Ultra-microscopic air-blown cable and air-blowing cable process

An ultra-miniature and optical cable technology, which is applied in the direction of optical fiber/cable installation, optics, light guide, etc., can solve the problems affecting the construction cost of the project, and achieve the effects of low production cost, reduced friction, and improved air blowing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

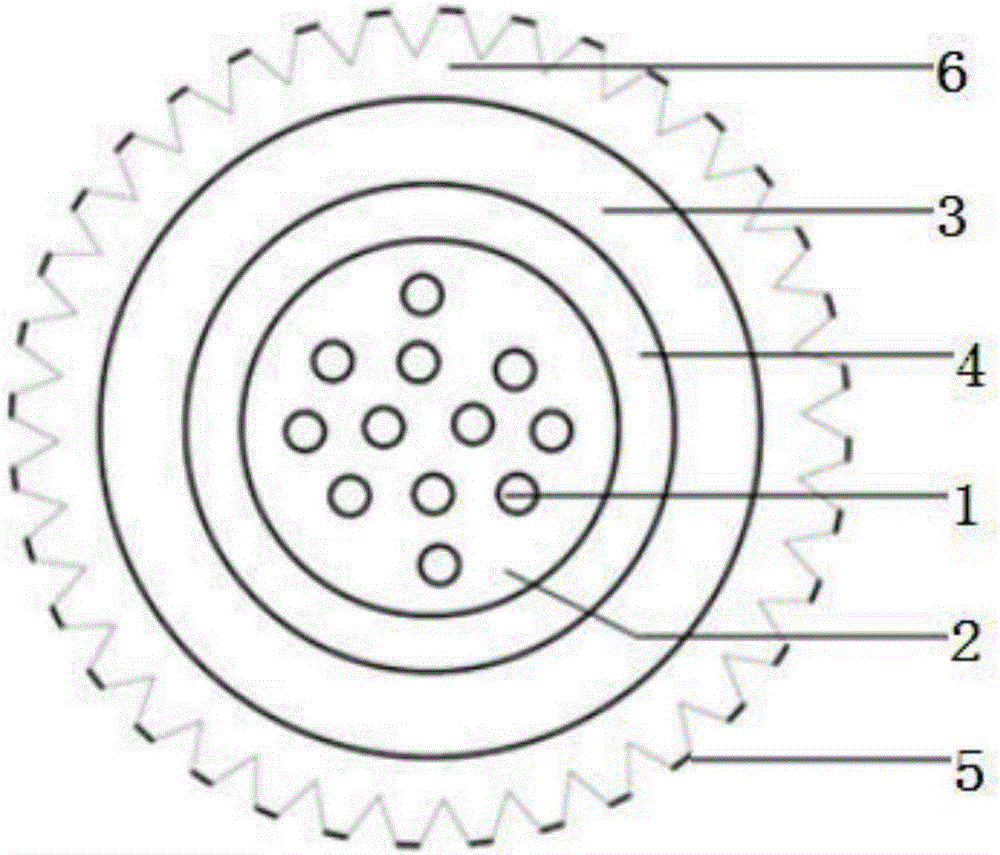

[0022] The present invention will now be described in further detail with reference to the drawings and embodiments. These drawings are simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, and therefore only show the constitutions related to the present invention.

[0023] Such as figure 1 As shown, a technical solution adopted by the present invention is: an ultra-miniature air-blown optical fiber cable, including: a loose tube 4, the loose tube 4 is wrapped with a plurality of optical fibers 1, and the loose tube 4 is filled with fiber paste 2. The loose tube 4 is sheathed with an outer sheath 6, a reinforcing material layer 3 is provided between the loose tube 4 and the outer sheath 6, and the outer wall of the outer sheath 6 is annularly provided with a number of serrated teeth , The end of the free end of the tooth is provided with a conductive layer 5, which is used to generate heat under the action of elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com