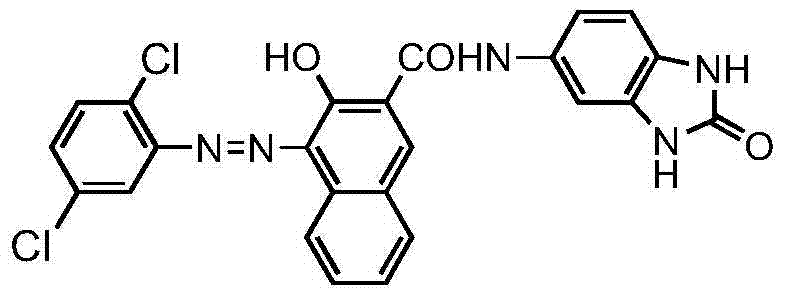

Preparation method of C.I. pigment brown 25

A pigment brown and pigment technology, applied in the field of preparation of C.I. Pigment Brown 25, can solve the problems of hard solid particles, long process time, no energy saving and environmental protection, etc., and achieves the effects of soft particles, bright colors, and improved color and tinting strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

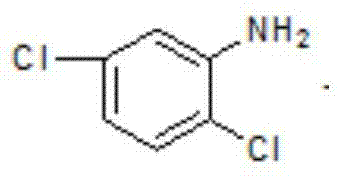

[0048] 32.6g 2,5-dichloroaniline, 54ml 30% hydrochloric acid and 250ml water were stirred and cooled to 5℃, and 35g 40% sodium nitrite solution was quickly diazotized within 2 minutes. At the end of diazonium, excess sodium nitrite is eliminated, and a diazonium salt solution is obtained.

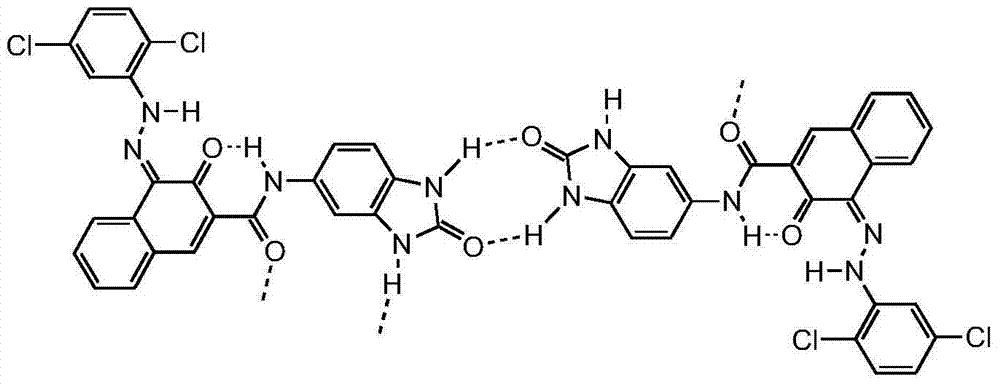

[0049] 65g of Chromol AS-BI (5-(2'-hydroxy-3'-naphthylcarboxamido)-2-benzimidazolone), dissolved in 40ml of sodium hydroxide aqueous solution with a concentration of 30% by mass and 600ml of water, Adjust the temperature to 5°C, add 72 ml of diluted hydrochloric acid with a mass concentration of 10% in a trickle, and stir at 50 revolutions per minute during the process of adding the diluted hydrochloric acid until the acid precipitation is over and the pH value is 6, to obtain a coupling solution. The aqueous sodium hydroxide solution can also be replaced by potassium hydroxide solution.

[0050] The diazonium salt solution was slowly added to the coupling solution within 3 hours for reaction. ...

Embodiment 2

[0053] 32.6g 2,5-dichloroaniline, 54ml 30% hydrochloric acid and 250ml water were stirred and cooled to 5°C, and 35g 40% sodium nitrite was quickly added within 3 minutes for diazotization. After the nitrogen ends, the excess sodium nitrite is eliminated, and the diazonium salt solution is obtained.

[0054] 65g of Chromol AS-BI, dissolved in 40ml of 30% by mass sodium hydroxide aqueous solution and 600ml of water, adjust the temperature to 15℃, add 92ml of dilute formic acid with a mass concentration of 10% in a trickle, and stir during the process of adding dilute hydrochloric acid It is 70 revolutions per minute until the end of acid precipitation, the pH is 6.5, and the coupling solution is obtained.

[0055] The diazonium salt solution was added to the coupling solution within 2.5 hours for reaction. During the coupling process, 31ml of sodium hydroxide with a mass concentration of 30% was used to control the pH of the reaction mixture to 6.0. After the coupling was completed,...

Embodiment 3

[0058] 32.6g 2,5-dichloroaniline, 54ml 30% hydrochloric acid and 250ml water were stirred and cooled to 5℃, and 35g 40% sodium nitrite was quickly added within 1 minute. After the nitrogen ends, the excess sodium nitrite is eliminated, and the diazonium salt solution is obtained.

[0059] 65g Chromol AS-BI, dissolved in 40ml sodium hydroxide aqueous solution with a concentration of 40% by mass and 600ml water, adjust the temperature to 10℃, add 120ml of dilute acetic acid with a mass concentration of 10% in a trickle, and stir during the process of adding dilute acetic acid It is 90 revolutions per minute, until the end of acid precipitation, the pH value is 6, and the coupling solution is obtained.

[0060] The diazonium salt solution was added to the coupling solution within 3 hours for reaction. During the coupling process, 26.5 g of sodium bicarbonate was used to control the pH of the reaction mixture to 6.5. After the coupling was completed, the temperature was increased to 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com