters the inner cavity 2 of the device from the feed port 3, and the inner cavity 2 is provided with a crushing knife 5 driven by a motor 10, and the crushing effect depends on the shape and arrangement of the crushing knife 5; there is also a steam pipe 7 under the crushing knife 5 , the steam pipe 7 is also provided with a vent hole 6; in this embodiment, the heat source for material heating is an external steam generator, and ...

no. 2 example

[0036] 2. The second embodiment: the method for processing pineapple beverage with high efficiency inactivating enzyme and protecting color

[0037] The process and equipment used in this example are basically the same as in Example 1, except that when the steam pressure reaches 0.18MPa and the temperature reaches 118°C, the pineapple (without peeling) after cleaning the cut end is cut into 4-5 block, and then directly put into the inner cavity of the fruit and vegetable enzyme crushing device; when the temperature of the material at the discharge port reaches 90°C, the discharge port is opened; the materials obtained from the discharge port include pulp and slag separation, deployment, Clarify, sterilize, and aseptically fill to obtain pineapple juice.

no. 3 example

[0038] 3. The third embodiment: the method for processing carambola beverage with high efficiency inactivating enzyme and protecting color

[0039] The process and equipment used in this example are basically the same as those in Example 1, the difference being that when the steam pressure reaches 0.15 MPa and the temperature reaches above 110°C, the cleaned carambola is directly put into the fruit and vegetable enzyme crushing device chamber; when the temperature of the material at the discharge port reaches above 87°C, the discharge port is opened; the material obtained from the discharge port includes separation of pulp and slag, deployment, clarification, sterilization, aseptic filling to obtain carambola juice .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com