Bamboo carbon fiber pearl stripe yarn dyed fabric and weaving method thereof

A technology of bamboo carbon fiber and pearls, which is applied in embossed fabrics, textiles, papermaking, fabrics, etc., can solve problems such as not being able to satisfy consumers, achieve the effects of improving research and development capabilities and technological innovation capabilities, good environmental protection, and novel and unique appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The weaving method of bamboo carbon fiber pearl stripe yarn-dyed fabric, specifically:

[0015] (1) Use 75D / 48F polyester filament semi-gloss black processing 800T / S as warp thread, 75D / 72F pure bamboo carbon fiber gray filament and 75D / 144F polyester ultra-fine denier filament are twisted to make weft thread 2:1 cycle, and interweave .

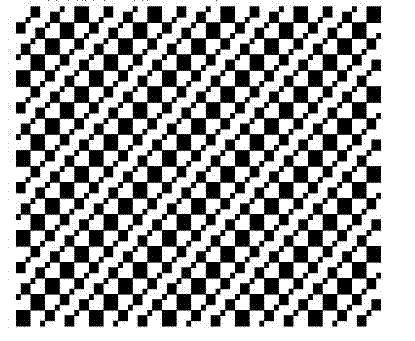

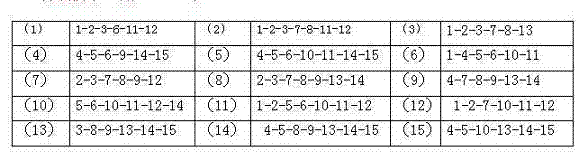

[0016] (2) Design the 15*15 new twill weave changing weave pattern, through the alternation of warp and weft floating length, form the three-dimensional texture of the appearance of the fabric in the shape of large and small pearls.

[0017] (3) The design of the weaving process is as follows: the total length is 12,768, 19# steel reed is used for 4 reeds, the reed width of the upper machine is 168cm, the weft density of the upper machine is 46 pieces / cm, and the sides are on the same ground; 15 pieces of heald frames are used for one thread In general, the double-jet dobby water-jet loom is used for trial production, and the pattern ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com