Explosion-proof spherical rotation measuring filling device

A dosing device, explosion-proof technology, applied in the direction of ammunition, weapon accessories, offensive equipment, etc., can solve the problems of high-sensitivity drugs that are easy to cause danger, large contact area, poor safety, etc., and achieve reliable conductivity treatment technology, friction area Small, material-optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

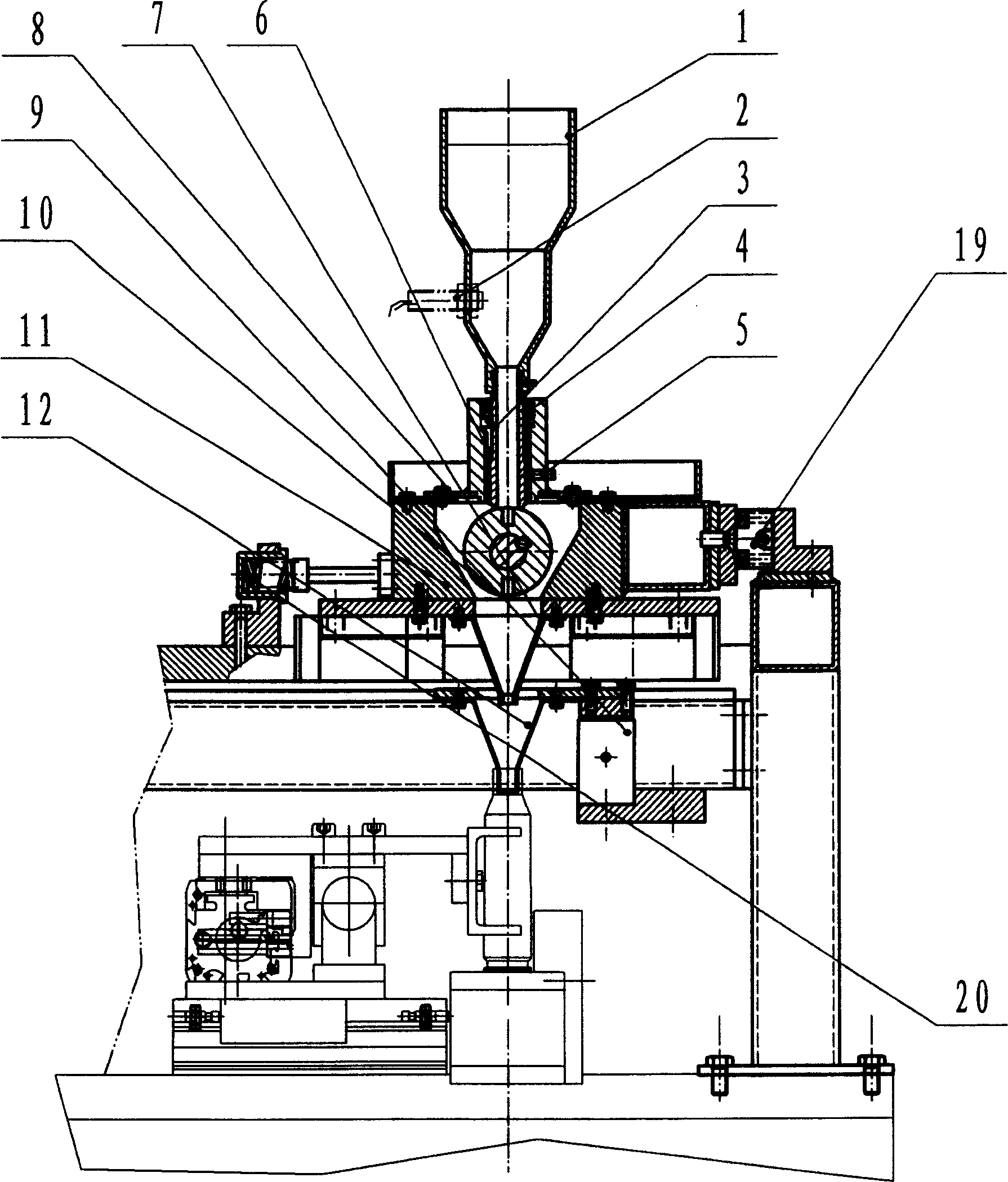

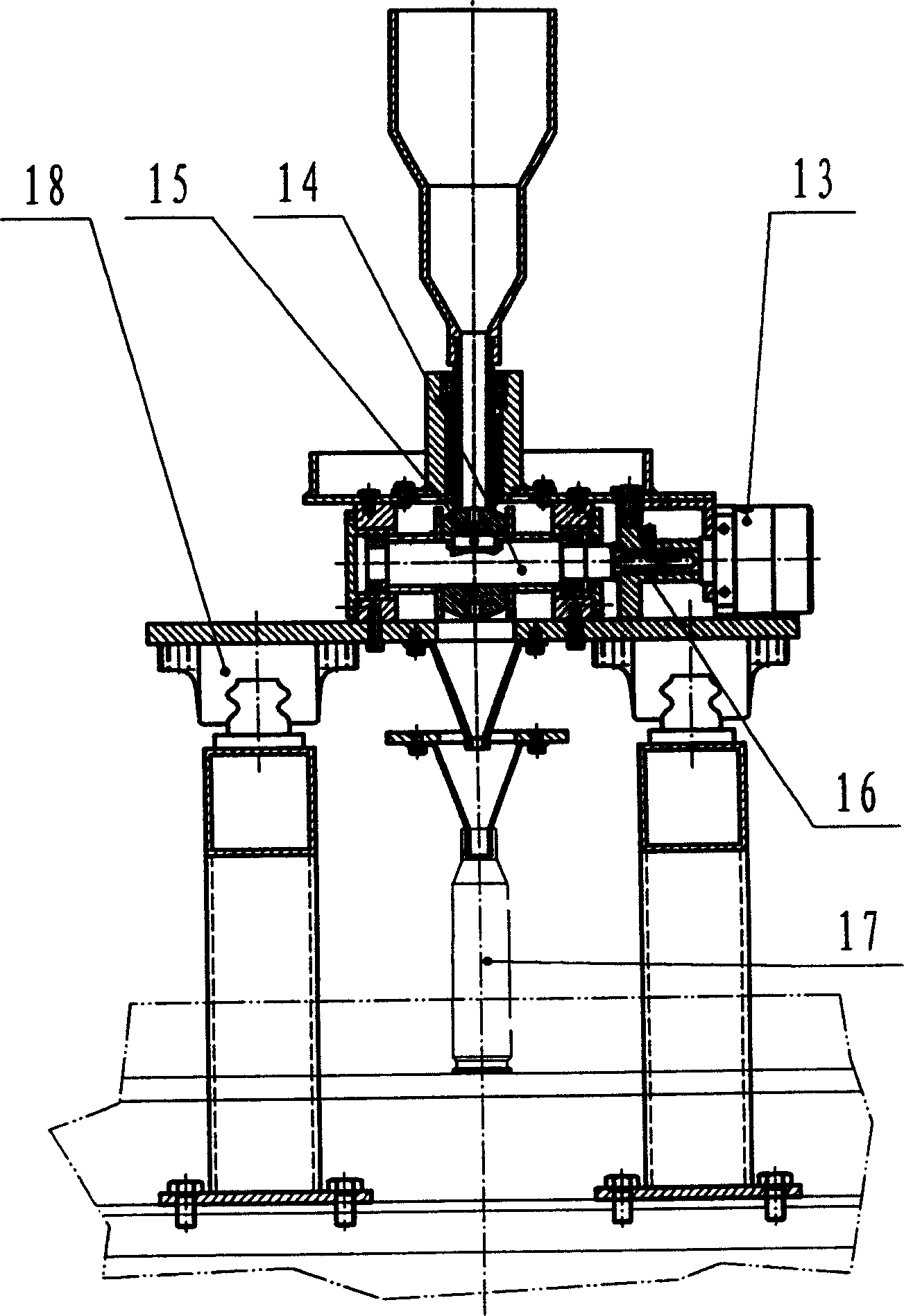

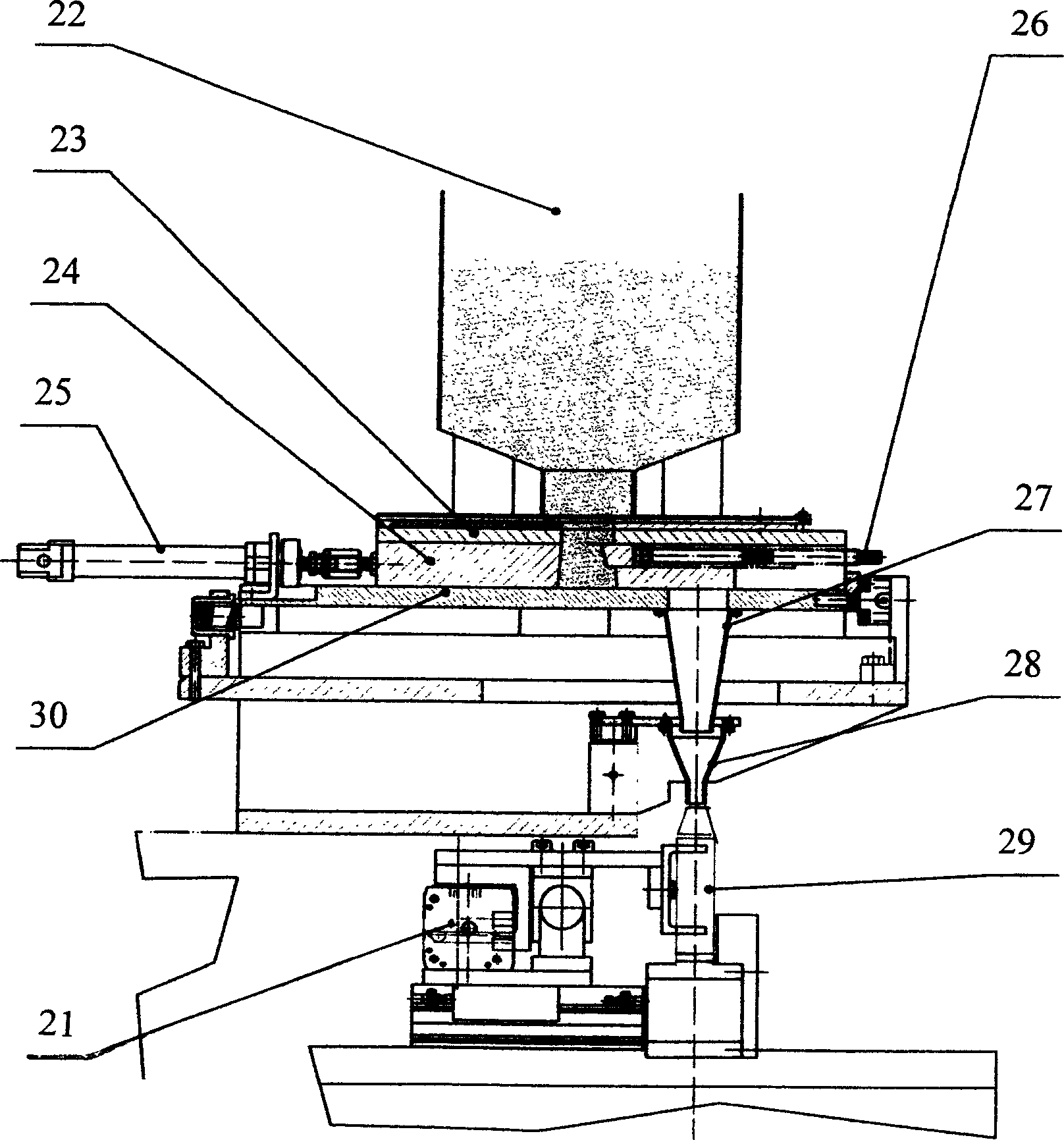

[0016] refer to figure 1 , figure 2 , the device of the present invention comprises a hopper 1, a fixed hopper 7, a movable hopper 12 and a casing support moving mechanism 21, that is, a sealing sleeve 3 and a hopper cover 8 are installed under the hopper 1, and a swing cylinder 13 and a fixed seat are fixed with screws on the bottom plate. 11. A sphere 10 is installed on the rotating shaft 14 of the swing cylinder, and a pair of metering holes or a sphere 10 with a metering hole are symmetrically opened on the same circumference and are in close contact with the sealing sleeve 3, and the two ends of the fixing seat 11 are respectively screwed with diaphragm vibration Cylinder 19 and recoil shock absorber 20, fixed funnel 7 is fixed with screws under the bottom plate, movable funnel 12 and movable funnel 12 lifting control cylinder 9 are fixed with screws under fixed funnel 7, linear guide rail 18 on the bottom plate is snapped to the track . Swing cylinder 13 rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com