Patents

Literature

31results about How to "No need to dye" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

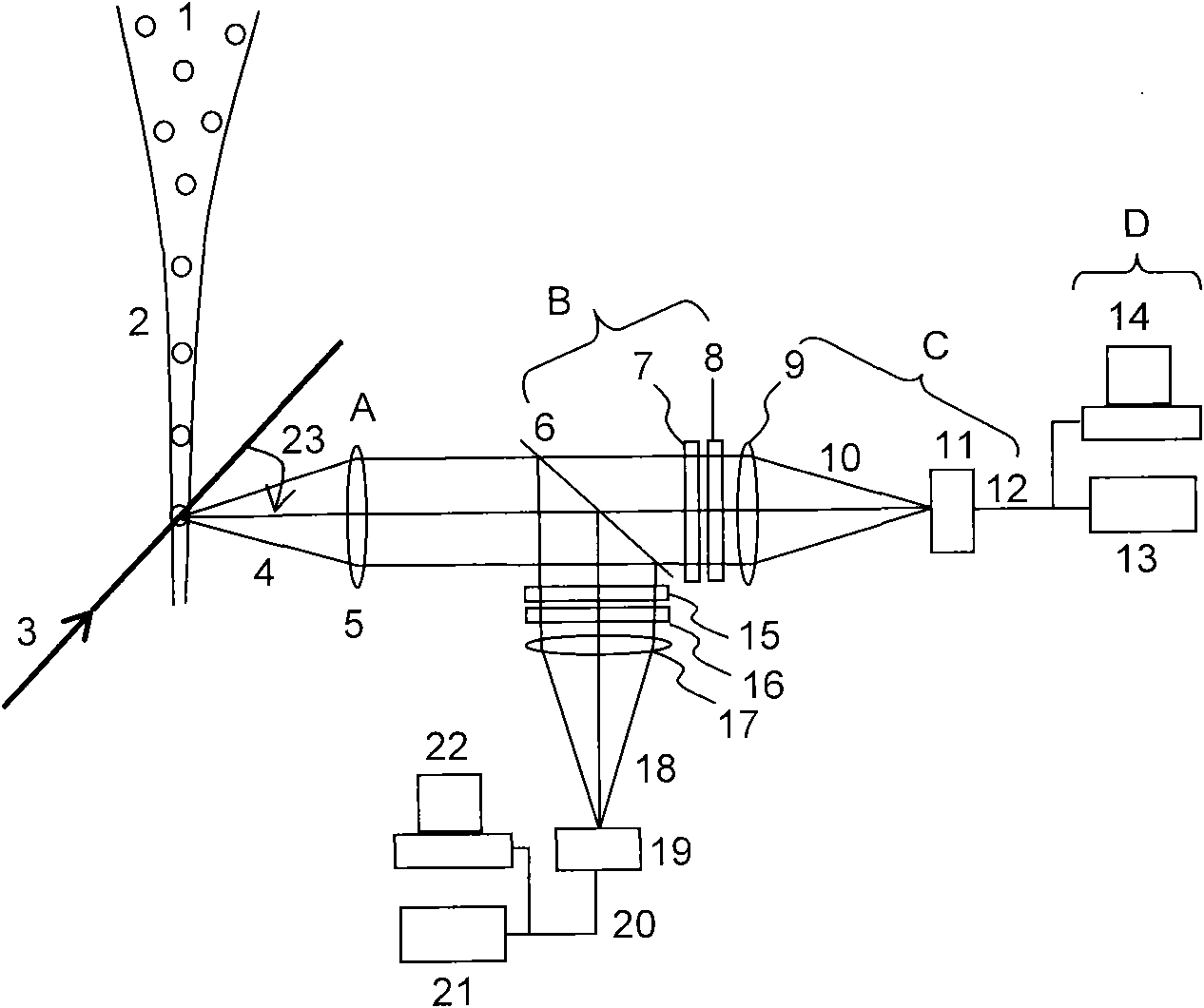

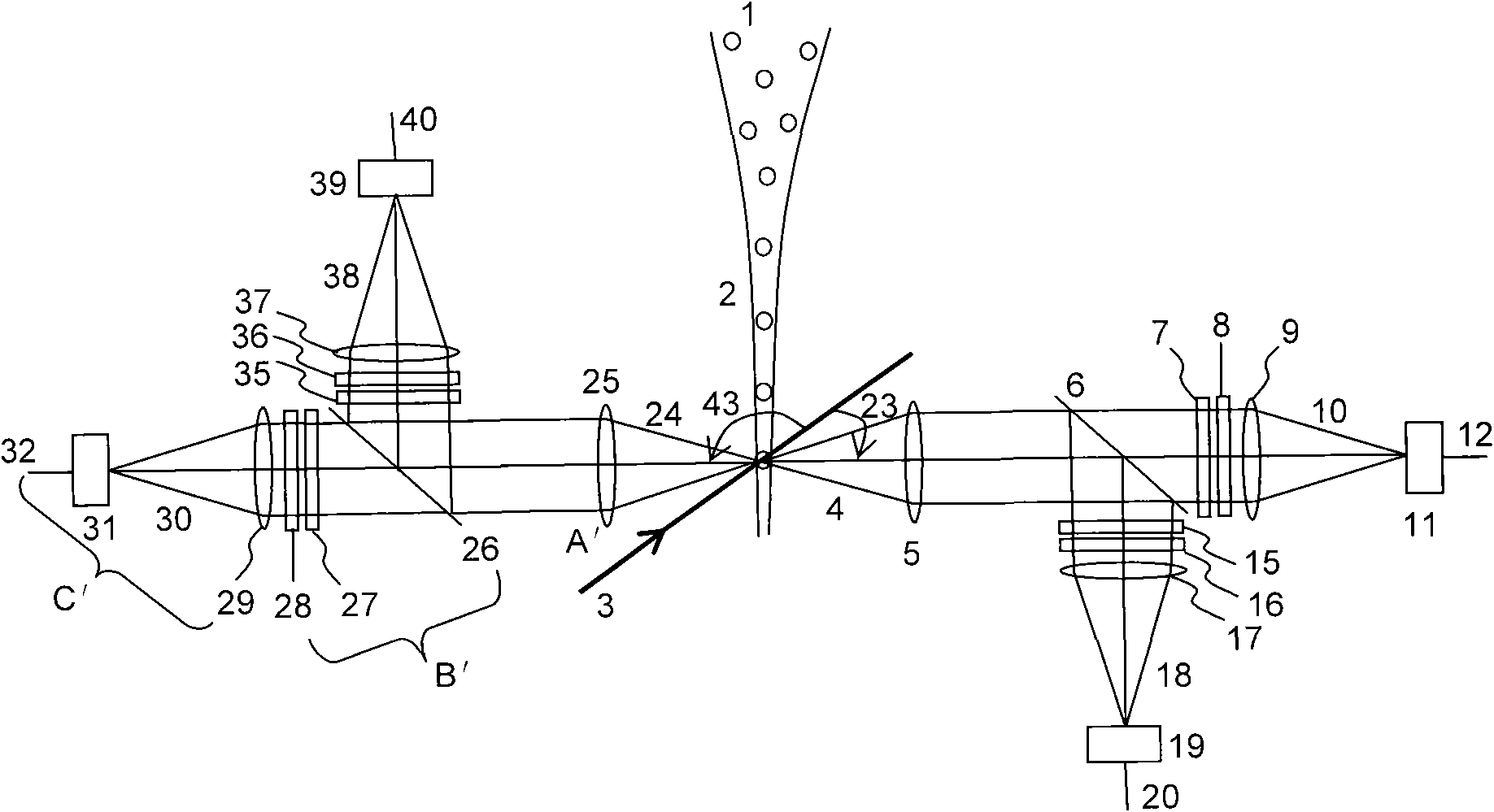

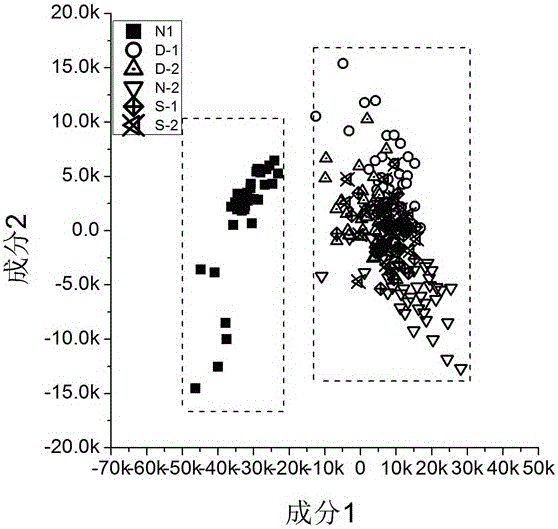

Measuring analytical system and measuring analytical method for distinguishing diffraction image of particles automatically

InactiveCN101943663ADoes not affect internal biochemical processesRapid Analysis ExtractionAnalysis by material excitationImaging processingLight beam

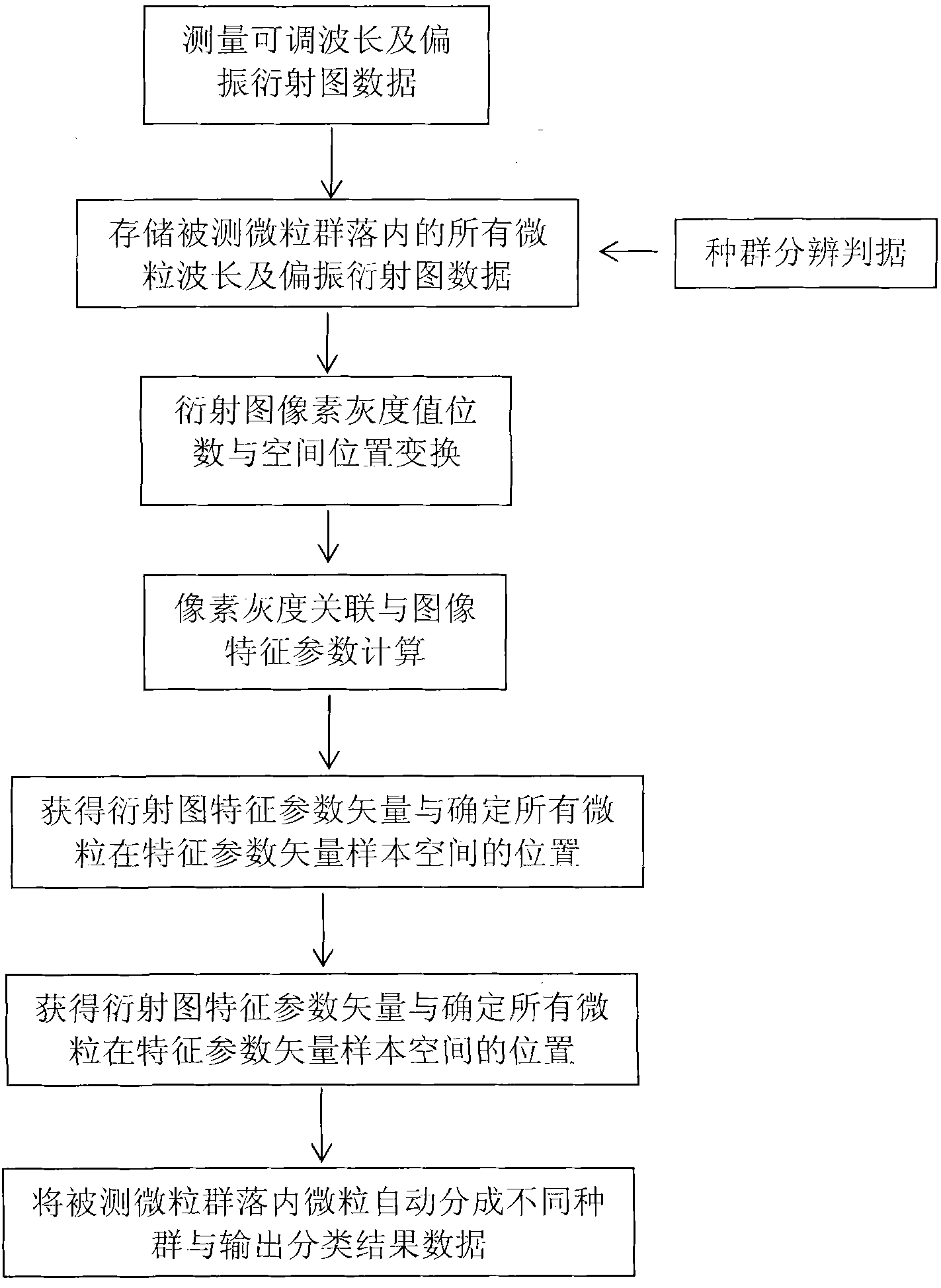

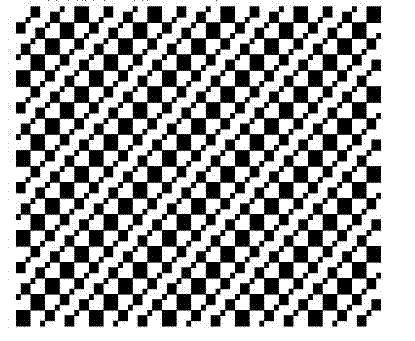

The invention relates to a measuring analytical system and a measuring analytical method for distinguishing a diffraction image of particles automatically. The system comprises a sample stream formed by flow particles, a coherent excitation light beam intersectant with the sample stream, a first scattered light receiving objective lens part with a first central scattering angle of a coherent scattering light beam, a first light split and filtering part, a first imaging measurement and data output part, an image processing circuit, a computer part and a display part connected with the image processing circuit and the computer part. The method comprises the following steps of: acquiring the corresponding adjustable wavelength and polarizing diffraction image data; storing the data; performing the conversion of image space coordinates; performing characteristic screening and selecting a characteristic area; selecting the characteristic of a diffraction image mode; and determining the position of the measured particles in the characteristic parameter vector sample space of the diffraction image. The measuring analytical system and the measuring analytical method haves the advantage that a large number of particles can be analyzed and distinguished quickly according to the characteristic of a three-dimensional structure in the particles, and the particles are not needed to be dyed.

Owner:董珂 +1

Recycled color yarn produced from waste polyester fabric and manufacturing method of recycled color yarn

InactiveCN110273197ANo need to dyeNo pollution in the processChemical industryPigment addition to spinning solutionYarnPolyester

The invention discloses a recycled color yarn produced from waste polyester fabric and a manufacturing method of the recycled color yarn. The recycled color yarn comprises the waste polyester fabric, esterified products, color masterbatches, brightening agents and chain extenders. The manufacturing method includes (1) pretreating the waste polyester fabric to form a foam material; after the foam material is put into a melting furnace to be smelted into a molten state, filtering the melt to remove non-melted impurities, extracting bubbles and oligomers in the melt through negative pressure to obtain a granulated semi-finished product, and subjecting the granulated semi-finished product to depolymerization, chain extension and ester exchange re-polymerization in a reaction kettle to obtain a granulated raw material; (2) subjecting the esterified products, the color masterbatches and the brightening agents to melt blending for extrusion granulation to obtain an esterified masterbatch; (3) adding the products of the step (1) and the step (2) into a reaction-type vented screw extruder for extrusion granulation to obtain a raw material of the recycled color yarn; (4) subjecting the product of the step (3) to melt spinning. The recycled color yarn and the manufacturing method thereof have the advantages that the waste polyester fabric is recycled, the printing and dyeing process of the recycled color yarn is simplified, environmental pollutants such as printing and dyeing wastewater are avoided, and the recycled color yarn is energy saving and environment friendly.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

Bamboo carbon fiber pearl stripe yarn dyed fabric and weaving method thereof

InactiveCN102828322AGuaranteed to be environmentally friendlyNovelty and unique appearanceSwivel-woven fabricsLappet-woven fabricsPolymer chemistryWeft yarn

The invention provides a bamboo carbon fiber pearl stripe yarn dyed fabric and a weaving method for the bamboo carbon fiber pearl stripe yarn dyed fabric. Almost no shell fabric which is a cloth product using bamboo carbon fibers is used for sportswear in the market at present, and demands of consumers cannot be met. The bamboo carbon fiber pearl stripe yarn dyed fabric adopts a double-spraying multi-arm hydraulic loom, selects 75D / 48F polyester filament yarns to conduct semi-finished black processing to be 800T / S to serve as warp yarns, adopts 75D / 72F pure bamboo carbon fiber gray filament yarns and 75D / 144F dacron ultra fine denier filament yarn to twist to serve as weft yarns to conduct 2:1 circulation, and interweaves. A 15*15 twill change texture interweaving rule is designed, and three-dimensional lines in a pearl shape outside the fabric are formed through alternative changes of floating lengths of the warp yarns and the weft yarns. Total number of the warp yarns is 12768, 19# reeds are used for conducting 4 denting, an acting reed width is 168cm, an acting weft density is 46 root / cm, and a side is same to a ground portion. 15 heald frames are adopted to sequentially draft, and arrangement of line nails is 15 weft / turn. Products of the bamboo carbon fiber pearl stripe yarn dyed fabric serve as a garment material.

Owner:SUZHOU DISHENG WEAVING FINISHING

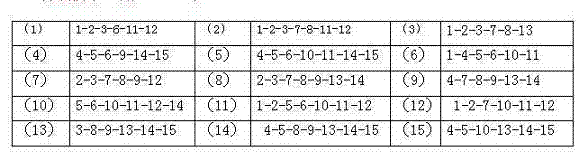

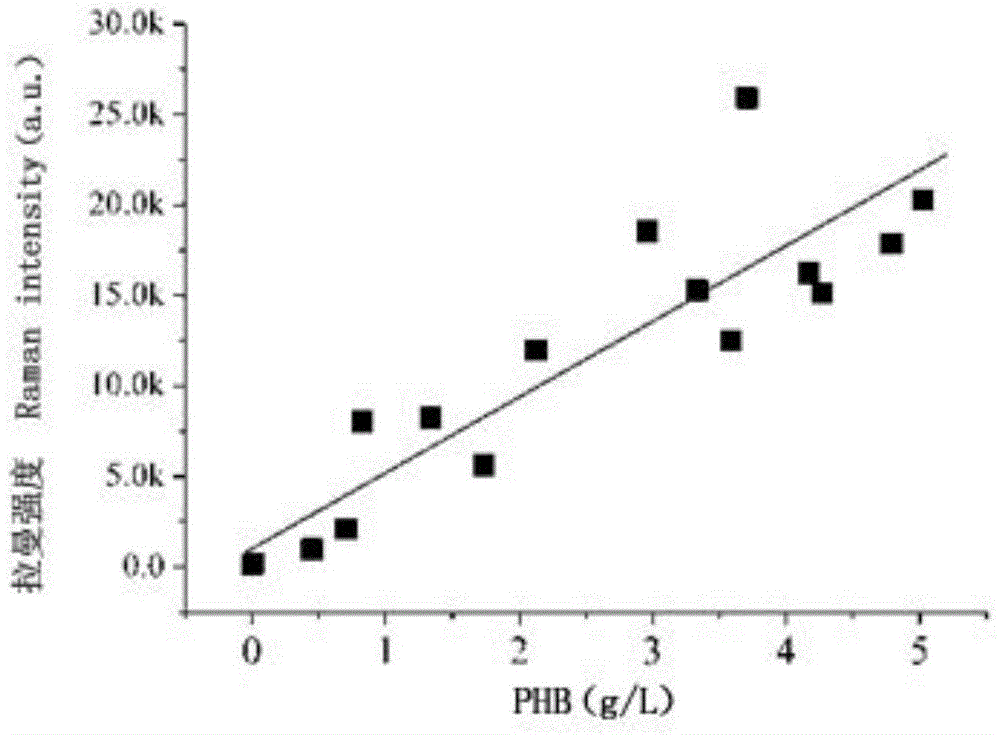

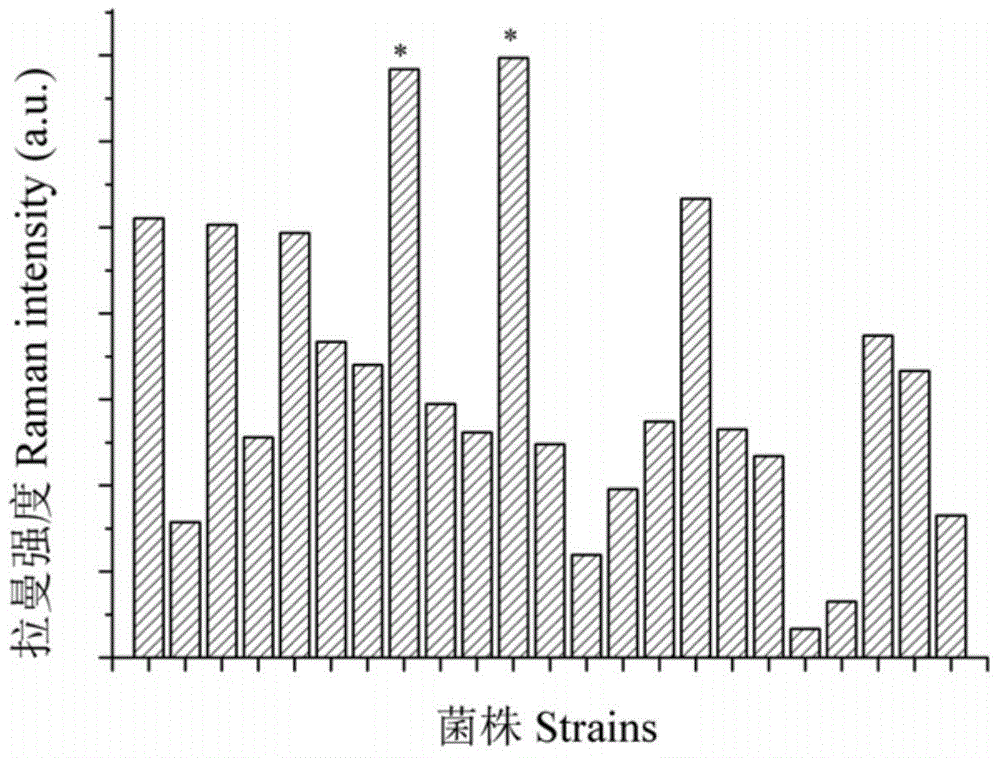

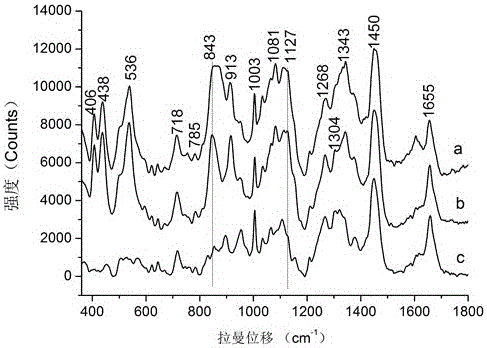

Method of screening strains for producing microorganism plastics

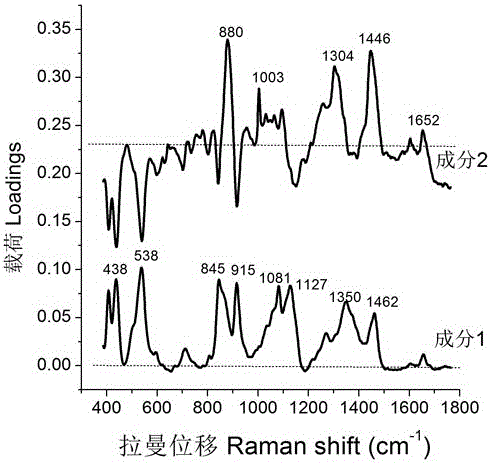

InactiveCN104830949ASimple and fast operationNo need to dyeMicrobiological testing/measurementRaman scatteringMicroorganismScreening method

The invention discloses a method of screening strains for producing microorganism plastics and belongs to the technical field of screening microbial strains. The method mainly comprises the following steps: by adopting the combination of laser tweezers and a single-cell Raman technique, judging the ability of microorganism cells in synthesizing the microorganism plastics, and further separating and purifying the strains for producing the microorganism plastics with high yield. The method is simple and convenient to operate and free from dyeing, and detection can be directly performed in aseptic water; the method is also capable of rapidly and intuitively screening the strains for producing the microorganism plastics without damaging the detected cells serving as samples, thereby being a simple, convenient, efficient and reliable method which is worthy of popularization and capable of screening the strains for producing the microorganism plastics with high yield.

Owner:GUANGXI ACAD OF SCI

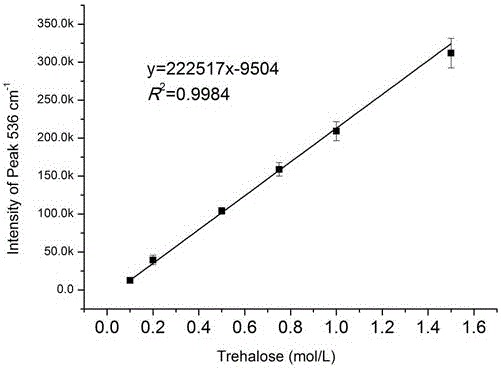

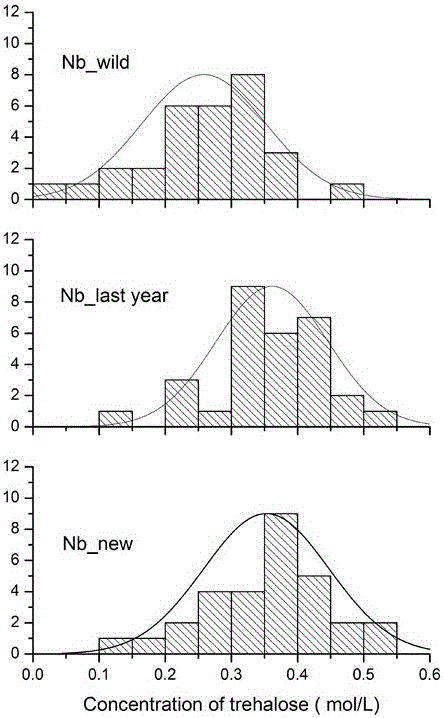

Method for quickly quantifying concentration of trehalose in single microsporidia spore

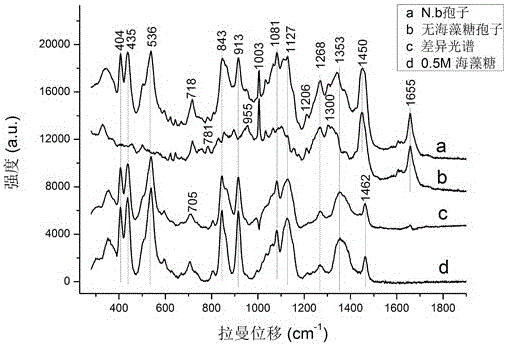

InactiveCN106770150AStrong signalImprove signal-to-noise ratioRaman scatteringMicrosporidiaTrehalose

The invention discloses a method for quickly quantifying the concentration of trehalose in a single microsporidia spore based on a single cell Raman spectrum, and belongs to the technical field of quantitative analysis. The method mainly adopts a single cell Raman spectrum technology and a pair of laser tweezers to quantitatively analyze the concentration of the trehalose in the single microsporidia spore. The method is easy and convenient to operate and pollution-free, and no chemical agents are needed; a spore sample is directly detected in germfree water, and the concentrations of the trehalose in the individual microsporidia spores from different sources can be quickly and intuitively quantified, so that heterogeneity of the concentration of the trehalose in the single spore in the same colony is obtained; the method has the advantages of simplicity, efficiency and reliability.

Owner:王桂文

Method for quickly detecting microsporidia spores

The invention discloses a method for quickly detecting microsporidia spores based on single cell Raman tweezers, belongs to the technical field of pathogenic bacterial detection. The method mainly adopts a pair of laser tweezers and a single cell Raman spectrum technology to judge spores of pathogenic bacteria microsporidia in a host body or the natural environment. The method is easy and convenient to operate, no staining is needed; detection is directly carried out in germfree water; furthermore, whether a sample contains the microsporidia spores or not can be quickly and intuitively judged; therefore, the method is worthy of being popularized and is simple, convenient, efficient and reliable for detection of the microsporidia spores.

Owner:王桂文

Optical fibre bio-sensor of acetylcholinesterase and its preparing process

InactiveCN1363687ALarge data capacityHigh sensitivityMicrobiological testing/measurementFiberPeripheral neuron

An optical fibre bio-sensor for distriminating the nature of peripheral nerve fibres is composed of optical fibre and sensing membrane which is fixed to the end of optical fibre by co-valent binding or physical adsorption. Said sensing membrane is prepared from high-molecular film containing oxygen indicator, choline oxidase and high-molecular membrane by one of three methods. Its advantages include no need of cutting nerve fibre, high speed and correctness and no poison and no wound to human body.

Owner:NANJING MEDICAL UNIV

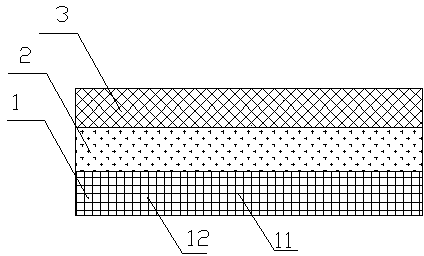

Anti-static waterproof patterned thermal textile fabric

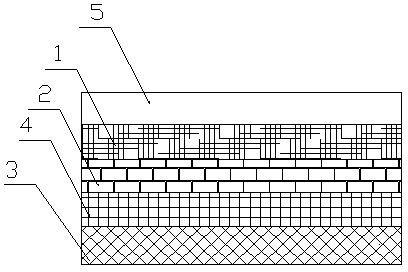

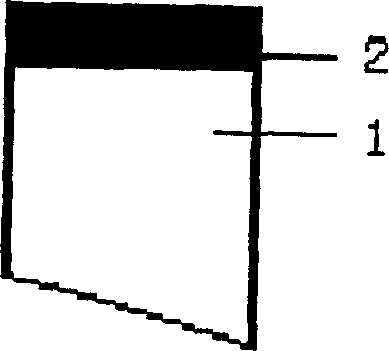

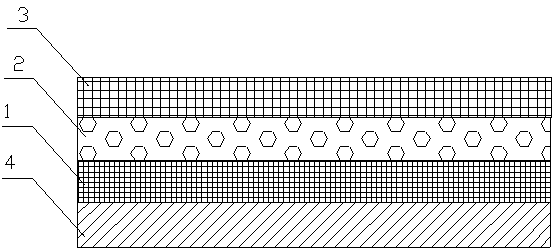

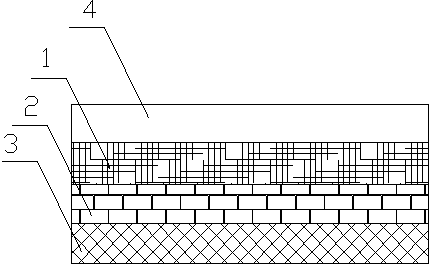

InactiveCN104385726AGood warmth retentionGuaranteed warmthSynthetic resin layered productsWoven fabricsInsulation layerEngineering

The invention relates to an anti-static waterproof patterned thermal textile fabric. The anti-static waterproof patterned thermal textile fabric sequentially comprises an outer layer (1), a fabric layer (2) and an inner layer (3), wherein the outer layer (1) and the fabric layer (2) are laminated; the outer layer (1) is a windproof water-resistant breathable film; the fabric layer (2) is a textile; the inner layer (3) is an insulation layer; an anti-static layer (4) is arranged between the inner layer (3) and the fabric layer (2) and formed by weaving warp yarns and weft yarns; the textile is formed by interweaving warp yarns and weft yarns and adopts the 3 / 1 woven twill tissue structure, the warp yarns are 800D terylene super bright FDY, the weft yarns are 800D terylene super bright FDY, the warp density is 25 / cm, the weft density is 16 / cm, and the warp yarns are Z-twisted by 180 / m. The anti-static waterproof patterned thermal fabric has a water-proof thermal effect. As the textile weave changes to form patterns, and after fabric manufacture, dyeing is not needed. As the warp yarns are twisted warp yarns, the textile is relatively stiff.

Owner:JIANGYIN BETTER TEXTILE

Environment-friendly food packaging paper

ActiveCN104032625AGood for healthNo decolorization requiredNon-fibrous pulp additionFlexible coversPullulanPapermaking

The invention belongs to the technical field of papermaking, and in particular relates to environment-friendly food packaging paper. The environment-friendly food packaging paper is prepared from the following raw materials in parts by weight: 100 parts of dried rice straw, 1-4 parts of pullulan, 1-4 parts of curdlan, 0.12-0.18 part of glucomannan and 40-50 parts of sterile water. The environment-friendly food packaging paper is prepared by crushing, pulping, steaming, paper film formation and drying, and has the characteristics of environment friendliness, nature, no toxicity, sanitation and the like.

Owner:ANQING TIANRUN PAPER PACKAGING

Method of utilizing waste textiles to produce rhombic fancy yarn

The invention discloses a method of utilizing waste textiles to produce rhombic fancy yarn. The method includes: treating the waste textiles into a mono-fiber state to obtain recycled fiber; blendingthe recycled fiber with strong fiber to obtain rough yarn of 600-800Tex in linear density; taking the rough yarn as core yarn, and utilizing a fancy twister to wrap first functional filament and second functional filament onto the rough yarn to obtain the rhombic fancy yarn, wherein wrapping twist is 30-50 twist / 10cm. The method overcomes the technical prejudice of current recycled fiber application, and the recycled fiber is applied to prepare the rhombic fancy yarn for the first time through proper process step and parameter adjusting, so that reutilization of the waste textiles is realized,cost is low, product additional value is increased, and the rhombic fancy yarn obtained by taking low-grade recycled fiber as a raw material can be widely used for high-grade products like high-gradegarments and decorative textiles.

Owner:TIANJIN POLYTECHNIC UNIV

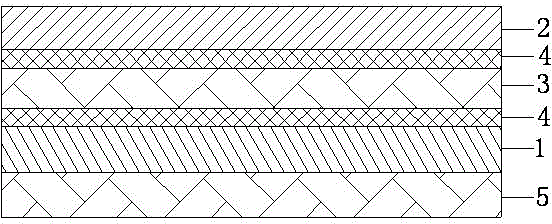

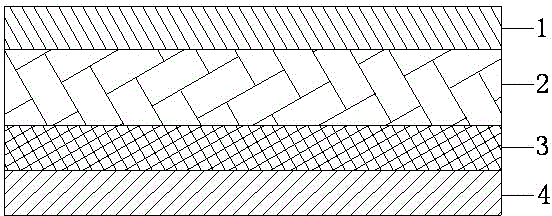

Plus material with patterns for moisture-absorption sweat-releasing fabric

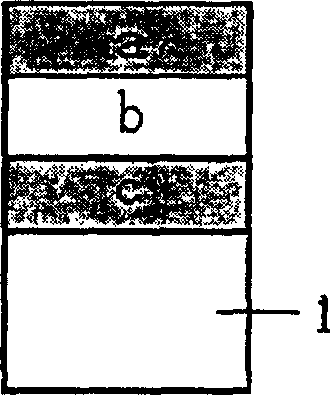

InactiveCN104770924APlay a breathable roleNo need to dyeSynthetic resin layered productsWoven fabricsFiber layerDyeing

The invention relates to a plus material with patterns for moisture-absorption sweat-releasing fabric. The plus material comprises a pure cotton plus material (1), wherein a bamboo carbon fiber layer (2) is arranged under the pure cotton plus material; a moisture-absorption sweat-releasing layer (3) is also arranged under the bamboo carbon fiber layer; a layer of blended fabric (4) covers the bottom of the moisture-absorption sweat-releasing layer (3), and a base layer (5) is compounded under the blended fabric (4). The base layer is made of fabric; the fabric is obtained through interweaving warp yarns and weft yarns; the tissue structure is a 3 / 1 interwoven twill-weave structure; the warp yarns are 800D dacron super bright FDYs (fully drawn yarns); the weft yarns are 800D dacron super bright FDYs; the warp density is 25 pieces / cm; the weft density is 16 pieces / cm, and the warp yarn Z twist yarn density is 180 pieces / m. The plus material with patterns for the moisture-absorption sweat-releasing fabric has the advantages that sweat can be absorbed away, and in addition, the sweat can be volatilized in time; the fabric forms patterns through the fabric tissue structure change, in addition, after the weaving completion, the dyeing is not needed, and meanwhile, warp yarns are twisted warp yarns, so that the fabrics are stiff.

Owner:JIANGYIN ZEWAN TRADE

Preparing process for optical fibre bio-sensor of acetylcholinesterase

InactiveCN1161478CLarge data capacityHigh sensitivityMicrobiological testing/measurementFiberPeripheral neuron

An optical fibre bio-sensor for distriminating the nature of peripheral nerve fibres is composed of optical fibre and sensing membrane which is fixed to the end of optical fibre by co-valent binding or physical adsorption. Said sensing membrane is prepared from high-molecular film containing oxygen indicator, choline oxidase and high-molecular membrane by one of three methods. Its advantages include no need of cutting nerve fibre, high speed and correctness and no poison and no wound to human body.

Owner:NANJING MEDICAL UNIV

Formula and processing technology of polyester filament yarn super-imitation cotton

InactiveCN108930085AHigh strengthImprove efficiencyWoven fabricsLiquid/gas/vapor textile treatmentPolymer scienceMachining process

The invention discloses a formula and a processing technology of polyester filament super-imitation cotton, and relates to the technical field of textiles. Raw material composition includes: polyesterstaple, breathable cotton threads, spin yarns, dyed yarns, and dyed corn fibers. The processing technology is as follows: step 1: weaving; step 2, superimposing, including after weaving, performing double-layer superimposition using a ripple stitch; step 3, performing a finishing process; step 4, performing finish machining; step 5. The formula improves strength, eliminates need for dyeing in a later stage, improves efficiency, saves time in manufacturing and is simple in process.

Owner:DANYANG DANQI YUYUE TEXTILE

Anti-static and anti-bacterial radiation-resistant patterned fabric

InactiveCN104385710AImprove securityHarm reductionSynthetic resin layered productsClothingsFiberRadiation resistant

The invention relates to an anti-static and anti-bacterial radiation-resistant patterned fabric. The anti-static and anti-bacterial radiation-resistant patterned fabric comprises a bottom layer (4), wherein a base layer (1) is compounded on the surface of the bottom layer and formed by mutually connecting warp yarns and weft yarns, which are both formed by spinning nano silver fibers; an aluminium alloy film (2) is bonded to the upper surface of the base layer through an adhesive; an anti-static layer (3) is arranged on the aluminium alloy film and formed by weaving warp yarns and weft yarns, the warp yarns are cotton yarns, and the weft yarns are conductive fibers; the bottom layer is made of a fabric, the fabric is formed by interweaving warp yarns and weft yarns and adopts the 3 / 1 woven twill tissue structure, the warp yarns are 800D terylene super bright FDY, the weft yarns are 800D terylene super bright FDY, the warp density is 25 / cm, the weft density is 16 / cm, and the warp yarns are Z-twisted by 180 / m. As the fabric changes from the weave structure to patterns, and after fabric manufacture, dyeing is not needed after fabric manufacture, and meanwhile, the fabric is relatively stiff.

Owner:JIANGYIN MINGPIN KNITTING

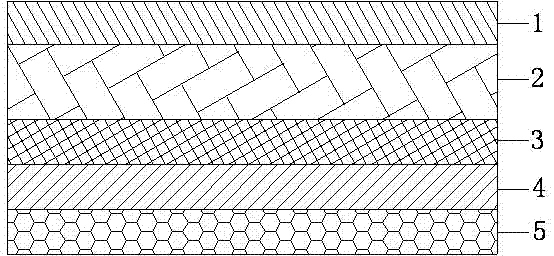

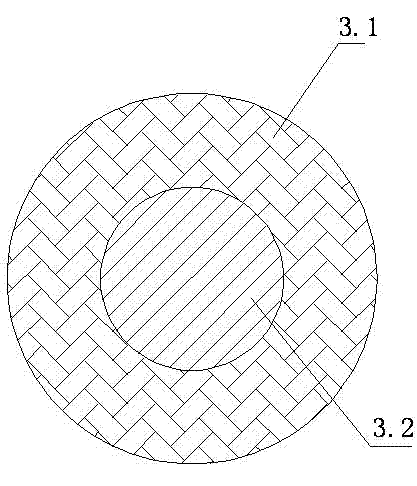

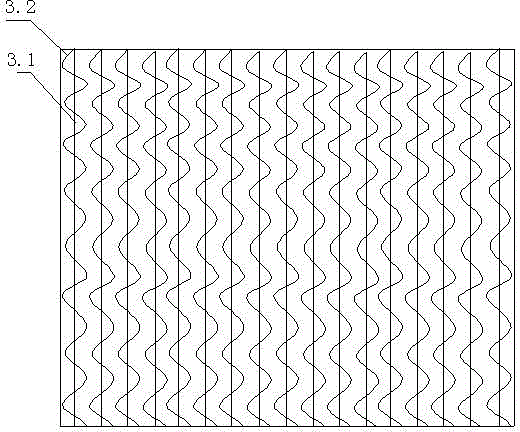

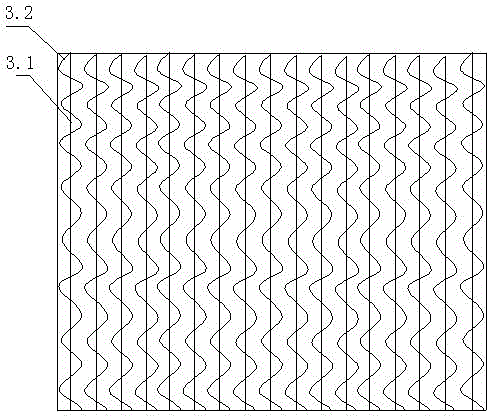

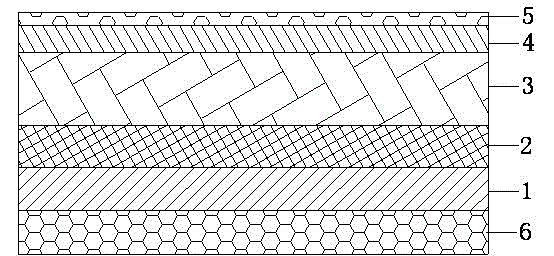

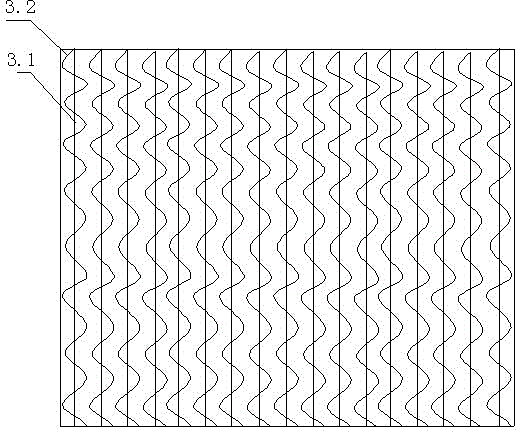

Patterned breathable fabric with ultraviolet-proof function

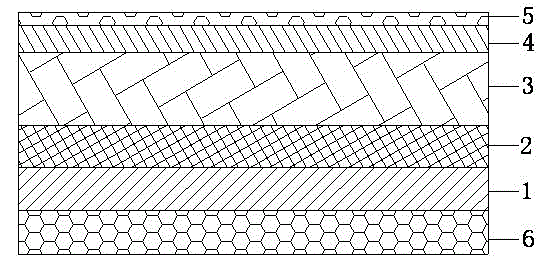

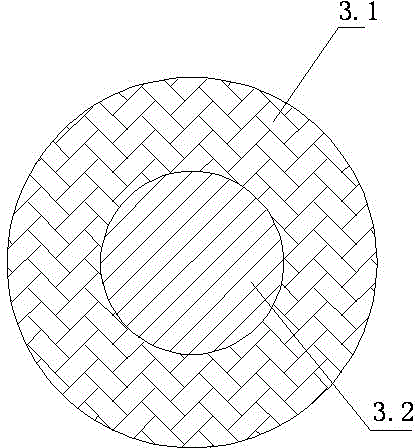

InactiveCN104783382ANo need to dyeGarment special featuresSynthetic resin layered productsYarnUltraviolet

The invention relates to patterned breathable fabric with an ultraviolet-proof function. The patterned breathable fabric with the ultraviolet-proof function comprises a lower cotton cloth layer (1), a wool layer (2) and an upper cotton cloth layer (3), wherein a base layer (6) is compounded under the lower cotton cloth layer (1); the surface of the upper cotton cloth layer is covered with a breathable layer (4) woven through polyester fibers (3.1) and polyamide fibers (3.2) in a blending mode; an ultraviolet-proof layer (5) is arranged on the surface of the breathable layer (4). The base layer is made of fabric interwoven through warp and weft, and is of a 3 / 1 interwoven twill weave structure, wherein the warp is 800D dacron super bright FDY, the weft is 800D dacron super bright FDY, the warp density is 25 filaments / cm, the weft density is 16 filaments / cm, and 180 Z twist yarns per meter are added to the warp. The patterned breathable fabric with the ultraviolet-proof function can resist ultraviolet, and has functions of ventilation and sweat discharging. Patterns are formed through changes of the fabric structure. The fabric does not need to be dyed after being woven. The warp is twisting warp, so that the fabric is stiff.

Owner:JIANGYIN GUORUN TEXTILE RAW MATERIALS SALES

Elastic flexible wire for intelligent spinning and production method thereof

InactiveCN112663190AGuaranteed electrical conductivityShorten the processing flowYarnElastomerPolymer science

The invention relates to the field of flexible wire production, in particular to an elastic flexible wire for intelligent spinning and a production method of the elastic flexible wire. The elastic flexible wire is composed of a colored fiber core-spun elastic wire, the elastic wire is composed of liquid metal and a thermoplastic elastomer in a composite mode; the production method comprises the following steps of a, blowing; b, cotton carding; c, drawing; d, roving; e, spinning; and f, post spinning; and in the step e of spinning, the pre-draft multiple is limited to be 4.5-6 times, the twist coefficient is increased to 380-420, the twist degree is controlled to be 35-47 twists / 10 cm in a rather big mode. The problems that wires in existing intelligent textiles are inelastic, easy to pull apart, poor in comfort and the like are solved, meanwhile, due to the application of colored fibers, the aesthetic feeling of the fabric can be enhanced in intelligent textile design, and the application range is wider.

Owner:WEIQIAO TEXTILE +1

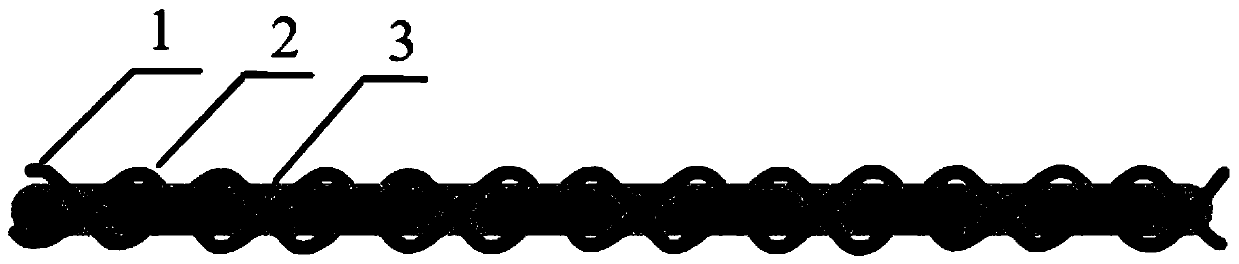

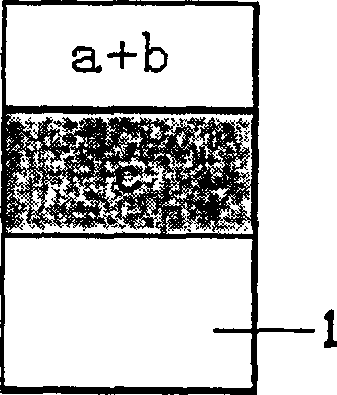

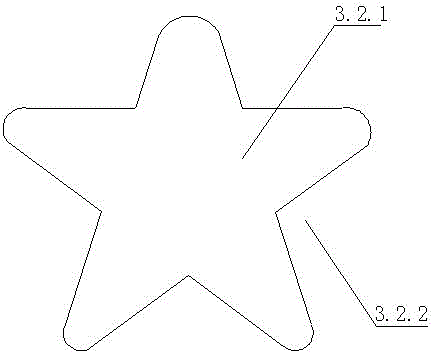

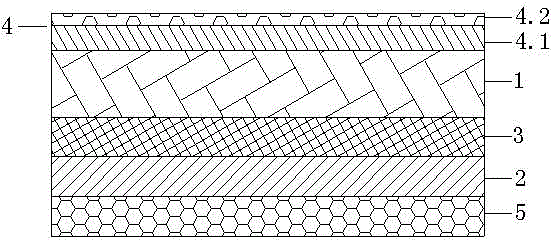

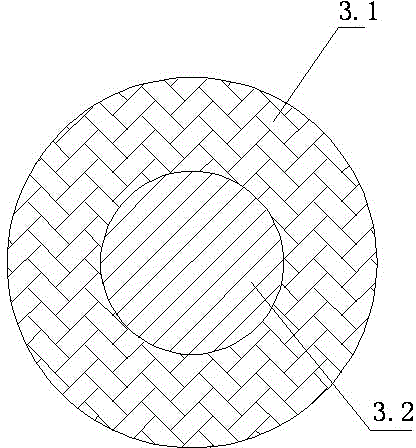

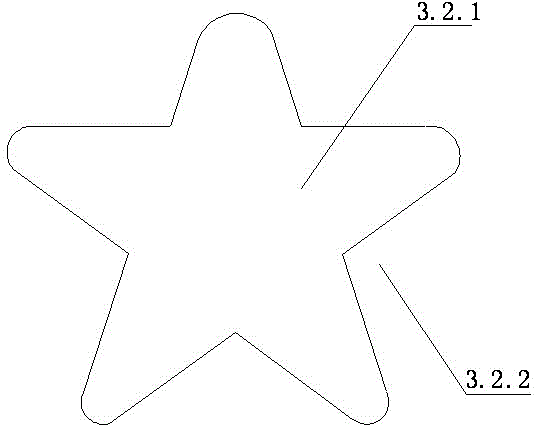

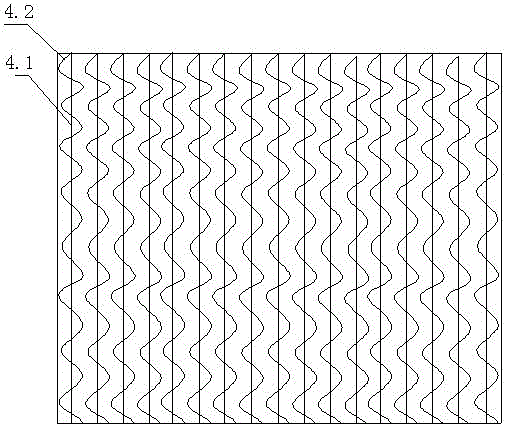

Flame retardant fabric material with patterns

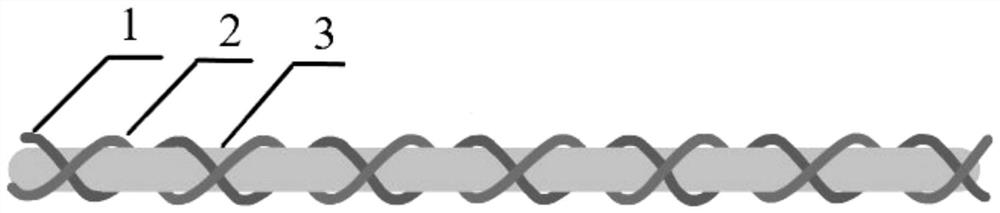

InactiveCN104859212AAnti-static hasSpecial rigiditySynthetic resin layered productsMetal layered productsYarnEngineering

The invention relates to a flame retardant fabric material with patterns. The flame retardant fabric material with the patterns comprises an upper cotton cloth layer (1) and a lower cotton cloth layer (2), a base layer (5) is arranged under the lower cotton cloth layer in a composite mode, an anti-static layer (3) is disposed between the upper cotton cloth layer and the lower cotton cloth layer, the anti-static layer is made of core spun silk fibers, the fibers comprise yarns (3.1) and metal silks (3.2), the metal silks wind the yarns, a flame retardant coating (4) cover surface of the upper cotton cloth layer, and the flame retardant coating comprises a flame retardant polyurethane layer (4.1) at the bottom and an organic silicone oil layer (4.2) at the top. The base layer is made of fabrics which are formed by interweaving of warps and wefts, the structure of the fabrics is a 3 / 1 interweaving twill weave structure, the warps are 800D dacron super bright FDY, the wefts are 800D dacron super bright FDY, the warp density is 25 / cm, the weft density is 16 / cm, and spinning twists of the warps are 180 / m. The flame retardant fabric material with the patterns has the advantages that the costs are low, and the material can be bent and changed. The patterns of the fabrics are formed through change of the fabric woven structure, and dyeing is not required after weaving is finished.

Owner:JIANGYIN BETTER TEXTILE

Breathable velvet shell fabric with textile provided with decorative patterns

InactiveCN105686177ANo need to dyeElegant surface shadeSynthetic resin layered productsWarp knittingYarnEngineering

The invention relates to a breathable velvet shell fabric with a textile provided with decorative patterns. The breathable velvet shell fabric comprises velvet cloth (1), wherein a spongy layer (2) is arranged below the velvet cloth, a breathable layer (3) is arranged below the spongy layer, and is formed by blending and weaving polyester fibers (3.1) and polyamide fibers (3.2), and a base layer (5) is compounded under the breathable layer (3). The base layer is formed by the textile, the textile is formed by interweaving warp yarns and weft yarns, and has a 3 / 1 interweaved twill weave structure, the warp yarns are 800D dacron super bright FDY, the weft yarns are 800D dacron super bright FDY, the warp yarn density is 25 yarns / cm, the weft yarn density is 16 yarns / cm, and the Z twisting amount of the warp yarns is 180 / m. The breathable velvet shell fabric is elegant in colour shade and luxuriant in design, is firm and wear-resisting, and has the breathability and sweat releasing properties. The textile has the floral designs through the tissue structure change, after weaving, dyeing is not needed, and the warp yarns are twisted warp yarns, so that the textile is stiff.

Owner:卞平芳

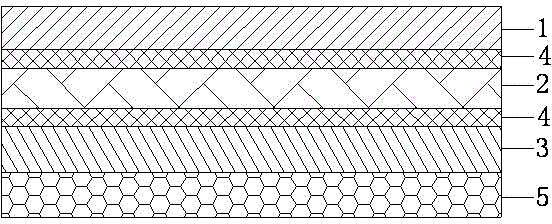

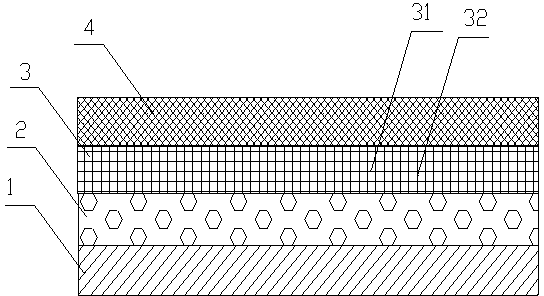

Bamboo charcoal fiber shell fabric with fabric provided with patterns

InactiveCN104790095ANo need to dyeSpecial rigidityLayered productsWoven fabricsRadiation resistantEngineering

The invention relates to a bamboo charcoal fiber shell fabric with fabric provided with patterns. The bamboo charcoal fiber shell fabric with the fabric provided with the patterns comprises bamboo charcoal fiber (1), the upper side of the bamboo charcoal fiber (1) is covered with a layer of non-woven fabric (2), the lower side of the bamboo charcoal fiber (1) is covered with a base layer (5), an anti-static layer (3) is further arranged between the non-woven fabric (2) and the bamboo charcoal fiber (1), the anti-static layer (3) is made of core-spun yarn fibers, the core-spun yarn fibers comprise yarns (3.1) and metal wires (3.2), and the metal wires (3.2) is wound by the yarns (3.1). The base layer is made of fabric, the fabric is formed by interweaving warp yarns and weft yarns, the organization structure is of a 3 / 1 interweaving twill-weave structure, the warp yarns adopt 800D dacron super bright FDY, the weft yarns adopt 800D dacron super bright FDY, the warp density is 25 yarns / cm, the weft density is 16 yarns / cm, and Z twist yarns are added into the warp yarns at the frequency of 180 yarns / m. The bamboo charcoal fiber shell fabric with the fabric provided with the patterns has the air permeability effect, the anti-static effect and the radiation-resistant effect. The bamboo charcoal fiber shell fabric with the fabric provided with the patterns forms the patterns through changes of the interweaving twill-weave structure of the fabric, no dyeing is needed after the interweaving is finished, meanwhile, the warp yarns are the yarns added with the twist yarns, and therefore the fabric is stiff.

Owner:JIANGYIN CHUNLAN TEXTILE

Waterproof insulation fabric with fabric with pattern

InactiveCN104339789AGood warmth retentionGuaranteed warmthSynthetic resin layered productsClothingsPolyesterInsulation layer

The invention relates to a waterproof insulation fabric with a fabric with a pattern. The fabric comprises an outer layer (1), a fabric layer (2) and an inner layer (3) in sequence, wherein the outer layer (1) and the fabric layer (2) are laminated; the outer layer (1) is formed by a windproof and waterproof breathable film; the fabric layer (2) is made from a fabric; the inner layer (3) is an insulation layer; the fabric is formed by interweaving warps and wefts; the weave structure of the fabric is a 3 / 1 interwoven twill weave structure; the warps and the wefts are 800D super bright polyester FDYs (fully drawn yarns); the warp density is 25 warps / cm; the weft density is 16 wefts / cm; 180 Z twists per meter are added to the warps. The fabric has good waterproof effects and cloth insulation effects; the pattern is formed through change of the fabric weave structure and is free from dyeing after being woven; meanwhile, the warps are twisted, so that the fabric is stiffer.

Owner:JIANGYIN KEHAO GARMENT & YARN DYE WEAVING

Anti-static anti-radiation fireproof textile fabric with patterns

The invention relates to an anti-static anti-radiation fireproof textile fabric with patterns. The fabric comprises a base layer (1), wherein the upper surface of the base layer is adhered with a layer of aluminum alloy thin film (2); an anti-static layer (3) is arranged on the aluminum alloy thin film and is formed by weaving warp yarns and weft yarns; the warp yarns are cotton yarns, and the weft yarns are conductive fibers; a fireproof layer (4) is arranged on the outer surface of the anti-static layer; the base layer is made of a textile; the textile is formed by interweaving warp yarns and weft yarns; the organization structure is a 3 / 1 interwoven twill weave structure; the warp yarns are 800D terylene super-bright FDY, and the weft yarns are 800D terylene super-bright FDY; the warp density is 25 pieces per centimeter, the weft density is 16 pieces per centimeter, and the warp yarns are twisted in a Z-shaped manner according to 180 pieces per meter. The anti-static anti-radiation fireproof textile fabric with the patterns is extremely high in anti-static property, radiation resistance and fire resistance. The patterns are formed according to the change of woven textile structures; after weaving is finished, dyeing is not needed; meanwhile, the warp yarns are twisted warp yarns, so that the textile is harder.

Owner:JIANGYIN YINGXIN WEAVING

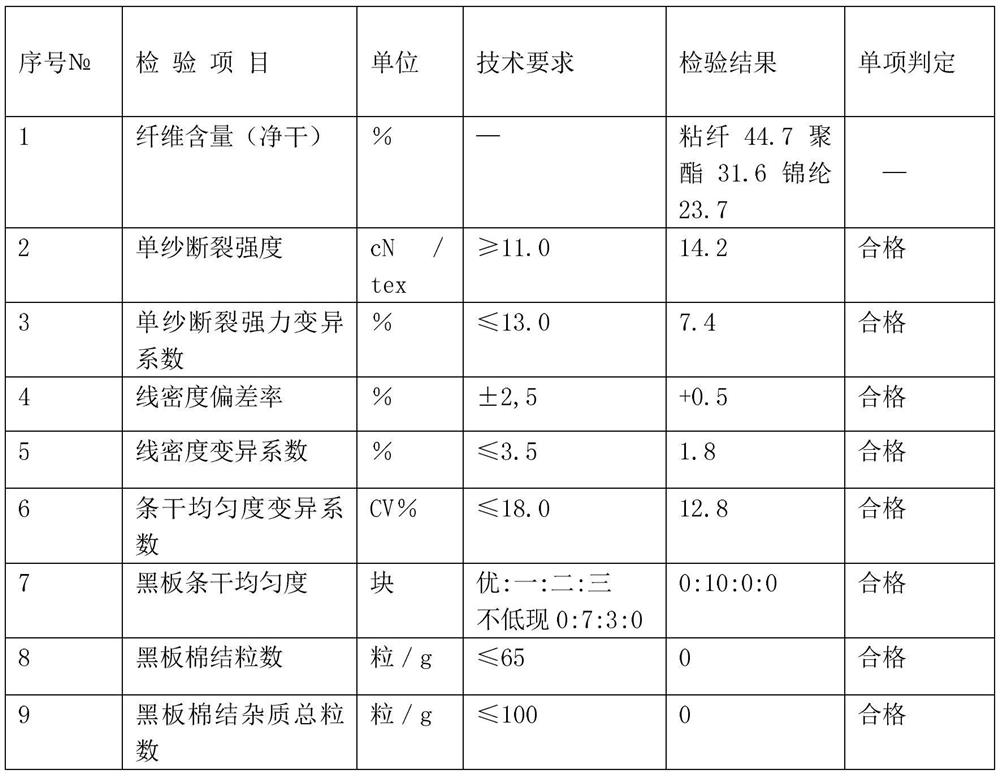

Brocade strip fabric and production method thereof

InactiveCN103388220BIncrease productivityImprove product qualityWoven fabricsYarnIndustrial engineeringWeft yarn

The invention discloses a brocade strip fabric and a production method thereof. The production method comprises the following steps: (1) selecting N20 / 1FDY as the warp yarn and TSC21S / 1 as the weft yarn; (2) next warp yarn (3) Warp the qualified warp yarns, and at this time, destaticize treatment; (4) Do drawing-in after the warp yarns are warped; (5) Warp the qualified warp yarns The weft and heald warp are placed on the air-jet loom for weaving; static electricity treatment is also required during weaving; (6) After the weaving is completed, the formed fabric is inspected; (7) The inspection The qualified fabric is finalized; (8) Finally, the cloth is rolled. The production method of the present invention is simple, the processing cost is low, and the processed brocade strip fabric has high tension and good flexibility; N20 / 1FDY is used as the warp yarn and the colored yarn is used as the weft yarn, so that the product does not need dyeing and sizing during processing, energy saving and environmental protection .

Owner:WUJIANG KINGSHILI WEAVING

Anti-ultraviolet fabric with patterns

InactiveCN104875436ASpecial rigidityRadiation resistantLayered productsWoven fabricsPolyesterUltraviolet

The invention relates to an anti-ultraviolet fabric with patterns. The anti-ultraviolet fabric with patterns comprises a lower cotton cloth layer (1), a wool layer (2) and an upper cotton cloth layer (3), wherein a base layer (6) is composited under the lower cotton cloth layer, an anti-static layer (4) is arranged on the surface of the upper cotton cloth layer (3) in a coating manner and is made of core spun silk fibers, the fiber comprises a yarn (4.1) and a metal wire (4.2), an anti-ultraviolet layer (5) is arranged on the surface of the anti-static layer (4), the base layer is made of a fabric which is formed weaving warp yarns and weft yarns, the texture structure is of a 3 / 1 interwoven twill weave structure, the warp yarn is 800D polyester FDY (fully drawn yarn) with luster, the weft yarn is 800D polyester FDY (fully drawn yarn) with luster, the warp density is 25 / cm, the weft density is 16 / cm, and the warp yarn is subjected to Z-shaped twisting by 180 / m. The anti-ultraviolet fabric with patterns is anti-ultraviolet, and has anti-static and anti-radiation functions; the fabric can form a pattern through change of the woven fabric structure, after weaving is finished, no dyeing is required, the warp yarns are twisted with the warp yarns, and the fabric is stiff.

Owner:JIANGYIN FANRONG YARN DYE FABRIC

A kind of environment-friendly food packaging paper

ActiveCN104032625BGood for healthNo decolorization requiredNon-fibrous pulp additionFlexible coversPullulanSterile water

The invention belongs to the technical field of papermaking, and particularly relates to an environment-friendly food packaging paper, which is made of the following raw materials in parts by weight: 100 parts of dry rice straw, 1-4 parts of pullulan, 1-4 parts of coagulated polysaccharide, glucomannan 0.12-0.18 parts of sugar and 40-50 parts of sterile water are prepared by crushing, refining, steaming, forming into film-shaped paper, and drying. It is environmentally friendly, natural, non-toxic, and hygienic.

Owner:ANQING TIANRUN PAPER PACKAGING

Preparation method of frozen slices of traditional Chinese medicine cinnamomum cassia

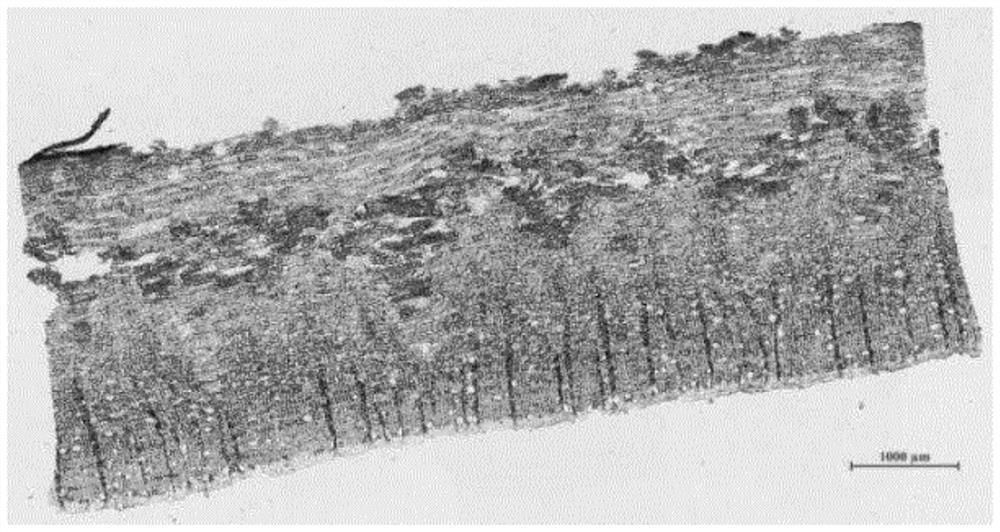

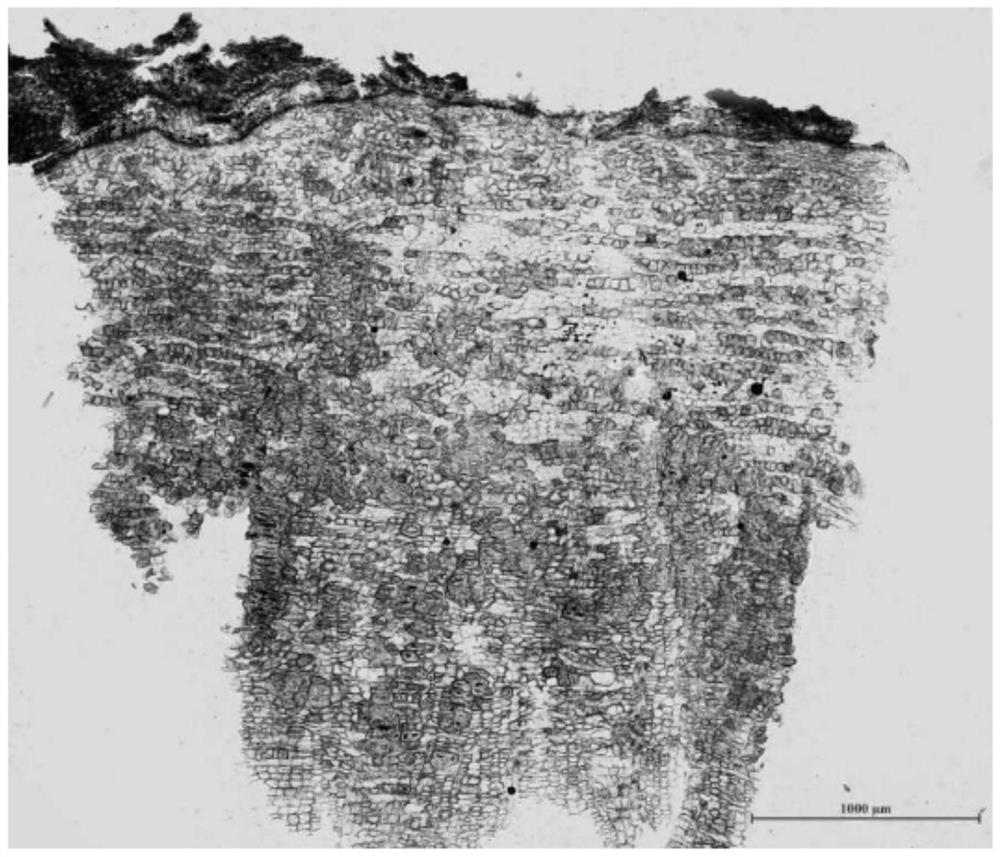

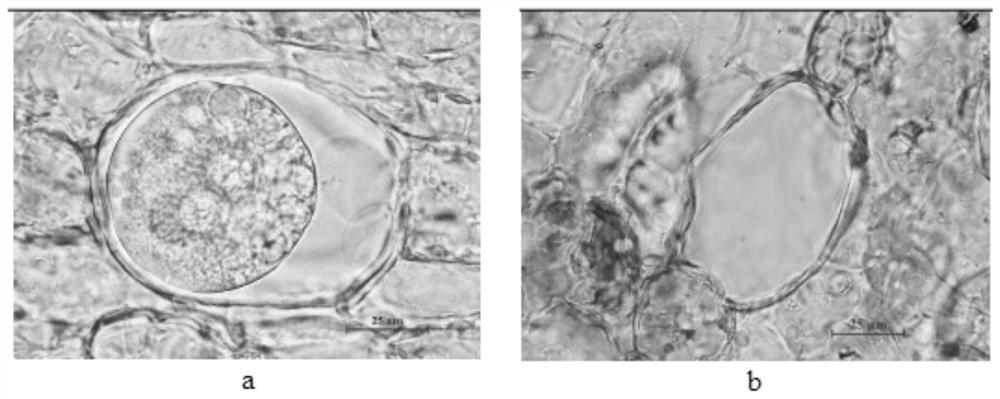

PendingCN112747980AUnbreakableClear structurePreparing sample for investigationMaterial analysis by optical meansStainingMicroscopic observation

The invention provides a preparation method of frozen slices of traditional Chinese medicine cinnamomum cassia. The preparation method comprises the following steps of: material pretreatment: soaking a traditional Chinese medicine cinnamomum cassia sample in a solution containing 70% ethanol and water in a volume ratio of 1-2:1 for 1-2h; then taking out the traditional Chinese medicine cinnamomum cassia sample, and cutting the sample into short sections with a length of 5-8mm and a width of 5-8mm; soaking the short-section samples for 2-3h, taking out the short-section samples, wiping the short-section samples, putting the short-section samples into a test tube filled with a chloral hydrate test solution, and performing heating until the short-section samples are boiled for 5-7 times; then taking out the samples and wiping the samples; sample embedding, freezing and fixing; freezing and slicing; and flattening and slice making. According to the method, the tissue structure is not easy to deform, and the sample is not easy to break during slicing; dyeing is not needed; the traditional Chinese medicine cinnamomum cassia frozen slice with a complete structure can be quickly obtained; the slice tissue structure is clear, and cell inclusions are completely reserved; the manufacturing period is short, and the whole process from pretreatment to microscopic observation photographing can be completed within 4-6h, so that a complete image is obtained; the method is of great significance in identifying the traditional Chinese medicine cinnamomum cassia, expanding the application range of cinnamomum cassia and formulating related standards.

Owner:鉴甄检测技术(上海)有限公司

A method for producing diamond-shaped fancy threads by using waste textiles

Owner:TIANJIN POLYTECHNIC UNIV

A kind of high imitation cashmere core-spun yarn and its preparation process

Owner:RUGAO CITY DINGYAN TEXTILE

Anti-radiation and antibacterial fabric with fabric with pattern

InactiveCN104339755AImprove radiation protection performanceImprove the protective effectClothingsMetal layered productsFiberPolyester

The invention relates to an anti-radiation and antibacterial fabric with a fabric with a pattern. The fabric comprises a base layer (1), wherein the base layer (1) is formed by connecting warps (11) with wefts (12); the warps (11) and the wefts (12) are formed by spinning nano-silver fibers; an aluminium alloy film (2) is bonded on the upper surface of the base layer (1); an antistatic layer (3) is arranged on the aluminium alloy film; the base layer is made from a fabric; the fabric is formed by interweaving warps and wefts; the weave structure of the fabric is a 3 / 1 interwoven twill weave structure; the warps and the wefts are 800D super bright polyester FDYs (fully drawn yarns); the warp density is 25 warps / cm; the weft density is 16 wefts / cm; 180 Z twists per meter are added to the warps. The fabric can shield radiation and can effectively inhibit occurrence of the phenomenon of electrostatic discharge; the fabric is stiffer.

Owner:JIANGYIN HULIAN DYEING & FINISHING

Velvet fabric with patterns on textile fabric

InactiveCN105644021ANo need to dyeUniform tensionSynthetic resin layered productsWoven fabricsPolyesterWear resistant

The invention relates to a velvet fabric with patterns on textile fabric, the velvet fabric includes velvet cloth (1), a sponge layer (2) is arranged under the velvet cloth (1), an anti-static layer (3) is arranged under the sponge layer (2), the anti-static layer (3) is made from core-spun yarn fiber, the core-spun yarn fiber includes a yarn (3.1) and a metal wire (3.2), the metal wire (3.2) winds the yarn (3.1), and a base layer (4) is arranged under the anti-static layer (3). The base layer (4) is made of a textile fabric, the textile fabric is interwoven by warp and weft yarns, the organization structure of the textile fabric is 3 / 1 interwoven twill weave organization structure, the warp yarns are 800 D polyester super bright FDY, the weft yarns are 800 D polyester super bright FDY, warp density is 25 / cm, weft density is 16 / cm, and Z twisting of the warp yarns is 180 / m. The velvet fabric is elegant, rich and gorgeous in color and light, firm, wear-resistant, not easy to deform, elastic, moisture-absorption and air-permeable. The velvet fabric with the patterns on the textile fabric is stiffening.

Owner:JIANGYIN HUADONG PLASTIC PROD

A kind of anti-deformation bamboo fiber bath towel

InactiveCN105002630BImprove microcirculationPrevent cardiovascular and cerebrovascular diseasesWoven fabricsYarnUltimate tensile strength

The invention discloses an anti-deformation bamboo fiber bath towel, the bottom material is made of 50%~55% bamboo fiber, 30%~35% combed cotton and 15%~20% superfine fiber blended, antibacterial and antibacterial, texture Tight, soft, high strength, no deformation; the loops are made of 60% bamboo fiber, 15% superfine fiber, 10% combed cotton, 5% milk fiber, 5% modal fiber and 5% tea fiber. Yarn, natural antibacterial, delicate, smooth, strong hygroscopicity, good air permeability; adding tea fiber into the bath towel, the color and luster is natural, without dyeing, can improve the microcirculation of the body when used, and improve the body function; the bamboo fiber bath towel of the present invention is easy to use Easy to wash and dry, high strength, no shrinkage, no deformation.

Owner:JIESHOU SHUANGXIN TEXTILE

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com