Manufacturing device of fertilizer for soil remediation

A manufacturing device and soil remediation technology, which is applied to fertilization devices, fertilizer mixtures, solid/semi-solid fertilizers, etc., can solve the problems of large repaired soil area, troublesome feeding, waste of manual labor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

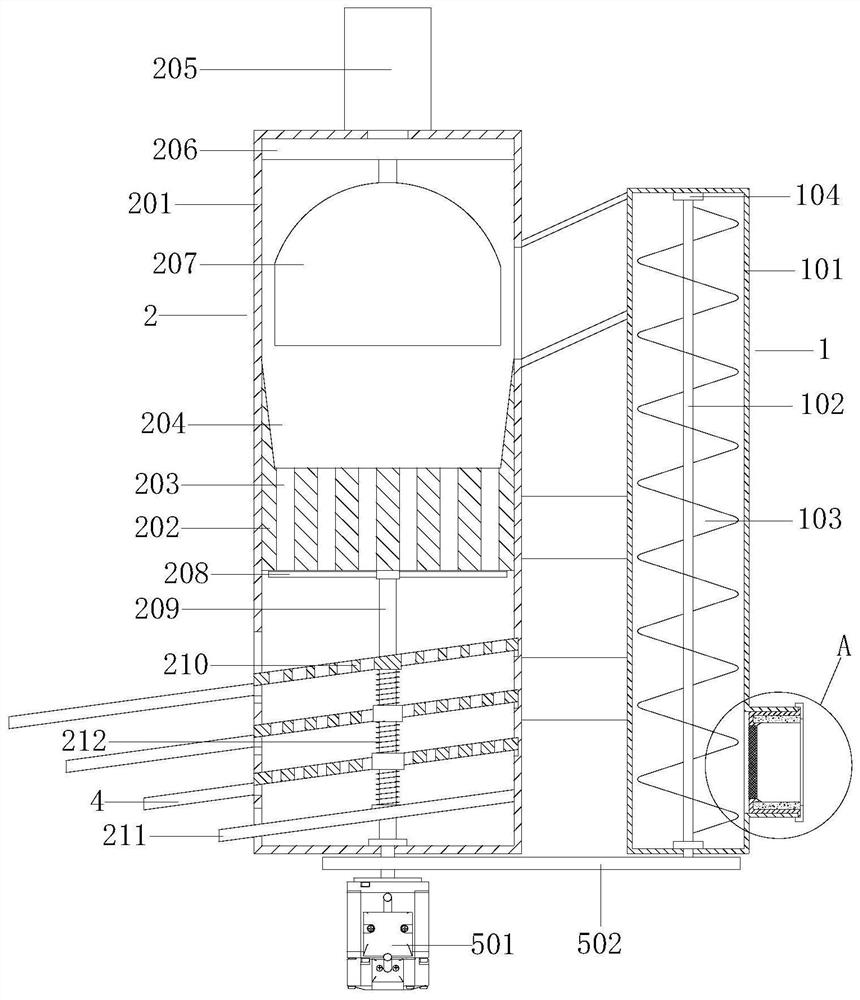

[0026] like figure 1 and figure 2 As shown, a kind of fertilizer manufacturing device for soil remediation of the present embodiment comprises a feeder 1 and a granulator 2, and the discharge port of the feeder 1 is connected to the feed port of the granulator 2, which is the granulator 2 Provide materials; the granulator 2 is provided with a particle cutting mechanism for cutting materials to realize material granulation. The particle cutting mechanism is connected with a driving mechanism to facilitate the control of the rotating speed of the particle cutting mechanism, thereby controlling the size of the particles. It is connected with the feeding machine 1 through transmission, so that it is convenient to control the feeding machine and the particle cutting mechanism to work at the same time through a driving mechanism; the inlet pipe of the feeding machine 1 is connected with a feeding filter mechanism, which is convenient for filtering materials; The elastically connec...

Embodiment 2

[0029] This embodiment is a further improvement made on the basis of Embodiment 1. The specific differences between this embodiment and Embodiment 1 are:

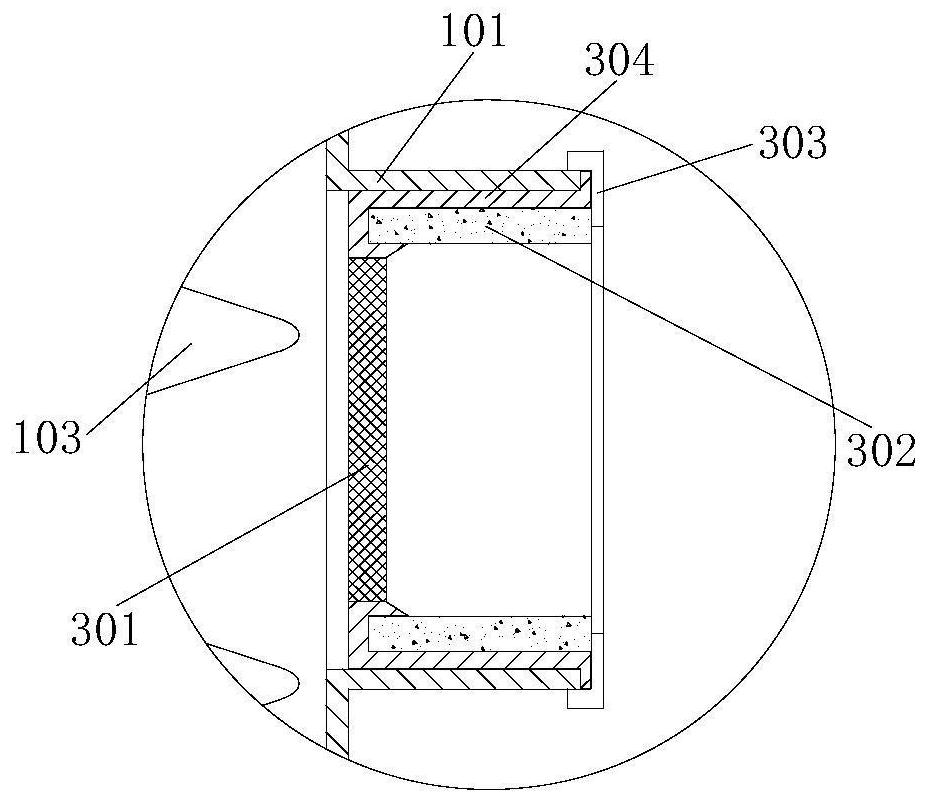

[0030] What needs to be further explained in this embodiment is that the feed filter mechanism includes a feed filter 301, an annular magnet 302 and a stopper 303, and the feed filter 301 is socketed in the inlet pipe of the feeder 1, which is convenient To filter out the larger impurities in the material, the ring magnet 302 is rotated and connected to the inlet pipe of the feeder 1, which is convenient for filtering out the iron material in the material, and the ring magnet 302 will rotate properly during the process of adding materials , so that any position of the ring magnet 302 can attract ferrous impurities well, so that the cleaning effect of the ring magnet 302 is better each time, and more impurities can be adsorbed; The inlet pipe is detachably connected to prevent the feed filter 301 and the ring magnet 302 from...

Embodiment 3

[0032] This embodiment is a further improvement made on the basis of Embodiment 2. The specific differences between this embodiment and Embodiment 2 are:

[0033] What needs to be further explained in this embodiment is that the feed filter mechanism also includes an annular sleeve 304, and one end of the annular sleeve 304 is clamped between the stopper 303 and the inlet pipe of the feeder 1, and the feed filter 301 Connected to the other end of the annular set 304, it is convenient to realize the loading and unloading of the feed filter 301 through the annular set 304; the annular set 304 is provided with an annular groove, and the opening of the annular groove faces the direction of the inlet end of the inlet pipe of the feeder 1 One end of the ring magnet 302 is sleeved in the ring groove, which is convenient for the ring magnet 302 to be preliminarily fixed and prevents the ring magnet 302 from sliding in the feeder 1; the limiter 303 is threadedly connected to the inlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com