Patents

Literature

77results about How to "Easy to wash and quick dry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bamboo carbon fiber pearl stripe yarn dyed fabric and weaving method thereof

InactiveCN102828322AGuaranteed to be environmentally friendlyNovelty and unique appearanceSwivel-woven fabricsLappet-woven fabricsPolymer chemistryWeft yarn

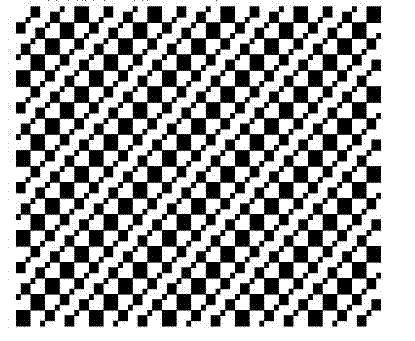

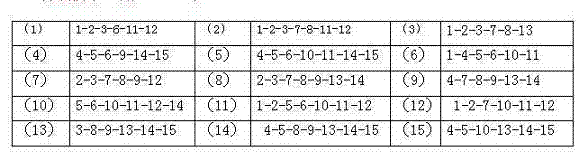

The invention provides a bamboo carbon fiber pearl stripe yarn dyed fabric and a weaving method for the bamboo carbon fiber pearl stripe yarn dyed fabric. Almost no shell fabric which is a cloth product using bamboo carbon fibers is used for sportswear in the market at present, and demands of consumers cannot be met. The bamboo carbon fiber pearl stripe yarn dyed fabric adopts a double-spraying multi-arm hydraulic loom, selects 75D / 48F polyester filament yarns to conduct semi-finished black processing to be 800T / S to serve as warp yarns, adopts 75D / 72F pure bamboo carbon fiber gray filament yarns and 75D / 144F dacron ultra fine denier filament yarn to twist to serve as weft yarns to conduct 2:1 circulation, and interweaves. A 15*15 twill change texture interweaving rule is designed, and three-dimensional lines in a pearl shape outside the fabric are formed through alternative changes of floating lengths of the warp yarns and the weft yarns. Total number of the warp yarns is 12768, 19# reeds are used for conducting 4 denting, an acting reed width is 168cm, an acting weft density is 46 root / cm, and a side is same to a ground portion. 15 heald frames are adopted to sequentially draft, and arrangement of line nails is 15 weft / turn. Products of the bamboo carbon fiber pearl stripe yarn dyed fabric serve as a garment material.

Owner:SUZHOU DISHENG WEAVING FINISHING

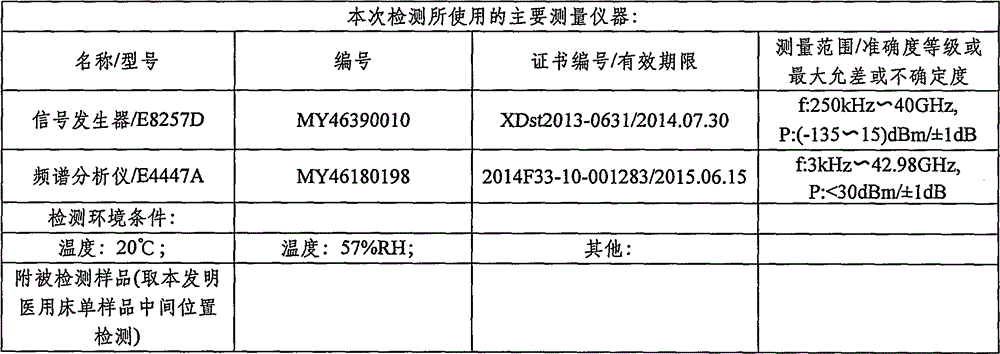

Multi-protective medical fabric

The invention discloses a multi-protective medical fabric. The medical fabric comprises a textile as a base layer, and a functional addition layer, wherein the textile is formed by interweaving 75D / 72F low-elasticity interlaced yarns, 6F conductive silks and radiation-protection metal wires as warp yarns and weft yarns, the warp tightness, the weft tightness, total warp yarn number and total weft yarn number of the textile are respectively 66.5, 41.0, 3322 teeth and 9968 teeth, the gram weight of each square meter of the textile is 118g / m<2>, the weft density is 41 / cm, the low-elasticity interlaced yarns comprise 96% polyester chemical filaments and 4% of composite carbon fiber components, and the textile is dyed with disperse dyes, and then is subjected to one-side or two-side coating or dipping by adopting Dubon Teflon. The invention provides a brandnew multi-protective medical fabric formula, which can be repeatedly used for many times, and the multi-protective medical fabric has multiple functions of being water-proof, blood-proof, bacteria-insulating, antistatic, radiation-proof, easy to dry, wrinkle-preventive, simple to wash and disinfect, and convenient and the like on the basis of basic performances of being breathable, comfortable and free from fiber falling, and other performances of the medical fabric.

Owner:大连裕辰科技发展有限公司

Moisture-absorbing quick-drying fabric and preparation method thereof

InactiveCN112410986AReduce touch pointsImprove performanceWeft knittingGrip property fibresPolymer scienceCombing

The invention provides moisture-absorbing quick-drying fabric and a preparation method thereof. The fabric comprises a hydrophilic inner layer and a quick-drying outer layer, wherein the hydrophilic inner layer is composed of bottom yarn, the quick-drying outer layer is composed of surface yarn, the bottom yarn is combed cotton yarn or twisted yarn of the combed cotton yarn and polyester filamentyarn, the surface yarn is special-shaped superfine denier polyester filament yarn, and the D value and the F value in specification of the bottom yarn are both larger than those in specification of the surface yarn. The preparation method of the fabric comprises the steps that the bottom yarn and the surface yarn are woven into gray fabric, and then after-treatment is carried out on the fabric toobtain the moisture-absorbing and quick-drying fabric; wherein the fabric after-treatment comprises alkali treatment and softening treatment; alkali treatment conditions are as follows: a 1wt.%-2wt.%sodium hydroxide solution is adopted, the bath ratio is 1:50, and the treatment is carried out at 90-100 DEG C for 30-40 minutes; softening treatment conditions are as follows: a silicon-free softening finishing agent is adopted, dipping is performed for 20-30 min at the temperature of 20-30 DEG C, then drying is performed for 3-4 min at the temperature of 100 DEG C, and finally baking is performed for 1-2 min at the temperature of 170-180 DEG C. The fabric has excellent moisture-absorbing and quick-drying properties and good durability.

Owner:义乌市鼎莎针织有限公司

Novel thin elastic textile fabric

The invention discloses novel thin elastic textile fabric which comprises hidden yarns, connection yarns and face yarns, wherein the hidden yarns and the face yarns are interwoven by the connection yarns; the hidden yarns are formed by blending viscose and protein fibers, and account for 30-35% of the weight of the fabric; the connection yarns are formed by blending synthetic fibers and hollow foreign fibers, and account for 40-45% of the weight of the fabric; and the face yarns are formed by blending polyethylene terephthalate fibers and polytrimethylene terephthalate fibers, and account for 25-30% of the weight of the fabric. With the adoption of the mode, the fabric has the characteristics of thinness, smoothness, super-elasticity, moisture absorption, wicking, easiness in washing, quickness in drying, and excellent air permeability, and can keep a body dry and comfort.

Owner:WUXI HOUSETEX INDS

Antistatic antibacterial fabric

InactiveCN103637407AImprove antistatic performanceImprove antibacterial propertiesUndergarmentsProtective garmentPolyesterPolymer science

The invention discloses antistatic antibacterial fabric. The antistatic antibacterial fabric is formed by weaving cuprous sulfide conductive polyacrylonitrile fibers, far-infrared polyester fibers, ramie fibers and hemp fibers in a blending manner, wherein the percentages by weight of the fiber components of the antistatic antibacterial fabric are respectively as follows: 12%-16% of the cuprous sulfide conductive polyacrylonitrile fibers, 15%-19% of the far-infrared polyester fibers, 29-33% of the ramie fibers and 32%-44% of the hemp fibers. The fabric is formed by weaving the cuprous sulfide conductive polyacrylonitrile fibers, the far-infrared polyester fibers, the ramie fibers and the hemp fibers in the blending manner, and the woven fabric has excellent antistatic property and antibacterial property, and guarantees human body safety and fabric cleanness; meanwhile, the fabric has the characteristics of being hygroscopic and ventilated, easy to clean and fast to dry, UV-resistant, cool and comfortable.

Owner:SUZHOU IND PARK YOUSHUN CLOTHING FACTORY

Easy-washing and quick-drying pillowcase fabric

InactiveCN104278590ABrighten the colorFull of three-dimensional senseBed linenWoven fabricsPolyesterEngineering

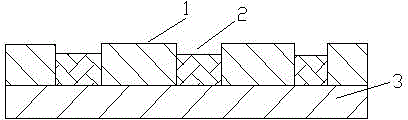

The invention relates to an easy-washing and quick-drying pillowcase fabric, which includes a fabric body (1). The upper layer of the fabric body (1) is partially covered by a tribute silk layer (2), which is a thickened layer with molded flower shape. The edge of the tribute silk layer (2) is fixed on the fabric body (1), and is provided with an embroidery lace (3), which covers the fixation line of the tribute silk layer (2) edge and the fabric body (1). Gold silk jacquard (4) is disposed on the tribute silk layer (2). The fabric body (1) is made of a textile, which is formed by interweaving of warp yarns and weft yarns. The warp yarns and the weft yarns are all core spun yarns of cotton baling polyester filaments, and the transverse section of the polyester filaments is pentagram shaped. The fabric provided by the invention is accord with the demands of modern high range and luxury life, and is easy to wash and quick to dry.

Owner:JIANGYIN SHENYING KNITWEAR & TEXTILE

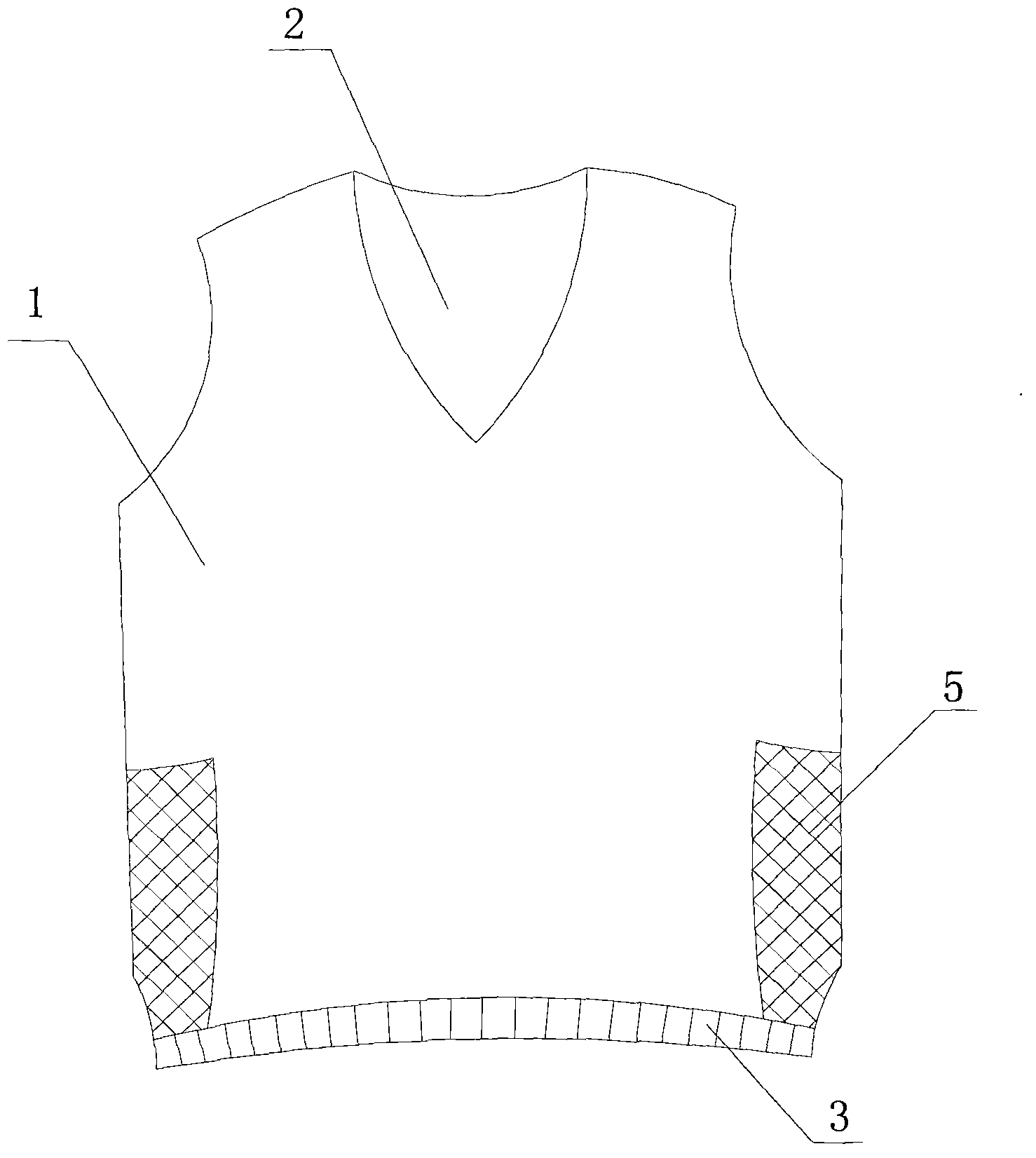

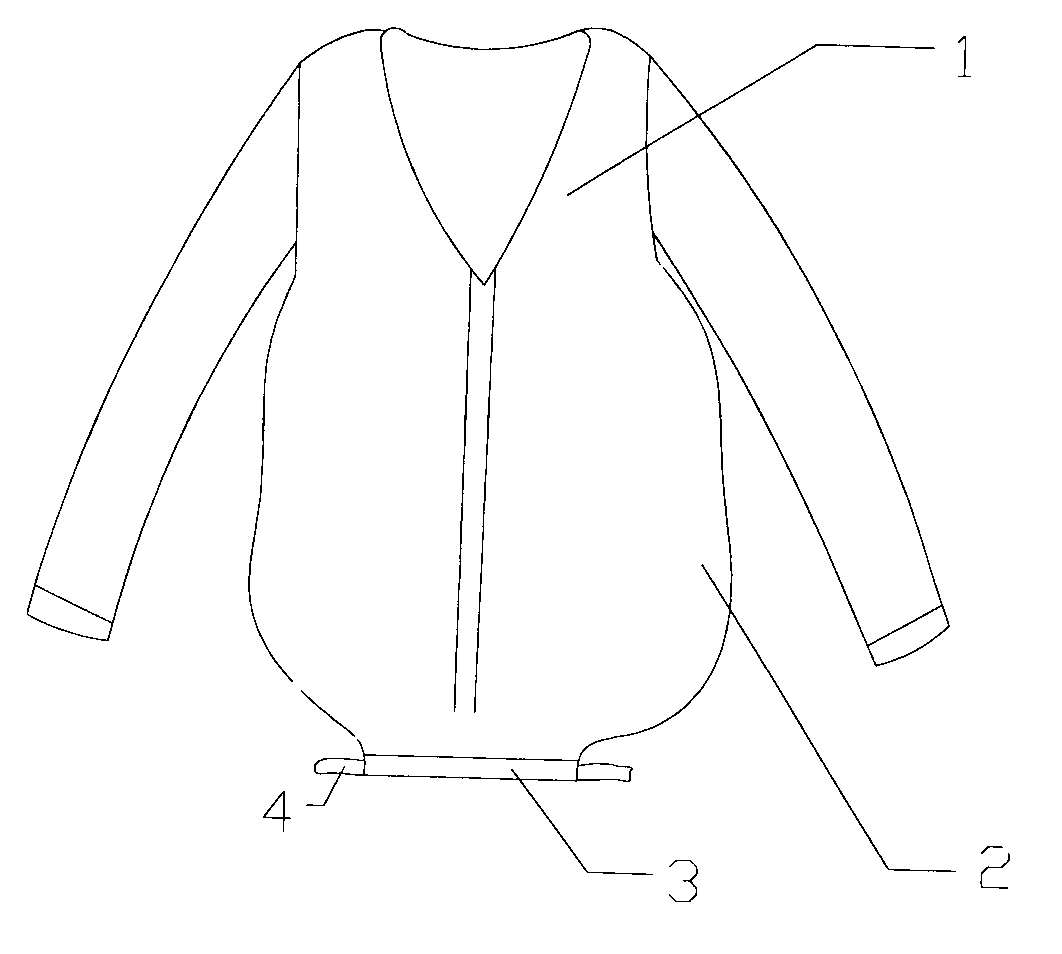

Easy-washing and quick-drying garment provided with waist-tightening elastic material

InactiveCN103799259AGuaranteed warmthReduce distanceWoven fabricsProtective garmentEngineeringFilament yarn

The invention relates to an easy-washing and quick-drying garment provided with a waist-tightening elastic material. The garment comprises a garment body (1) which is made of pure cotton and provided with a V-shaped collar (2), wherein a lower hem (3) is arranged at the bottom of the garment body (1) and adopts an elastic band knitted at the bottom of the garment body (1); a lining layer (4) is woven on the back of the garment body (1) and made of cashmere wool; two pieces of elastic fabric (5) are woven at the waist part of the garment body (1) and made of high-elasticity spandex filaments; the garment body (1) is made of fabric interwoven by warp yarn and weft yarn, the warp yarn and the weft yarn adopt covering yarn of cotton covered polyester filament yarn, and the cross section of the polyester filament yarn is in a pentagram shape. The garment can keep warm effectively, has a windproof effect, and is easy to wash and quick to dry.

Owner:徐文杰

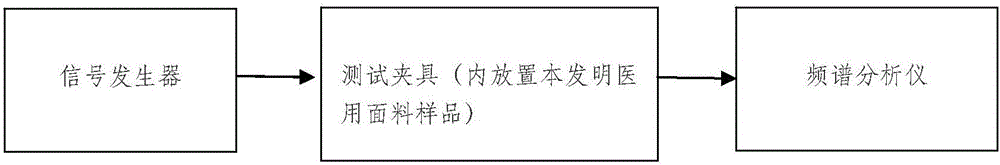

Fabric with characteristics of moisture absorption and sweat discharge, and foamability test process thereof

InactiveCN107764983APlay the function of moisture absorption and perspirationEasy to wash and quick dryCellulosic plastic layered productsTextile testingMoisture absorptionEngineering

The invention relates to a fabric with characteristics of moisture absorption and sweat discharge, and a foamability test process thereof. The fabric is characterized in that the fabric layers of thefabric are connected through spinning threads, each fabric layer is formed by interweaving and blending radial threads and weft threads, the radial threads are viscose fibers, a plurality of micro-pores are arranged on the fabric layer, and the surface of the fabric layer is covered with a layer of a moisture absorption and sweat discharge film. According to the present invention, the sweat is rapidly discharged through the micro-pores arranged on the fabric layer, and the moisture absorption is performed through the moisture absorption and sweat discharge film, such that the functions of moisture absorption and sweat discharge are achieved; and the fabric further has effects of easy washing and rapid drying.

Owner:JIANGYIN QUANSHUN TEXTILE CO LTD

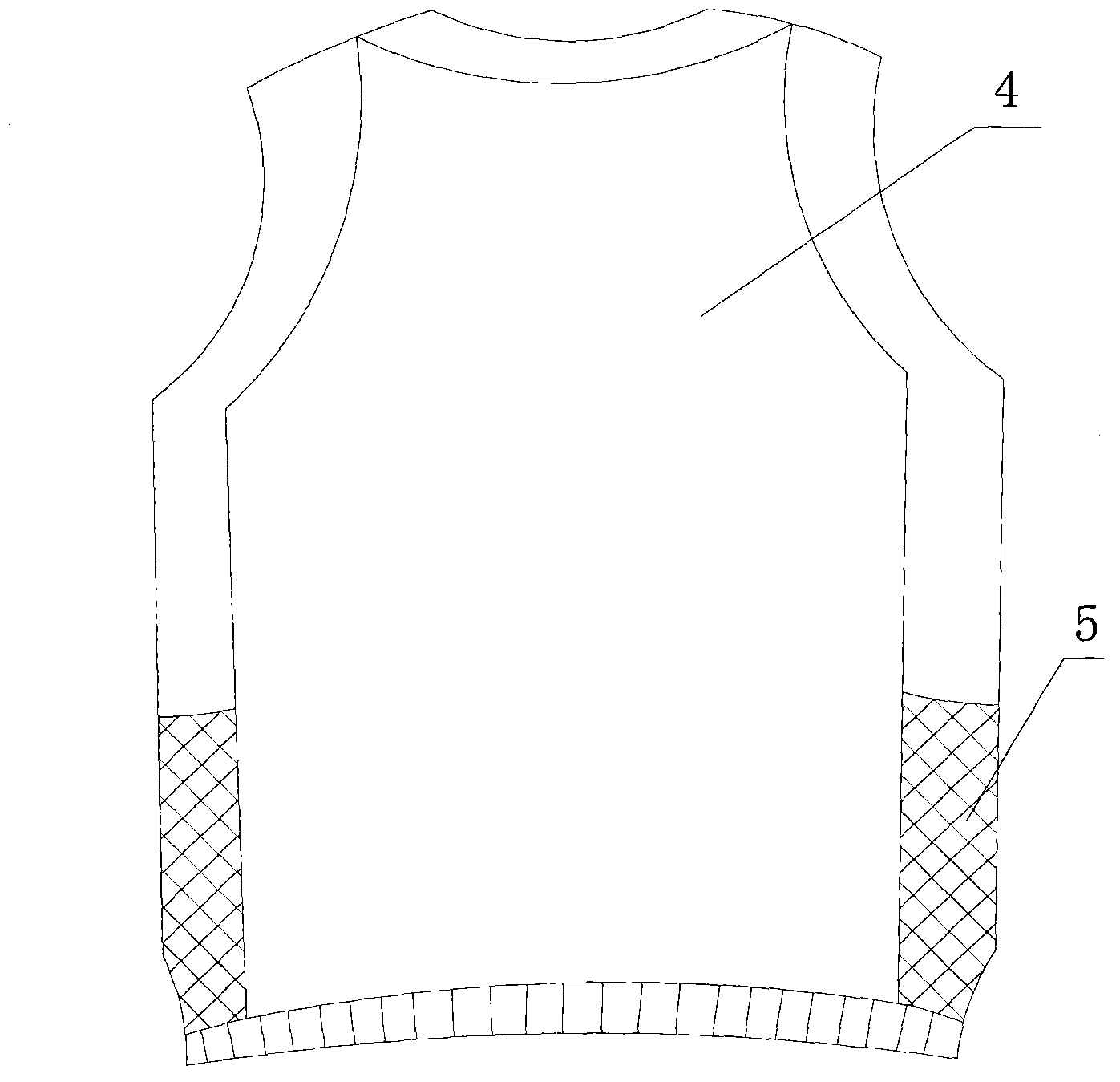

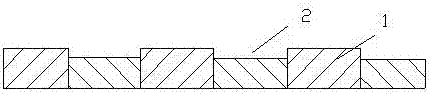

Stereoscopic printed easy washing and quick drying fabric

InactiveCN103879075ASoft and comfortableEnhance hazeLayered productsFilament/thread formingPolyesterEngineering

The invention relates to a fabric, particularly a stereoscopic printed easy washing and quick drying fabric, which comprises a base cloth (1). The upper surface of the base cloth (1) is a printed layer (2), and a fluff layer (3) is arranged on the printed layer (2). The printed layer (2) includes printed flowers (21), and the fluff layer (3) includes fluff flowers (31) and fluff flowers blocks (32), and the fluff flowers (31) cover parts of the printed flowers (21). The base cloth (1) is made from a fabric, which is formed by interweaving of warp yarns and weft yarns, the warp yarns and weft yarns are both core yarns of cotton covered polyester filaments, and the cross sections of the polyester filaments are in a pentagram shape. According to the invention, the obscure sense and stereoscopic sense of the stereoscopic printed easy washing and quick drying fabric are enhanced. The fabric provided by the invention is easy to wash and quick drying.

Owner:沈卫军

Moisture absorbing and sweat discharging fabric and combing method thereof

InactiveCN107791597APlay the function of moisture absorption and perspirationEasy to wash and quick dryCellulosic plastic layered productsClothingsCombingEngineering

The invention relates to a moisture absorbing and sweat discharging fabric and a combing method thereof. The moisture absorbing and sweat discharging fabric is characterized in that the fabric layersof the fabric are connected through spinning threads, each fabric layer is formed by interweaving and blending radial threads and weft threads, the radial threads are viscose fibers, a plurality of micro-pores are arranged on the fabric layer, and the surface of the fabric layer is covered with a layer of a moisture absorbing and sweat discharging film. According to the present invention, the sweat is rapidly discharged through the micro-pores arranged on the fabric layer, and the moisture absorption is performed through the moisture absorbing and sweat discharging film, such that the functions of moisture absorption and sweat discharge are achieved; and the moisture absorbing and sweat discharging fabric further has effects of easy washing and rapid drying.

Owner:JIANGYIN QUANSHUN TEXTILE CO LTD

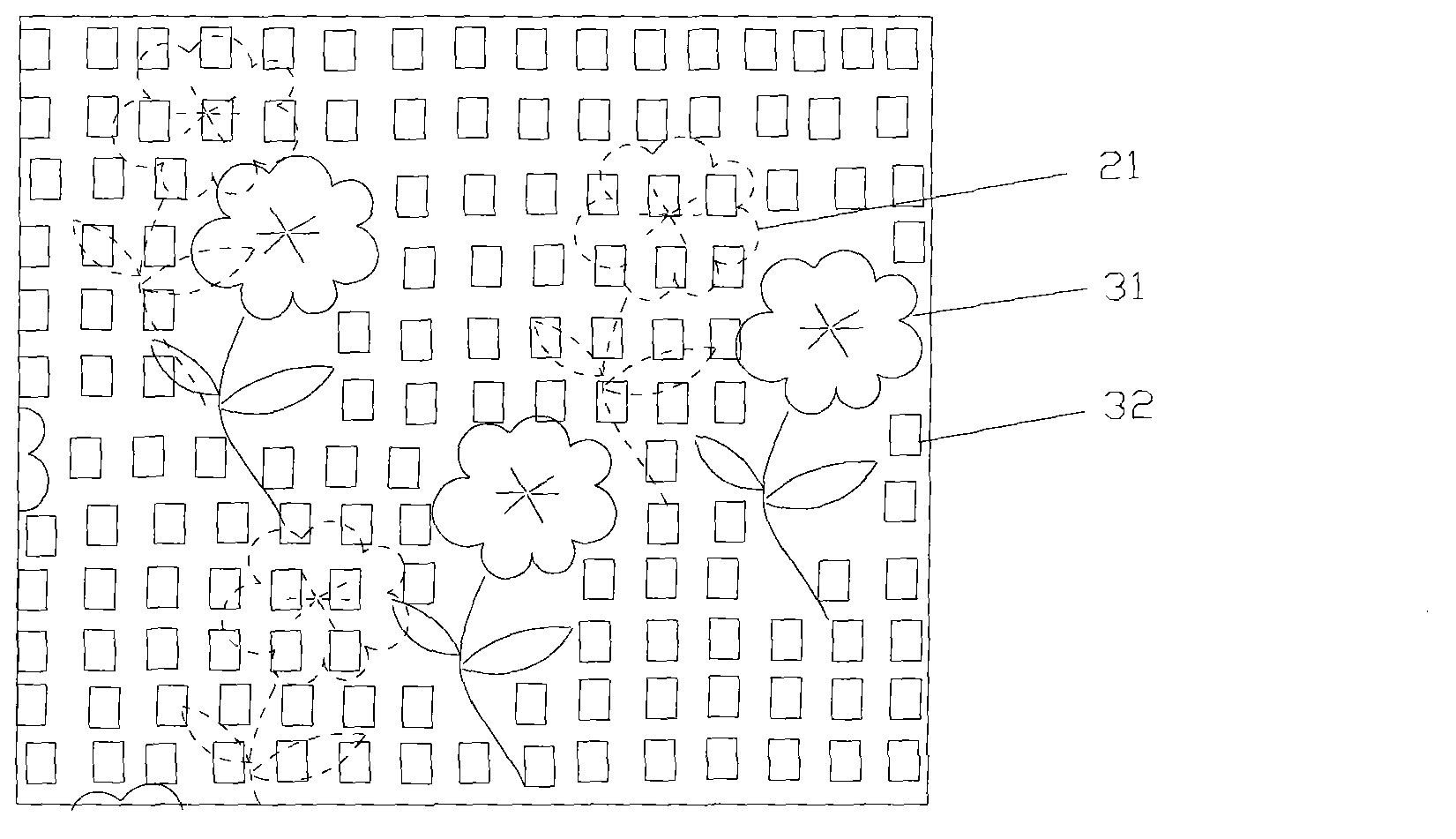

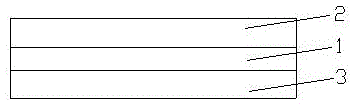

Easy-to-wash quick-to-dry heat insulating fabric with antifouling function

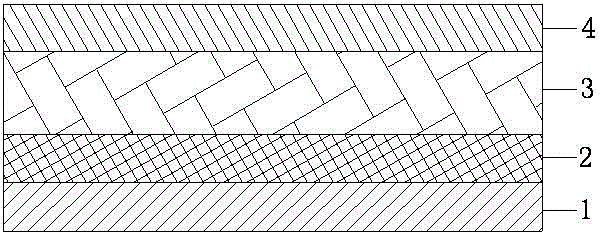

InactiveCN104872877AAntifoulingWith anti-fouling functionSynthetic resin layered productsProtective garmentEngineeringDry heat

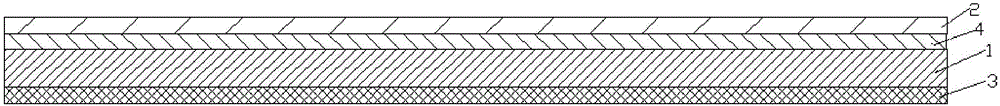

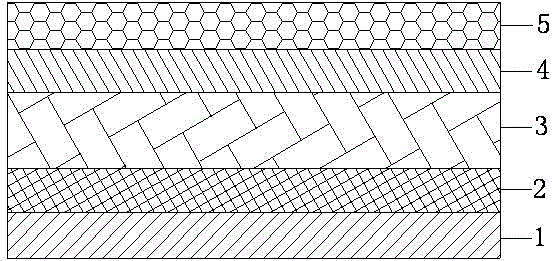

The invention relates to easy-to-wash quick-to-dry heat insulating fabric with an antifouling function. The easy-to-wash quick-to-dry heat insulating fabric comprises a fabric body (1), a heat insulating layer (2) covers the fabric body, a waterproof layer (3) covers the heat insulating layer, and a polyurethane coating layer (4) covers the surface of the waterproof layer and is made by fluorine monomer waterborne polyurethane. The fabric body is made by textile which is formed by interweaving warp yarn and weft yarn, each of the warp yarn and the weft yarn is core spun yarn formed by covering polyester filament yarn by cotton, and cross section of is polyester filament yarn is pentacle-shaped. The easy-to-wash quick-to-dry heat insulating fabric is less prone to fouling, waterproof and breathable. Grooves are formed in the polyester filament yarn, so that gas and water can be quickly discharged from the grooves, functions of absorbing moisture and discharging sweat are realized, and the fabric is easy to wash and quick to dry.

Owner:JIANGYIN HANXIN TEXTILE

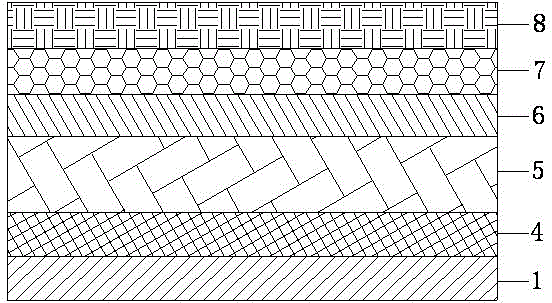

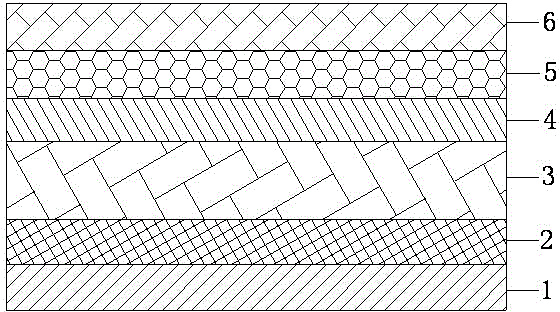

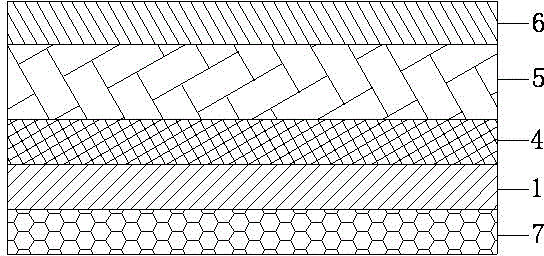

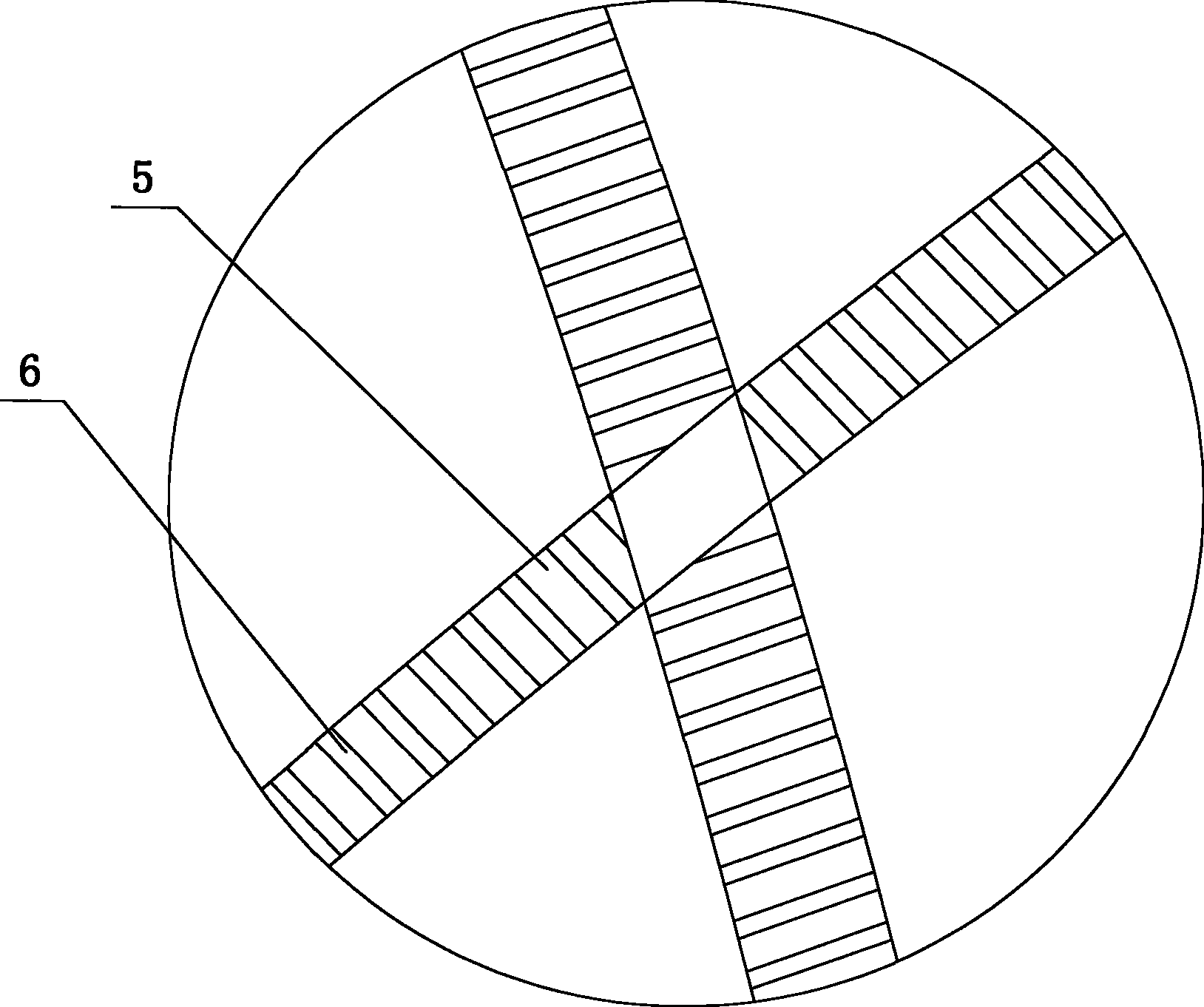

Medical easy-to-wash quick-drying fabric with shape memory function

InactiveCN104886843AHygroscopicWith moisture-wicking fibers, the polyurethane membrane is water-resistantSynthetic resin layered productsFilament/thread formingEngineeringFlax fiber

The invention relates to a medical easy-to-wash quick-drying fabric with the shape memory function. The medical easy-to-wash quick-drying fabric comprises a fabric body, wherein the fabric body adopts a latticed structure formed by interlacing of warps and wefts; the warps are made of memory fiber terylene; the front side of the fabric body is coated with a polyurethane film (4); the front side of the polyurethane film is coated with a flax fiber layer (5); the surface of the flax fiber layer is coated with a bamboo charcoal fiber layer (6); the surface of the bamboo charcoal fiber layer is coated with a layer of moisture adsorption and sweat discharge fibers (7); and the back side of the fabric body is coated with a base layer (8) made of a fabric formed by mutual interlacing of warp yarns and weft yarns, the warp yarns and the weft yarns are cotton-baled polyester filament yarn core-spun yarns, and the cross sections of the polyester filament yarns are star-shaped. The medical easy-to-wash quick-drying fabric has extremely good anti-wrinkling function and resiliency and also has an easy-to-wash quick-drying effect.

Owner:JIANGYIN NEW QUANSHENG TEXTILE PRINTING & DYEING

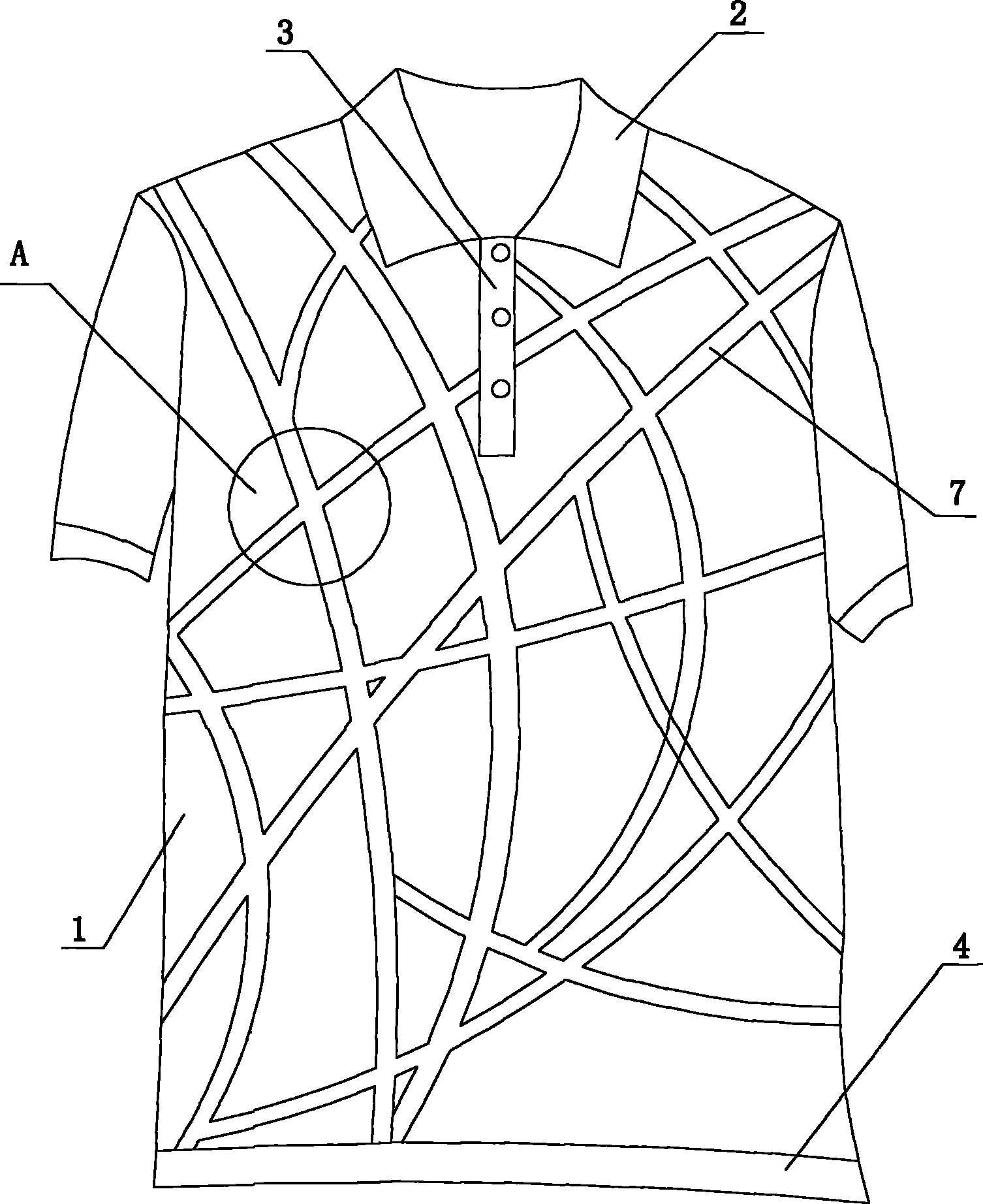

Easy-washing quick-drying garment with moisture absorbing and sweat releasing functions

InactiveCN103799365AOrnamentalStrong three-dimensional senseGarmentsWoven fabricsMoistureFilament yarn

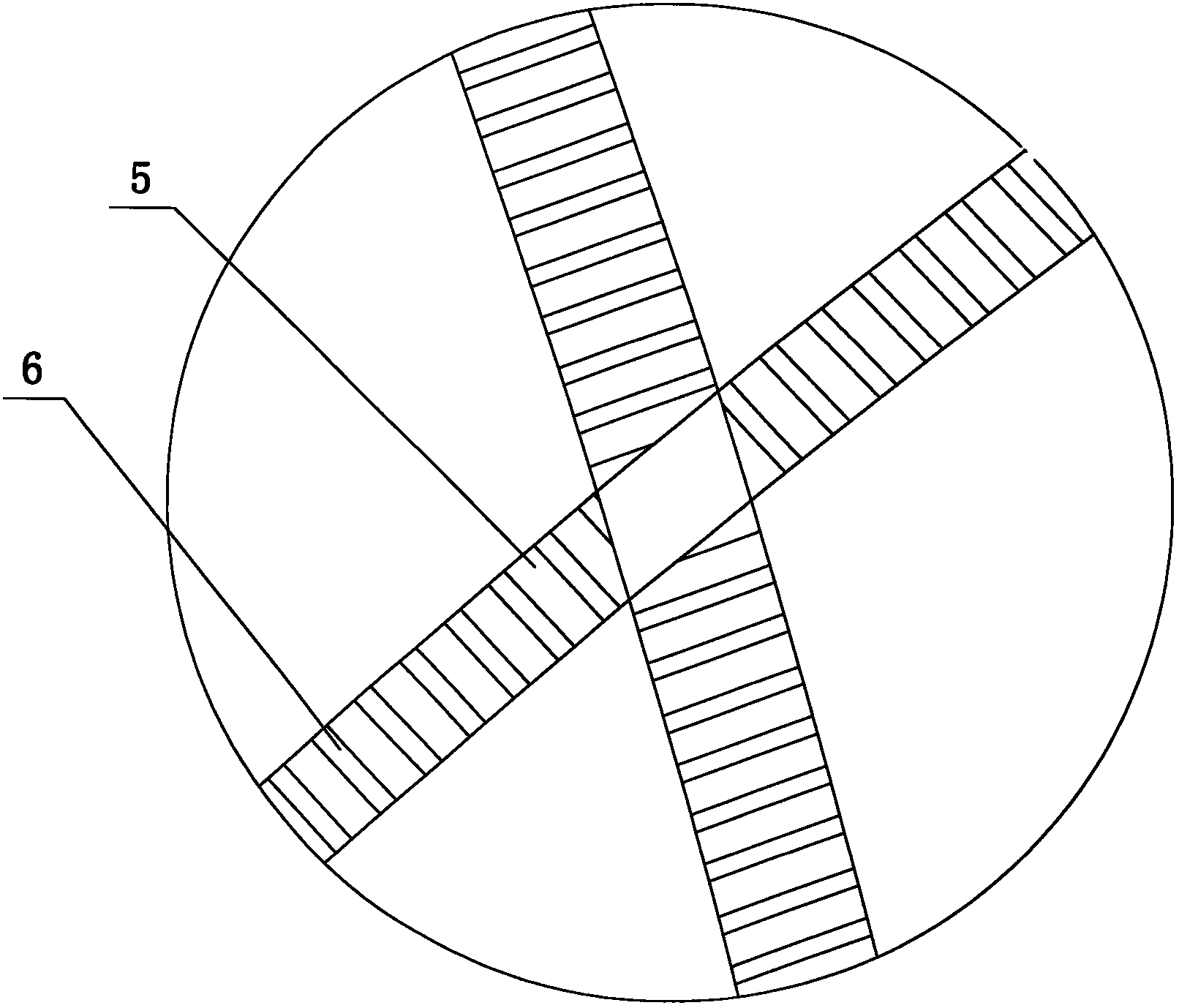

The invention relates to an easy-washing quick-drying garment with moisture absorbing and sweat releasing functions. The easy-washing quick-drying garment is characterized by comprising a garment body (1), wherein a plurality of grooves (5) are formed in the front and back of the garment body (1); cords (6) are densely distributed in each groove (5), so that a plurality of concave-convex lines (7) are formed on the garment body (1) and arranged in a staggered manner; and the garment body (1) is made of fabric formed by interweaving warp and weft, both the warp and the weft adopt core-spun yarn of cotton / polyester filament yarn, and the cross section of the polyester filament yarn adopts pentagram. The easy-washing quick-drying garment with the moisture absorbing and sweat releasing functions has higher layering and better texture and can volatilize sweat timely.

Owner:周忠平

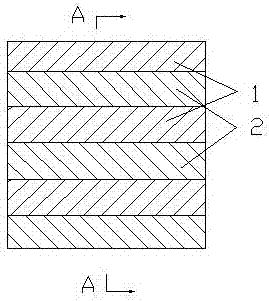

Striped napped easily-washed quick-drying fabric with breathable layer

InactiveCN104921372AAdd dimensionIncrease warmthSynthetic resin layered productsProtective garmentConvex structureBiomedical engineering

The invention relates to a striped napped easily-washed quick-drying fabric with a breathable layer, comprising a fabric body (1). The fabric body (1) is provided with a plurality of stripes (2) in crisscross distribution; the stripes (2) are embedded in the plane of the fabric body (1) and are integrally connected with the fabric body (1), forming a concave-convex structure; the back of the stripes (2) and the fabric body (1) is provided with a napper layer (3); the fabric body (1) is made of cloth made by interweaving warps and wefts; both the warps and the wefts are core-spun yarns of cotton-covered polyester filament yarns; the cross section of the cotton-covered polyester filament yarns is pentagram shaped. The concave-convex structure allows the fabric to be more stereoscopic; the napped layer on the back allows the fabric to be warmer; the fabric is easily washable and quickly dries.

Owner:JIANGYIN HULIAN DYEING & FINISHING

Easy washing and quick drying pillowcase fabric with antifouling function

InactiveCN105774151AAntifoulingWith anti-fouling functionPillowsSynthetic resin layered productsPolyesterEngineering

The present invention relates to an easy washing and quick drying pillowcase fabric with an antifouling function. The pillowcase fabric includes a fabric main body (1). A breathable layer (2) coats the upper surface of the fabric main body, a waterproof layer (3) coats the upper surface of the breathable layer, an antibacterial layer (4) coats the waterproof layer, a polyurethane coating layer (5) coats the upper surface of the antibacterial layer and is fluoro-monomer waterborne polyurethane, and a flocking layer (6) coats the upper surface of the polyurethane coating layer. The fabric main body is made of a textile, the textile is woven by interlacing of warp and weft yarns, and the warp and weft yarns are both cotton wrapped polyester filament covering yarns, and cross-sections of the polyester filaments present pentagrams. The pillowcase fabric has waterproof and breathable effects, and is good in hand feeling. Grooves are formed in the filaments, gas and water can be rapidly discharged from the grooves, so that the pillowcase fabric has moisture absorbing and sweat releasing functions, and easy washing and quick drying effects.

Owner:WUXI HUALIAN PLASTIC PROD CO LTD

Polyester fiber half cardigan fabric

InactiveCN109234891AEasy to wash and quick dryMoisture wickingMercerising of indefinite length fabricsSingeingPolyesterYarn

The invention provides a polyester fiber half cardigan fabric which comprises a bottom layer. The bottom layer is composed of polyester fibers and spandex yarn, the mass ratio of the polyester fibersto the whole fabric is 92%, and the mass ratio of the spandex yarn to the whole fabric is 8%. Compared with the prior art, the fabric has the following advantages that the polyester fibers and the spandex yarn are arranged, so that the fabric is easy to wash, quick to dry, capable of absorbing moisture absorption and removing sweat, antibacterial and resistant to odor.

Owner:相里海霞

Waterproof, washable and quick-drying fabric with high safety

InactiveCN104875456APrevent penetrationImprove smoothnessSynthetic resin layered productsPolyurethane coatingMoisture

The invention relates to a waterproof, washable and quick-drying fabric with high safety. The fabric comprises a fabric body (1), wherein the surface of the fabric body is covered by a polyurethane film (2); the surface of the polyurethane film is covered by moisture adsorption and sweat removing fibers (3); the surfaces of the moisture adsorption and sweat removing fibers are provided with air holes; the surfaces of the moisture adsorption and sweat removing fibers (3) are covered by a waterproof layer (4); the surface of the waterproof layer (4) is covered by a polyurethane coating layer (5); the fabric body is made from a fabric; the fabric is formed by interweaving warps and wefts; both the warps and the wefts adopt core-spun yarns of cotton-covered polyester filament yarns; the cross sections of the polyester filament yarns are shaped like a pentagram. The fabric has the beneficial effects that the smoothness of the fabric can be improved, so that the fabric is not easy to stain; the fabric has waterproof and breathable effects; the fabric is washable and quick-drying.

Owner:JIANGYIN YUEDA DYEING & PRINTING

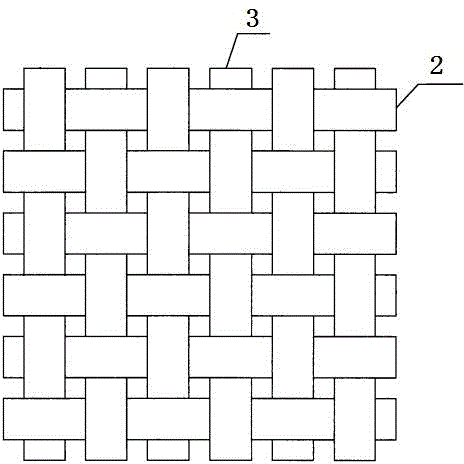

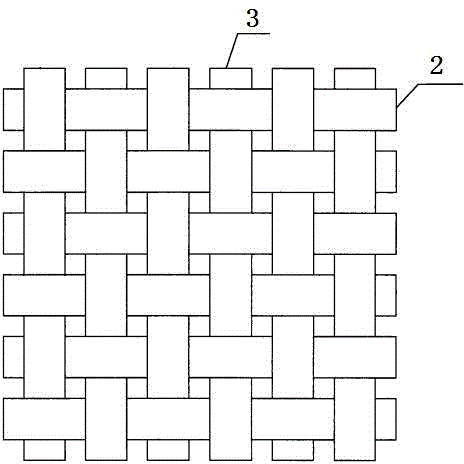

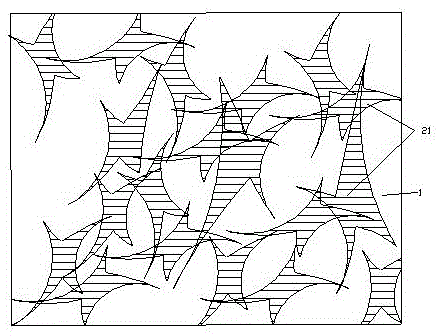

Composite mesh layer easy washing quick-drying fabric with composite silk fabric layer

InactiveCN105011439ARich layersMoisture wickingLayered productsTextile decorationSurface layerEngineering

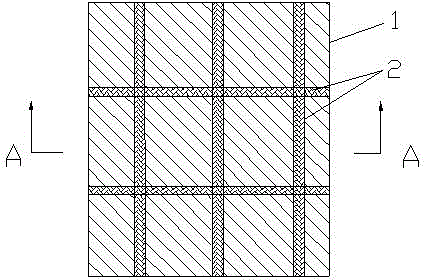

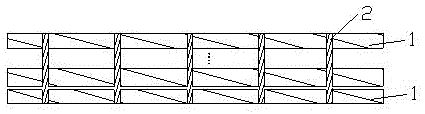

The present invention relates to a composite mesh layer easy washing quick-drying fabric with a composite silk fabric layer. The composite mesh layer easy washing quick-drying fabric with the composite silk fabric layer comprises a plurality of mesh surface layers (1), the mesh surface layers (1) are mesh surface fabrics and are equipped with a plurality of non mesh surface fabrics (11), and the adjacent two mesh surface layers (1) are in stagger arrangement orderly and are connected up and down by bright silk threads (2). The mesh surface fabrics are made of fabrics, the fabrics are formed by interlacing warp yarns and weft yarns mutually, the warp yarns and the weft yarns are both covering yarns of cotton bale polyester filament yarns, and the cross-sections of the polyester filament yarns are pentagram-shaped. The composite mesh layer easy washing quick-drying fabric with composite silk fabric layer of the present invention adds the bright colors, and is easy to wash and quick to dry.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

Easily-washed and rapidly-dried garment free of trademark touch sense

InactiveCN103799077ATactile reachMoisture wickingProtective garmentSpecial outerwear garmentsTouch SensesEngineering

The invention relates to an easily-washed and rapidly-dried garment free of the trademark touch sense. The easily-washed and rapidly-dried garment comprises a garment body (1). A smooth rectangular cloth piece (2) adheres to the inner side of a trademark of the garment body (1) and covers stitches of the inner side of the trademark. The garment body (1) is made of fabric interwoven from warps and wefts, the warps and the wefts are covering yarn with cotton covering polyester filament yarn. The cross section of the polyester filament yarn is of a pentacle shape. The easily-washed and rapidly-dried garment free of the trademark touch sense can achieve the effect of being free of the trademark touch sense.

Owner:李国平

High-thermal-conductivity graphene foam modified bamboo fiber yarn and preparation method thereof

The invention provides high-thermal-conductivity graphene foam modified bamboo fiber yarn and a preparation method thereof. The method comprises the following steps that (1) graphene foam and a polymer are mixed evenly to prepare a composite solution of the graphene foam and the polymer, wherein the graphene foam is a graphene hollow sphere, and the polymer is selected from one or more of polyvinyl alcohol, polycaprolactone, polyacrylonitrile and polystyrene; (2) the composite solution obtained in the step (1) is made into nano-fibers; and (3) bamboo fibers and the nano-fibers obtained in thestep (2) are blended, and thus the high-thermal-conductivity graphene foam modified bamboo fiber yarn is obtained. By being tested, the high-thermal-conductivity graphene foam modified bamboo fiber yarn provided by the invention has an outstanding bacteria resistance and inhibition effect; bacteria can hardly survive on the yarn, even after hundreds of washing tests, the bacteria inhibition effectis still higher than 90%, and the function fastness is outstanding.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Washable, quick-drying and fireproof fabric

InactiveCN104875433AImprove breathabilityEnhance layeringSynthetic resin layered productsEngineeringFlax fiber

The invention relates to a washable, quick-drying and fireproof fabric. The fabric comprises a fabric body, wherein the fabric body is of a latticed structure formed by interweaving warps and wefts; the wefts adopt memory polyester fibers; the front of the fabric body is covered by a flax fiber core (3); the surface of the flax fiber core is covered by a ramie fiber layer (4); the surface of the ramie fiber layer is covered by a flame retardant layer (5); flame retardant powder adheres to the flame retardant layer; the surface of the flame retardant layer (5) is covered by a flocking layer (6); the back of the fabric body is covered by a base layer; the base layer is made from a fabric; the fabric is formed by interweaving warps and wefts; both the warps and the wefts adopt core-spun yarns of cotton-covered polyester filament yarns; the cross sections of the polyester filament yarns are shaped like a pentagram. The fabric has the beneficial effects that the fabric has better breathability and high comfortableness; the filament yarns are provided with grooves and gases and moisture can be quickly discharged from the grooves, thus achieving the functions of moisture adsorption and sweat removing; the fabric also has the washable and quick-drying effects.

Owner:JIANGYIN YASHUN GARMENT

Washable and quick-drying fabric provided with hollow patterns and stripes and applied to socks

InactiveCN107031133AAdd dimensionMoisture wickingSynthetic resin layered productsCellulosic plastic layered productsConvex structureSOCKS

The invention relates to washable and quick-drying fabric provided with hollow patterns and stripes and applied to socks. The washable and quick-drying fabric provided with the hollow patterns and the stripes and applied to the socks comprises hollow pattern parts and colorful stripe parts, the hollow pattern parts and the colorful stripe parts are strip-shaped, have the same width, are located in the same plane, are staggered with one another and are in parallel connection, and a concave-convex structure is formed; the hollow pattern parts are made of textile fabric, the textile fabric is formed by interweaving warp yarn and weft yarn which are core-spun yarn adopting cotton / polyester filament yarn, and the cross sections of the polyester filaments are pentagram. With the adoption of the concave-convex structure of the washable and quick-drying fabric provided with the hollow patterns and the stripes and applied to the socks, the stereoscopic sensation of the washable and quick-drying fabric provided with the hollow patterns and the stripes and applied to the socks is enhanced.

Owner:郭亚娟

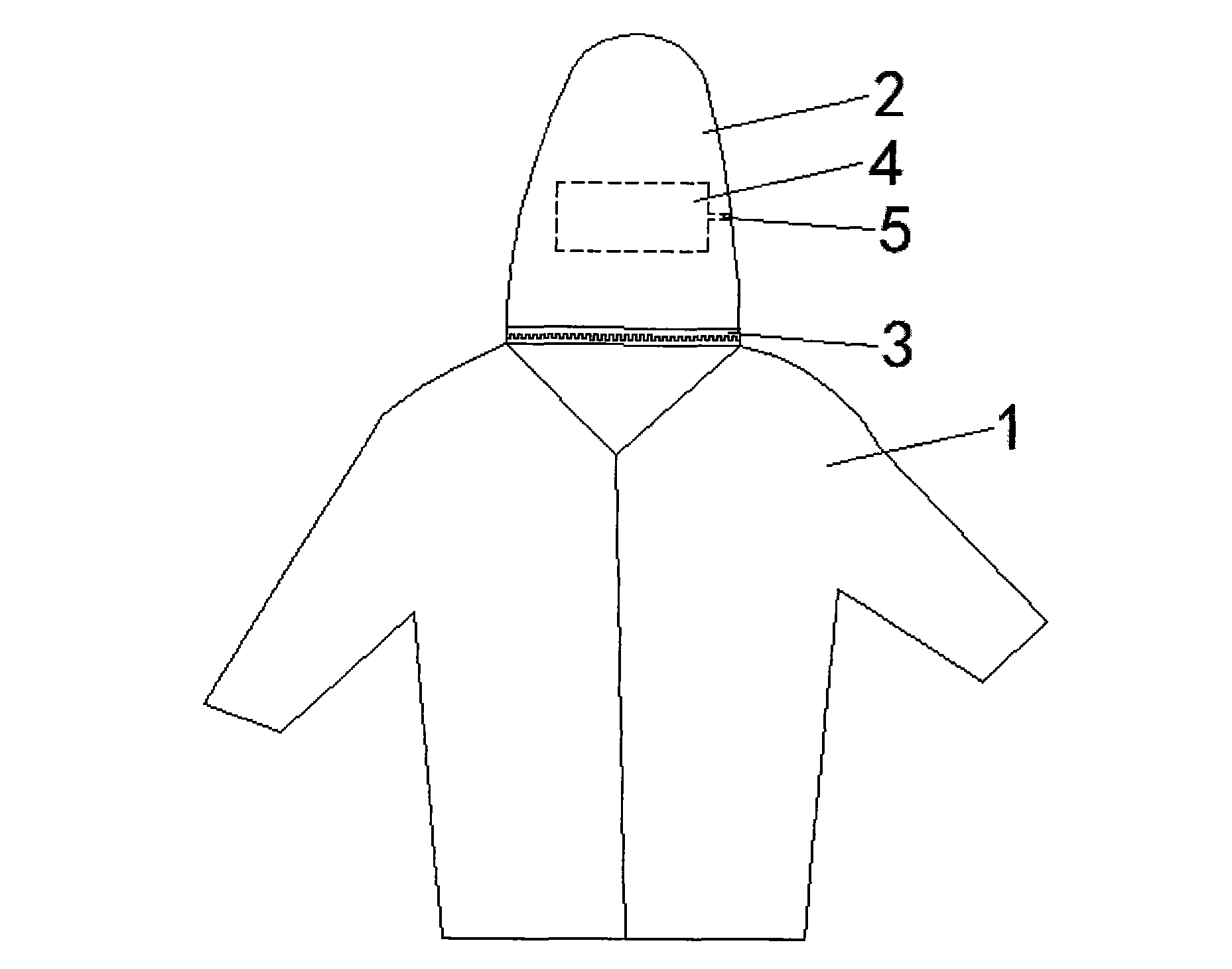

Garment with detachable hat and air bag and easy to wash and quick to dry

The invention relates to a garment with a detachable hat and an air bag and easy to wash and quick to dry. The garment comprises a garment body (1) which is provided with the hat (2), the hat (2) is combined with the garment body through a zipper (3), the air bag (4) is arranged in the hat (2) and is connected with an inflation hole (5) with an air hole plug, the garment body (1) is made of fabric formed by interweaving warps and wefts, the warps and the wefts are covering yarns formed in the mode that polyester filaments are wrapped with cotton, and the cross section of each polyester filament is in a pentacle shape. The garment cannot make a wearer feel pressed or uncomfortable.

Owner:徐文杰

Weaving method for moisture absorbing and sweat releasing fabric

InactiveCN106364074APlay the function of moisture absorption and perspirationEasy to wash and quick dryCellulosic plastic layered productsWoven fabricsViscoseEngineering

The invention relates to a weaving method for a moisture absorbing and sweat releasing fabric. The weaving method is characterized in that one fabric layer and other fabric layer of the fabric are connected through spinning lines, warps and wefts are interwoven and blended to form each fabric layer, the warps are viscose fibers, a plurality of micro pores are formed in the fabric layers, and the surface of each fabric layer is wrapped by a moisture absorbing and sweat releasing film. According to the weaving method, the micro pores are formed in the fabric layers, sweat is rapidly discharged through the micro pores, moisture is absorbed by the moisture absorbing and sweat releasing film, so that moisture absorbing and sweat releasing functions are achieved, and the fabric has the advantages of easiness in washing and rapidness in drying.

Owner:JIANGYIN DONGFA GARMENT MAKING

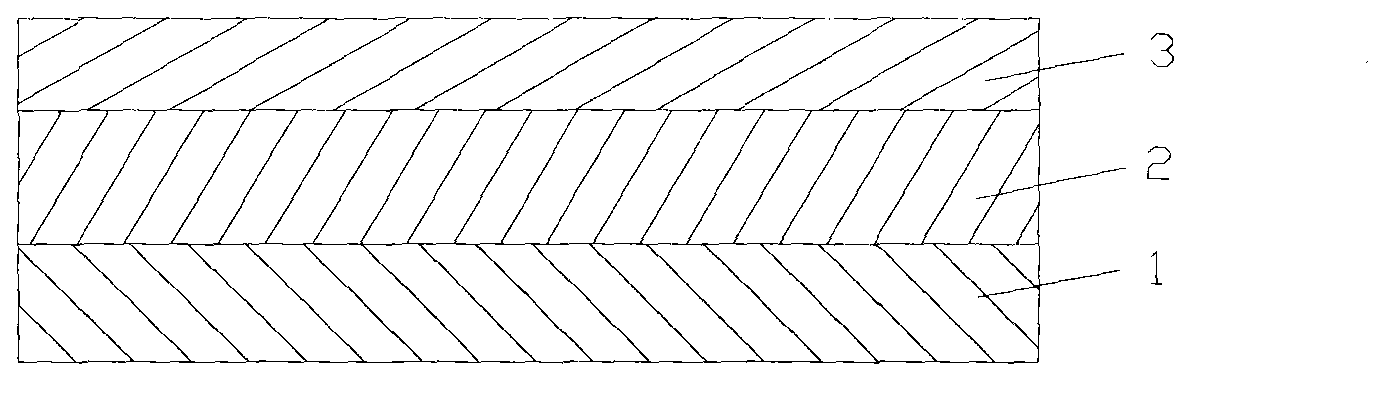

Multilayer easily-washable quickly-drying mesh fabric with antibacterial fabric layer

InactiveCN106335222AEnhance layeringMoisture wickingSynthetic resin layered productsEngineeringWeft yarn

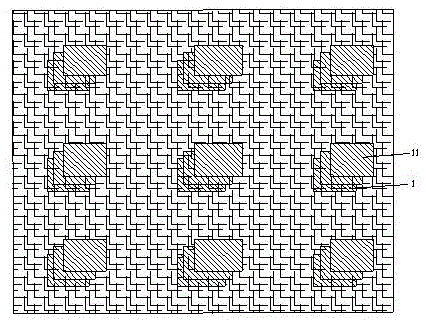

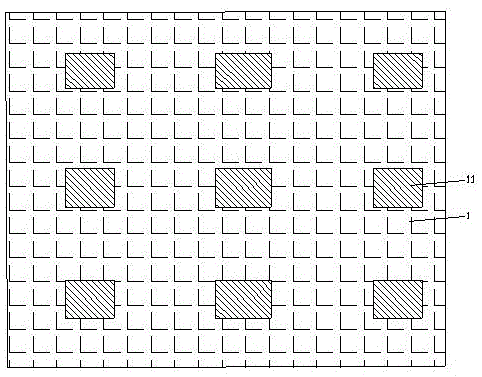

The invention relates to a multilayer easily-washable quickly-drying mesh fabric with an antibacterial fabric layer, belonging to the field of textile fabrics. The multilayer easily-washable quickly-drying mesh fabric comprises a fabric body (1); the upper surface of the fabric body (1) is provided with a mesh layer (2) while the lower surface of the fabric body (1) is provided with a figured layer (3); the mesh layer (2) is provided with a plurality of mesh pieces (21); the figured layer (3) is fixed on the lower surface of the fabric body (1); and the fabric body (1) is prepared from a fabric which is prepared from warp yarns and weft yarns through interweaving, wherein the warp yarns and weft yarns are core-spun yarns prepared by coating polyester filament yarns with cotton, and the transverse cross sections of the polyester filament yarns are in the shape of a pentagram. The interlaced and superimposed mesh pieces and bright threads embedded in the edges of the mesh pieces improve the hierarchical sensation of the multilayer easily-washable quickly-drying mesh fabric with the antibacterial fabric layer. The fabric provided by the invent is easy to wash and quick to dry.

Owner:展平

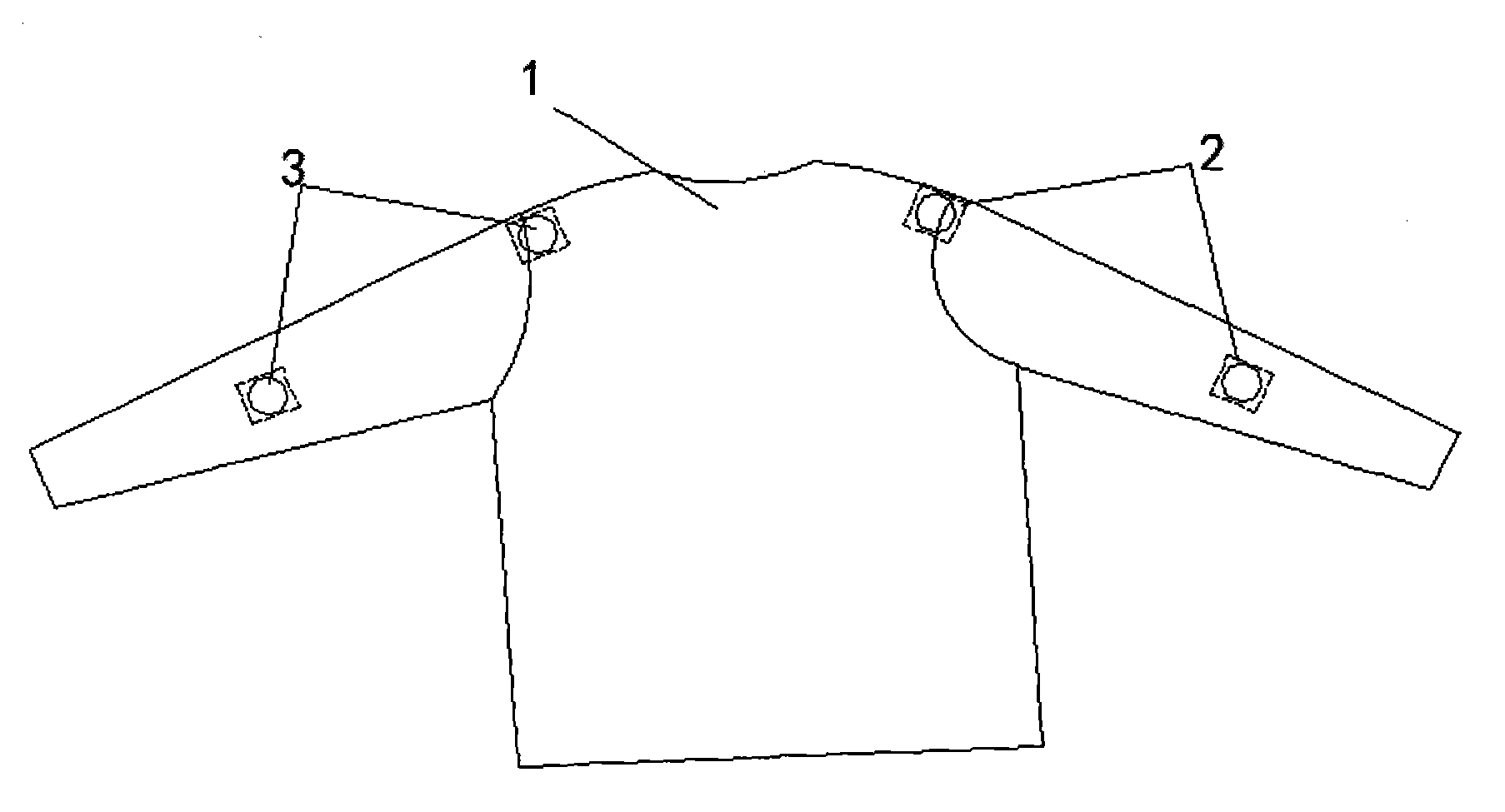

Easily-washed quickly-dried clothes capable of being disassembled for protection

InactiveCN103799579AConvenient for daily lifeMoisture wickingWoven fabricsProtective garmentEngineeringShoulder joint capsule

The invention relates to clothes, in particular to a piece of easily-washed quickly-dried clothes capable of being disassembled for protection. The piece of the clothes comprises a clothes body (1) and is characterized in that hidden bags (2) are arranged on elbow joints and shoulder joints of the clothes body (1) and are sewn on the inner side of the clothes body, protective articles (3) are stored in the hidden bags (2) and can be taken out from the hidden bags (2), the clothes body (1) is made of a fabric formed by interweaving warps and wefts, both the warps and the wefts are core spun yarn formed by wrapping polyester filaments through cotton, and the cross sections of the polyester filaments are of five-pointed star shapes. The piece of the clothes facilitates daily life and has the functions of being easy to wash and quick to dry.

Owner:王世杰

Easy-to-wash quick-drying clothes with inflating bag

InactiveCN103799573APractice self-helpMoisture wickingBody suitsProtective garmentWhole bodyGas-filled tube

The invention relates to easy-to-wash quick-drying clothes with an inflating bag. The easy-to-wash quick-drying clothes with the inflating bag comprises a clothes body (1); the whole clothes body (1) is provided with the inflating bag (2); a longer inflating pipe (3) is arranged in front of the chest part of the inflating bag (2); the inflating pipe (3) is connected with a simple, easy and fast manual inflating pump (4); the inflating pipe (3) and the inflating pump (4) are placed in a pocket in front of the chest part; the clothes body (1) is made of a fabric; the fabric is formed by interweaving warp yarns and weft yarns; the warp yarns and weft yarns are covering yarns formed by covering polyester filament yarns covering with cotton; the cross sections of the polyester filaments are pentacle. When falling into water, a person can lift the inflating pipe and the inflating pump above water to inflate the inflating bag, after the inflating bag is fully inflated, the person is lifted out water due to buoyancy, and self rescue is realized. The easy-to-wash quick-drying clothes with the inflating bag is easy to wash and quickly dried.

Owner:赵万兴

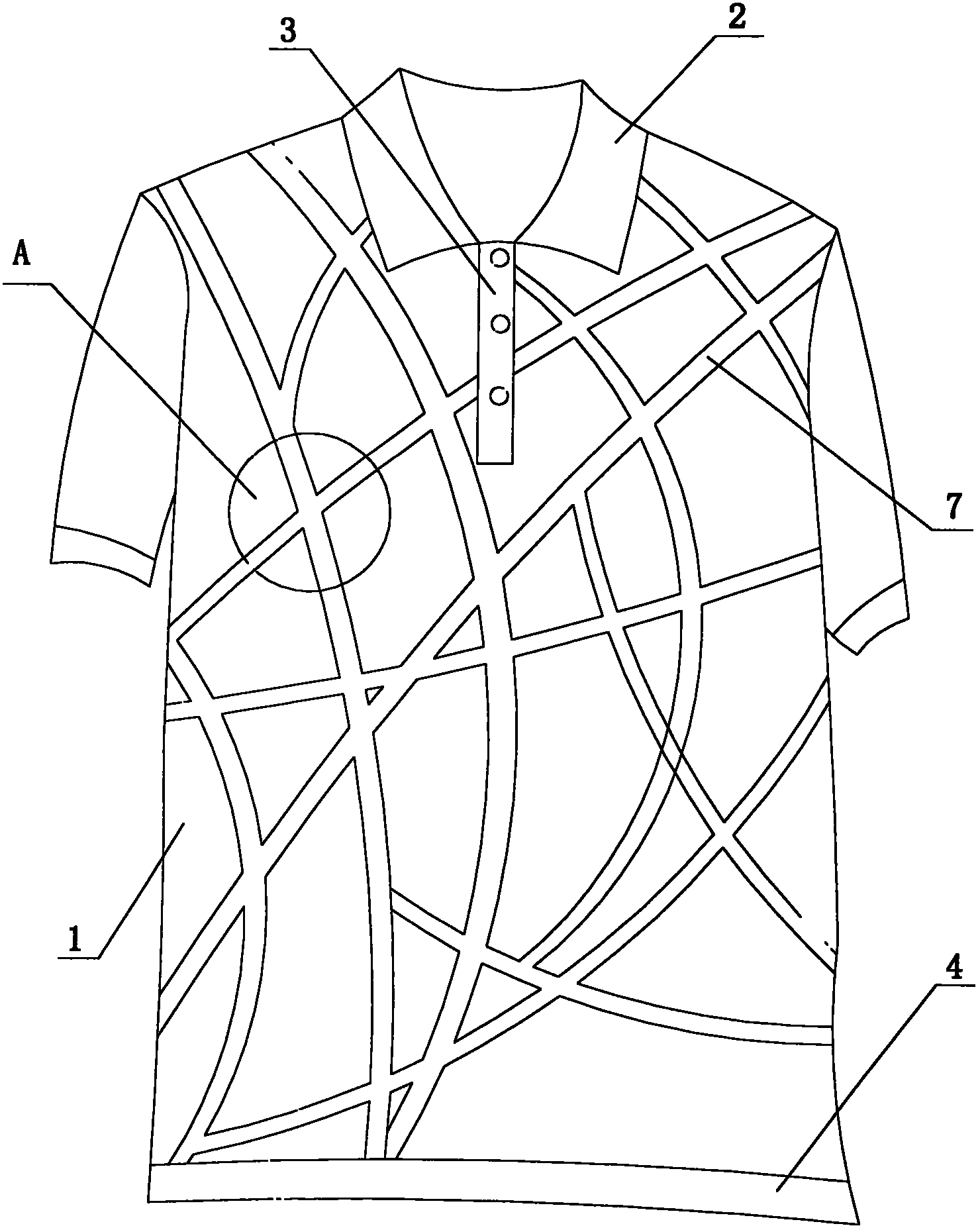

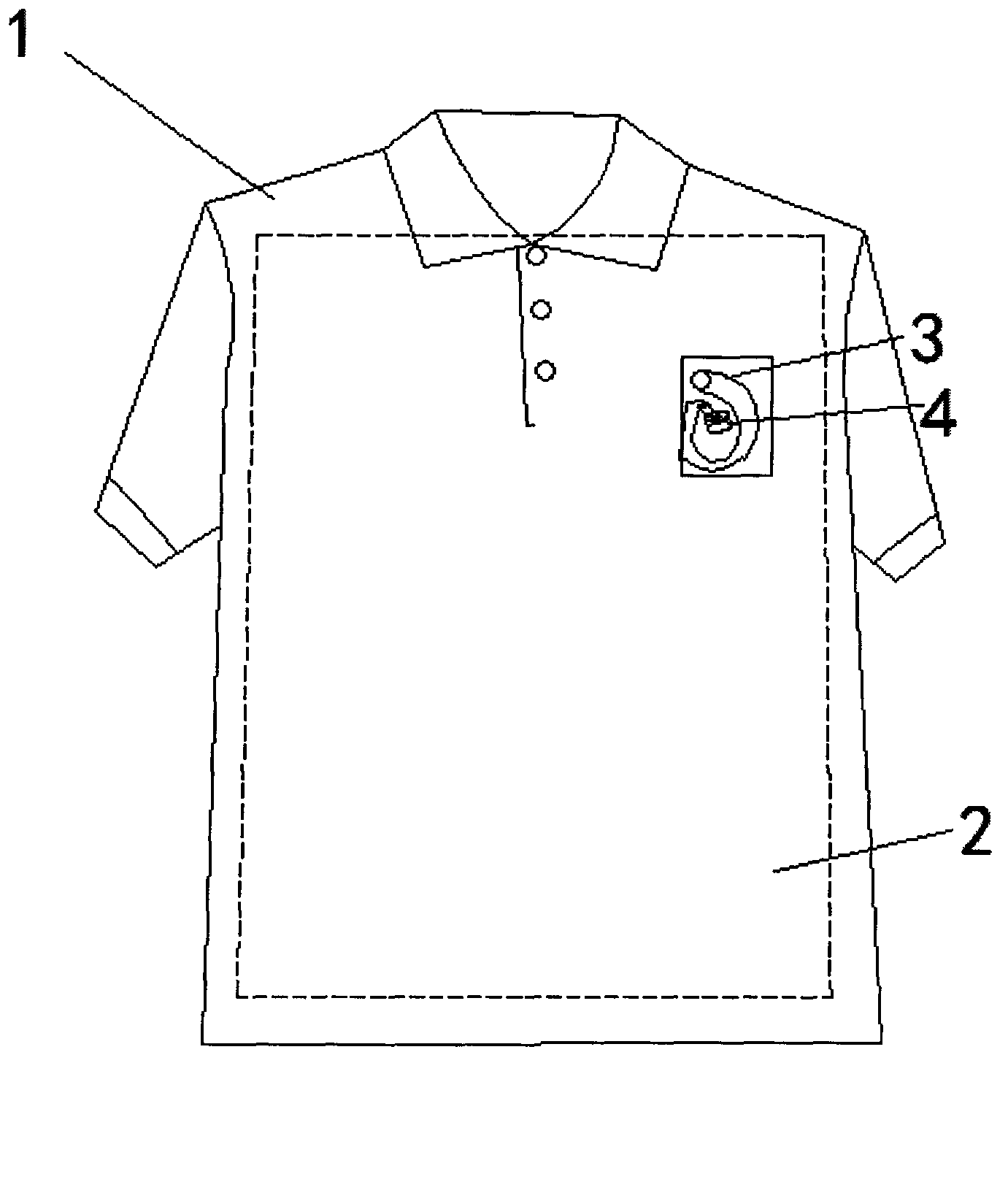

Garment with concave-convex lines and easy to wash and quick to dry

InactiveCN103876330AStrong three-dimensional senseOrnamentalProtective garmentSpecial outerwear garmentsEngineeringFilament yarn

The invention relates to a garment with concave-convex lines and easy to wash and quick to dry. The garment comprises a garment body (1) with a collar (2), a top fly (3) is arranged below the collar (2), a lower hem (4) is arranged at the bottom of the garment body (1), the front and the back of the garment body (1) are both provided with a plurality of grooves (5), convex stripes (6) are densely distributed in the grooves (5) to form a plurality of concave-convex lines (7) on the garment body (1), and the plurality of concave-convex lines (7) are in staggered arrangement. The garment body (1) is made of a fabric which is made by interweaving warps and wefts, and the warps and the wefts are covering yarns of cotton polyester filament yarns with cross sections in shapes of pentagrams. The garment with the concave-convex lines and easy to wash and quick to dry looks layered and is high in stereoscopic impression and ornamental value.

Owner:张英

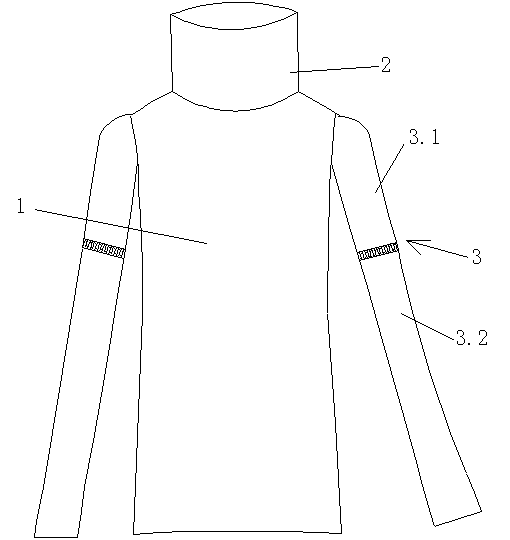

Easy-to-wash quick-drying garment with removable sleeves

InactiveCN104273705AConvenient cooling and ventilationWork won't get in the wayGarment special featuresProtective garmentBiomedical engineeringFilament yarn

The invention relates to an easy-to-wash quick-drying garment with removable sleeves. The easy-to-wash quick-drying garment comprises a garment body (1), the garment body (1) is provided with a collar (2) and the sleeves (3), each sleeve (3) is composed of an upper sleeve body (3.1) and a lower sleeve body (3.2), each upper sleeve body (3.1) is connected with the corresponding lower sleeve body (3.2) through a zipper or a hasp, the garment body (1) is made of fabric formed by interweaving warps and wefts, the warps and the wefts are core spun yarns formed by covering polyester filament yarns with cotton, and the cross sections of the polyester filament yarns are each in the shape of a pentacle. The easy-to-wash quick-drying garment not only can facilitate heat dissipation and ventilation but also cannot hinder work. The garment is easy to wash and dries quickly.

Owner:JIANGYIN CHUNZHILAN SPECIAL YARN

Easy-washing and quick-drying close-fitting coat

The invention relates to an easy-washing and quick-drying close-fitting coat which comprises a coat body (1). The coat body (1) comprises a clothing body (2) and a lower hem (3), the lower width of the clothing body (2) is larger than the width of the upper part of the clothing body (2), the width of the lower hem (3) is smaller than that of the two shoulders, the lower hem (3) is made of elastic materials, and a lace (4) is arranged on the outer edge of the lower hem (3). The coat body (1) is made of fabrics, the fabrics are formed through interweaving of warp yarns and weft yarns, the warp yarns and the weft yarns are all covering yarns of cotton covered polyester filaments, and the cross section of the polyester filaments is a pentagram. The easy-washing and quick-drying close-fitting coat can prevent cold air from entering the coat body, and people cannot feel cold.

Owner:王凤华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com