Differential pressing roller type peony seed unshelling and cleaning device

A cleaning device, the technology of peony seeds, is applied in the direction of shelling, separating solids from solids by air flow, and fat oil/fat production, etc. The effect of high removal rate and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

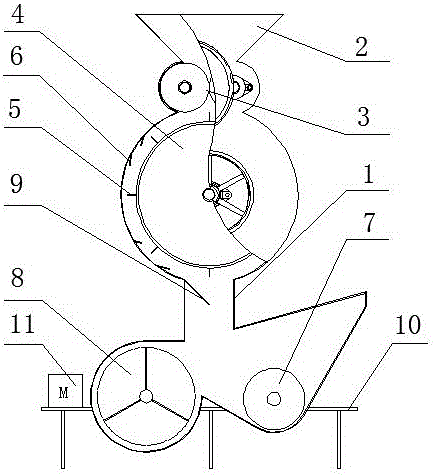

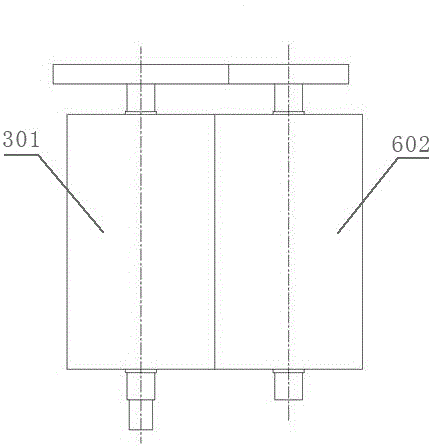

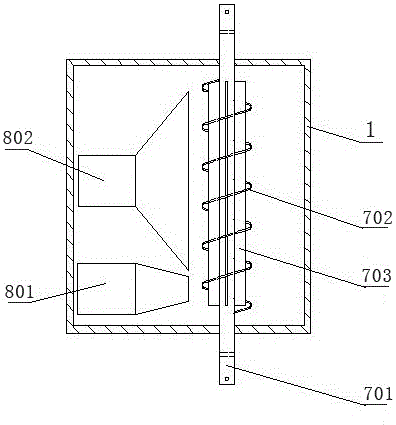

[0024] Such as Figure 1 to Figure 3 As shown, a differential pressure roller type peony seed shelling and cleaning device of the present invention separates the peony seeds from their shells through a two-step method, and then completely separates the peony seeds from their shells through multiple winnowing. Described cleaning device comprises casing 1, and this casing 1 is fixedly arranged on the frame 10, thereby guarantees the stability of complete machine, is provided with conical feeding hopper 2 above casing 1, is used for feeding casing 1. The material is continuously fed inside. The casing 1 itself is made of a casting, which can play a good role in supporting and fixing other components. In the cavity of the casing 1, a shell breaking system, a separation system and a winnowing system are sequentially arranged from top to bottom.

[0025] The shell breaking system of the present invention includes two pressure rollers 3 used to initially crush material shells, incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com