Elastic flexible wire for intelligent spinning and production method thereof

A flexible wire and production method technology, applied in textiles, papermaking, yarn, etc., can solve the problems of inelasticity of flexible wires, inability to apply elastic flexible substrates, etc., and achieve the effects of reliable electrical conductivity, flexible style retention, and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

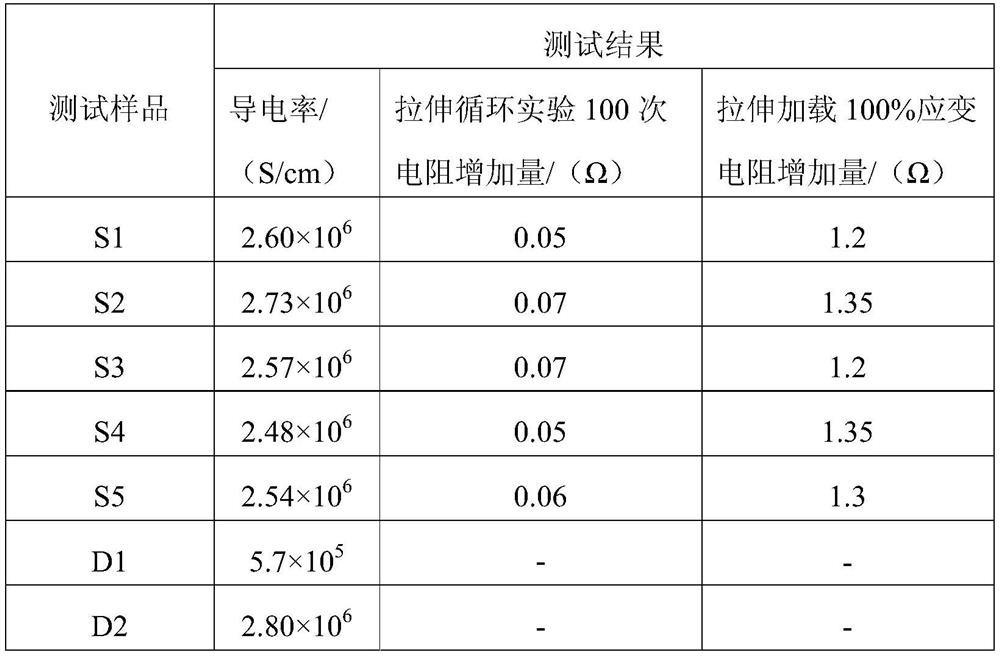

Examples

Embodiment 1

[0032] An elastic flexible wire S1 for smart textiles, which uses a colored cellulose fiber core-wrapped elastic wire, the outer layer is colored cellulose fiber, and the inner layer is an elastic wire. Examples will not be repeated); the mass ratio of the colored cellulose fiber to the elastic wire is 30:70, the cross-sectional diameter of the elastic wire is 0.3 mm, and the comprehensive yarn count of the elastic flexible wire is 6 lbs.

[0033] The control points of two important indicators in the production process of the elastic flexible wire:

[0034] Broken core yarn affects the conductive effect: the joint treatment method at the broken end can prevent broken core yarn, and the elastic wire joint is welded with conductive metal. The conductive metal is made of silver, copper and other metal materials. Continuous wires can be formed after fusion cooling.

[0035] Poor coating such as exposed core affects the conductive effect and aesthetic comfort: choose fibers with g...

Embodiment 2

[0044] The graphene composite fiber core-spun elastic flexible wire S2 of the present invention is a graphene-cored elastic wire, the mass ratio of graphene to the elastic wire is 50:50, the cross-sectional diameter of the elastic wire is 0.3mm, and the comprehensive yarn count of the elastic flexible wire is It is 5.5 pounds.

[0045] The difference between this embodiment and Example 1 is that the total draft ratio of the spun yarn is changed from 17.86 times to 13.91 times, the twist is adjusted from 47 twists / 10cm to 42 twists / 10cm, and the pre-draw ratio of the spun steel wire is 4.2 times .

Embodiment 3

[0047] The difference between the elastic flexible wire S3 of this embodiment and the embodiment 1 is that the total draft ratio of the spun yarn is 10.35, the twist is too large to be 45 twists / 10cm, and the pre-draw ratio of the spun steel wire is 4.5 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com