Patents

Literature

49results about How to "Simple dress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

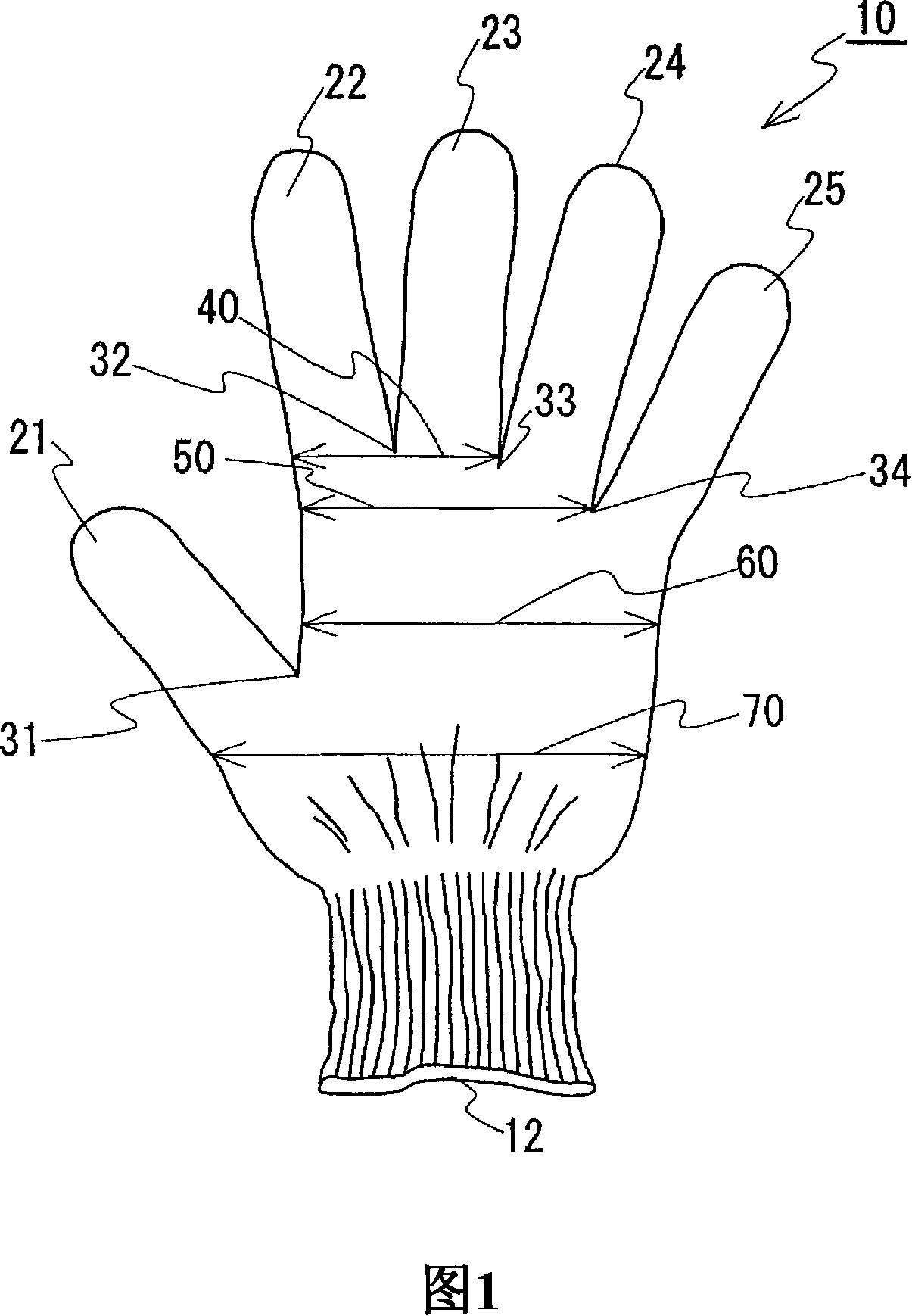

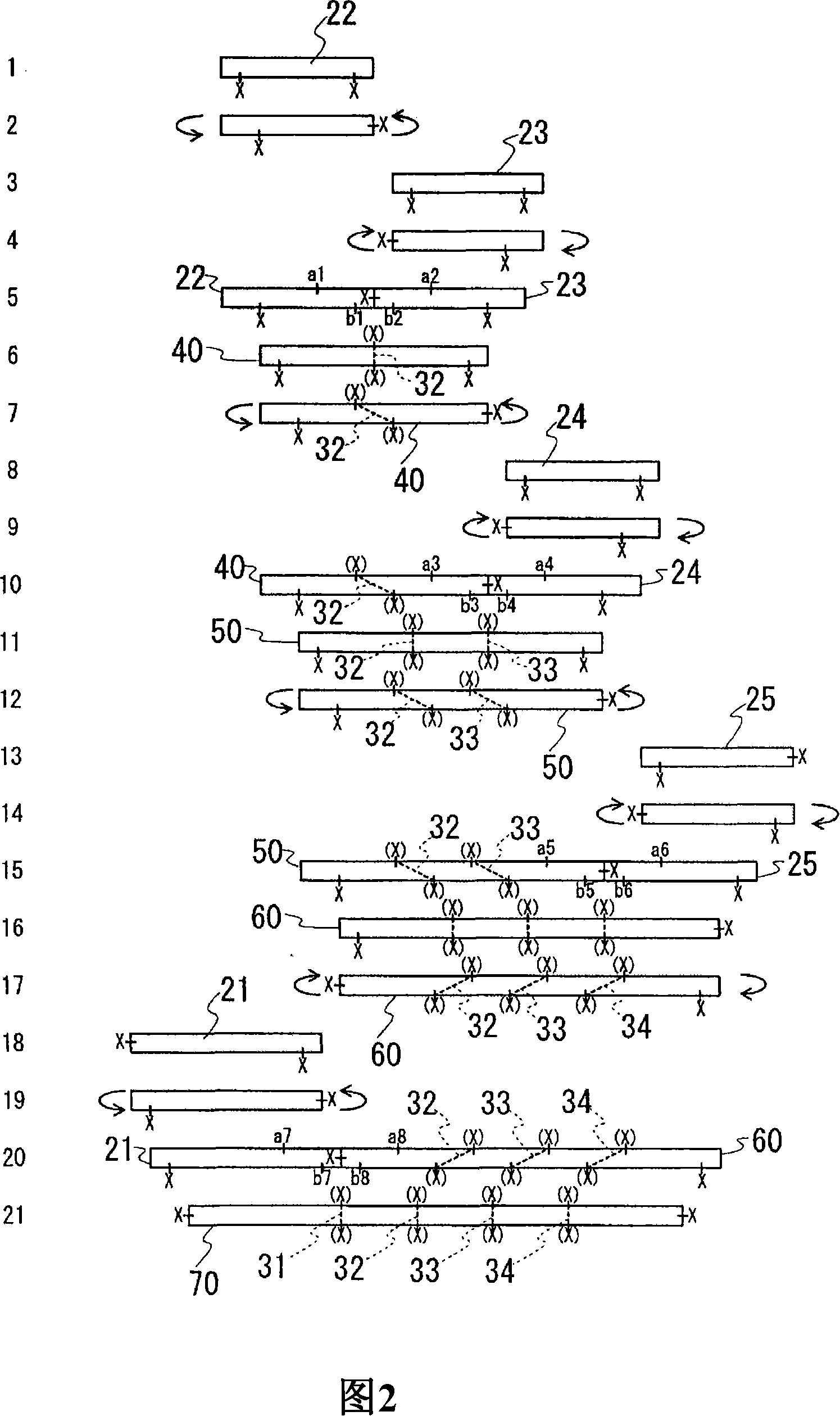

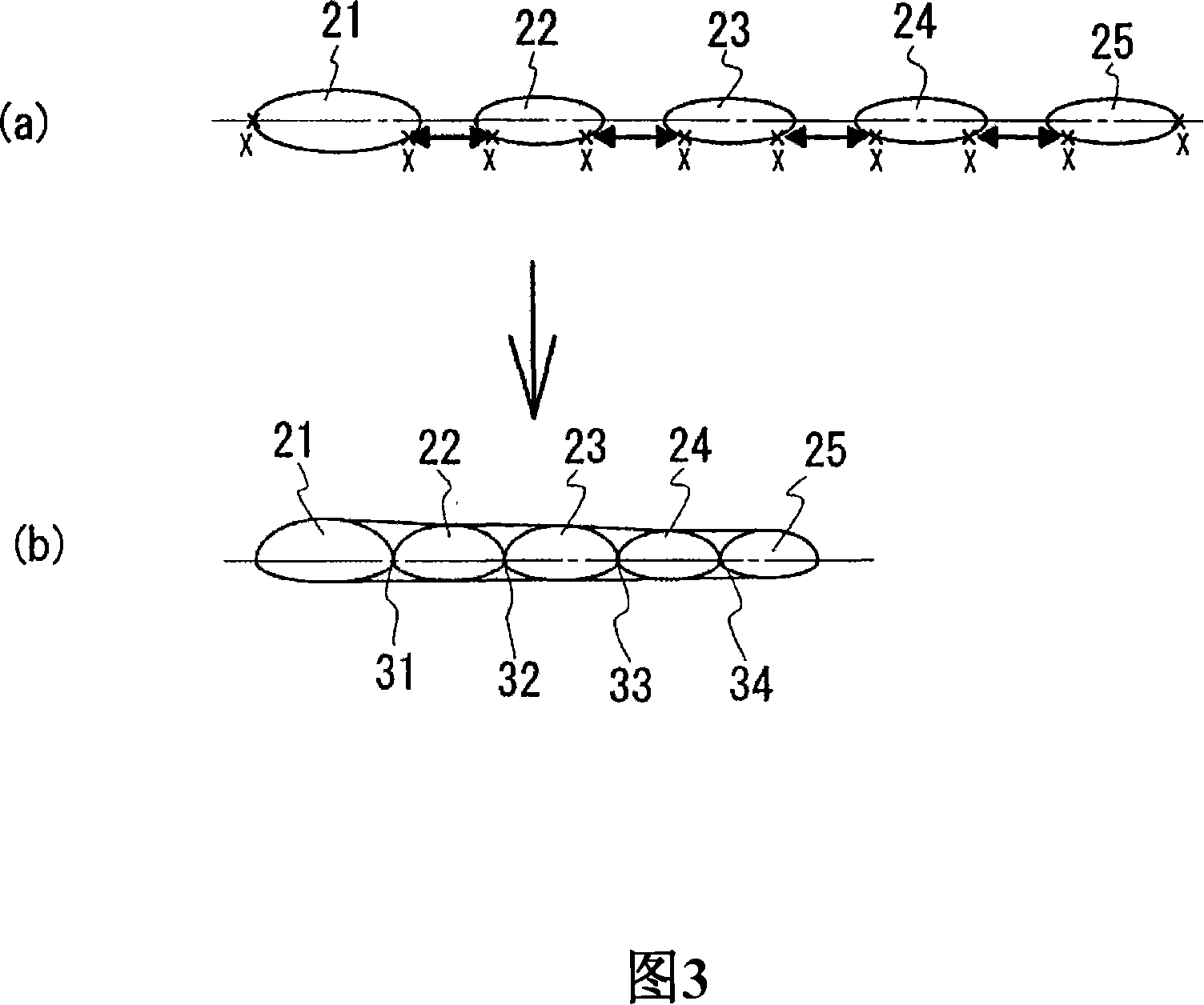

Knitting method of tubular knitted fabric

A knitting method provides an easy-to-wear knitted tubular knitted fabric which gives little stretching feeling and exhibits high fitness upon wearing by joining at least three tubular parts. The method of a tubular knitted fabric using a flat knitting machine having at least a pair of front and back needle beds extending in a transverse direction and disposed opposite to each other in a cross direction, at least either of which is racked in the transverse direction so that loops can be transferred between the front and back needle beds comprises an operation of joining two tubular parts at a boundary of front and back knitted fabrics to form a tubular part is repeated; wherein the boundary is set so that the front knitted fabric and the back knitted fabrics are different in length in a knitting width direction immediately before joining for at least one tubular part; the tubular part in which the front and back knitted fabrics are different in length in the knitting width direction and the boundary to be joined is not positioned between the front and back needle beds is rotated so that the boundary is positioned between the front and back needle beds; and two adjacent tubular parts having the boundaries opposed to each other between the needle beds are joined while holding the boundary in between after the rotation.

Owner:SHIMA SEIKI MFG LTD

Production process of flax socks

The present invention relates to the production process of socks with flax yarn as main amterial and belongs to the field of textile technology. Flax material is combined with other fibers to produce comfortable and durable socks capable of rpeventing smelly foot. Technologically, the present invention features that flax yarn and cotton yarn are double and then matched with Chinlon yarn and urethane elastic fiber yarn in knitting socks and the flax content in the material is 25-55%. The socks are penetrant, hygroscopic, bacteriostatic, bad smell preventing and comfortable.

Owner:姜元麒 +1

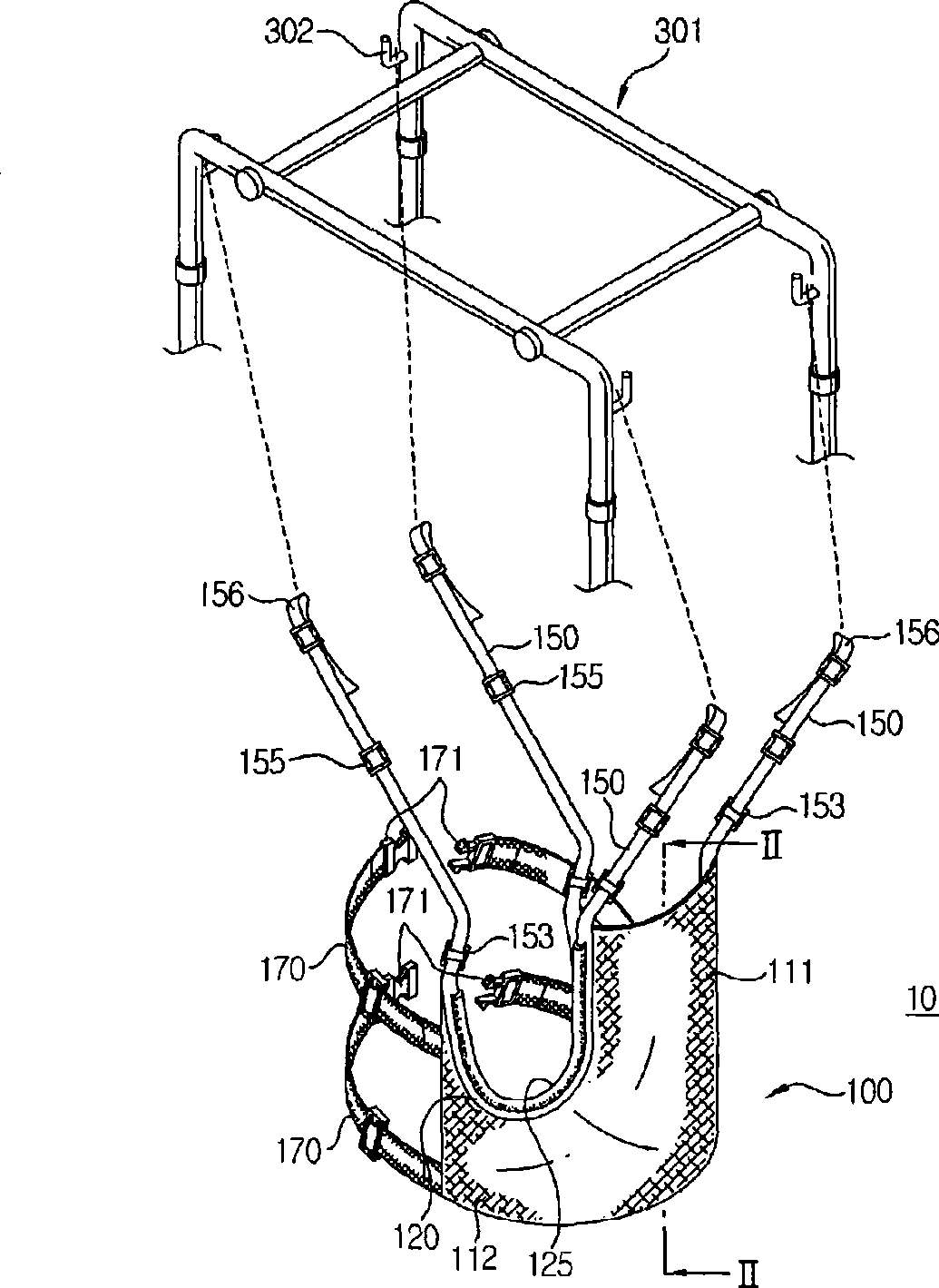

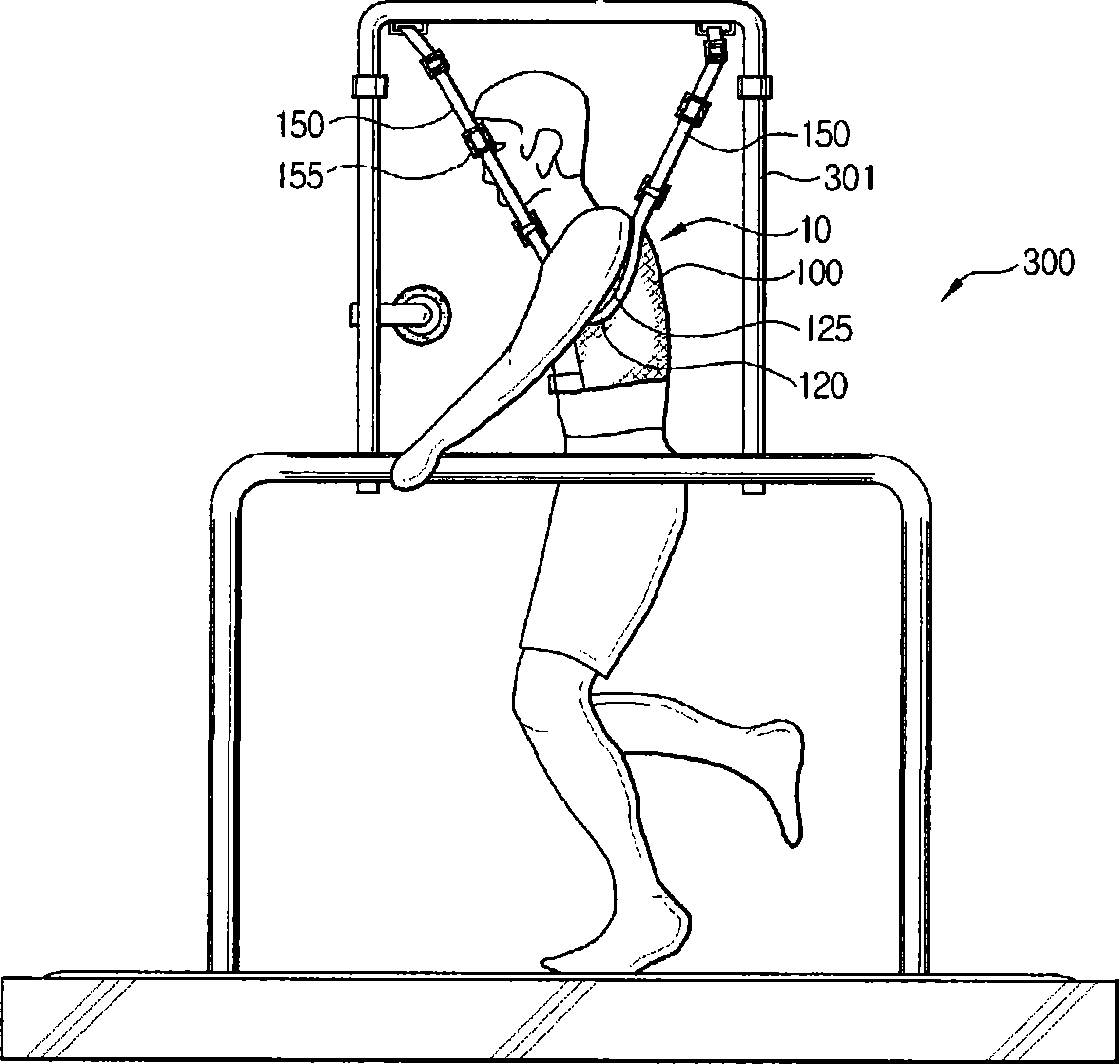

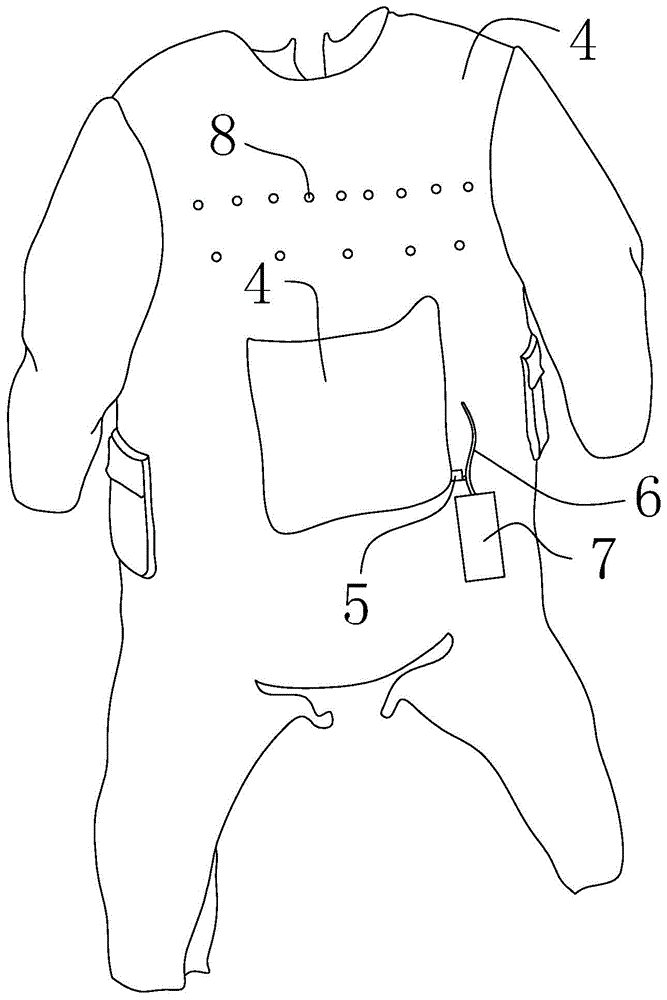

Safe jacket for senior and patient who need remedial exercise and exercising apparatus having the same

Owner:金世坤 +1

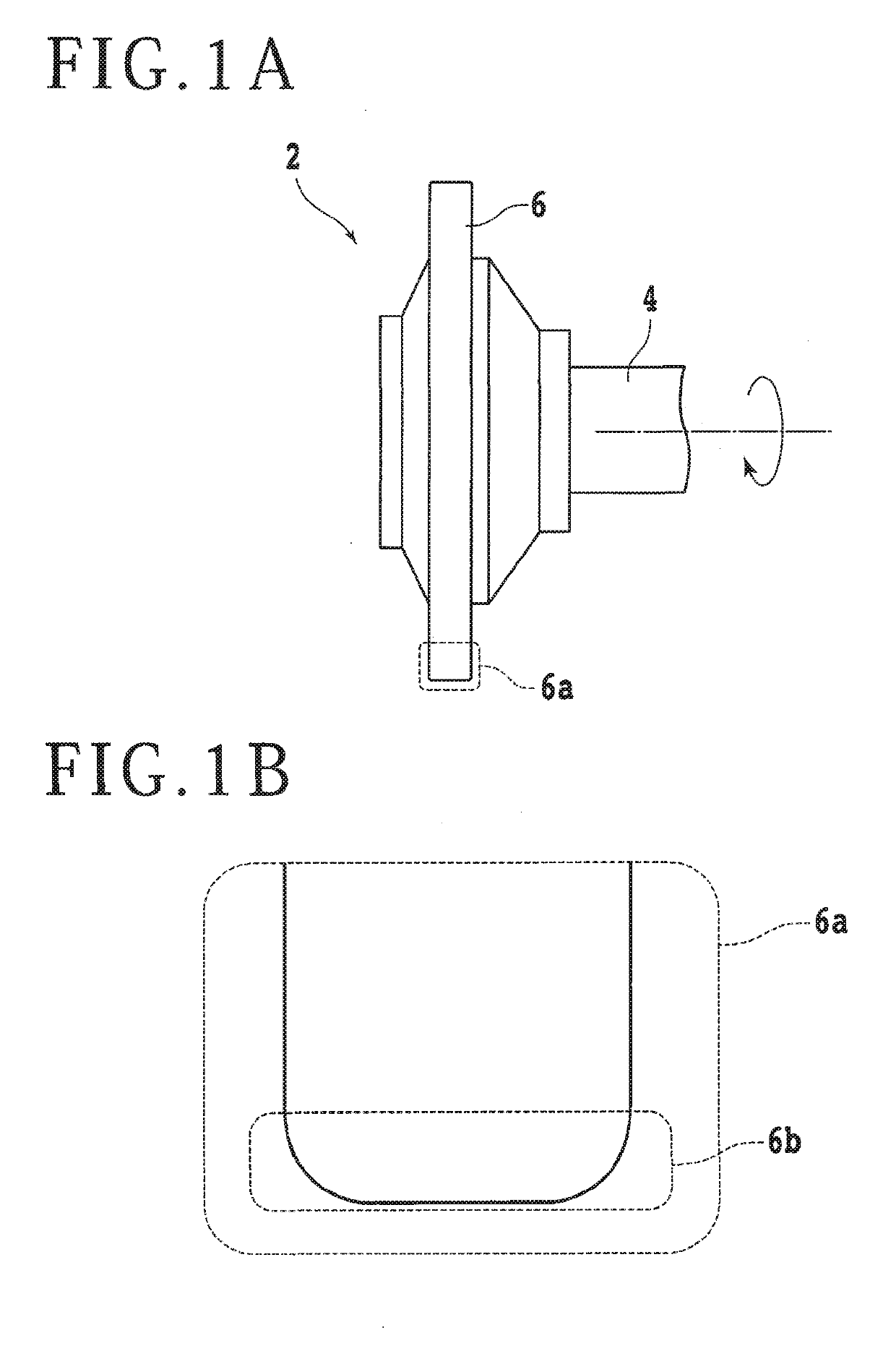

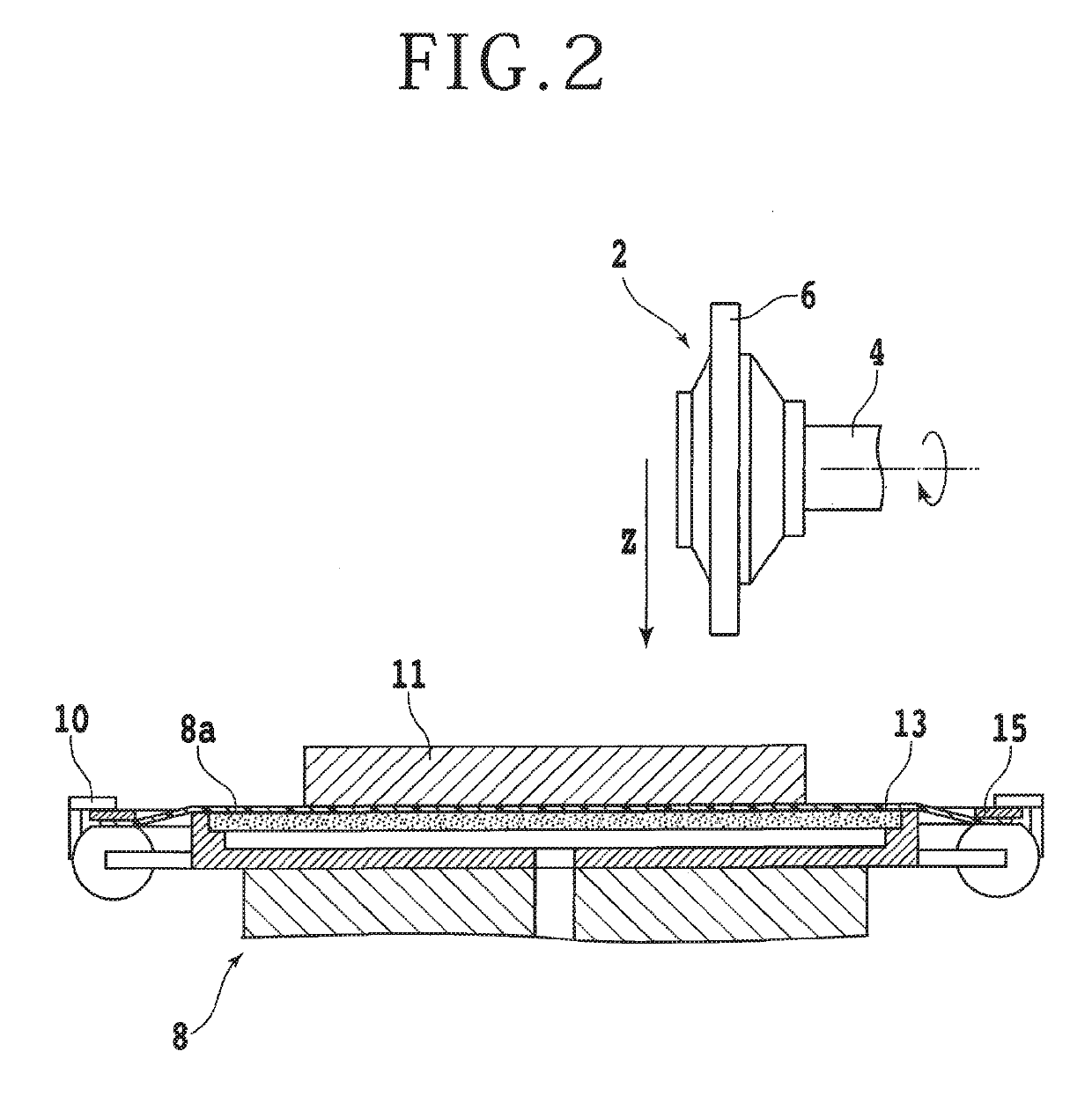

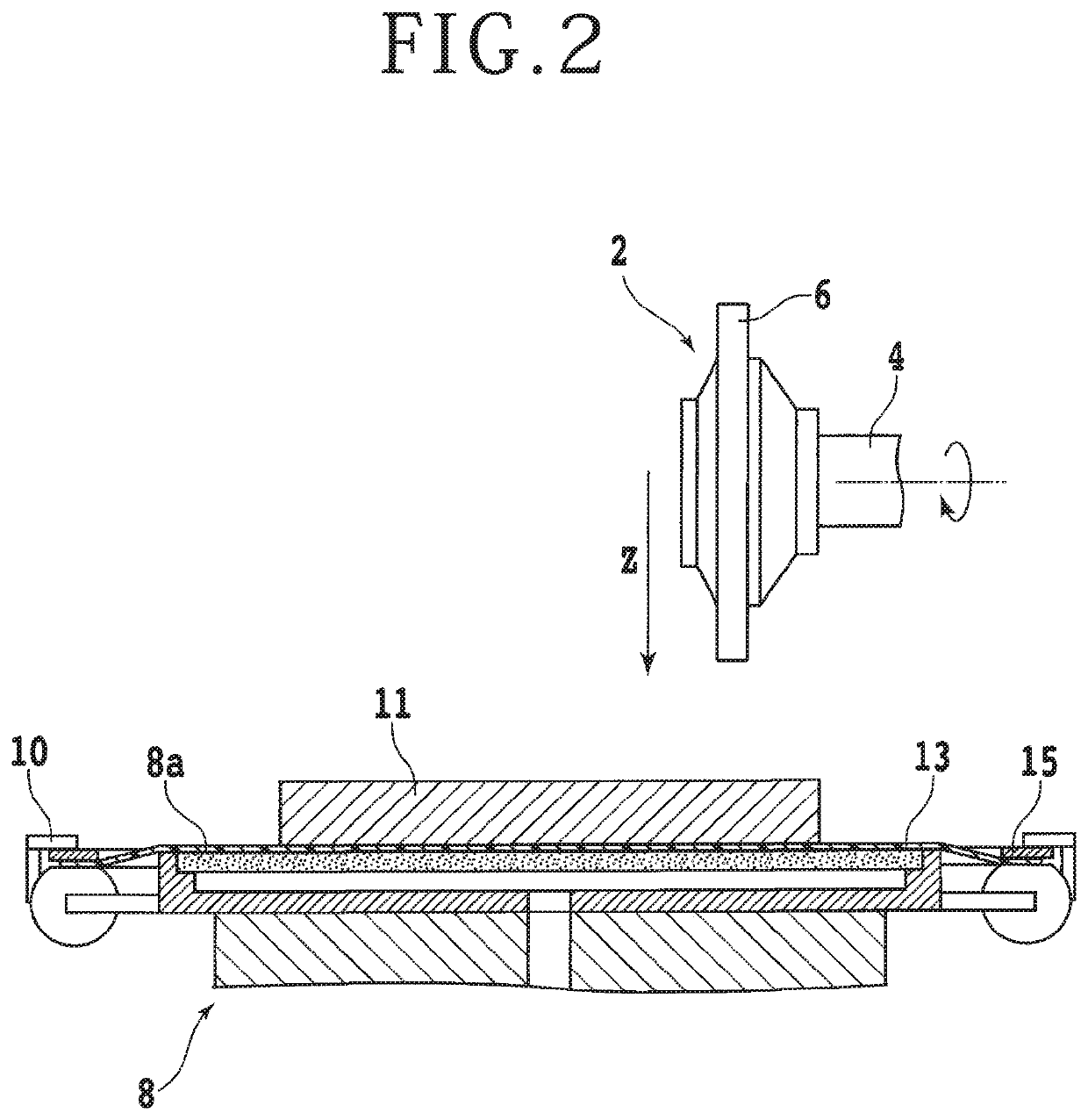

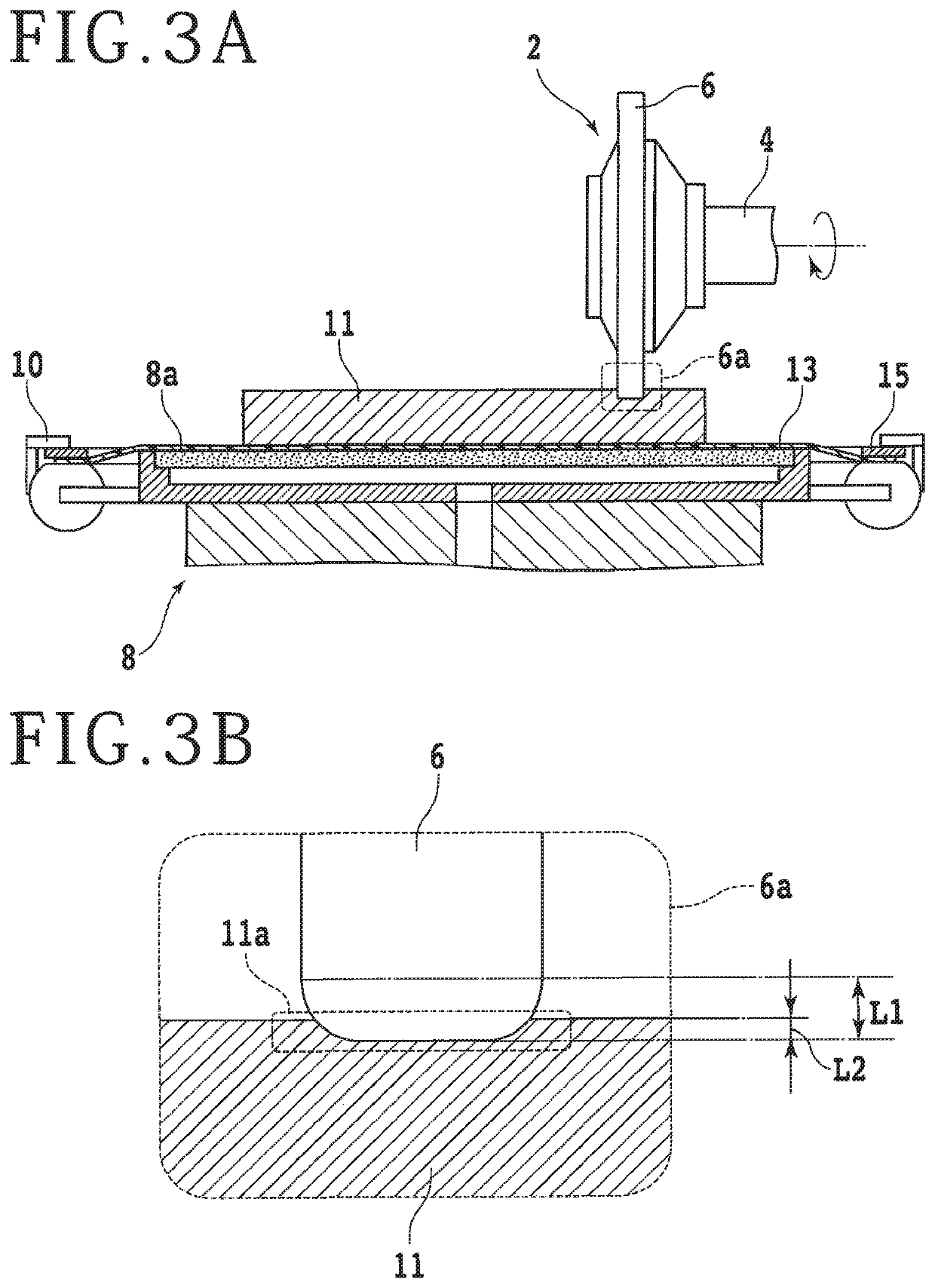

Dressing method of cutting blade

ActiveUS20190202018A1Easy to wearIncrease the number of timesSemiconductor/solid-state device manufacturingSawing tools dressing arrangementsEngineeringKnife blades

A dressing method of a cutting blade includes a first cutting step of causing the cutting blade to cut into a dressing board held by a holding surface of a chuck table with a cutting depth that does not surpass the length of the region of roundness in the radial direction of the cutting blade to form a cut groove in the dressing board, and a second cutting step of causing the cutting blade to further cut into the groove bottom of the cut groove formed in the first cutting step with a cutting depth that does not surpass the length of the region of roundness in the radial direction of the cutting blade to carry out cutting on the groove bottom with tracing of the cut groove.

Owner:DISCO CORP

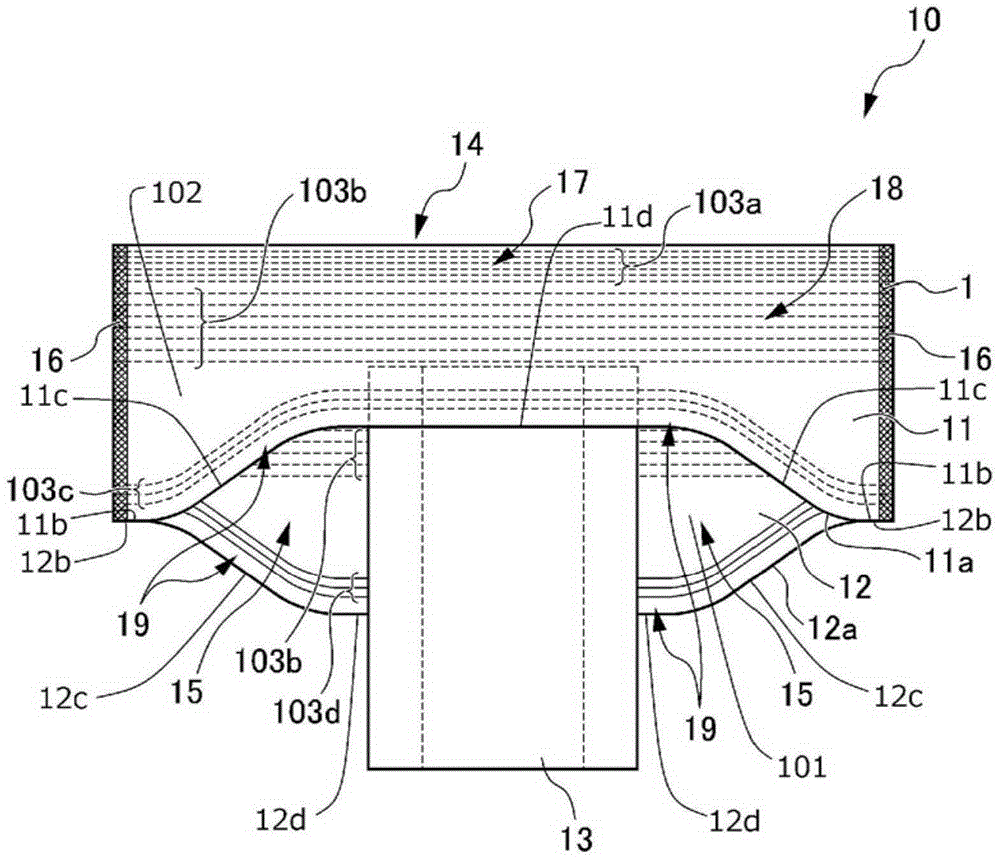

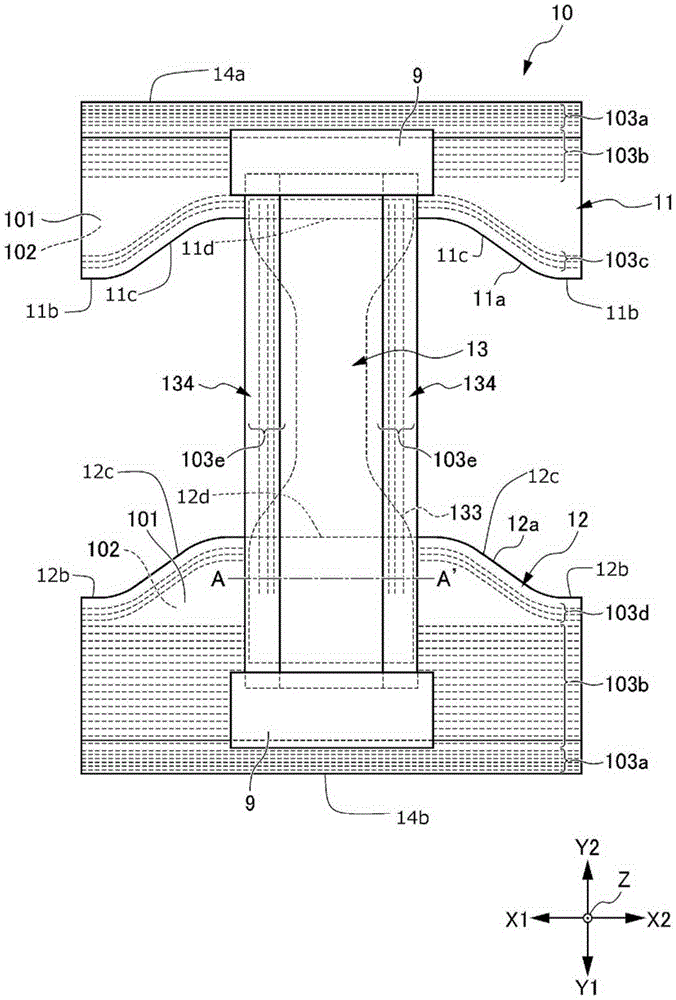

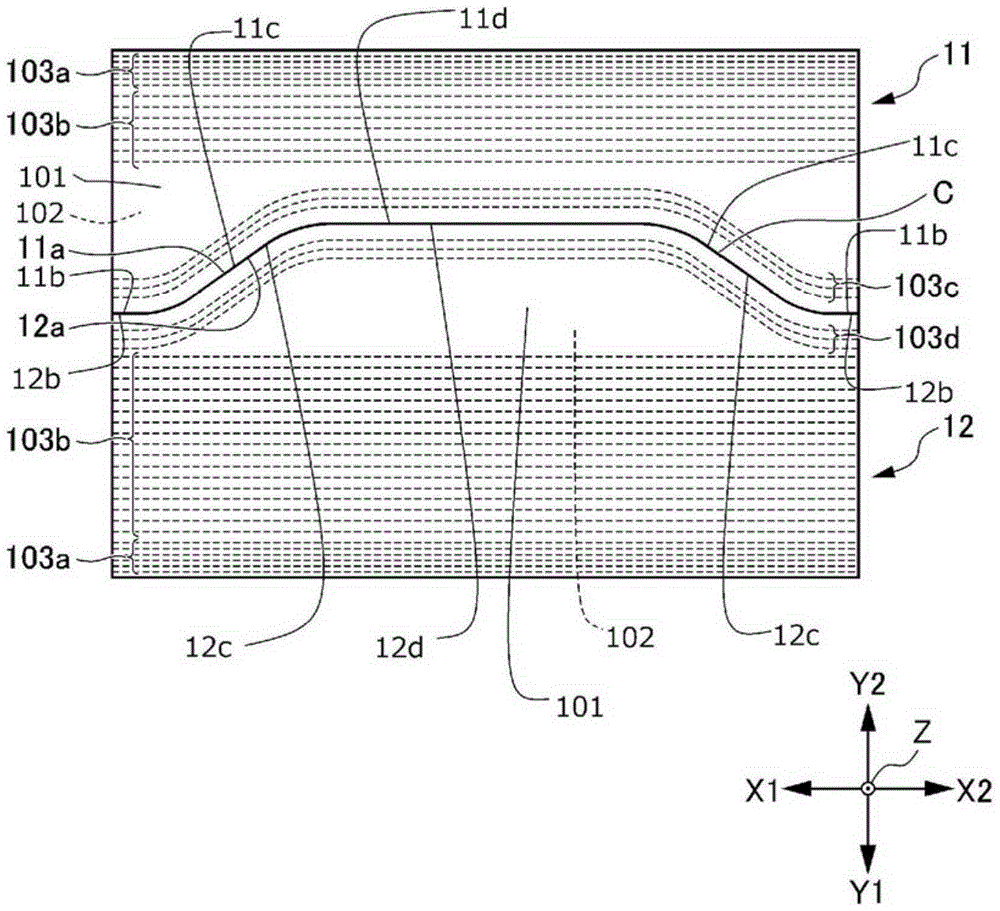

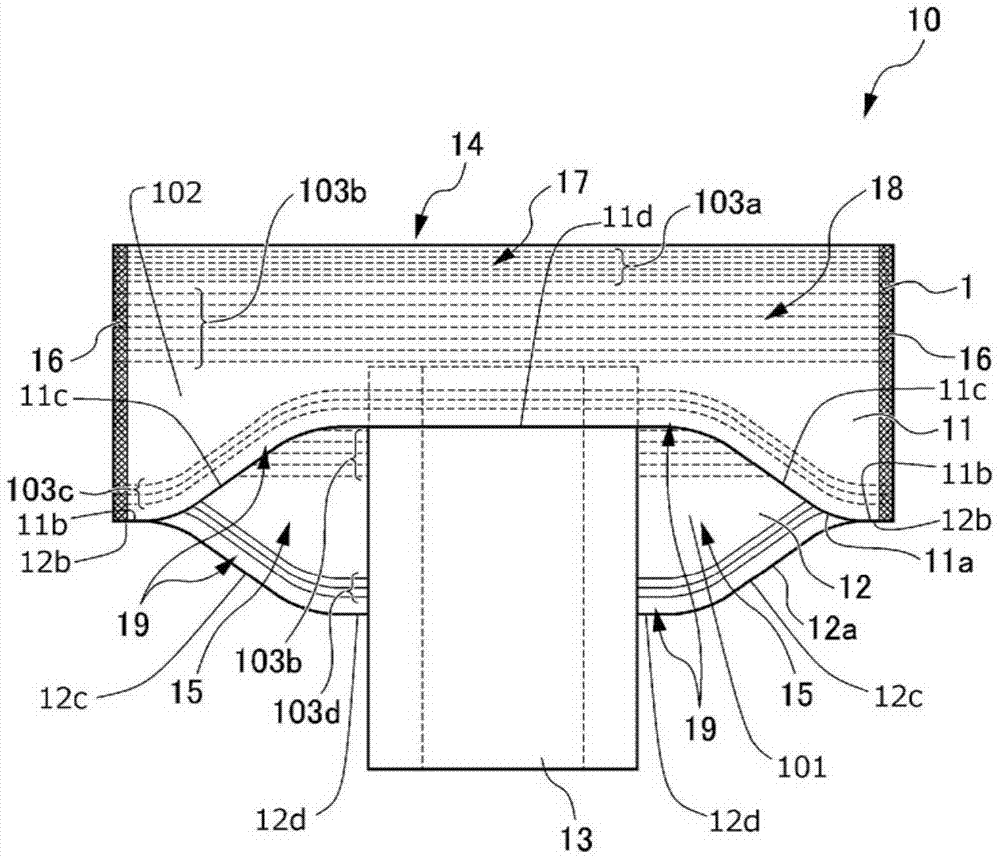

Disposable pant-type underwear, and manufacturing method therefor

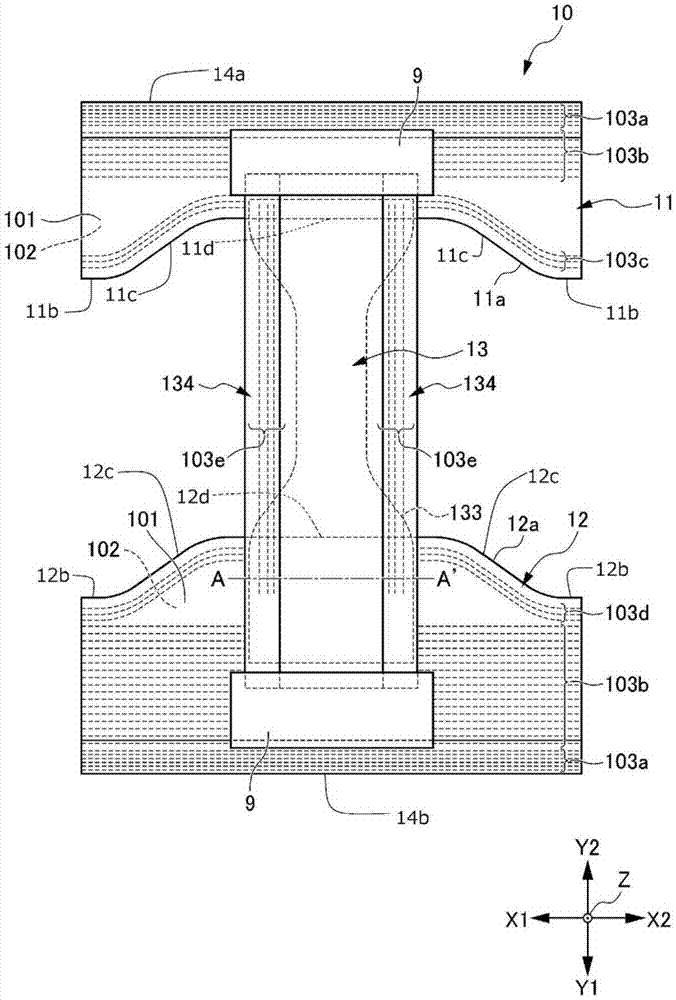

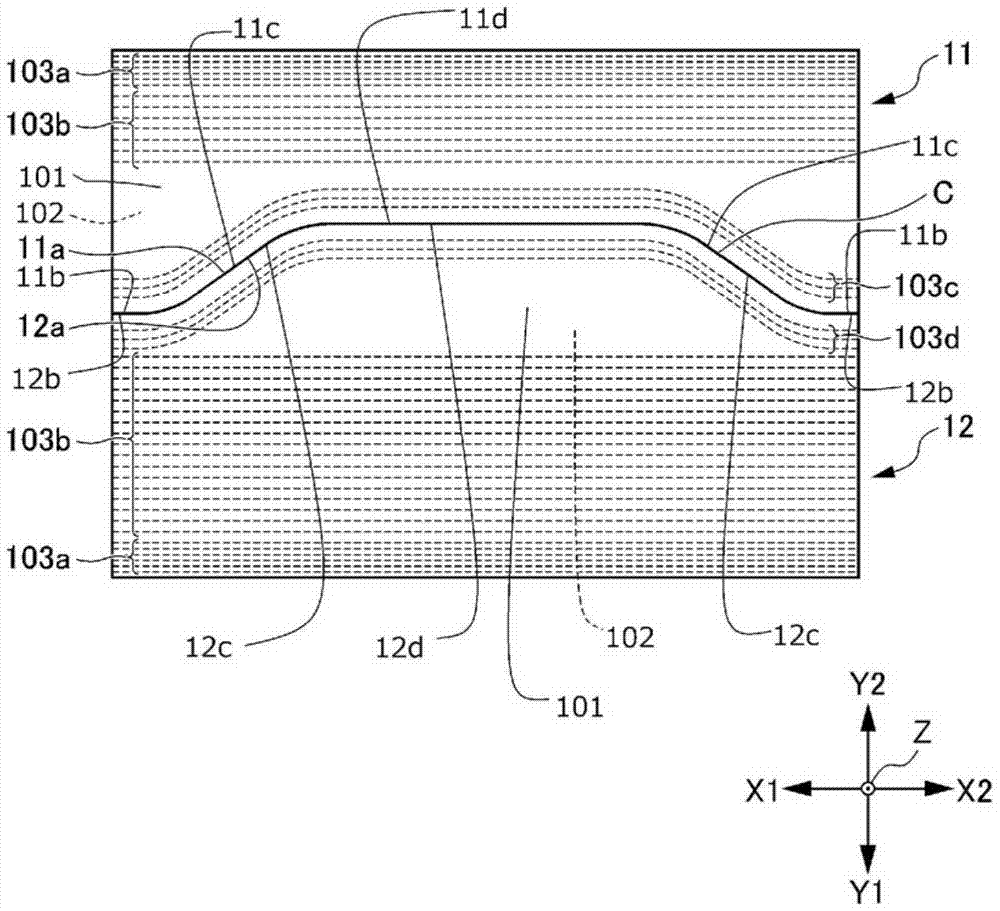

Provided are disposable pant-type underwear, and a manufacturing method therefor, the disposable pant-type underwear being easy to wear, having a good fit to the body of the wearer, and requiring little material for production. The method for manufacturing disposable pant-type underwear (10) is characterized by comprising: a step for forming a layered body (100A) in which elastic bodies (103) are bonded between a webbed inner-surface sheet (101) and an outer-surface sheet (102); a step for cutting the layered body (100A) along a cutting guidance line (C) along which crotch-side edges (11a, 12a) shared by a ventral member (11) and a dorsal member (12) are periodically continuous in the web flow direction; a step for positioning, in each period, a crotch member (13) so as to span the central portion of both the ventral member (11) and the dorsal member (12) and bonding the crotch member thereto; and a step for folding a continuous body (100B) in which the crotch members (13) have been bonded, and, for each individual period, bonding the continuous body (100B) at both ends (16, 16) that are perpendicular to the direction in which the web flows, and cutting along both ends (16, 16). The method is further characterized by the cutting guidance line (C) for each period including: two end lines (11b, 11b, 12b, 12b) that are parallel to the direction in which the web flows; a pair of inclined lines (11c, 11c, 12c, 12c) that are inclined towards the ventral member (11) from the two end lines toward the center; and central lines (11d, 12d) that connect both inclined lines.

Owner:KOYO CORP

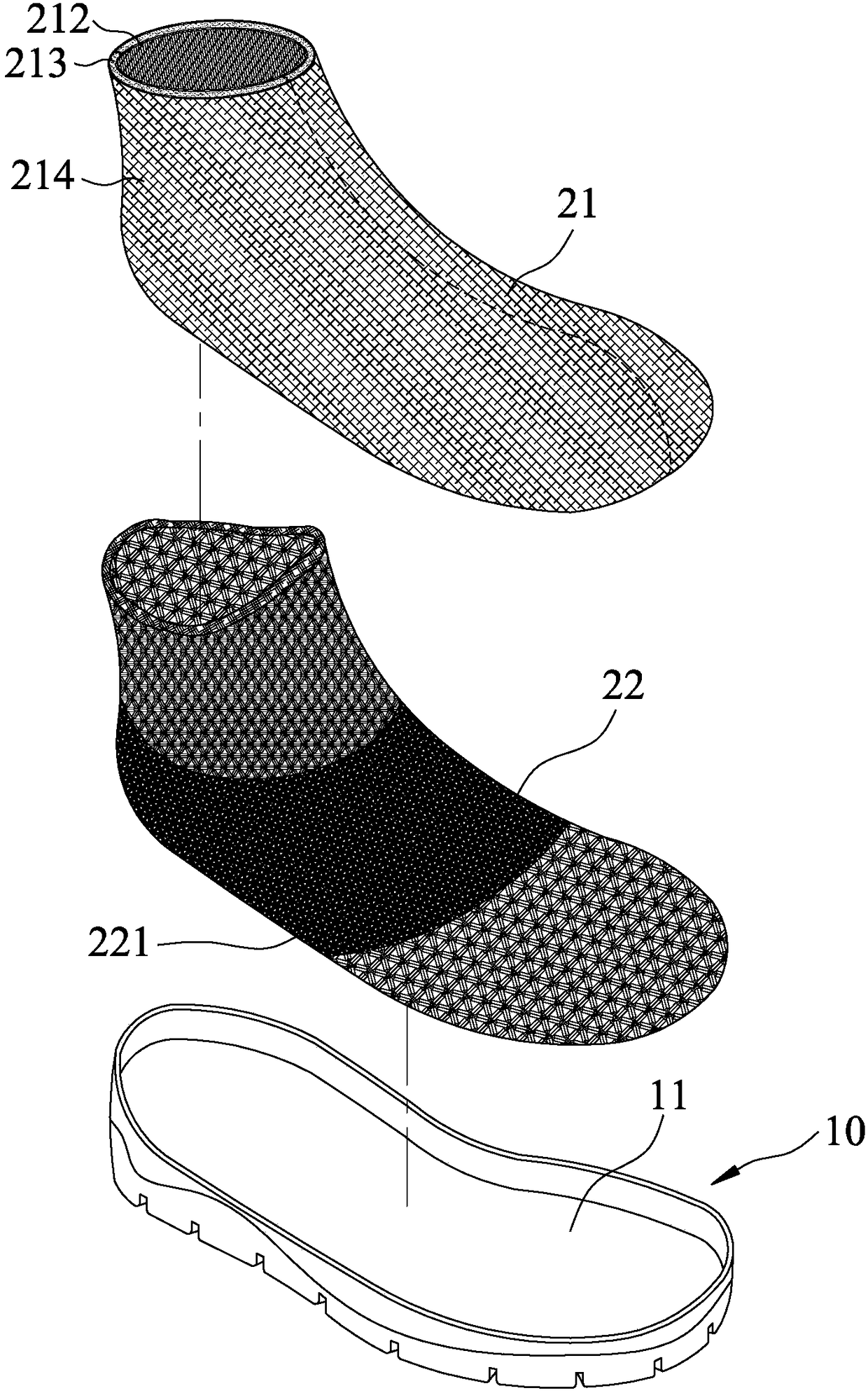

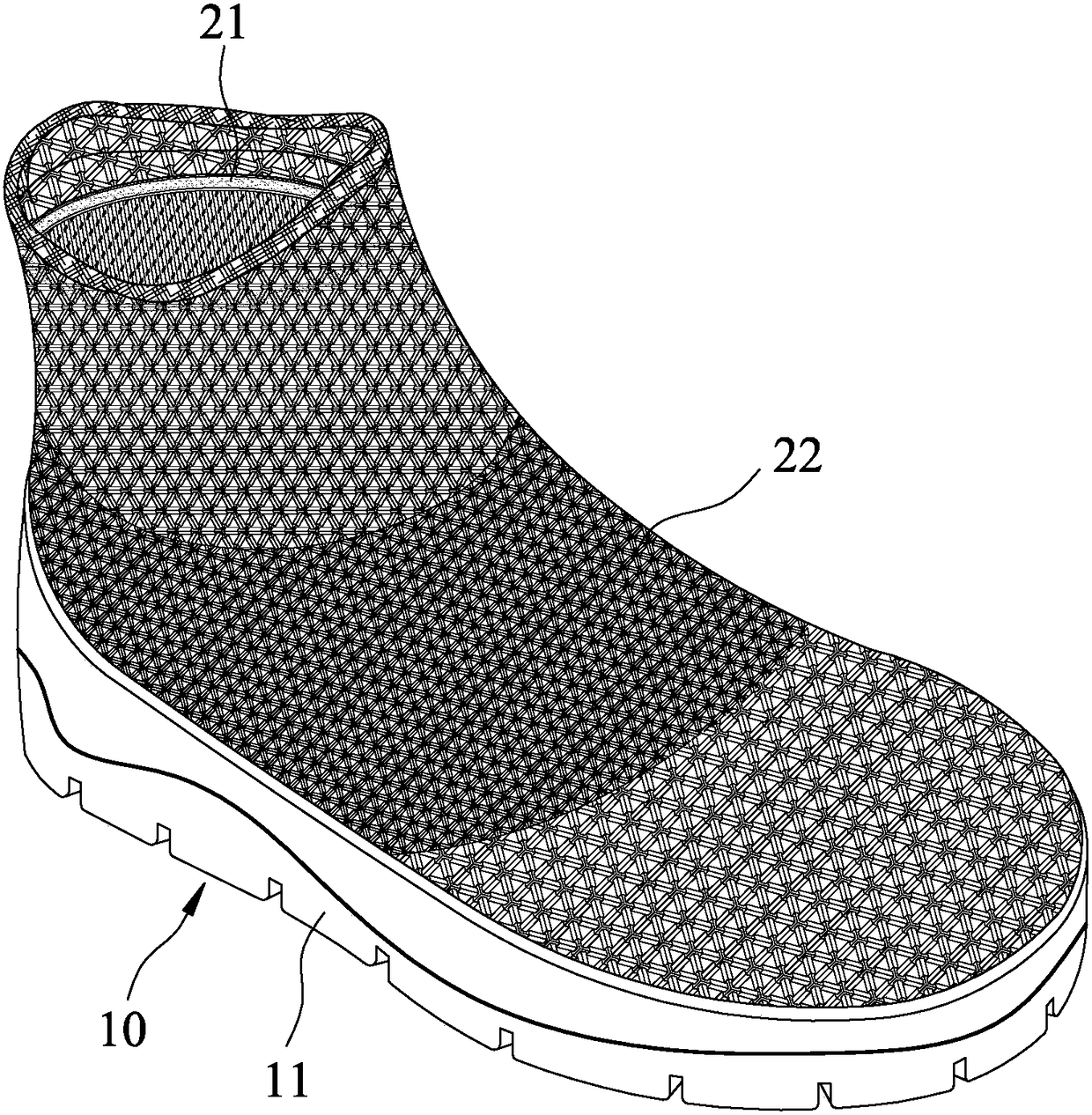

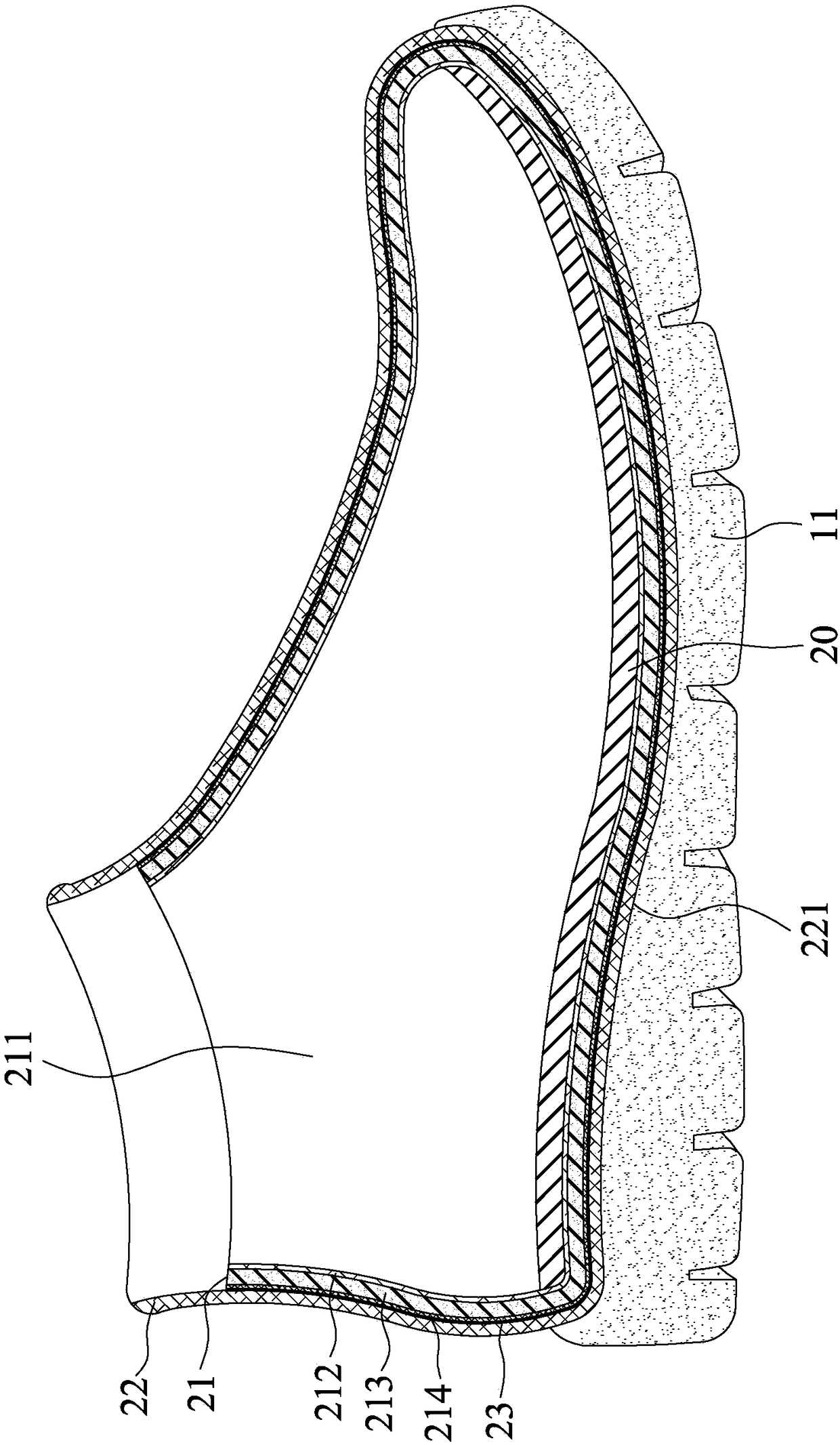

Three -dimensional sock shoe

InactiveCN109077381AIncrease elasticityNice and easy to wearSolesInsolesThree-dimensional spaceThree dimensional shape

A three-dimensional sock shoe includes a sole unit, a foam shoe sleeve, an outer sock body, and at least one joint layer; the sole unit includes a sole; the foam shoe sleeve is formed by butt-jointingand sewing at least two layered structures; a last is arranged in the foam shoe sleeve to define a foot three-dimensional space, and the foam shoe sleeve successively includes, from inside to outer side, an inner lining layer, a foam layer, and an outer cloth layer; the outer sock body sleeves the foam shoe sleeve, and has a bottom connected to the shoe; the shape of the outer sock body is shapecorresponding to the foot three-dimensional space; and the joint layer is disposed between the outer cloth layer and the outer sock body so as to the outer sock body to be closely attached to the outer cloth layer. The foam shoe sleeve has good elasticity, and can enable the three-dimensional sock shoe to maintain a three-dimensional shape without sinking inward while the three-dimensional sock shoe is not put on; the three-dimensional sock shoe is beautiful, is easy to wear for a user, can selectively arrange a moisture-permeable waterproof sleeve, and can further achieve a moisture-permeablewaterproof effect.

Owner:SHUANG BANG IND

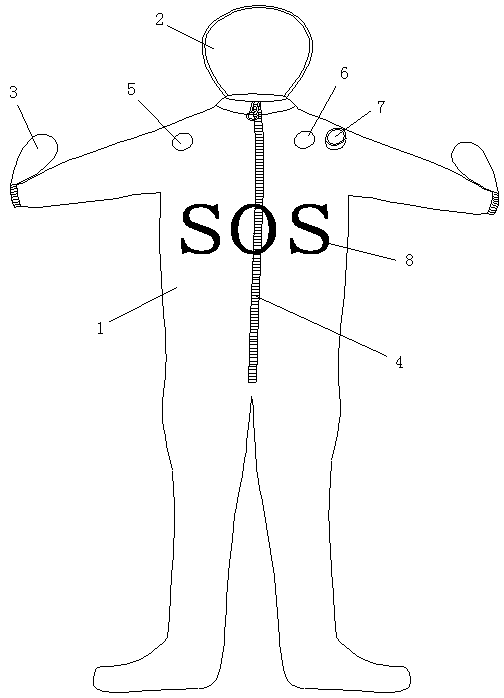

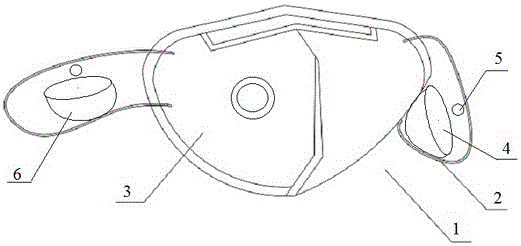

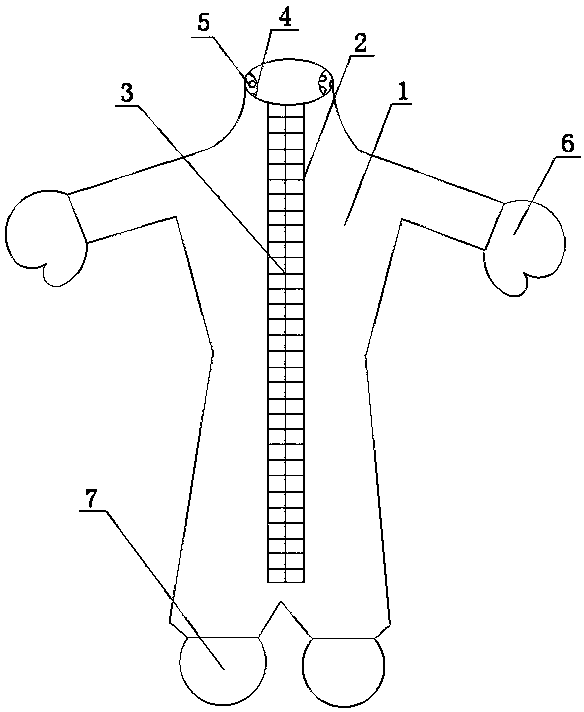

Life jacket

The invention discloses a life jacket which comprises a life jacket body which is a clothes-shaped body with an integrated structure, wherein the body is an air bag body with an inner layer structure and an outer layer structure; an inflating device is arranged on the body and used as a self-service built-in inflating device; the whole body has a closed structure; the inflating device is communicated with a front part, a back, sleeves and trouser legs which form the body through inner hollow cavities of the body; and a zipper is arranged on the front part of the body, and is a waterproof zipper. Compared with the existing life jacket, the life jacket disclosed by the invention has the advantages that: 1, the life jacket is integrated, so that a human body can be protected from being contacted with water to the maximum extent, a phenomenon of heat loss is avoided, physical strength and body temperature consumption of people falling into the water is reduced, and a phenomenon that the people falling into the water is prevented from being frozen to death in the cold water is avoided; 2, by adopting the self-service built-in inflating device, the life jacket is relatively convenient and easy to wear, and a user can inflate the life jacket by own after wearing the life jacket; and 3, the whole structure is relatively simple, the cost is relatively low, and the life jacket is relatively convenient to use.

Owner:淮安博土信息科技有限公司

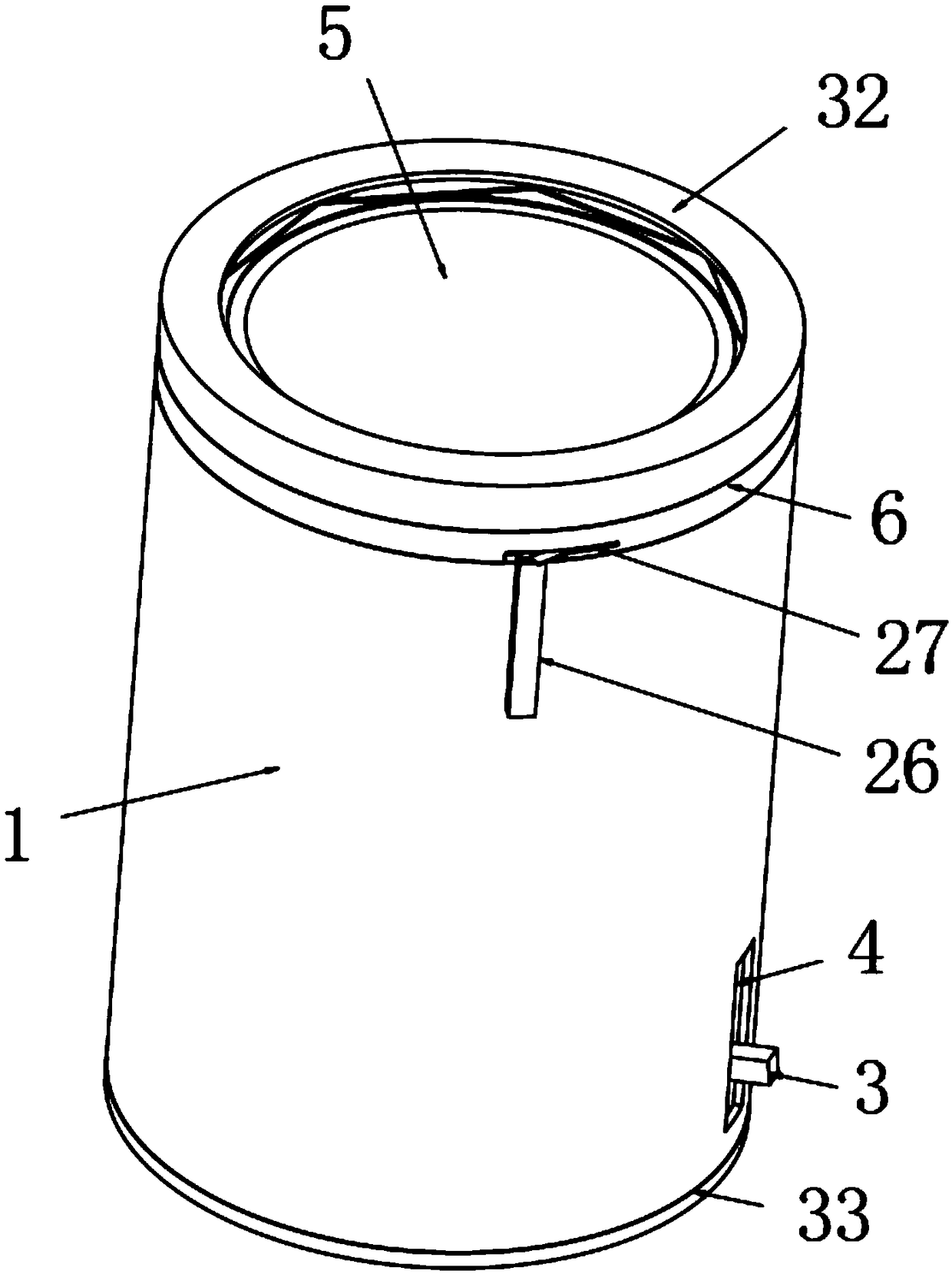

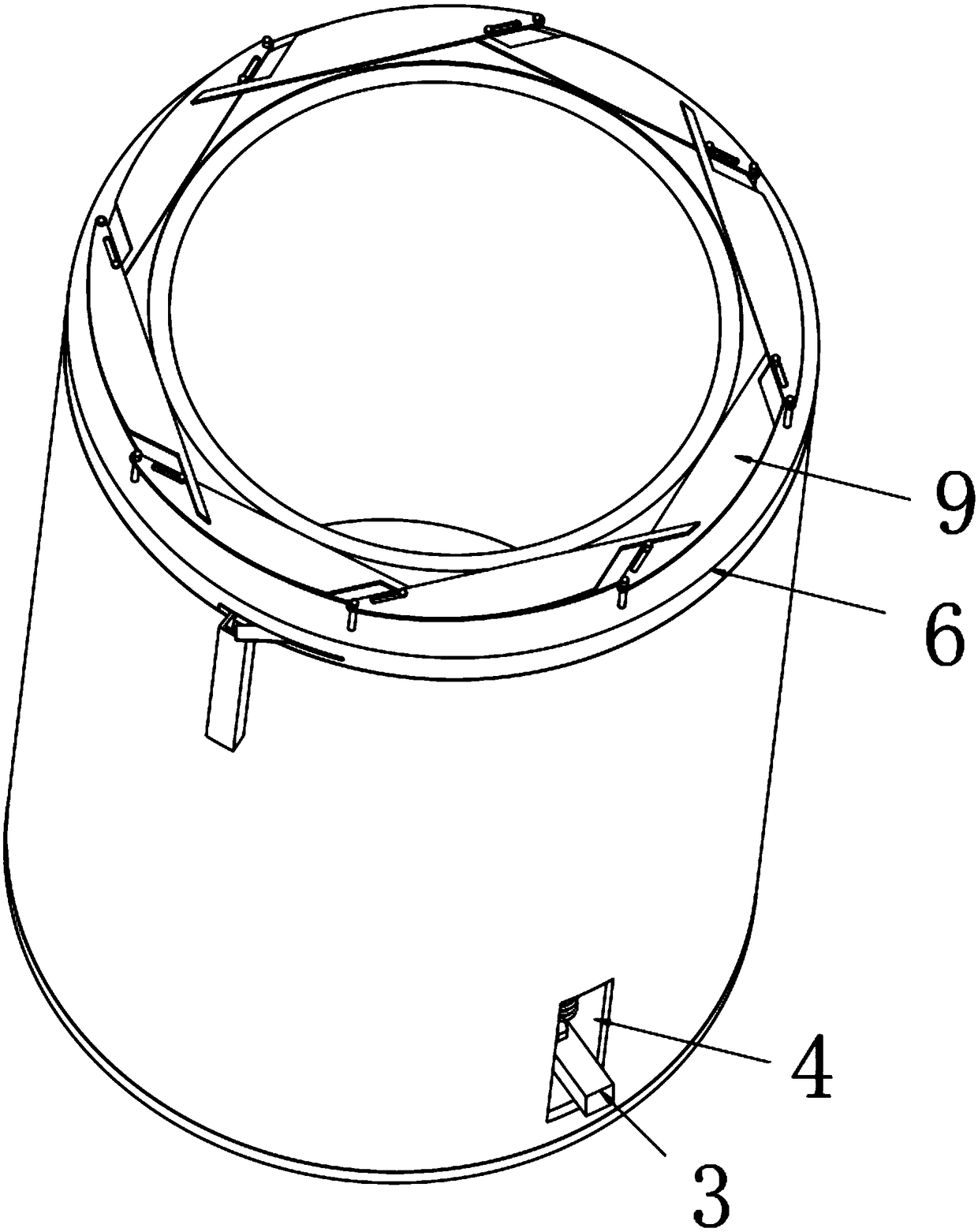

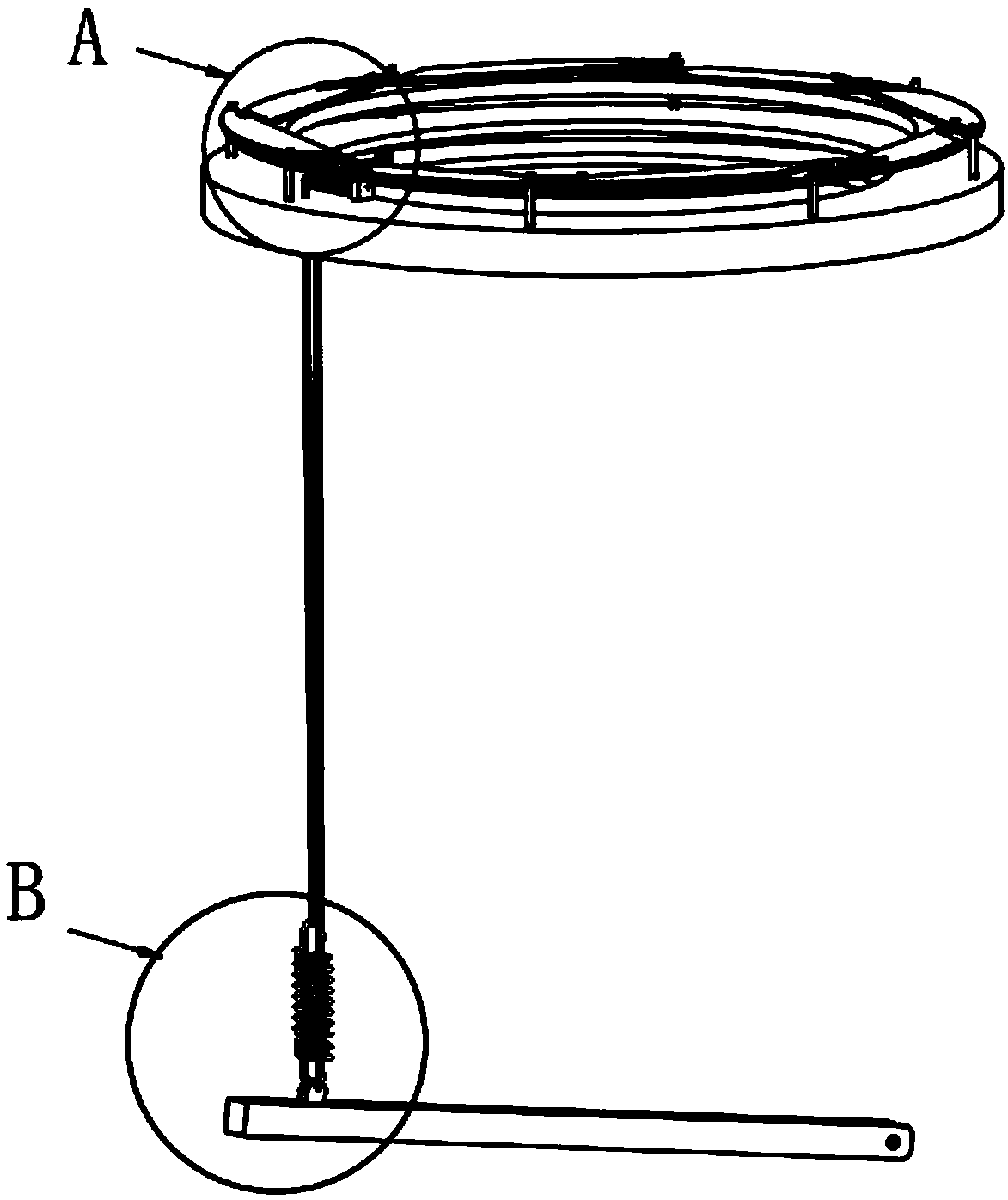

Self-packaging rubbish bin

The invention discloses a self-packaging rubbish bin. The self-packaging rubbish bin comprises a shell, a pedal, a liner, an annular connecting plate, a shifting piece, a first nail claw, a second nail claw and a nail box. A mounting base is fixedly arranged on the inner wall of the bottom of the shell. The outer side of the mounting base is connected with the pedal through a dowel in a rotating mode. A long hole is formed in the side wall of the shell. The end, far away from the mounting base, of the pedal penetrates through the long hole and is exposed in the air. The liner is arranged on the inner side of the shell and the pedal is located under the liner. The outer side of the liner is fixedly connected with the annular connecting plate in a sleeved mode. The bottom of the annular connecting plate is fixedly connected with the top of the shell. The top of the liner is connected with a shifting piece control panel in a rotating mode. According to the self-packaging rubbish bin, rubbish bags can be packaged automatically by tightening and bundling the rubbish bags, the bundling process is made easy by feeding nails automatically, and practicability is higher; and there is no needfor people to touch the rubbish bags in the bundling process, pollution to the hands of people by bacteria is avoided and more sanitation is achieved.

Owner:钟岳锋

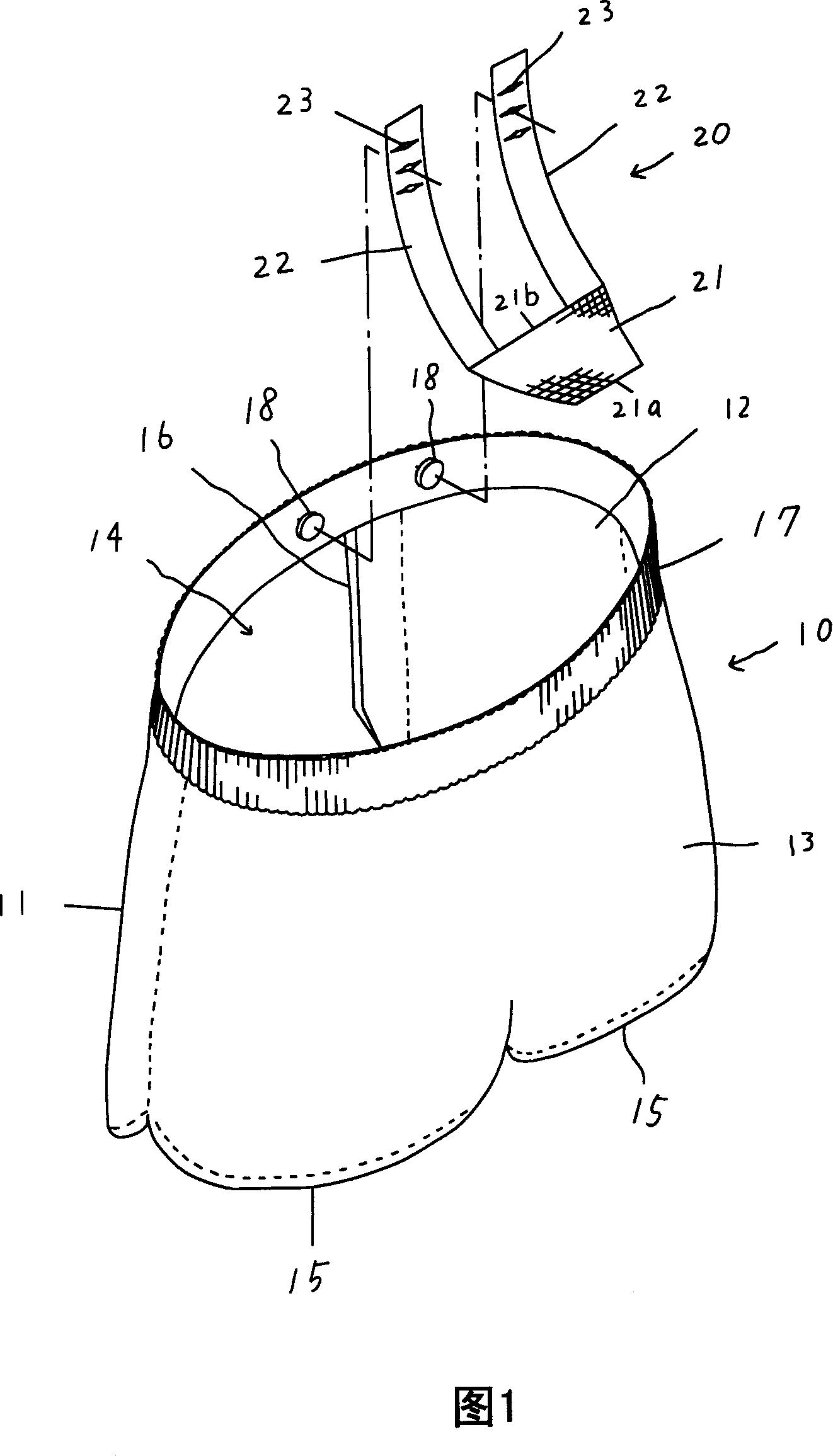

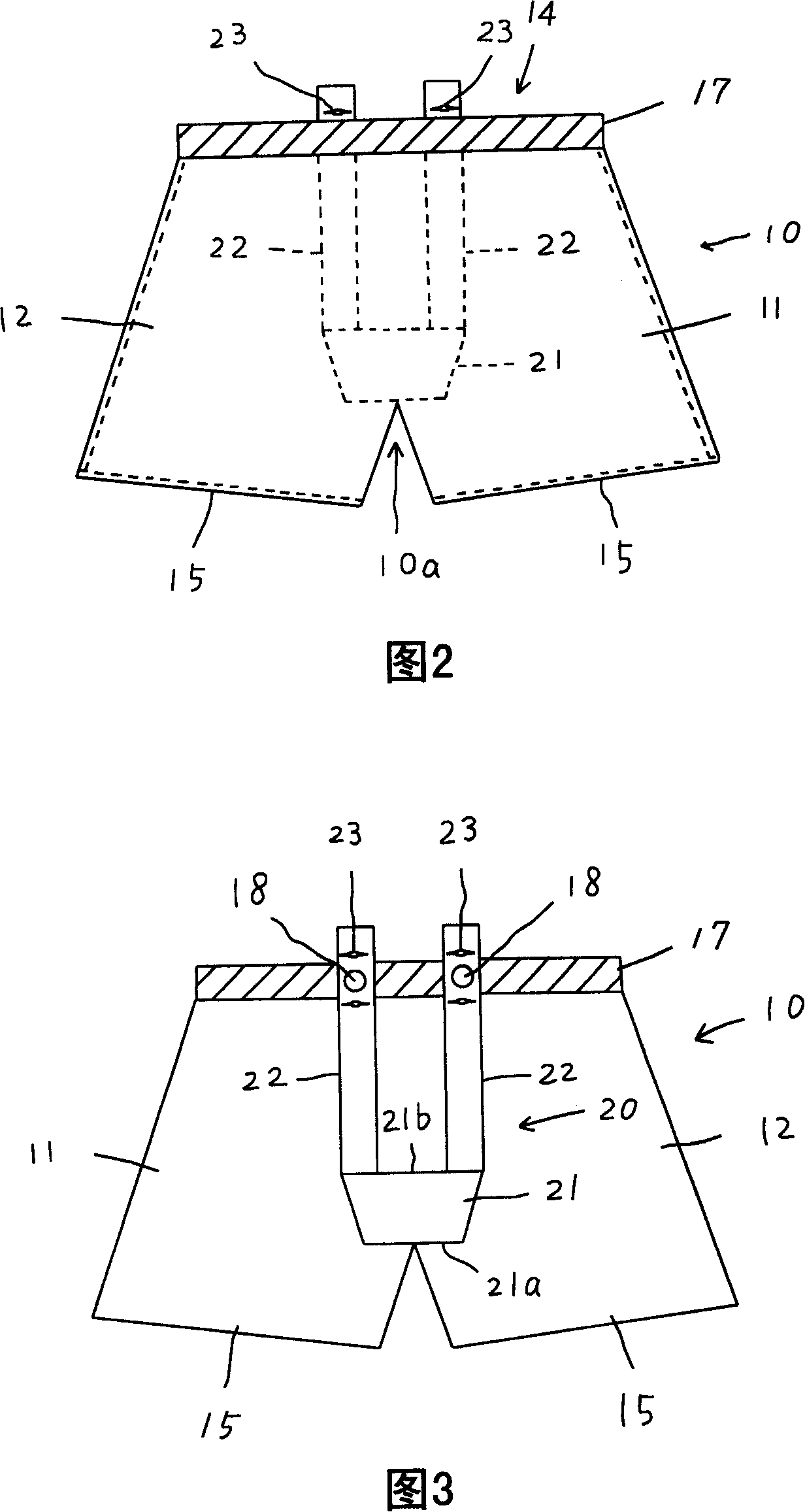

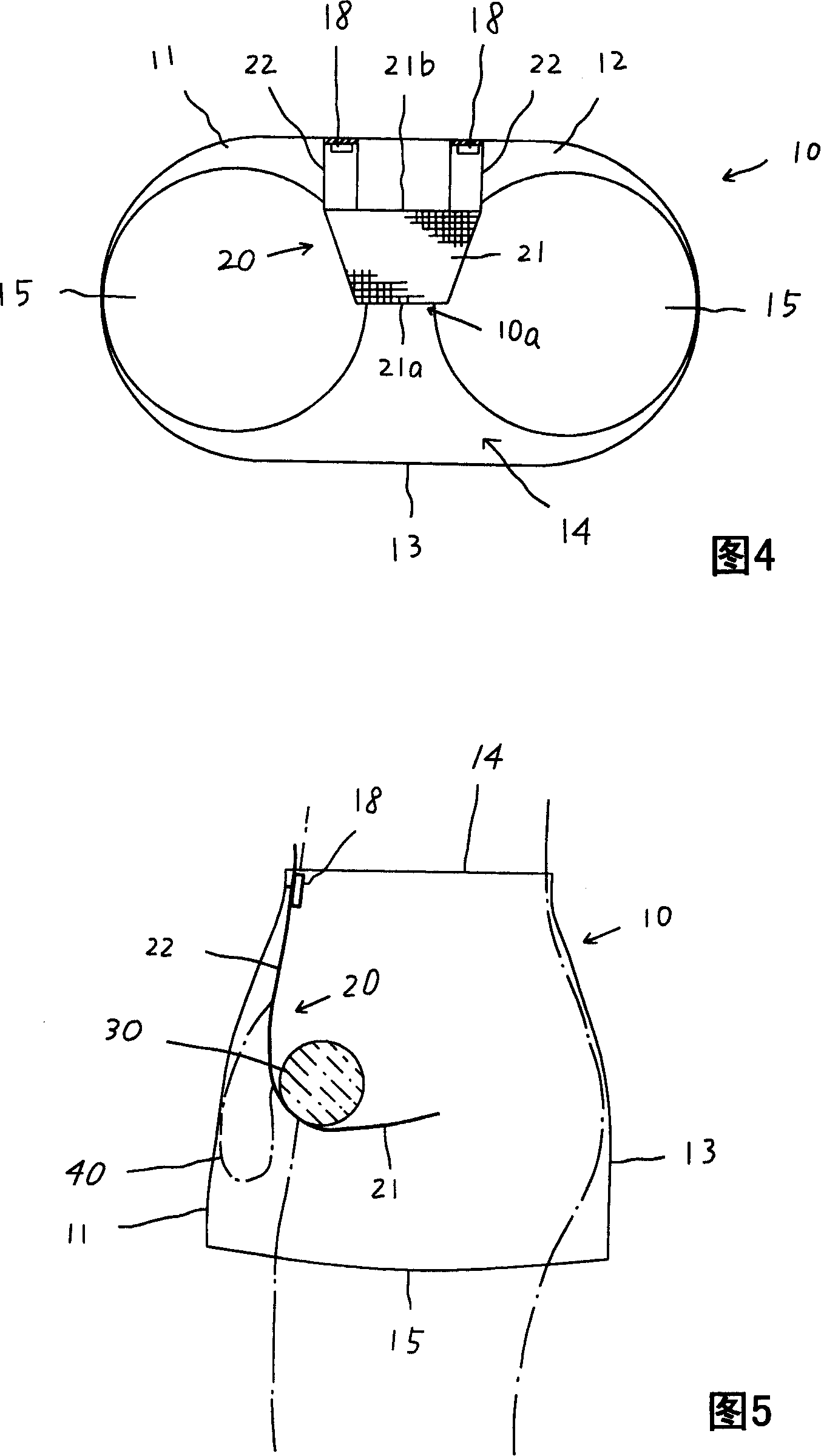

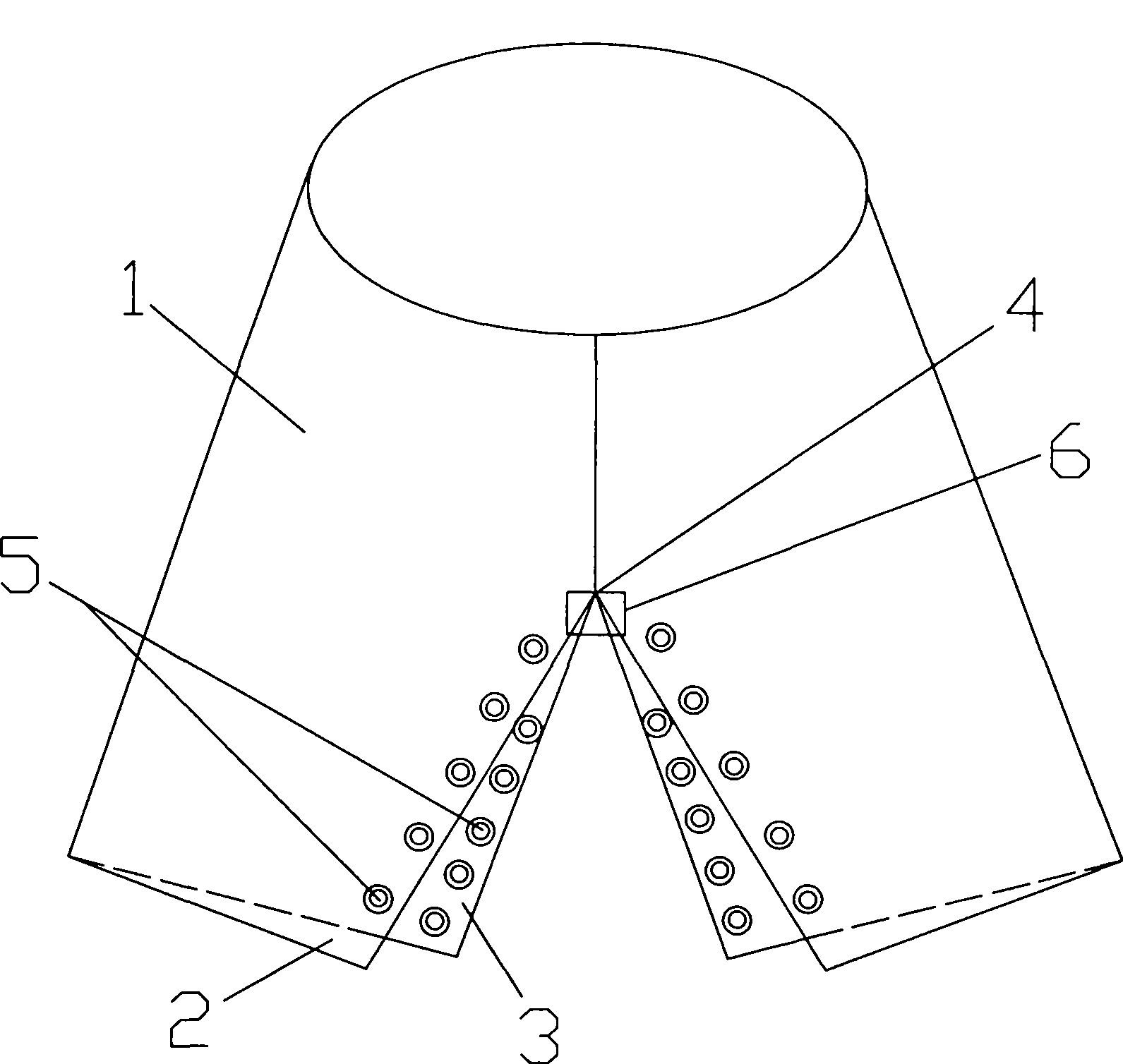

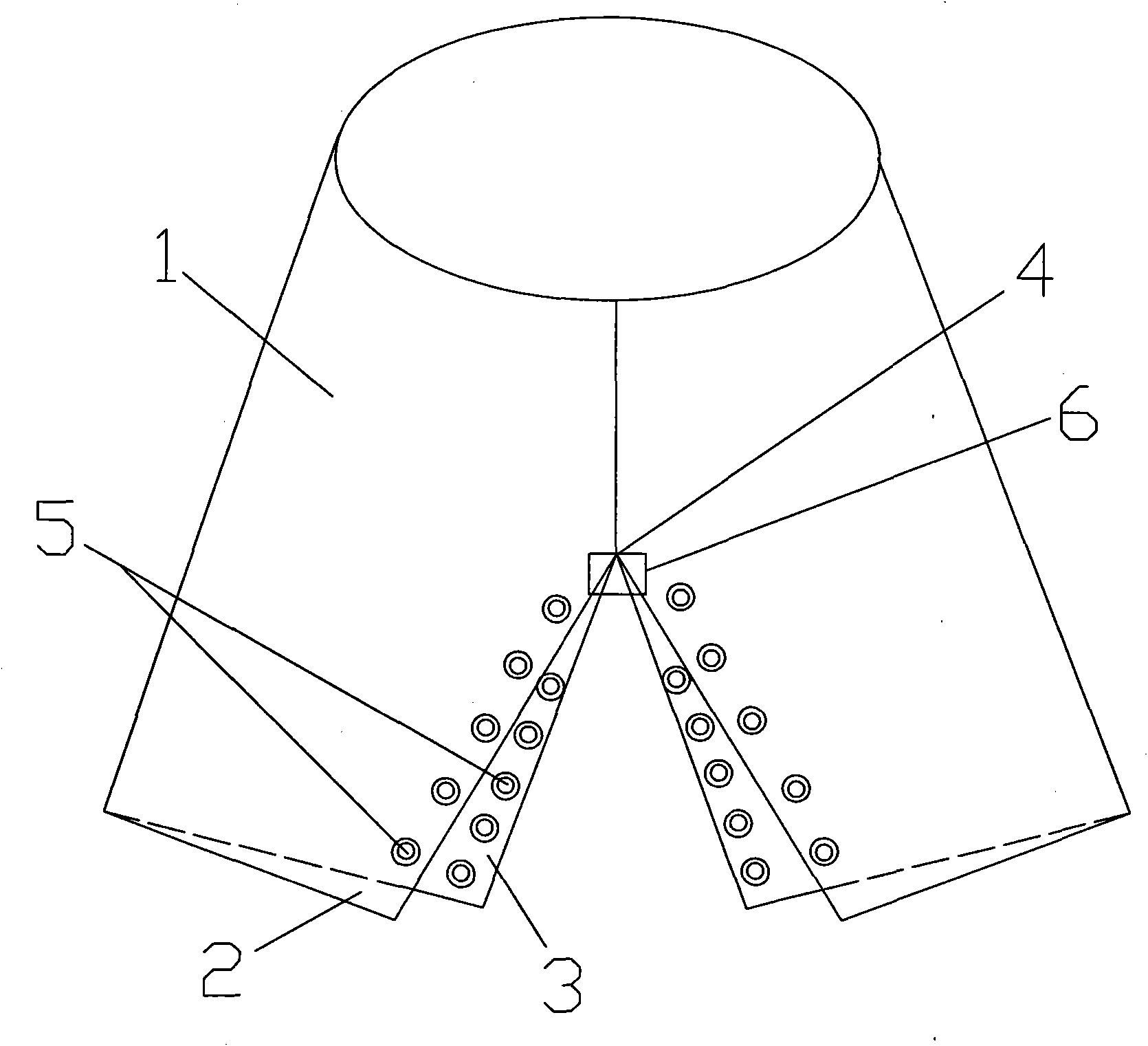

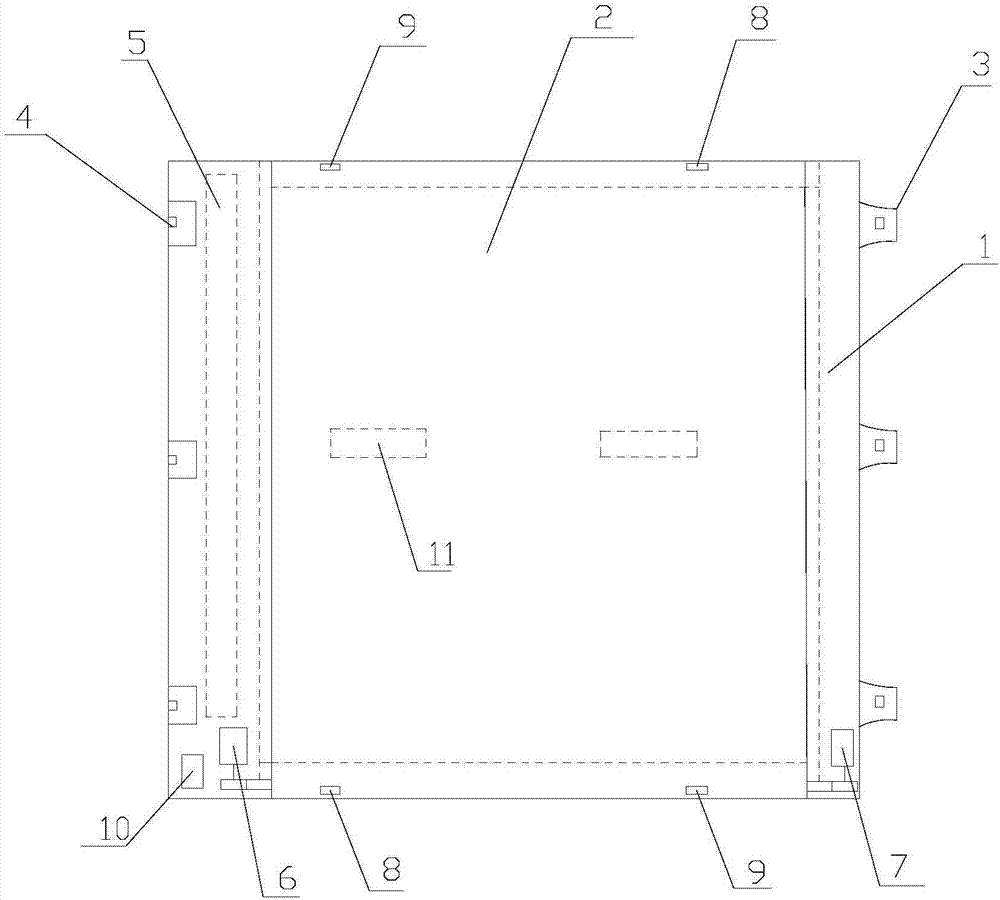

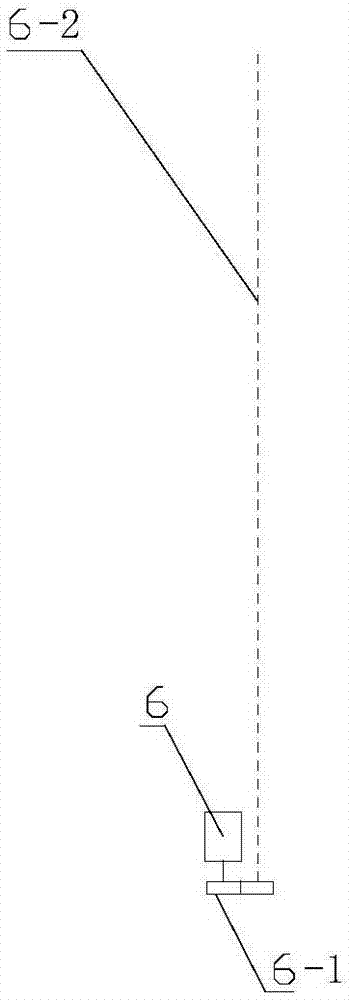

Sport type short pants

The present invention provides simple motion-type short pants, which do no harm to the original permeability of motion-type short pants and can prevent a scrotum from being stuck on the inner laterals of legs. The present invention is the motion-type short pants, the inner lateral of a motion-type short pants body (10) of which is equipped with an athletic supporting elastic fabric (20) for supporting the scrotum (30) of a wearer. The athletic supporting elastic fabric (20) consists of a tongue part (21) which coats the lower part of the scrotum (30) and a pair of a left and a right hanging hand parts (22, 22), which is continuously formed with the tongue part. One end edge (21a) of the tongue part (21) against the hanging hand parts (22, 22) is seamed to a crotch part (10a) of the short pants body (10). The front end laterals of the hanging hand parts (22, 22) are connected with the front part of the short pants body (10).

Owner:DONGGANG DEV

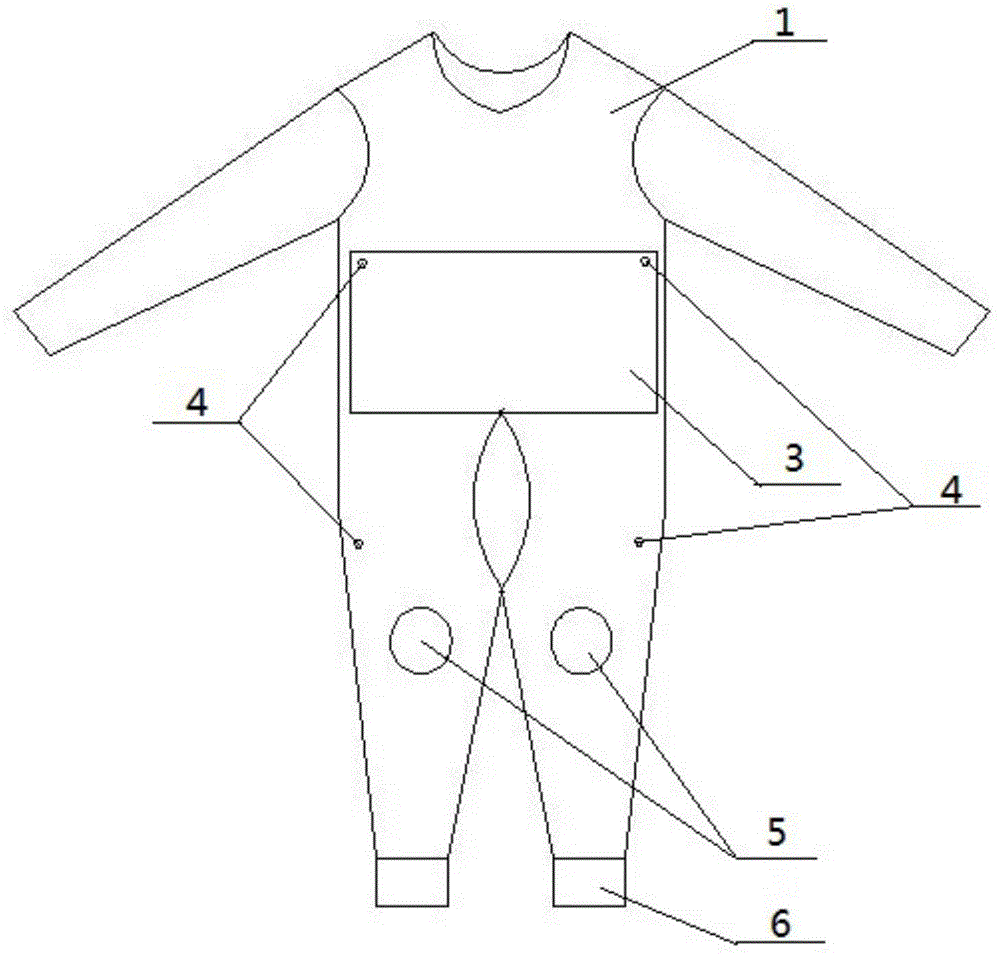

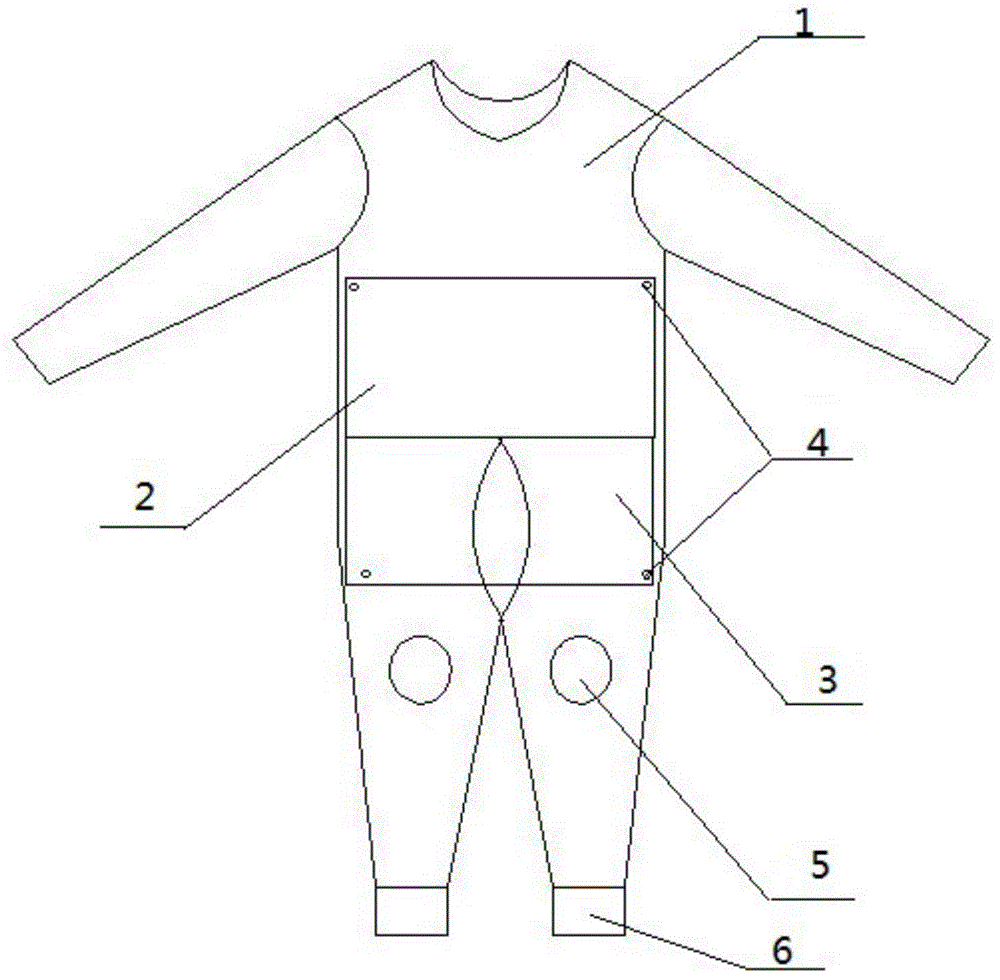

Infant jumpsuit

The invention provides an infant jumpsuit which comprises a jumpsuit body, an auxiliary cloth piece I, an auxiliary cloth piece II, connecting parts, auxiliary cloth pieces III and anti-sliding elastic band openings, wherein the jumpsuit body is a crotch opening or detachable crotch jumpsuit; the auxiliary cloth piece I is arranged at the waist of the jumpsuit body; the auxiliary cloth piece II is arranged on the auxiliary cloth piece I; the connecting part is arranged on the auxiliary cloth piece II; the connecting parts are arranged at legs of the jumpsuit body; the auxiliary cloth pieces III are arranged at knees of the jumpsuit body; the anti-sliding elastic band openings are formed at the trouser legs of the jumpsuit body. The infant jumpsuit has the beneficial effects that due to special setup of the auxiliary cloth pieces, the belly of an infant in the crawling period can be effectively covered and is prevented from being cooled by the ground, and meanwhile the exposed lower body of the infant with the crotch jumpsuit can be protected and prevented from being cooled or abraded, and due to adoption of the auxiliary cloth pieces at the knees, abrasion to the knees of the infant in crawling can be reduced, and the infant jumpsuit is comfortable to wear, simple in structure, and high in security feasibility.

Owner:TIANJIN TF SUNNY GARMENT

Garment for skirt and trouser purposes

InactiveCN102396798AGracefully flutteringEasy to wearTrousersSkirtsMechanical engineeringLeisure time

The invention discloses a garment for skirt and trouser purposes, which comprises a skirt body, wherein the front skirt piece and rear skirt piece of the skirt body are slit from the middle to the crutch part; connecting pieces which may be zippers and hidden buttons are arranged along the edges of the slits of the front skirt piece and the rear skirt piece; the edges on the same side of the front skirt piece and the rear piece are connected by the connecting pieces, and thus, the trousers are formed; when the edges of the front skirt piece as well as the edges of the rear skirt piece are connected by the connecting pieces, a skirt is formed; and a shielding piece is formed at the crutch part. The invention has the advantages that: the garment for skirt and trouser purposes can be worn on various occasions; the garment can be made into a skirt conveniently in leisure time with the skirt pieces flying elegantly while a user walks and with the coolness and elegance of a skirt; while doing various sports, the user can wear the garment as trousers; therefore, the garment can be worn easily, conveniently and in different styles and is very economic and practical.

Owner:CHANGSHU HENGQIN GARMENT

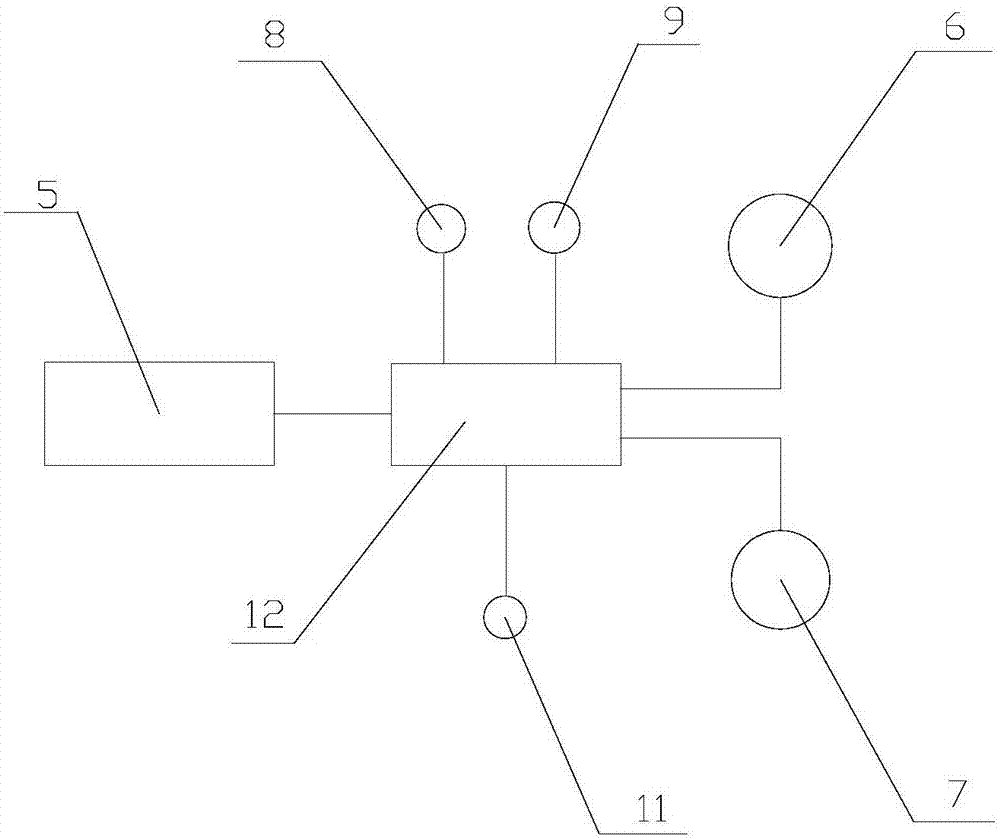

Intelligent protective device for thorax-abdomen surgical incision and using method of intelligent protective device

InactiveCN107374823AIntelligent adjustment of tightnessReduce labor intensityDiagnostic recording/measuringSensorsMicrocontrollerSurgical incision

The invention discloses an intelligent protective device for a thorax-abdomen surgical incision. The intelligent protective device comprises a bandage outer covering layer and an inner layer bandage, the bandage outer covering layer is wrapped outside the inner layer bandage, and a socket, a power supply, a microcontroller and an upper section bandage adjusting device are arranged at one end of the inner layer bandage; a plug and a lower section bandage adjusting device are arranged at the other end of the inner layer bandage, and the plug is matched and buckled with the socket to form a bandage ring; a pressure sensor and a myoelectrical sensor are arranged at the upper section edge and the lower section edge of the middle of the inner layer bandage; the microcontroller is electrically connected with the upper section bandage adjusting device, the lower section bandage adjusting device, the myoelectrical sensor and the pressure sensor; and the invention further discloses a using method of the intelligent protective device. The intelligent protective device for the thorax-abdomen surgical incision is simple and convenient to use in the binding process, can intelligently adjust the tightness of the surgical incision bound by the bandage, and the labor intensity of medical workers is relieved.

Owner:韩巨山 +1

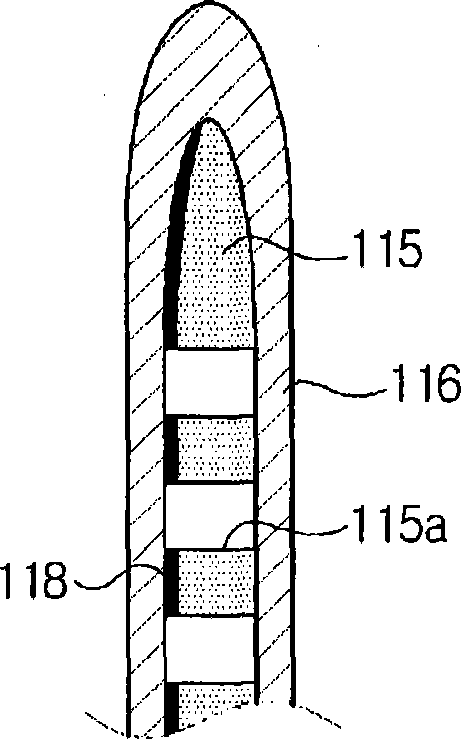

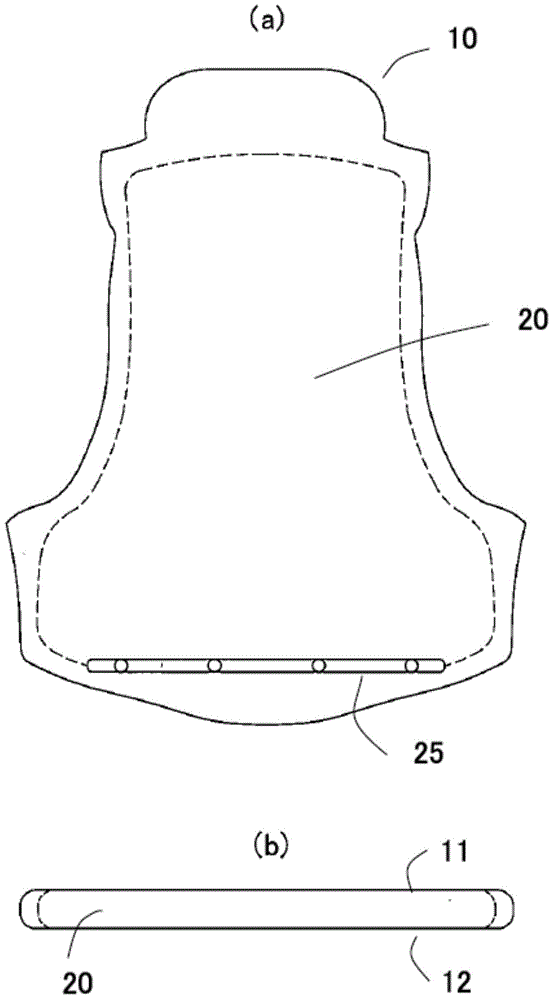

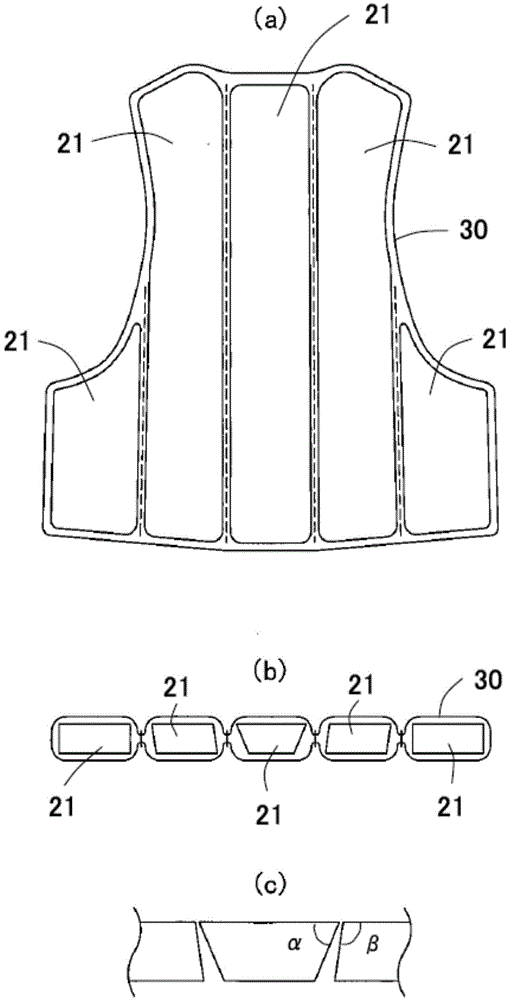

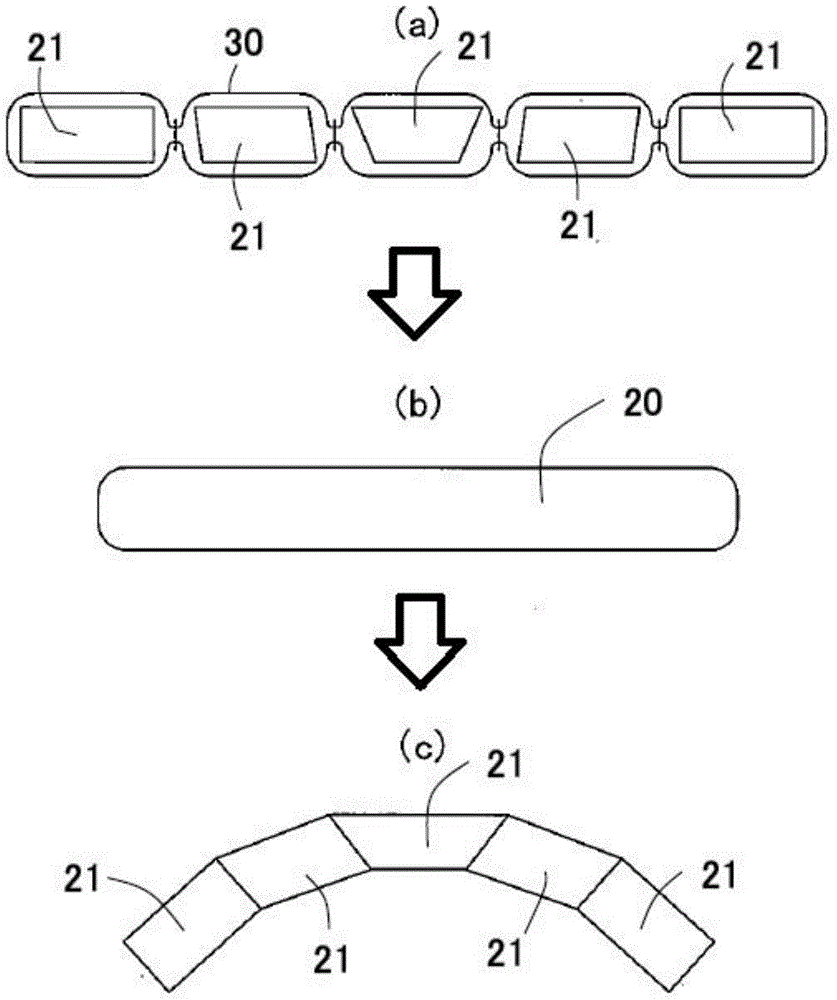

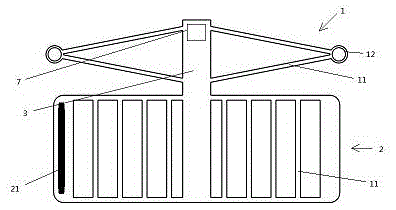

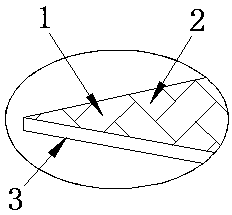

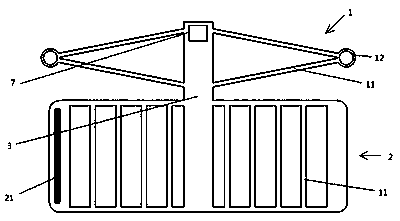

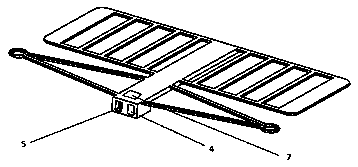

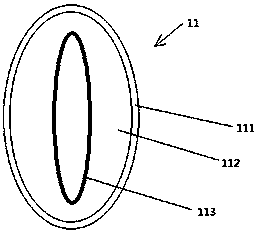

Floating vest and buoyant material thereof

In a floating vest which can be provided with buoyant materials, the closed-fit feeling of a wearer is poor, and the buoyant material in the floating vest can sometimes delicately shift. A holding part for holding the buoyant materials is arranged between an external cloth and an internal cloth of the floating vest, at least one of the external cloth and the internal cloth is telescopic, each buoyant material is a lengthwise tabular body the cross section of which is rectangular or trapezoidal, more than three buoyant materials the cross sections of which are rectangular or trapezoidal or more than three buoyant materials the cross sections of which are trapezoidal are combined in parallel and held in the holding part. The crosswise width of the holding part of the floating vest is slightly smaller than the whole maximum width of the paralleled held buoyant materials, the bottom edge sides of the more than three buoyant materials are used as external cloth sides, the elasticity of the external cloth is overcome, and therefore the buoyant materials are forced to be held in the holding part, and the floating vest is curved.

Owner:DAIWA SEIKO CORPORATION

Garment

InactiveCN104872859AReduce manufacturing costIngenious structureGarment special featuresProtective garmentWater storageCheck valve

The invention relates to a garment comprising a moisture-proof interlayer which covers at least part of a trunk. The interlayer comprises an inner layer and an outer layer which are separable. A plurality of intake hoses are disposed in the moisture-proof interlayer; two ends of every intake hose are fixed to the inner layer and the outer layer, respectively; the intake hoses are bendable; the wall of each intake hose is provided with an air outlet; the intake hoses can push the outer layer out during inflating. The moisture-proof interlayer is provided with an exhaust hole and a water outlet both facing out; both the exhaust hole and the water outlet are provided with check valves. The garment is further provided with a water storage bag, a mist generator, a blower and a semiconductor refrigerating component; an exhaust tube of the blower is communicated with the intake hoses; a mist generation hole of the mist generator is connected to the exhaust tube of the blower; the semiconductor refrigerating component comprises a semiconductor refrigerator and a power supply connected with the semiconductor refrigerator; a refrigerating face of the semiconductor refrigerator is embedded in a mist outlet of the mist generator.

Owner:江阴市红邦服饰科技发展有限公司

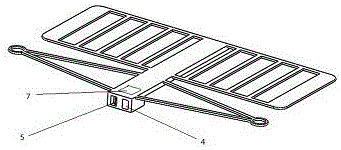

Pet traction sleeve capable of achieving heating

InactiveCN105532505ASimple dressEasy to cleanTaming and training devicesGrooming devicesPower switchingIsolation layer

The invention discloses a pet traction sleeve capable of achieving heating. The pet traction sleeve comprises a traction rope and a sleeve body; the sleeve body comprises a foot sleeve portion, a power supply and a power switch, the foot sleeve portion comprises composite ropes, and each composite rope is composed of an isolation layer, a heat preservation layer and a heating layer from outside to inside; the traction rope comprises a power supply and a traction rope USB interface, and the power supply can be controlled by intelligent control equipment to supply power to the heating layers of the composite ropes for heating. According to the pet traction sleeve, by adopting the common rope sleeve structure design, a pet can conveniently wear the pet traction sleeve, and the pet traction sleeve can be conveniently cleaned; the good air permeability is kept when the pet traction sleeve is not conducted, and warmth can be supplied when the pet traction sleeve is conducted. The pet traction sleeve is good in stability when the pet traction sleeve is fixed on the pet body, high in air permeability, good in warm keeping effect and suitable for being used in autumn and winter.

Owner:陈韶华

Dressing method of cutting blade

ActiveUS10898983B2Easy to wearOccurrence of the region of roundness generated due to the dressing can be suppressedSemiconductor/solid-state device manufacturingSawing tools dressing arrangementsStructural engineeringKnife blades

A dressing method of a cutting blade includes a first cutting step of causing the cutting blade to cut into a dressing board held by a holding surface of a chuck table with a cutting depth that does not surpass the length of the region of roundness in the radial direction of the cutting blade to form a cut groove in the dressing board, and a second cutting step of causing the cutting blade to further cut into the groove bottom of the cut groove formed in the first cutting step with a cutting depth that does not surpass the length of the region of roundness in the radial direction of the cutting blade to carry out cutting on the groove bottom with tracing of the cut groove.

Owner:DISCO CORP

Health care mask

InactiveCN106333399AThe magnetic field is smooth and uniformSoft and comfortable to wearElectrotherapyLight therapyHuman bodySurface layer

The invention relates to a health care mask which comprises a mask body and lug pieces arranged on two sides of the mask body, wherein the mask body comprises a mask outer surface layer, a filter layer, a mask magnetic layer and a mask inner surface layer which are arranged from outside to inside; the mask magnetic layer is a far infrared fiber layer; a plurality of magnetic micro-particles are embedded in the far infrared fiber layer; a lug hole is formed in each lug piece, and an earmuff is connected to each lug piece; the first end of each earmuff is fixedly connected with one side of the corresponding lug hole; and the second end of each earmuff is detachably connected to the surface of the corresponding lug piece. By adopting the structure, the health care mask has far infrared ray and magneto-therapeutic double health care functions to reinforce the effects and functions of a health care product, is an upgrading product of far infrared health products, and can be used for effectively protecting human body health. The mask has the function of the earmuff based on the function of the mask, has multiple functions, and has a wide application range.

Owner:CHENGDU DUOMAO CULTURE COMM CO LTD

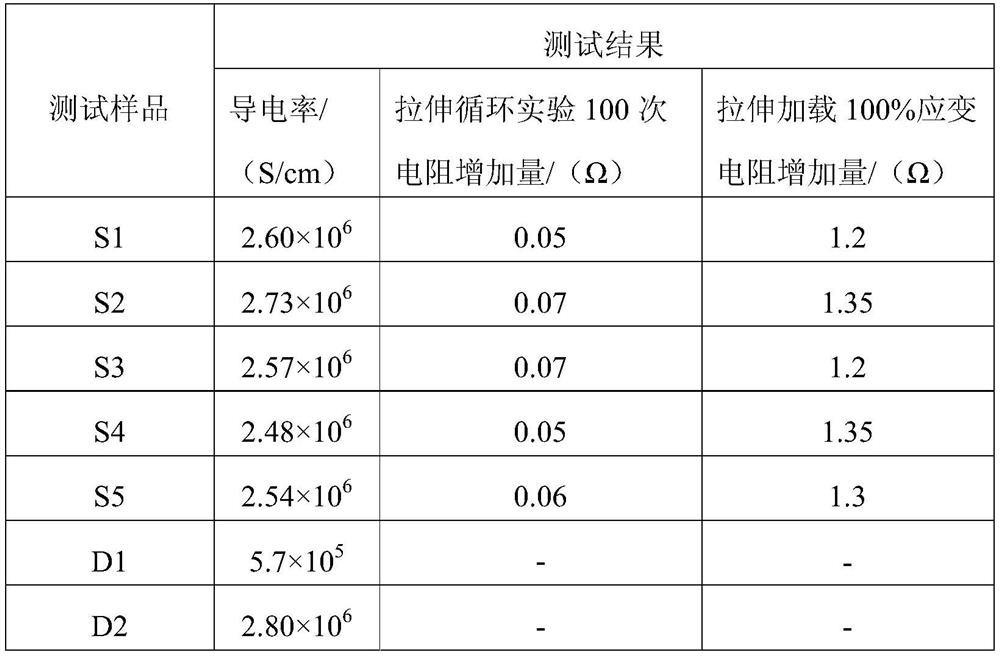

Elastic flexible wire for intelligent spinning and production method thereof

InactiveCN112663190AGuaranteed electrical conductivityShorten the processing flowYarnElastomerPolymer science

The invention relates to the field of flexible wire production, in particular to an elastic flexible wire for intelligent spinning and a production method of the elastic flexible wire. The elastic flexible wire is composed of a colored fiber core-spun elastic wire, the elastic wire is composed of liquid metal and a thermoplastic elastomer in a composite mode; the production method comprises the following steps of a, blowing; b, cotton carding; c, drawing; d, roving; e, spinning; and f, post spinning; and in the step e of spinning, the pre-draft multiple is limited to be 4.5-6 times, the twist coefficient is increased to 380-420, the twist degree is controlled to be 35-47 twists / 10 cm in a rather big mode. The problems that wires in existing intelligent textiles are inelastic, easy to pull apart, poor in comfort and the like are solved, meanwhile, due to the application of colored fibers, the aesthetic feeling of the fabric can be enhanced in intelligent textile design, and the application range is wider.

Owner:WEIQIAO TEXTILE +1

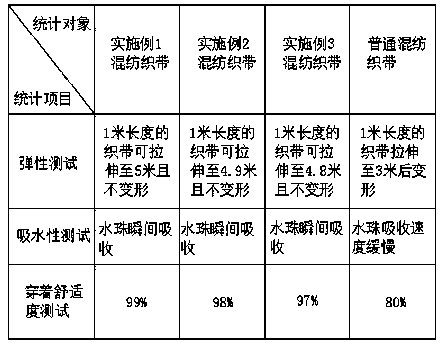

Unlikely-to-deform elastic blended woven tape

The invention discloses an unlikely-to-deform elastic blended woven tape which comprises warps and wefts, the warps and wefts are cross-woven by a textile machine to form the woven tape, and the warpsand wefts comprise the following raw materials in parts by weight: 20-30 parts of cotton fibers, 6-15 parts of bamboo fibers, 7-15 parts of polyester fibers, 6-8 parts of superfine fibers, 8-12 partsof synthetic fibers and 15-20 parts of copper ammonia fibers. The invention relates to the technical field of fabric textiles. According to the unlikely-to-deform elastic blended woven tape, the firmness and good elasticity of the woven tape are guaranteed by using the cotton fibers and the polyester fibers as base materials, and the elasticity and resilience of the woven tape are further improved by adding the synthetic fibers and the bamboo fibers, so that the woven tape is unlikely to deform; at the same time, the woven tape has natural antibacterial, bacteriostatic, acarus-killing, deodorant, anti-ultraviolet and radiation-protecting functions; by adding the copper ammonia fibers, the woven tape is soft in gloss, silky in touch and soft in hand feeling, and the production steps are simple, feasible, and easy to promote.

Owner:广东威信纺织有限公司

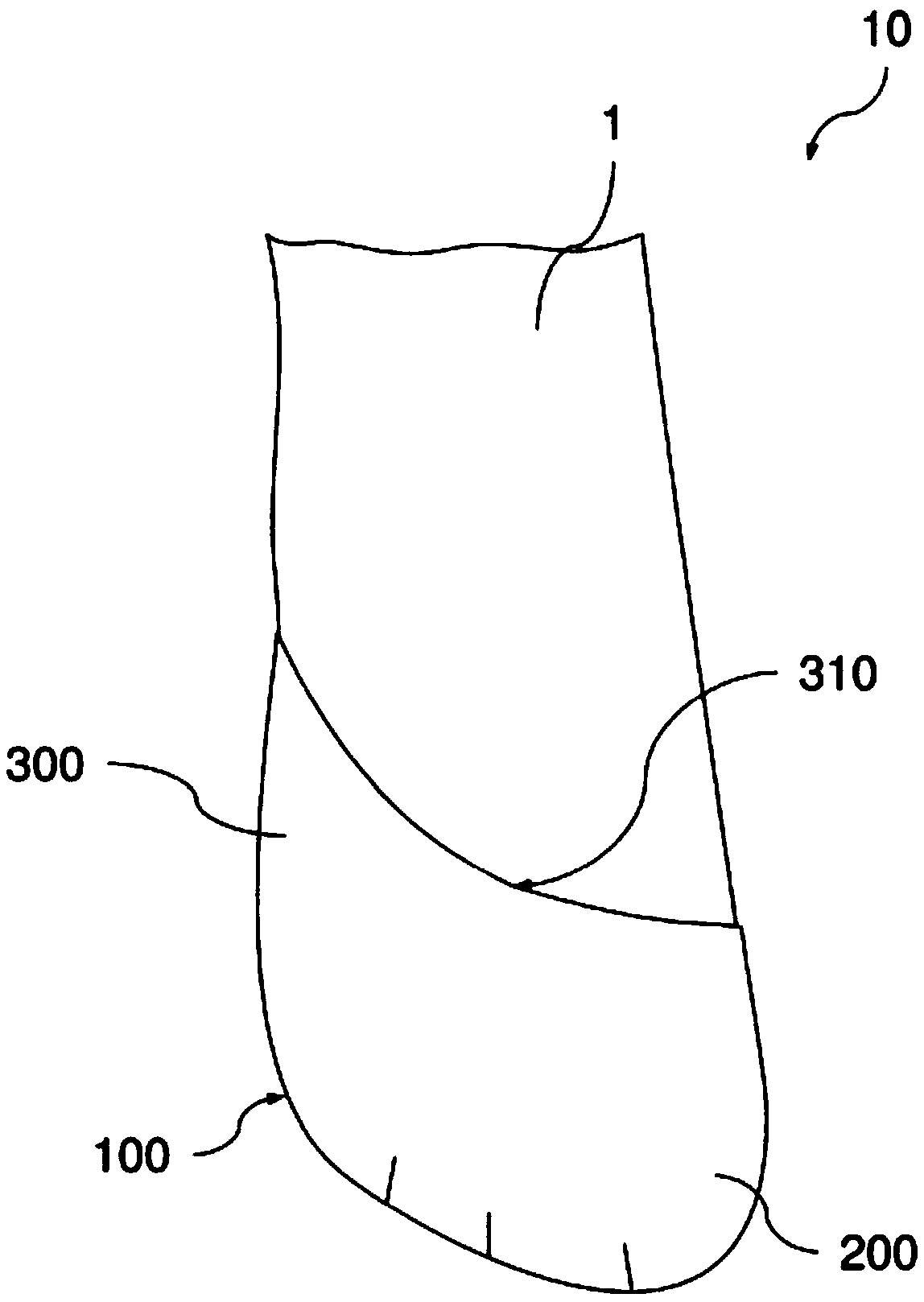

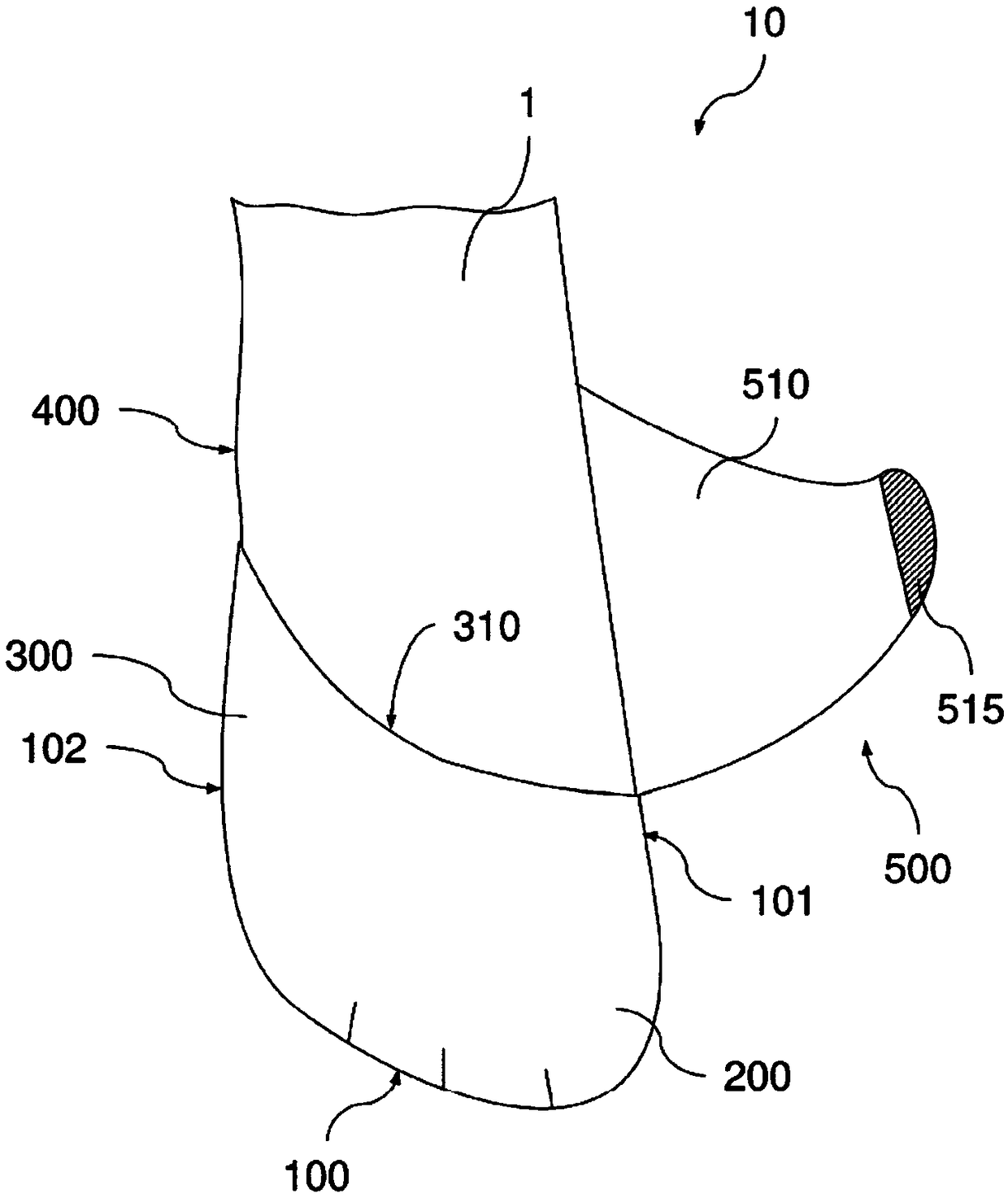

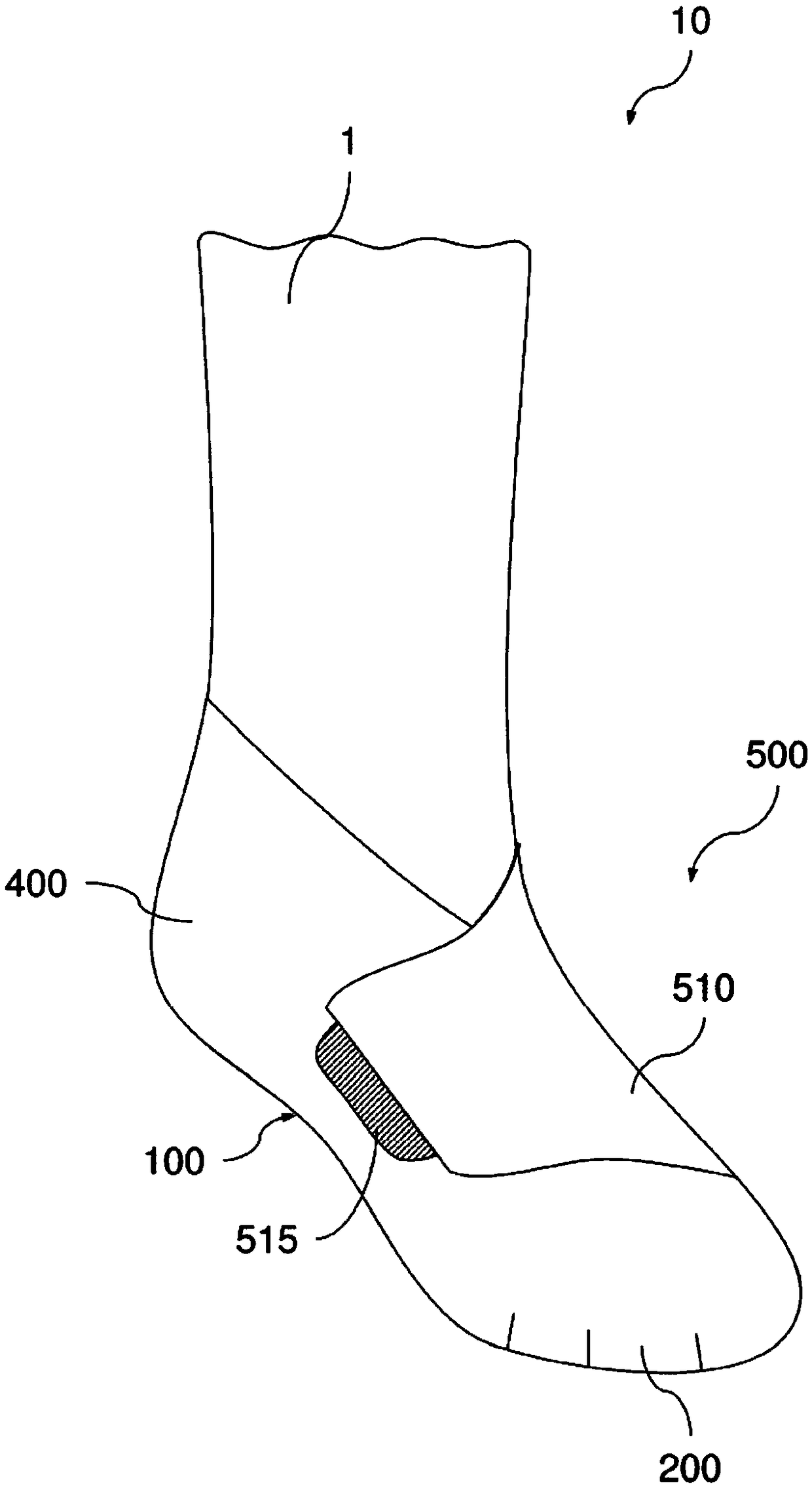

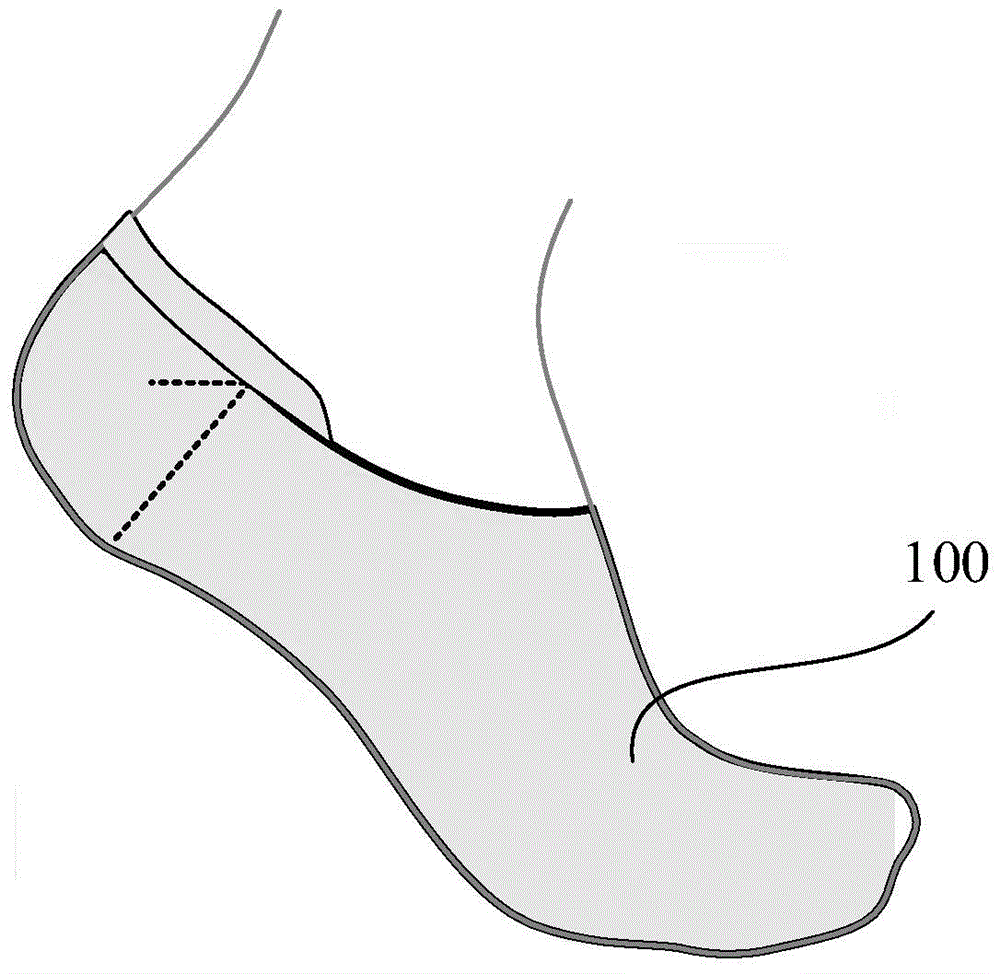

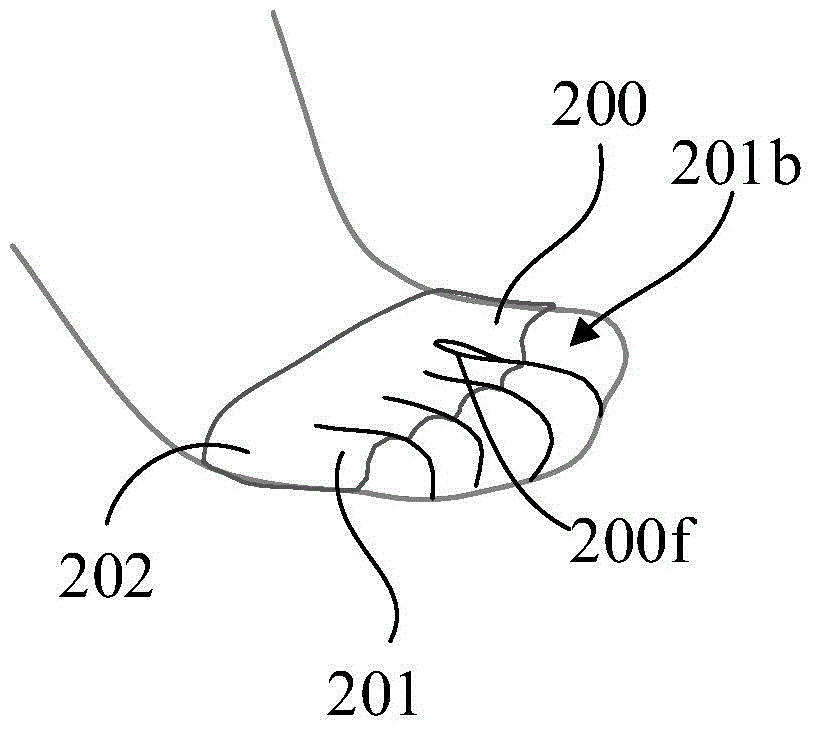

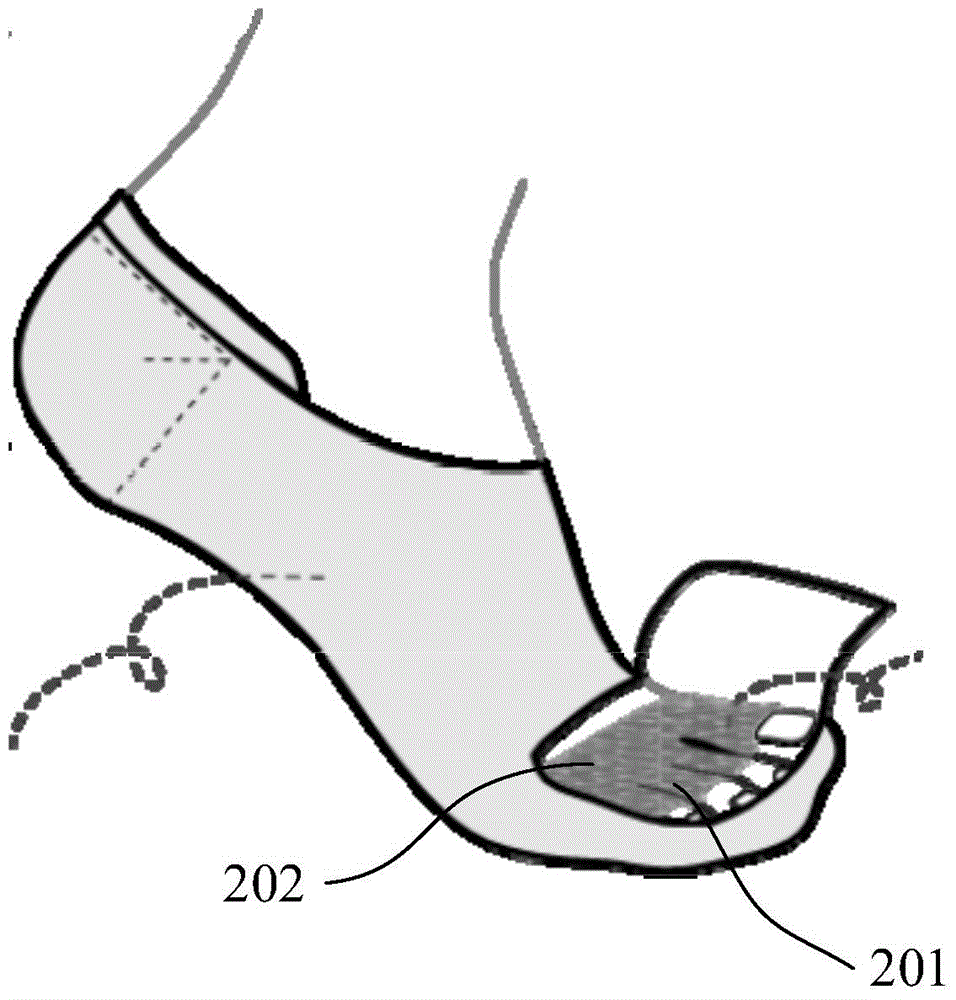

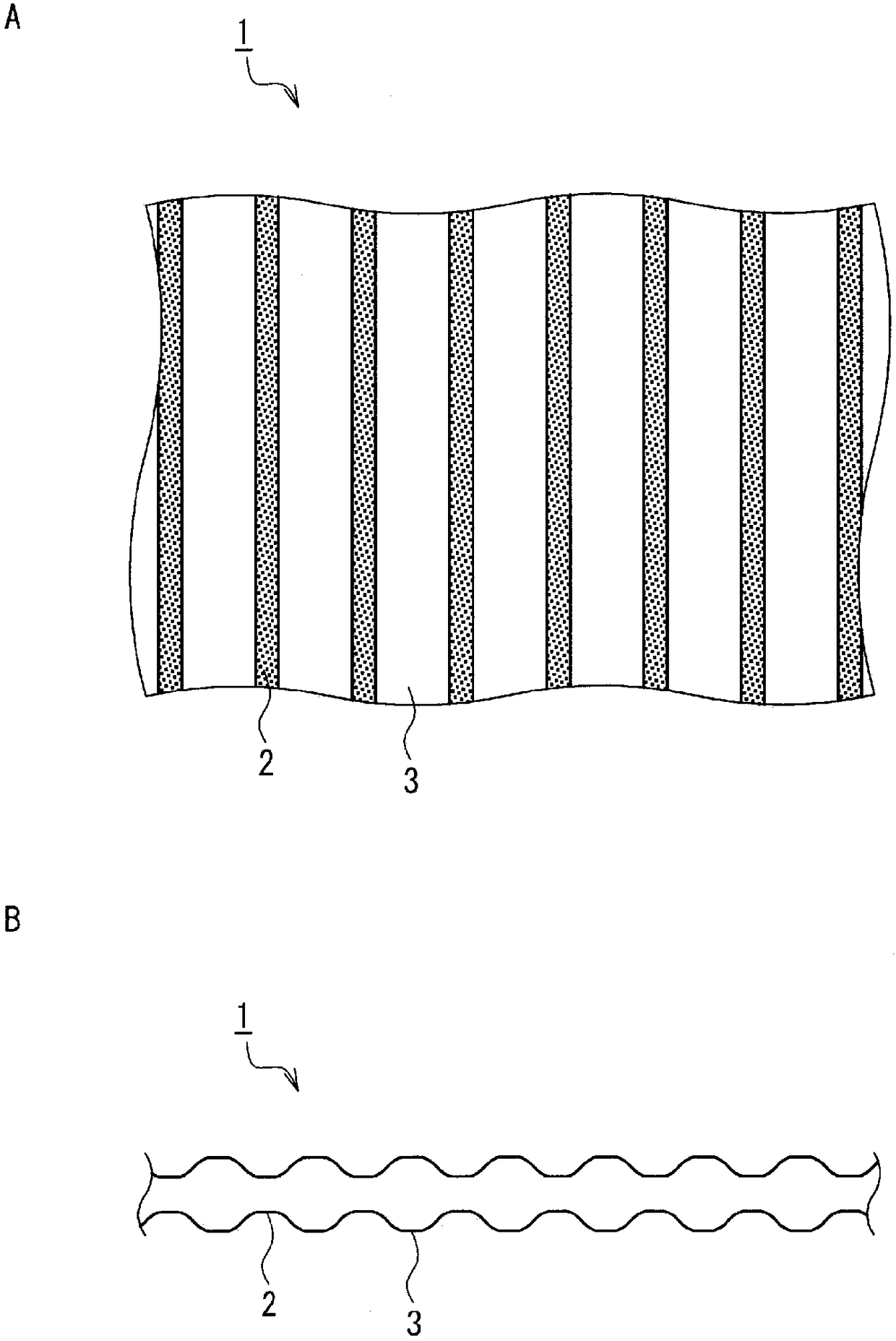

Sock

ActiveCN109068763ASimple dressHandkerchiefsBaby linensPhysical medicine and rehabilitationFoot soles

The invention relates to a sock (10). The sock (10) has a sole part (100) which is suitable for covering the sole of a foot (1) when the sock (10) is being worn. Furthermore, a toe region (200) of thesock (10) is suitable, together with the sole part (100), for receiving the entire toe region of the foot (1) when the sock (10) is being worn. The sock (10) furthermore comprises an instep part (300) which is suitable for at least partially covering the arch of the foot (1) when the sock (10) is being worn. A heel part (400) of the sock (10) is suitable for covering the heel of the foot (1) whenthe sock (10) is being worn. The sock (10) comprises an ankle closure part (600) which is suitable for closing the sock (10) in a releasable manner at the ankle of the foot (1) when the sock (10) isbeing worn.

Owner:PEDILAY CARE GMBH

Toe Socks

ActiveCN104305533BReduce manufacturing costTo achieve the purpose of ventilationHandkerchiefsBaby linensHuman bodyEngineering

The invention relates to a sock structure and discloses a five-finger sock. The five-finger sock comprises an outer-layer sock body wrapping the foot of a human body and an inner-layer sock body arranged on the inner side of the outer-layer sock body. The inner-layer sock body comprises, at least, finger sleeve portions wrapping toes and extending portions extending from the finger sleeve portions to the sole of the foot. The finger sleeve portions consist of at least two finger sleeves arranged in parallel, wherein the finger sleeves extend in the length directions of the toes. One end of each finger sleeve is connected with the corresponding extending portion, and the other end of each finger sleeve completely wraps the whole corresponding toe or is provided with an opening enabling the corresponding toe to be exposed out of the front end at least. The extending portions extend in the peripheral direction of the sole of the foot of the human body and wrap at least one part of the front foot sole. The five-finger sock further comprises a connecting portion, wherein the connecting portion is used for connecting the outer-layer sock body with the inner-layer sock body. The five-finger sock has the advantages that the problem that the foot of the human body feels air-permeable badly and mould is easily bred is solved, the five-finger sock is the same as a common sock in appearance, and the difficulty of a manufacturing process is greatly reduced.

Owner:杭州悍将体育科技有限公司

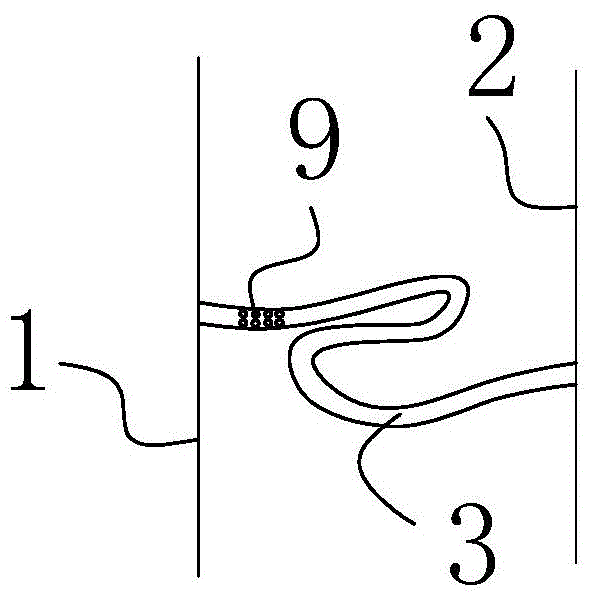

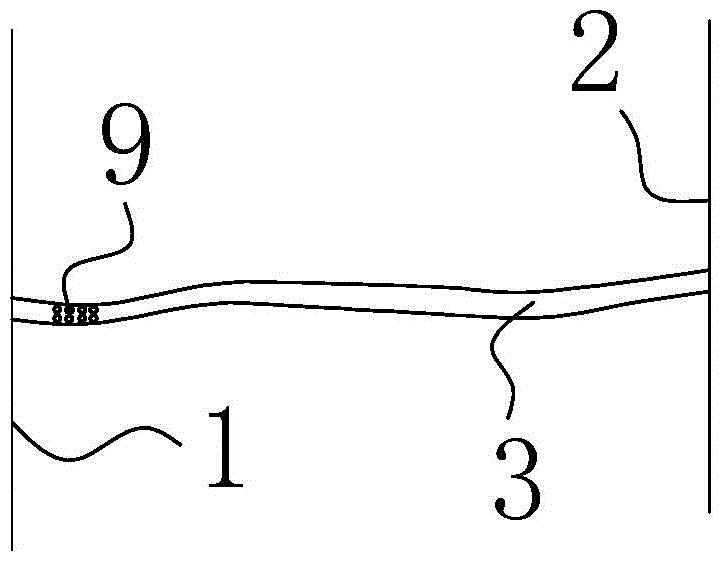

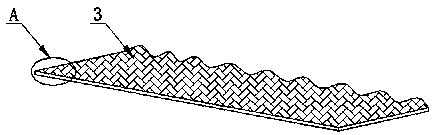

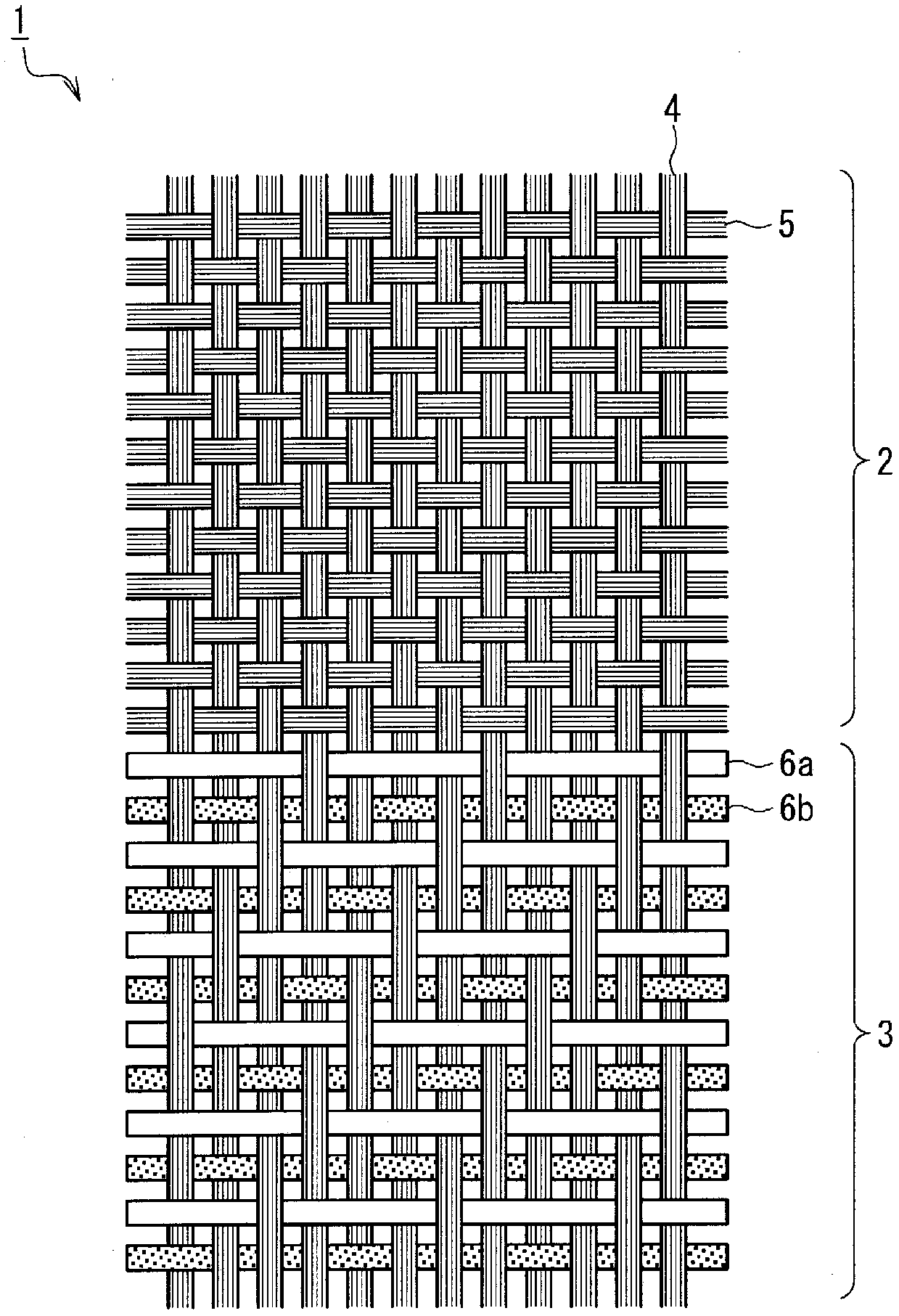

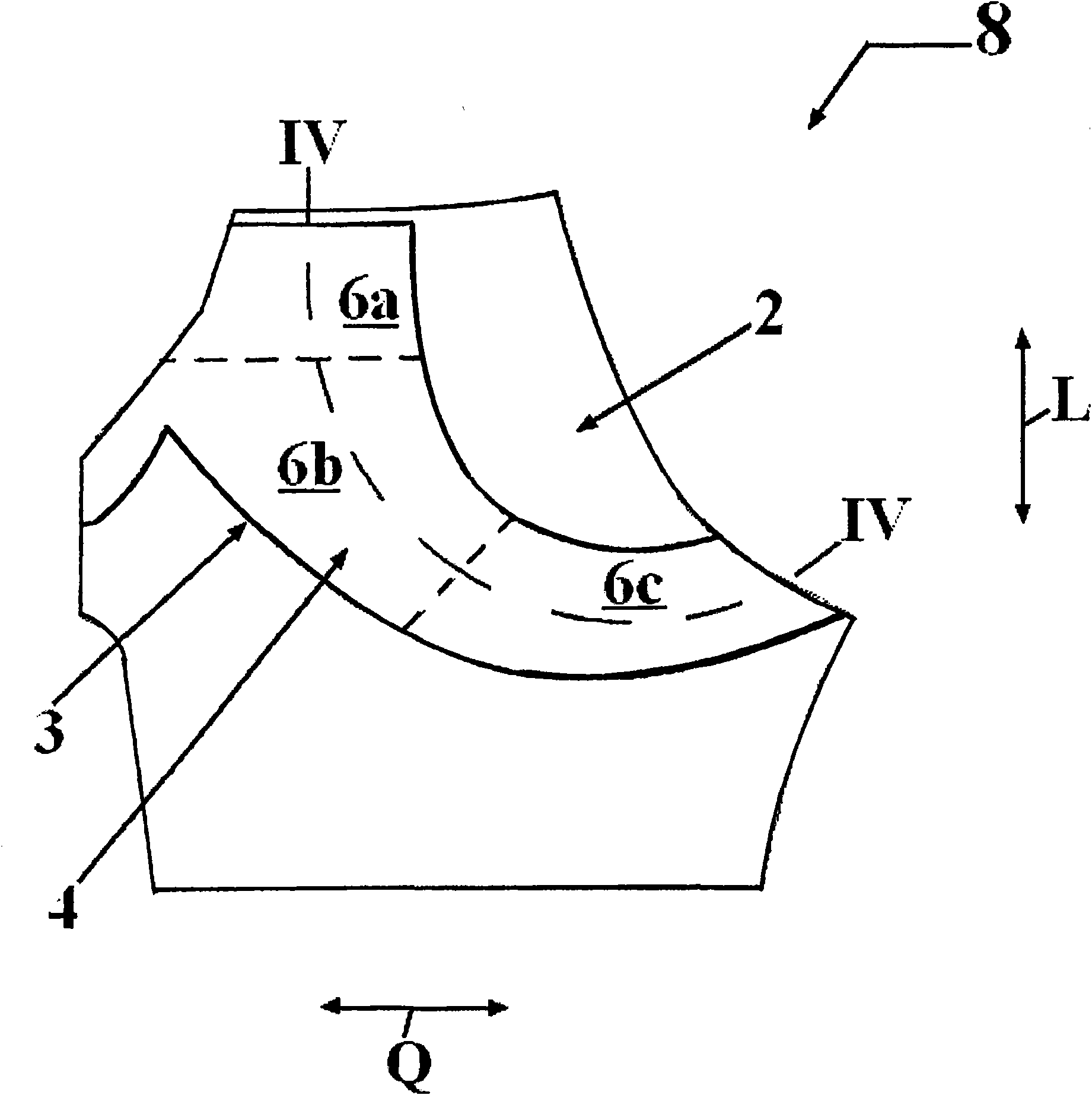

Stretchable fabric and sportswear and swimwear containing the stretchable fabric

ActiveCN106133223BImprove scalabilitySimple dressGarment special featuresMulti-ply fabricsWater flowEngineering

The stretchable fabric (1) of the present invention contains elastic yarns arranged on warp threads (4) and weft threads (5, 6a, 6b), the stretchable fabric has stretchability in two directions, and the plain weave part (2 ) and the double weave part (3) are alternately repeated. Since the double weave part (3) is reinforced by arranging more elastic threads than the plain weave part (2), stretchability is improved and it is easy to wear. In addition, since the plain weave part is a concave part, the double weave part is a convex part, and the concave and convex parts are arranged in one direction as a whole to form a striped structure, so when making, for example, a swimsuit, when the When the stripe shape is used on the position, the surface frictional resistance with the water flow can be reduced. Thereby, a stretchable fabric having high stretchability, easy to wear, and low surface frictional resistance, and sportswear and swimwear including the stretchable fabric are provided.

Owner:MIZUNO CORPORATION +1

Fabric with anti-fatigue function and preparation method thereof

PendingCN114381850AWith anti-fatigue functionAnti-fatigue function does not affectWeft knittingHeating/cooling textile fabricsPolymer scienceEngineering

The invention provides a preparation method of a fabric with an anti-fatigue function, which comprises the following steps: raw material preparation: raw materials comprise two yarns, one is a yarn with an anti-fatigue function and the yarn count is 30S-60S, and the other is a yarn with an anti-fatigue function and the yarn count is 30S-60S; the other kind is spandex filaments, and the yarn count is 50-70 D; a weaving machine with the specification of 34 ''28G102F is selected for weaving grey cloth, cloth inspecting, grey cloth matching, preshrinking and pre-shaping are conducted, the pre-shaping temperature is 170-195 DEG C, and the pre-shaping speed is 10-15 m / min; binding edges and dyeing, wherein the gray fabric accounts for 70% of the volume of a dyeing vat; dewatering, wherein the moisture content of the dewatered gray fabric is 10-30%; the temperature is 140-175 DEG C, and the speed is 10-13m / min. The prepared fabric with the anti-fatigue function is more environmentally friendly, can promote blood circulation of a human body and enhance metabolism of a wearer, can resist fatigue after being worn for a long time, and meets the use requirements.

Owner:WUXI TAIBO GARMENT

Disposable panty-type underwear and its manufacturing method

The present invention provides disposable panty-type underwear which is easy to wear, has high fit to the wearer's body, and can be manufactured with a small amount of material, and a manufacturing method thereof. The manufacturing method of disposable panty-type underwear (10) is characterized by comprising: forming a laminated body in which each elastic body (103) is bonded between a net-shaped inner surface sheet (101) and an outer surface sheet (102) The process of (100A), along the crotch side end edge (11a, 12a) shared by the abdominal part (11) and the back side part (12) in the conveying direction of the net, the predetermined line of cutting (C) that is periodically continuous is paired. The process of cutting the laminated body (100A), the process of bridging the crotch part (13) at the two central parts of the abdominal part (11) and the back side part (12) of each cycle, the crotch part (13) is The jointed continuum (100B) is bent, and the two ends (16, 16) perpendicular to the conveying direction of the net are joined and cut according to each period; the planned cutting line (C) of each period includes: Two end lines (11b, 11b, 12b, 12b) parallel to the feeding direction of the net, a pair of inclined lines (11c, 11, 12c, 12c) inclined from the two end lines to the center and to the ventral part (11) side, the two The central line (11d, 12d) connecting the oblique lines.

Owner:KOYO CORP

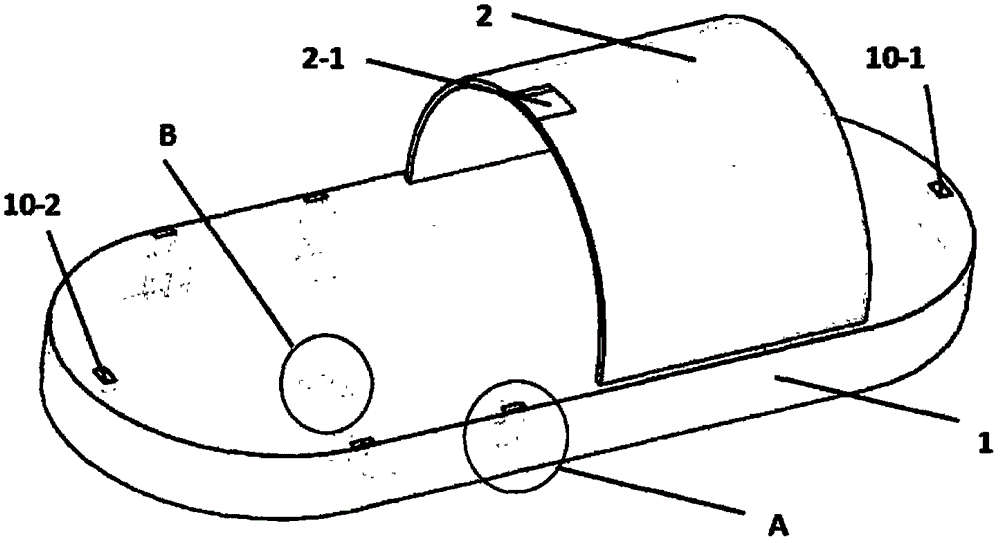

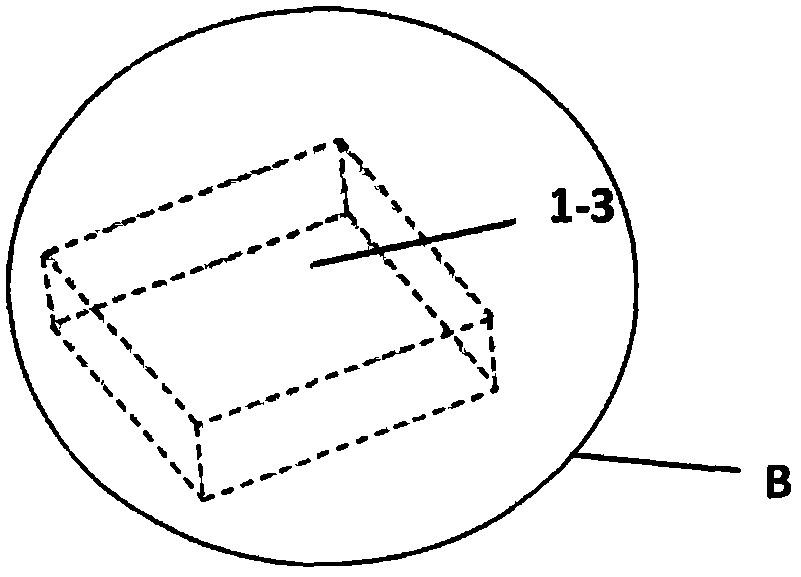

Electric shoe mold used by being matched with disposal slipper

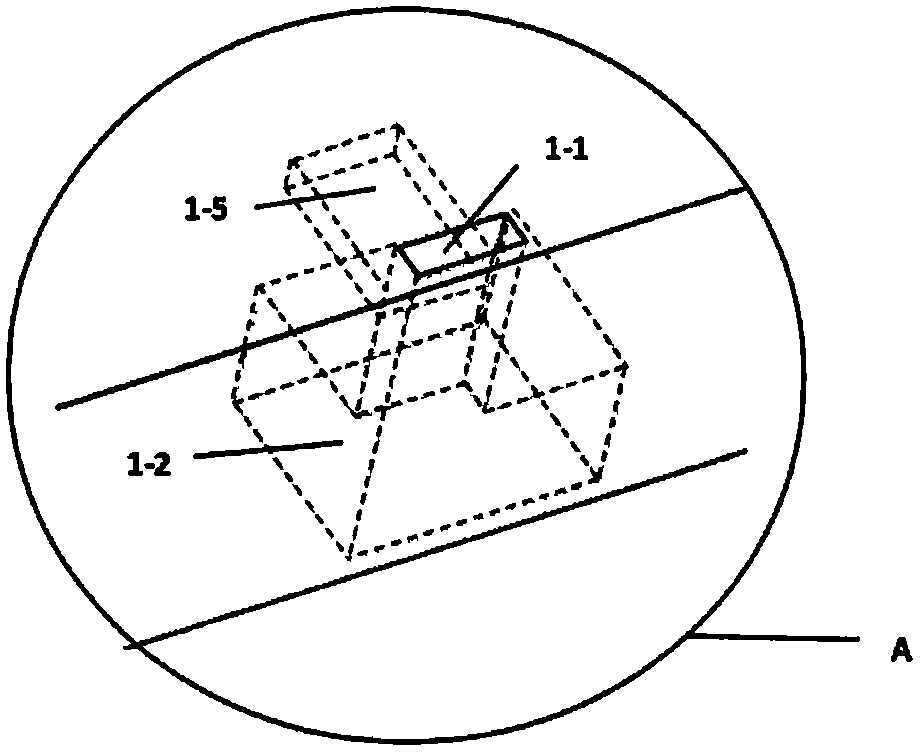

The invention discloses an electric shoe mold used by being matched with a disposal slipper. The structure of the electric shoe mold comprises a shoe sole (1) and a shoe upper (2). The electric shoe mold is characterized in that the two sides of the heel portion of the shoe sole (1) are each provided with at least one rack hole (1-1), a micro electromotor groove (1-2) and a magnet groove (1-5) are arranged in each rack hole (1-1), a power supply groove (1-3) is formed in the shoe sole (1), at least two photoelectric sensors are arranged on the front portion and the back portion of the shoe sole (1), a shoe upper groove (2-1) is formed in the surface of the side, close to the heel, of the shoe upper (2), shoe sole fixing devices (4) are arranged in the rack holes (1-1), the shoe upper groove (2-1) is matched with a shoe upper fixing device (3), micro gears (6) and micro electromotors (5) are installed in the micro electromotor grooves (1-2), a battery (7) is arranged in the power supply groove (1-3), and magnets (9) are arranged in the magnet grooves (1-5). The electric shoe mold is very convenient to use and comfortable.

Owner:张亚东

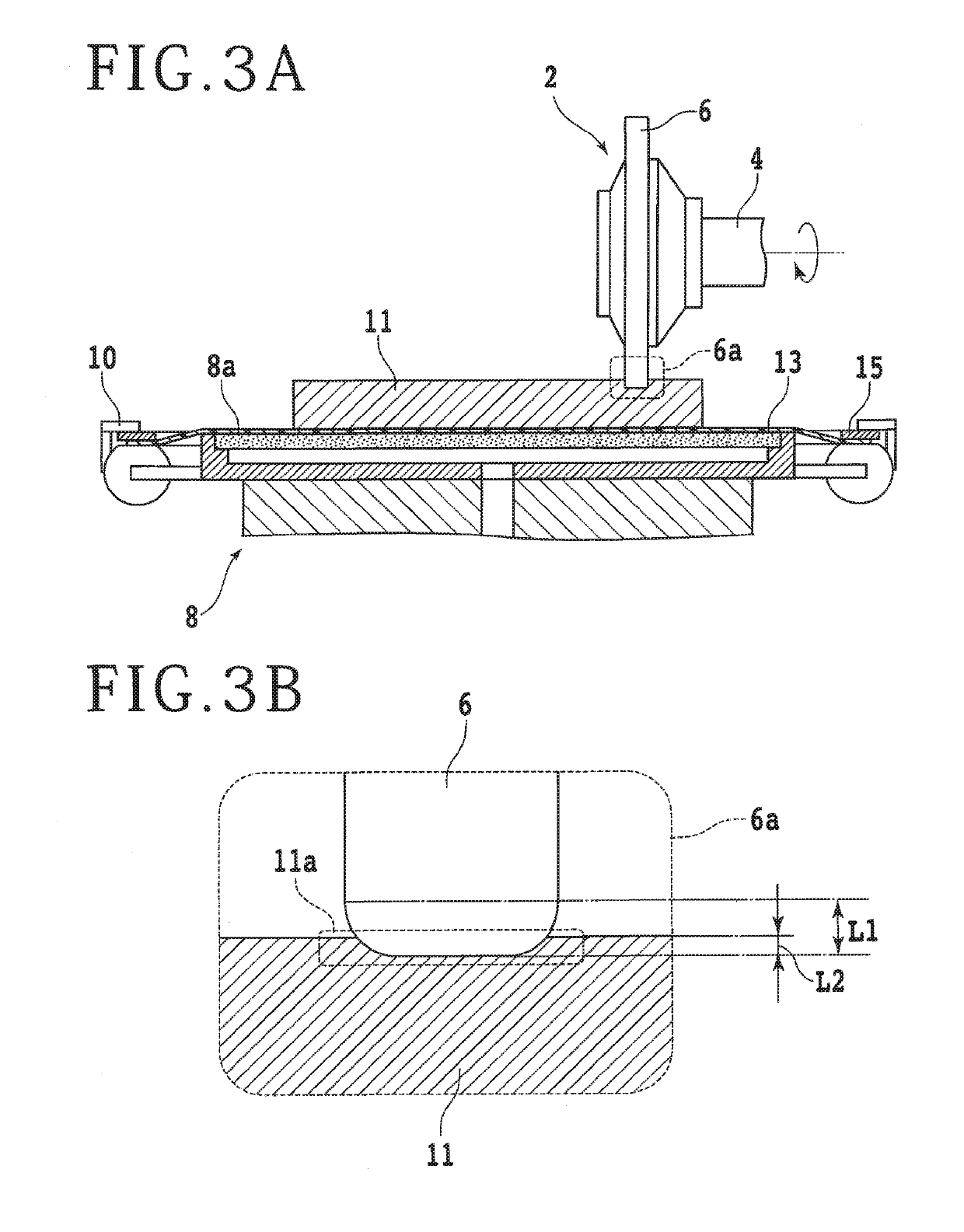

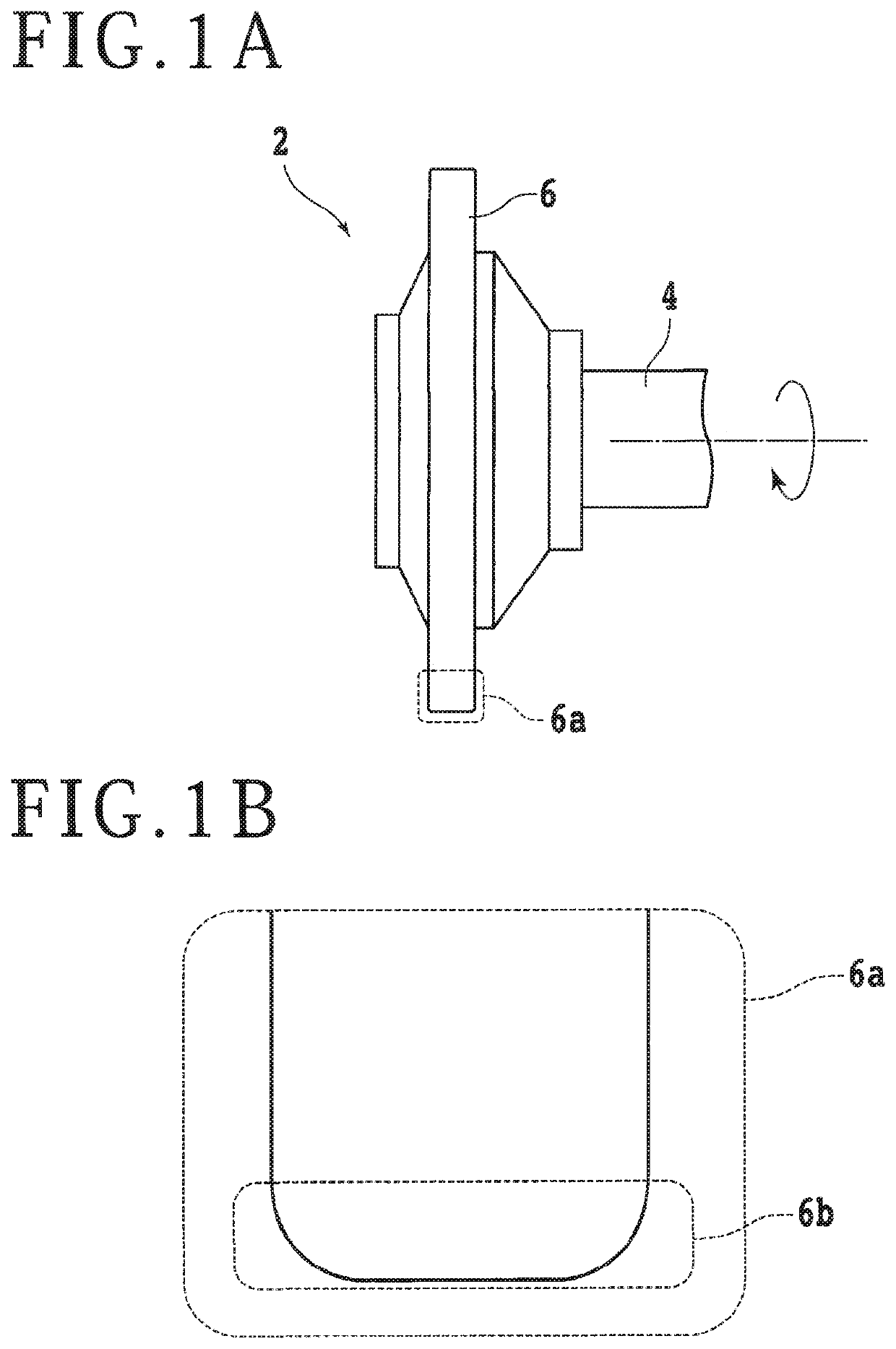

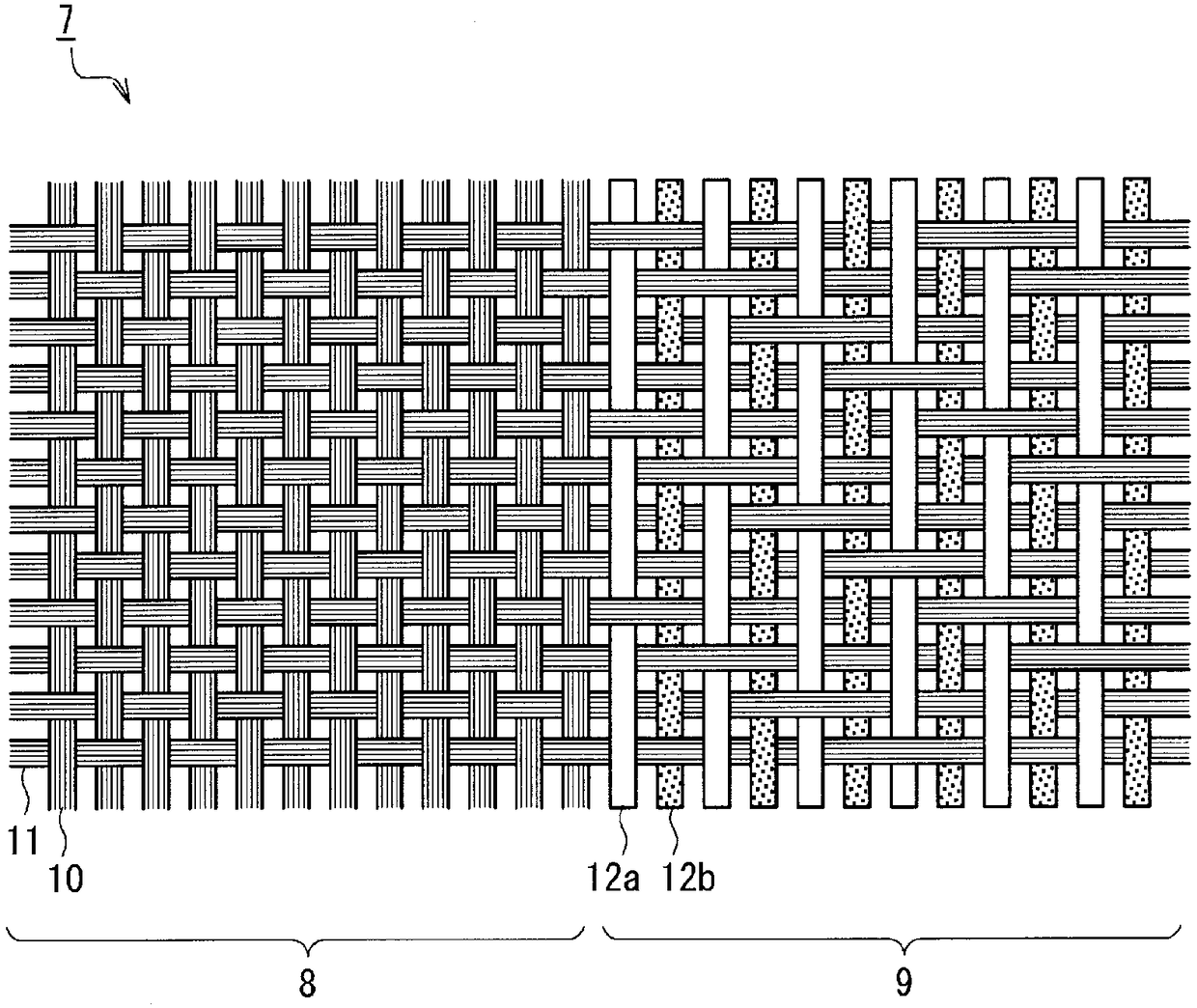

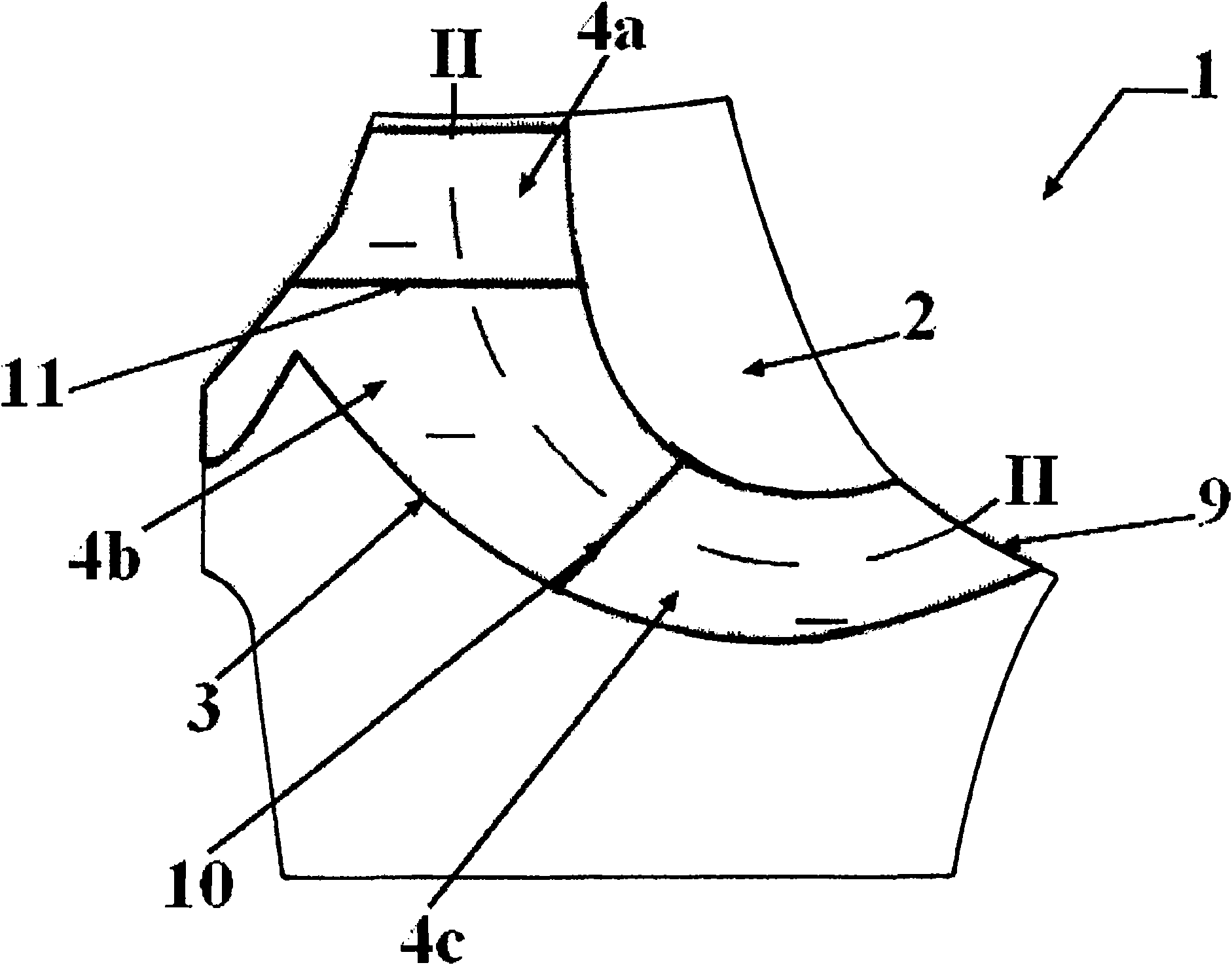

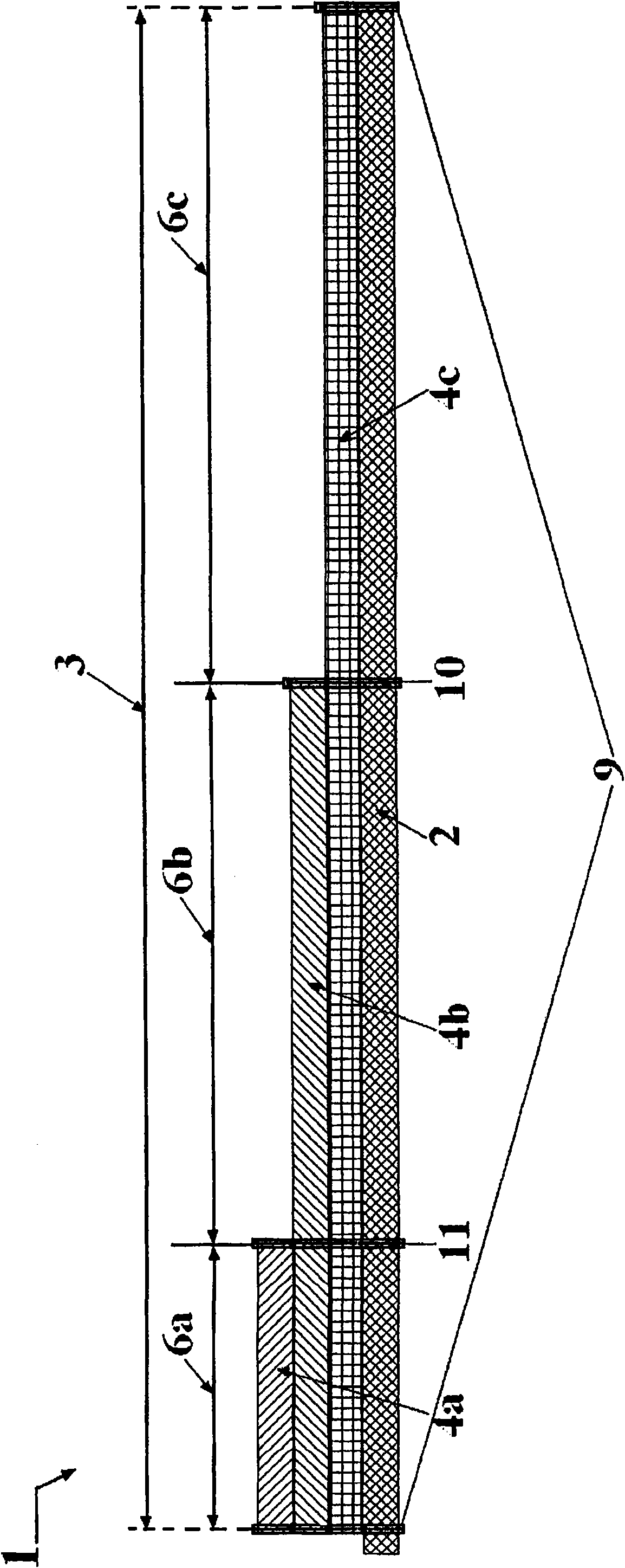

Material blank for clothes, especially for underwear

InactiveCN102029737AHigh weight per unit areaHigh elastic modulusLayered productsBrassieresEngineeringElastic modulus

The invention relates to a material blank (8) for clothes with upper materials (2) connected with lower materials (4) in a reinforcing area (3), wherein the connection is realized via adhesive layers (5a, 5b, 5c) between the upper materials (2) and the lower materials (4). The material blank (8) is provided in the reinforcing area (3) with at least two surface parts (6a, 6b, 6c) with different elastic modulus. According to the proposal of the invention, the weight per unit area of the adhesive layers (5a, 5b, 5c) in the surface parts (6a, 6b, 6c) with relatively large elastic modulus is greater than that in the surface parts (6a, 6b, 6c) with relatively small elastic modulus. In addition, the invention relates to a piece of clothing made by such a material blank (8).

Owner:TRIUMPH INTERTRADE

A heatable pet leash

InactiveCN105557548BImprove comfortGuaranteed slow releaseTaming and training devicesGrooming devicesTraction cordEngineering

The invention discloses a pet traction sleeve with the heating function. The pet traction sleeve with the heating function comprises a foot sleeve part, a power source, a power source switch and an intelligent control device. A sleeve body comprises the foot sleeve part, the power source, the power source switch and the intelligent control device. The foot sleeve part comprises a composite rope body. A traction rope body comprises a composite rope body. Each composite rope body is composed of an isolation layer, a heat-preserving layer and a heating layer from outside to inside. The power source can be controlled by the intelligent control device to supply power to the heating layer of each composite rope body so that the corresponding heating layer can achieve the heating function. The design of a common rope sleeve structure is adopted, the pet traction sleeve can be conveniently worn on a pet, cleaning is convenient, good breathability is kept while the pet traction sleeve is not conductive, and the pet traction sleeve can have the warming function when being conductive. The pet traction sleeve is good in stability, high in breathability and good in warm-keeping effect when fixed to the body of a pet and is suitable for being used in autumn and winter.

Owner:JIAXING MINSHI MASCH CO LTD

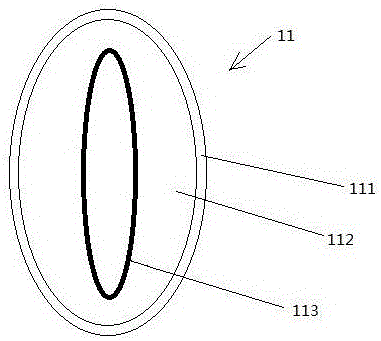

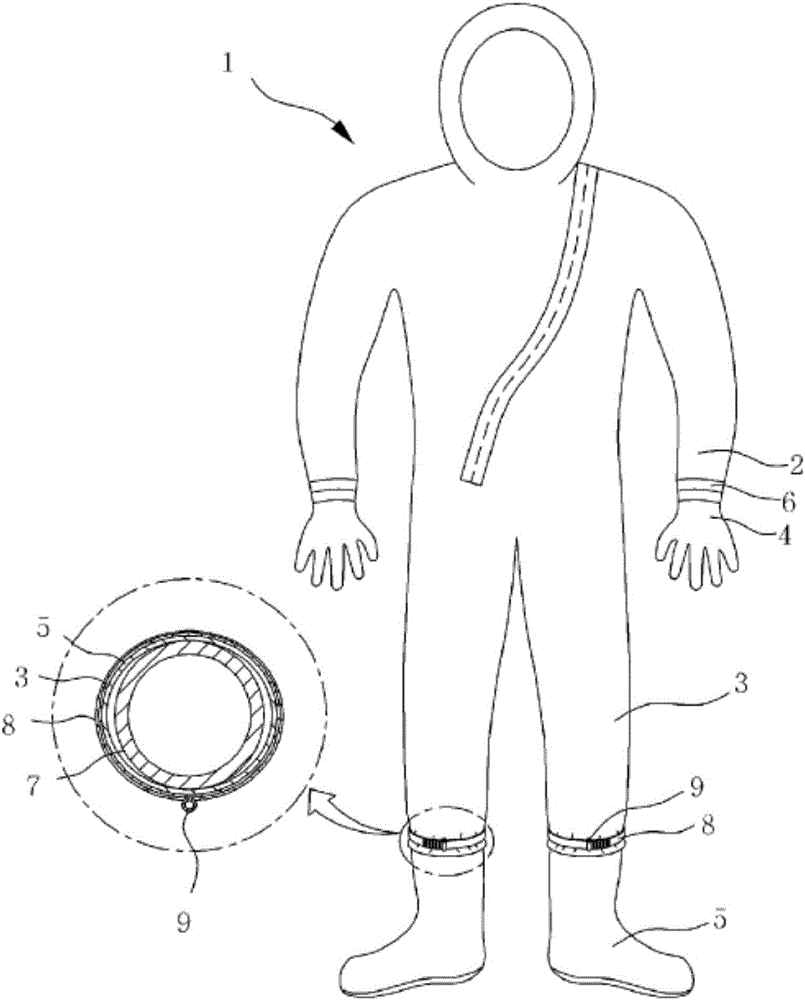

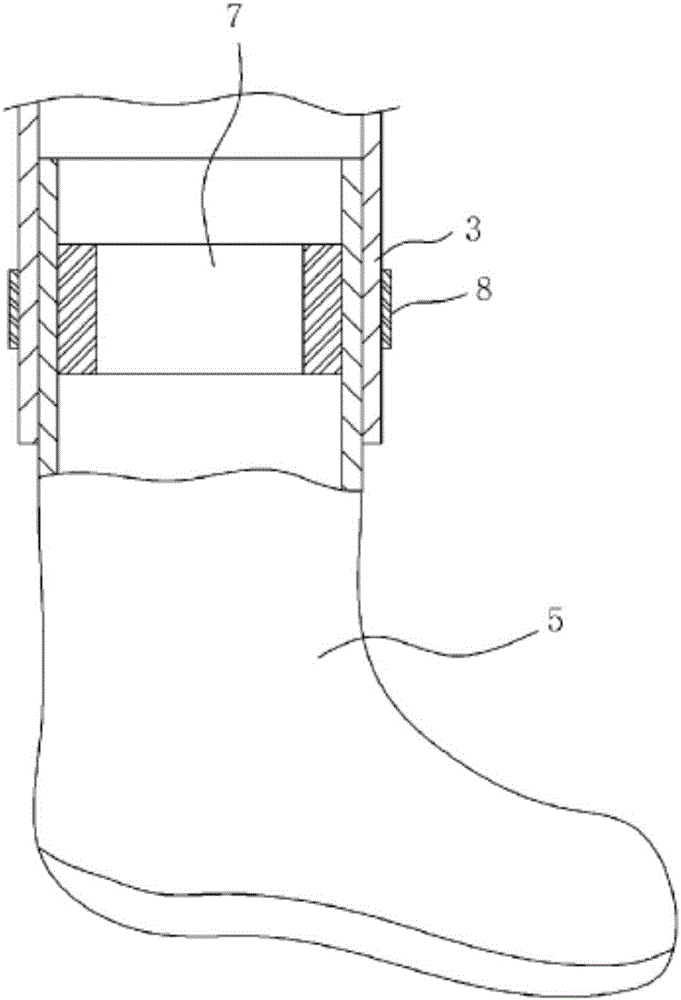

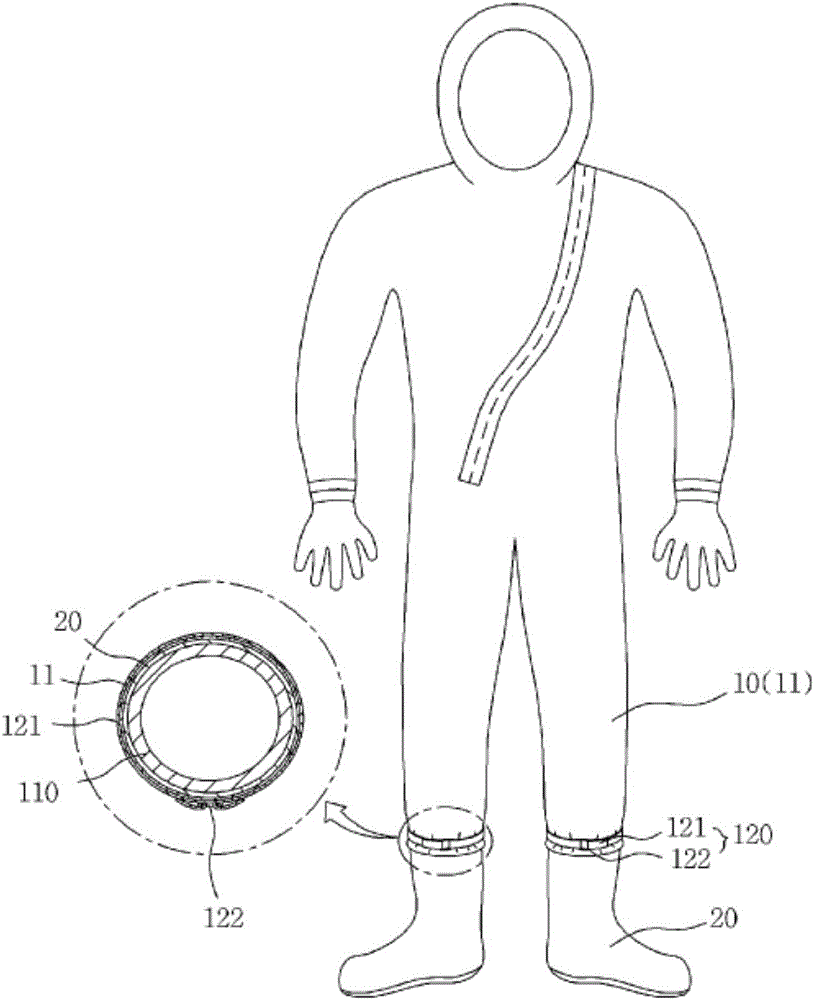

Connecting structures for protective boots for chemical protective clothing

The present invention relates to connecting structures for protective boots for chemical protective clothing, which connect the protective boots integrally to the bottoms of the protective clothing and which comprise: rings, which are fitted on the inner circumferential surfaces of the protective boots, and the longitudinal diameter of which is larger than the transverse diameter thereof; and bands, which are installed in a contracted state on the outside of the bottoms covering the outside of the protective boots and press, by contracting, the outer circumferential surfaces of the rings along the circumferential direction thereof, thereby fixing the protective boots integrally to the bottoms.

Owner:株式会社翰科来福开恩

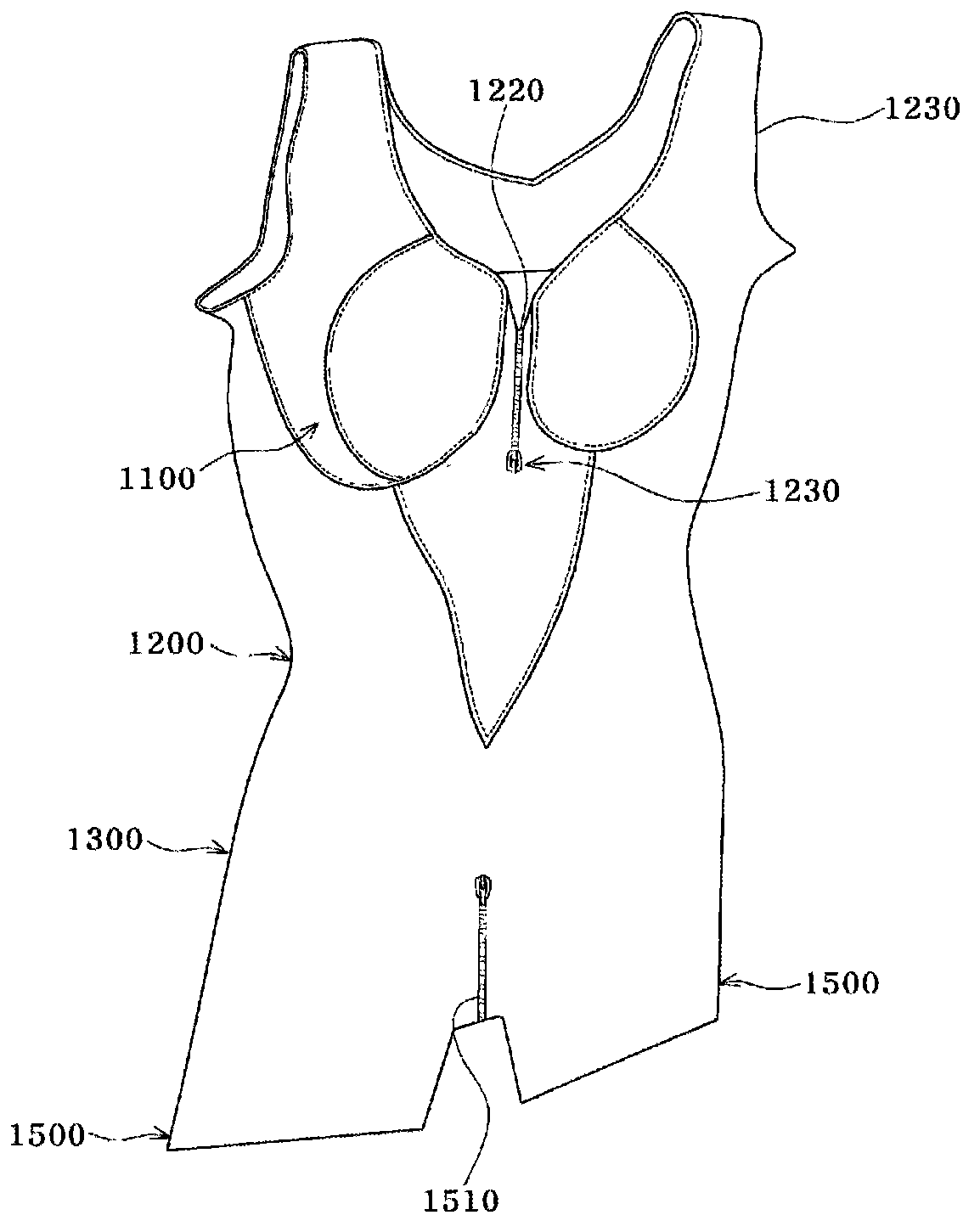

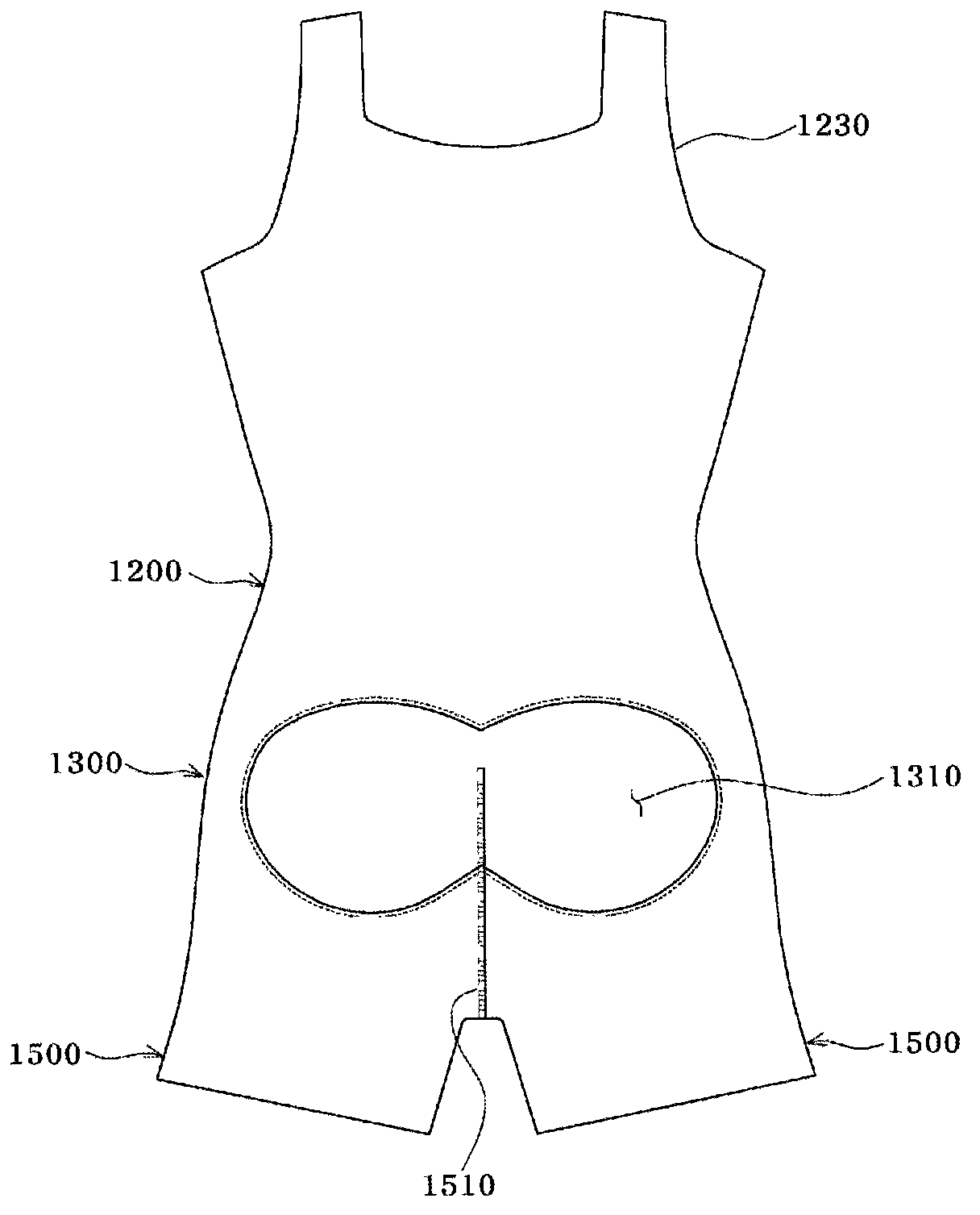

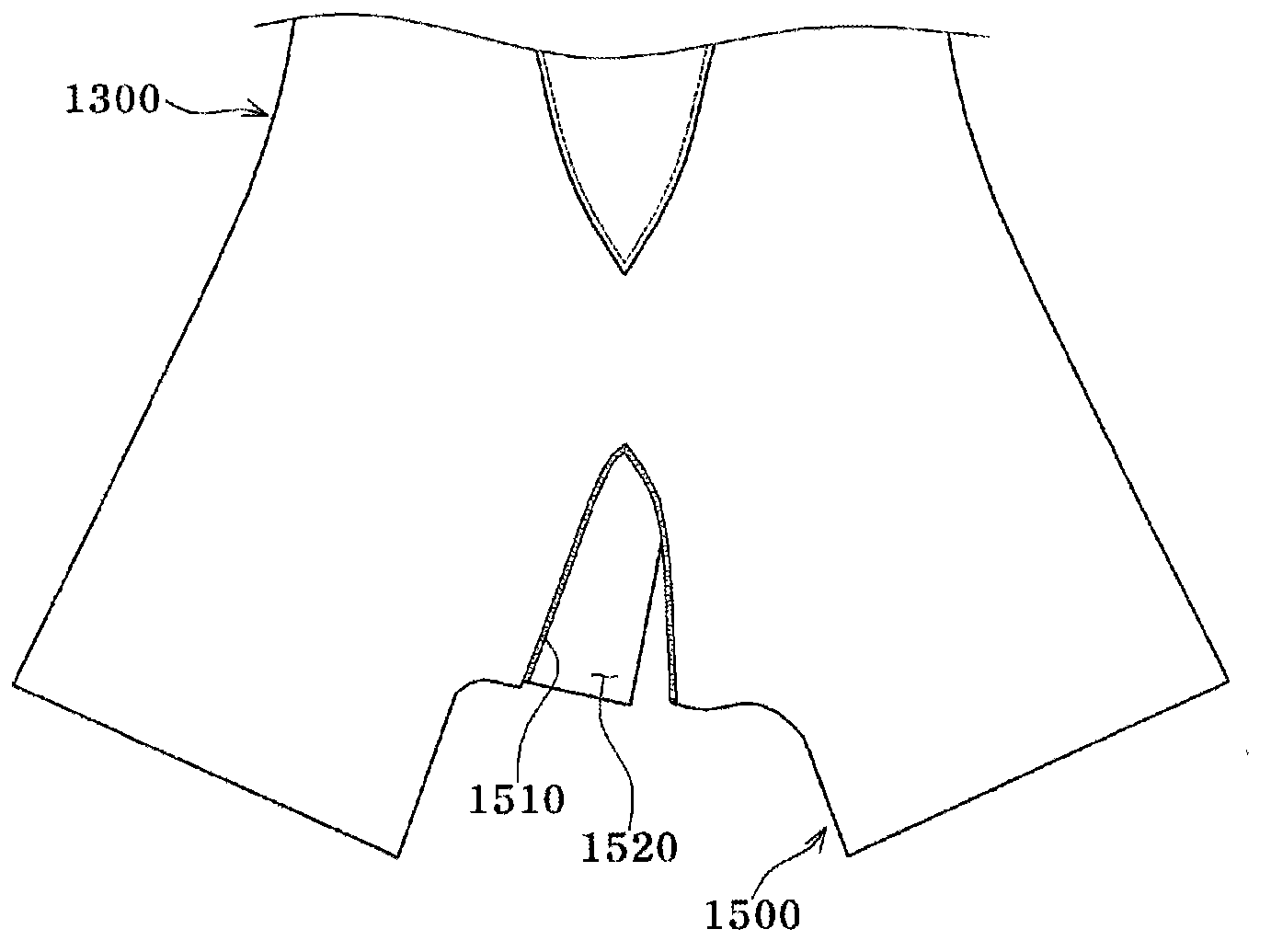

All-in-one underwear

InactiveCN104284607ASimple dressSolve the physiological phenomenon of excretionSlide fastenersBrassieresThighNavel

The present invention relates to all-in-one underwear, and particularly, to all-in-one underwear for improving the shapeliness of the hips and the thighs by elastically wrapping the hips and the thighs without wearing separate briefs, and allowing the forearm to look slender by forming the flexor muscle region of an arm using a dual power net fabric having remarkable elasticity and restoring force compared with a fabric for a shoulder region and an elbow region. The all-in-one underwear of the present invention comprises a brassiere portion (1100), a nipper portion (1200) and a girdle portion (1300) which are integrated, wherein the girdle portion (1300) comprises: integrated leg insertion portions (1500) extended by a predetermined length from the lower portion of the groin toward the knee; a lower zipper (1510) openably / closably provided from a navel region to a coccyx region of the hips in the middle of the leg insertion portions for solving the physiological phenomena of excretion; and a pad (1520) provided on the inner surface of a lower zipper region by predetermined length and width so as to allow longitudinal one surface thereof to be fixed for preventing the damage to the skin when a slider of the lower zipper is opened or closed.

Owner:金南镐

Improved thermal clothes for children

The invention relates to improved thermal clothes for children. The improved thermal clothes comprises a thermal clothes body and is characterized in that the thermal clothes body is jumpsuit, an opening is formed in the middle of a front piece of the thermal clothes body, a connecting device is arranged at the opening, bulges are arranged at the neckline of the thermal clothes body, a thermal material is filled in the bulges, a pair of gloves are connected to the cuffs of the thermal clothes body, and foot tubes are connected to the leg openings of the thermal clothes body. The improved thermal clothes has the advantages of simple structure, convenience for use and good thermal effect and is simple to wear; people are unlikely to get a cold even kicking off a quilt.

Owner:顾美娟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com