Three -dimensional sock shoe

A three-dimensional technology for socks and shoes, applied in the field of socks and shoes, can solve the problems of lack of stiffness, poor wearing, technical threshold and high cost, and achieve the effect of beautiful wearing and easy wearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same numerals.

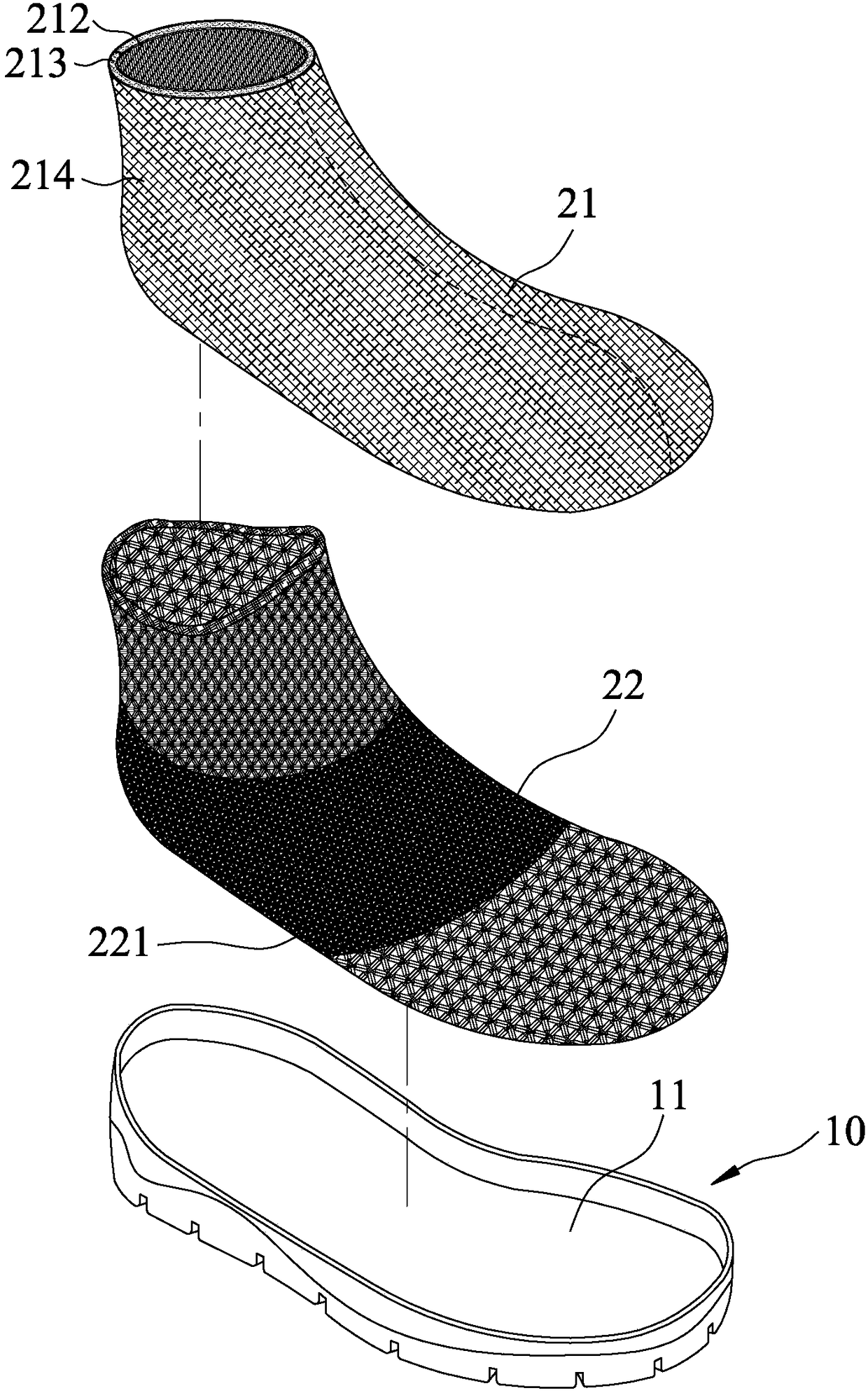

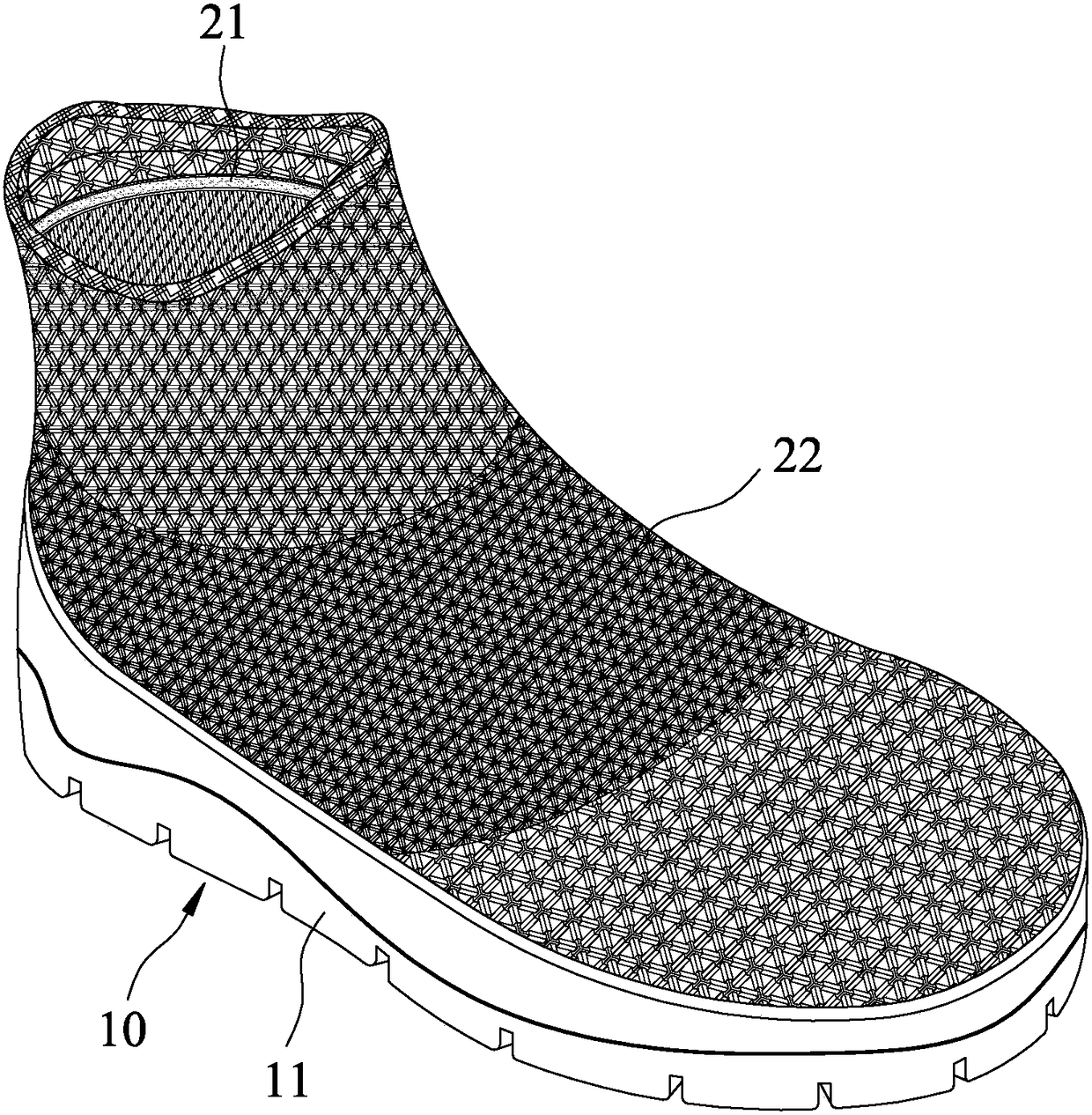

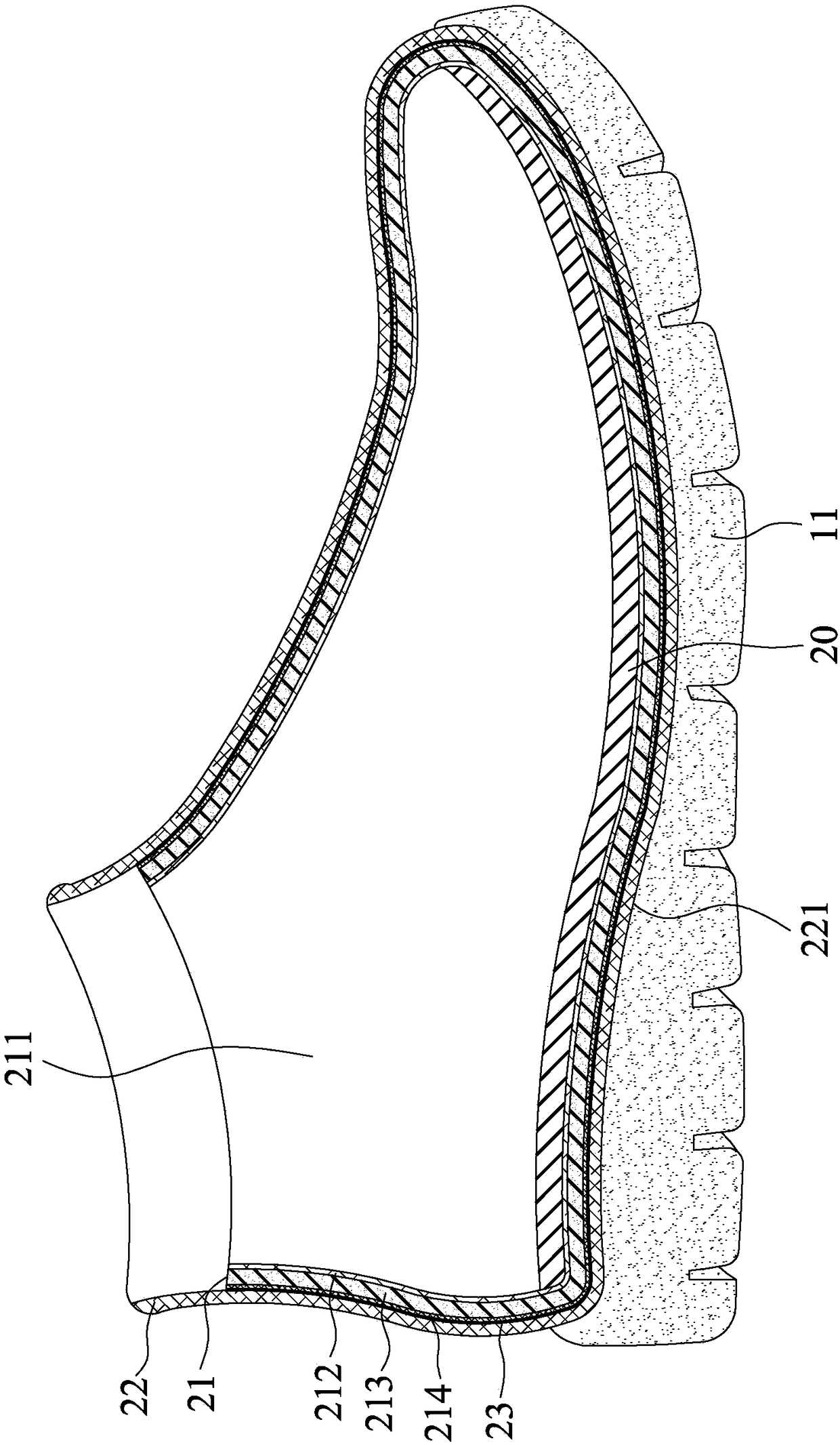

[0030] Such as Figures 1 to 3 As shown, a first embodiment of the three-dimensional socks of the present invention includes a sole unit 10 , an insole 20 , a foam shoe cover 21 , an outer sock body 22 , and a joint layer 23 .

[0031] The sole unit 10 includes a sole 11 .

[0032] Such as Figures 2 to 4 As shown, the foam shoe cover 21 is formed by butt jointing of two layered structures (see Figure 4 ), the foam shoe cover 21 is inserted into a shoe last to define a three-dimensional space 211 for the foot where the insole 20 is set, and the foam shoe cover 21 is sequentially provided with an inner layer 212, a One layer of foam layer 213 and one layer of outer cloth layer 214 are fixed by adhesive between each layer. The insole 20 can absorb the impact force when walking. In order to make the user wear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com