Interpenetrating polymer network core-shell emulsion and preparation method thereof

A technology of interpenetrating polymer and core-shell emulsion, which is applied in the field of core-shell type silicone-styrene acrylic emulsion and its preparation, can solve the problem of difficulty in preparing special and special-shaped polymer particles, the influence of water resistance of emulsion coating film, and the limitation of emulsion polymer. Application and other issues, to achieve the effect of improving load-bearing wetting capacity, water resistance, and scrub resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

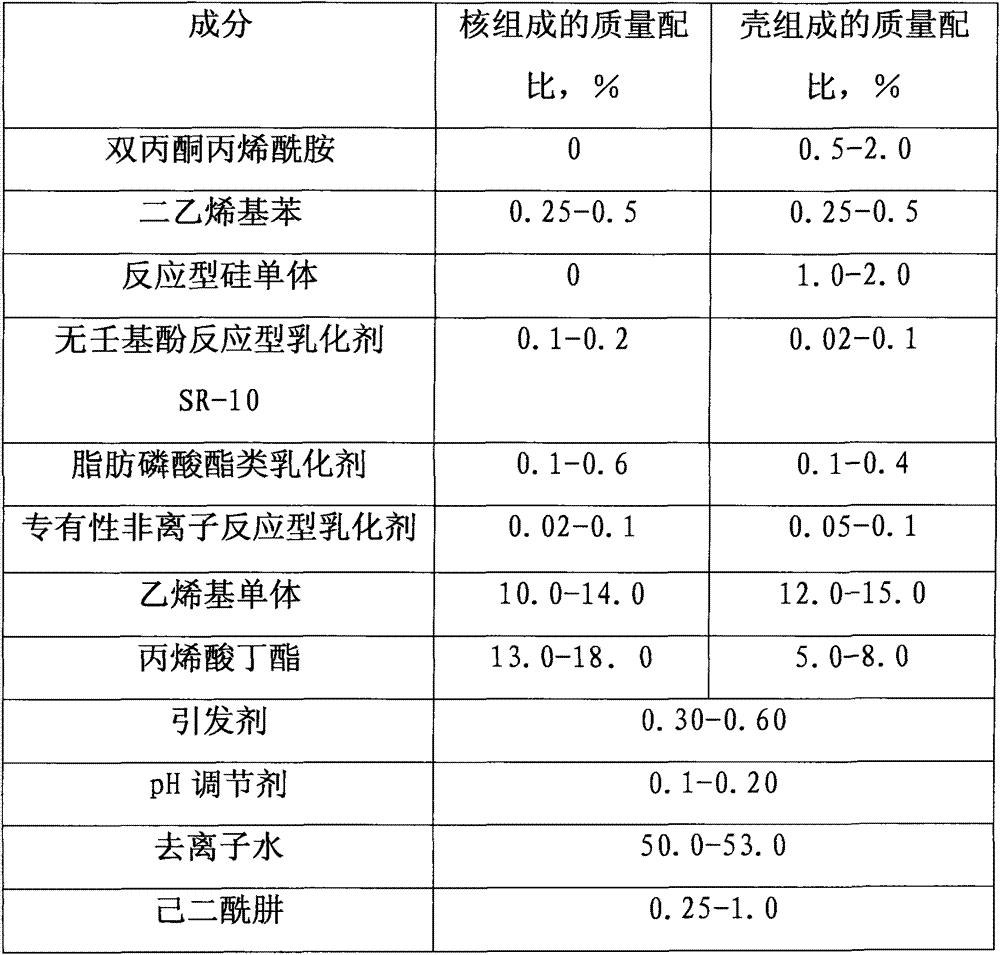

Method used

Image

Examples

Embodiment

[0032] Example: Mix 130.0 grams of styrene, 110.0 grams of butyl acrylate, 3.0 grams of divinylbenzene and 6.0 grams of acrylic acid to obtain a core mixed monomer; mix 100.0 grams of styrene, 110.0 grams of butyl acrylate, and 3.0 grams of divinyl Benzene, 4.0 g of acrylic acid, and 3.0 g of diacetone acrylamide are mixed to obtain a shell mixed monomer

[0033]Place a 1000m1 four-necked bottle in a constant temperature water bath, and assemble a series of devices such as a spherical condenser, a tetrafluoroethylene blade stirring rod, a thermometer, and a nitrogen conduit on the four-necked bottle. Add 2.0 grams of nonylphenol-free reactive emulsifier SR-10, 6.0 grams of fatty phosphate emulsifier, 1 gram of non-ionic reactive emulsifier, and 210 grams of deionized water into a four-necked bottle, and at the same time add 1.0 grams of carbonic acid Sodium hydrogen was used as a pH regulator in a four-neck flask. Control the temperature of the water bath at 84-85°C and start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com