Patents

Literature

64results about How to "Anti-static has" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

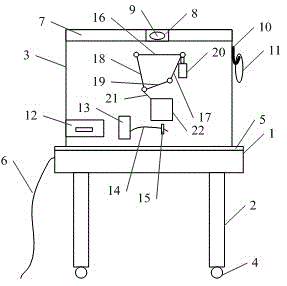

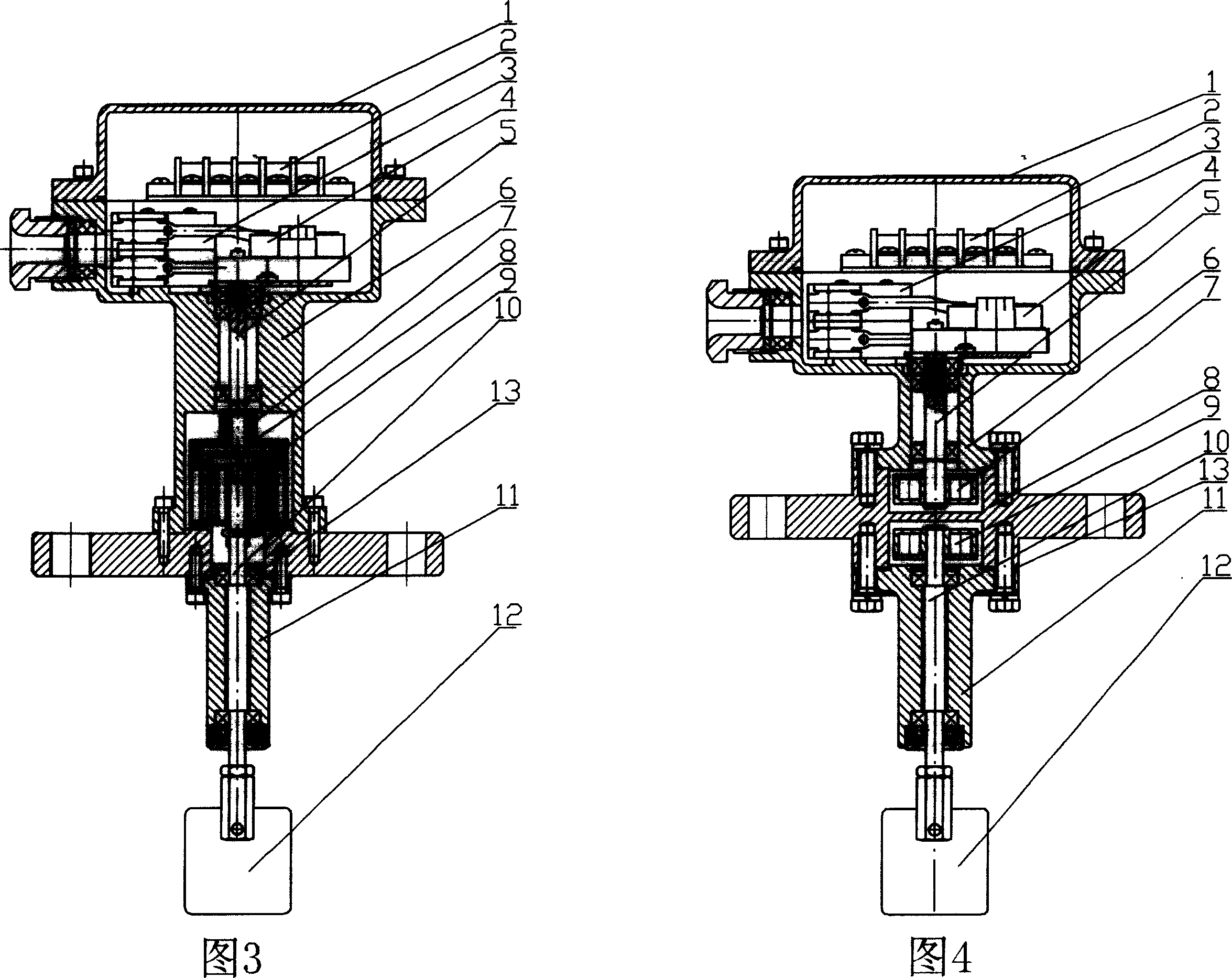

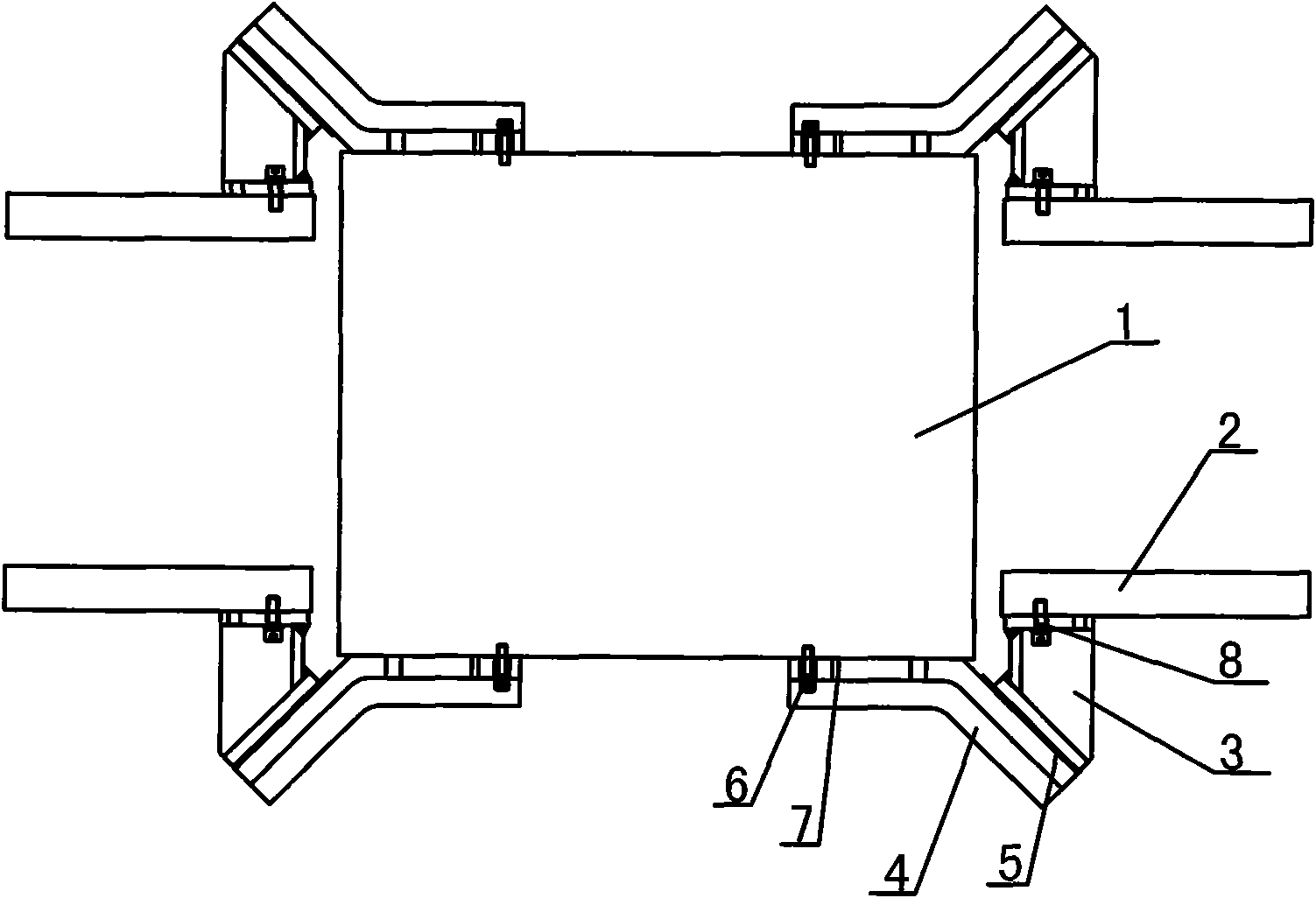

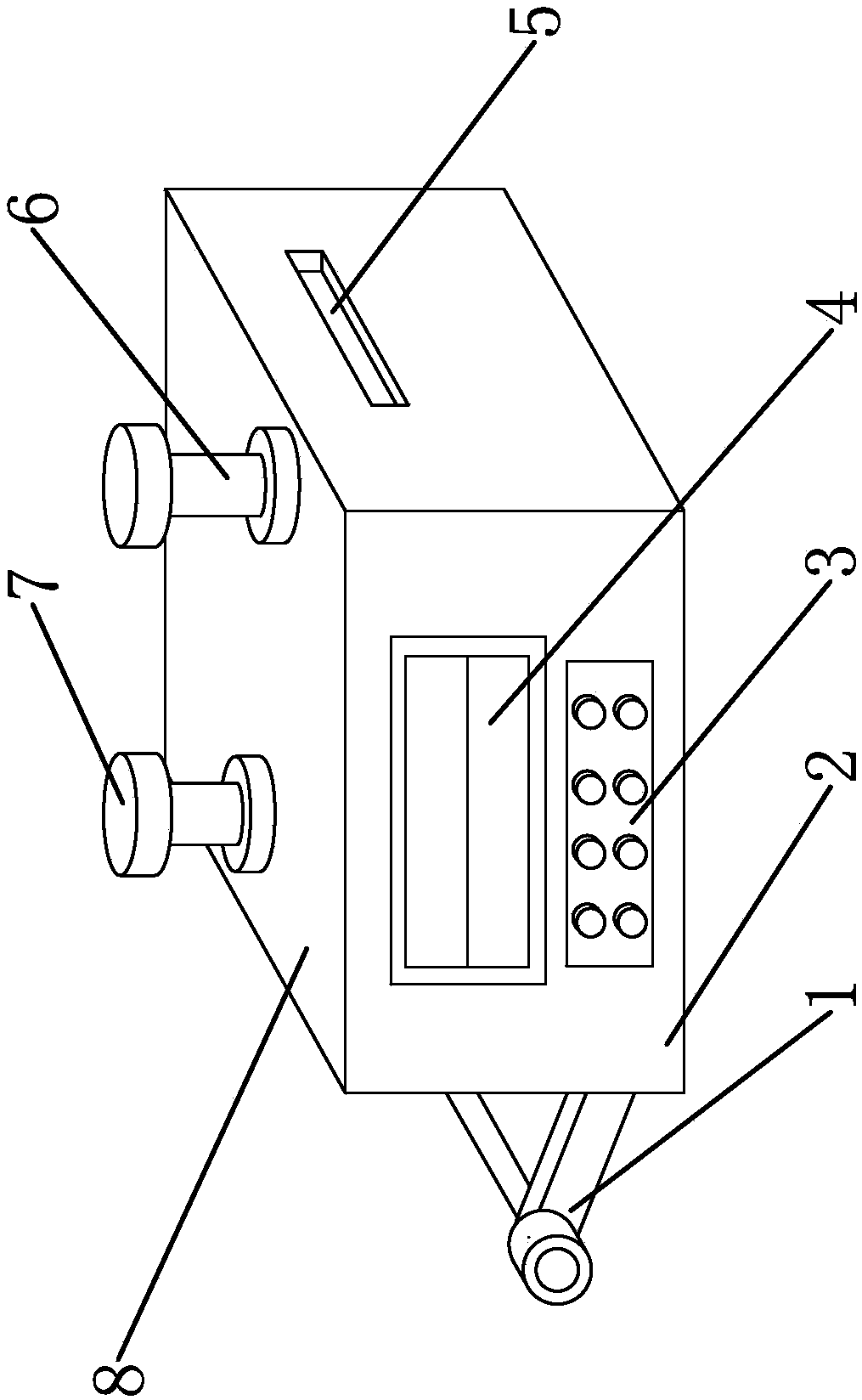

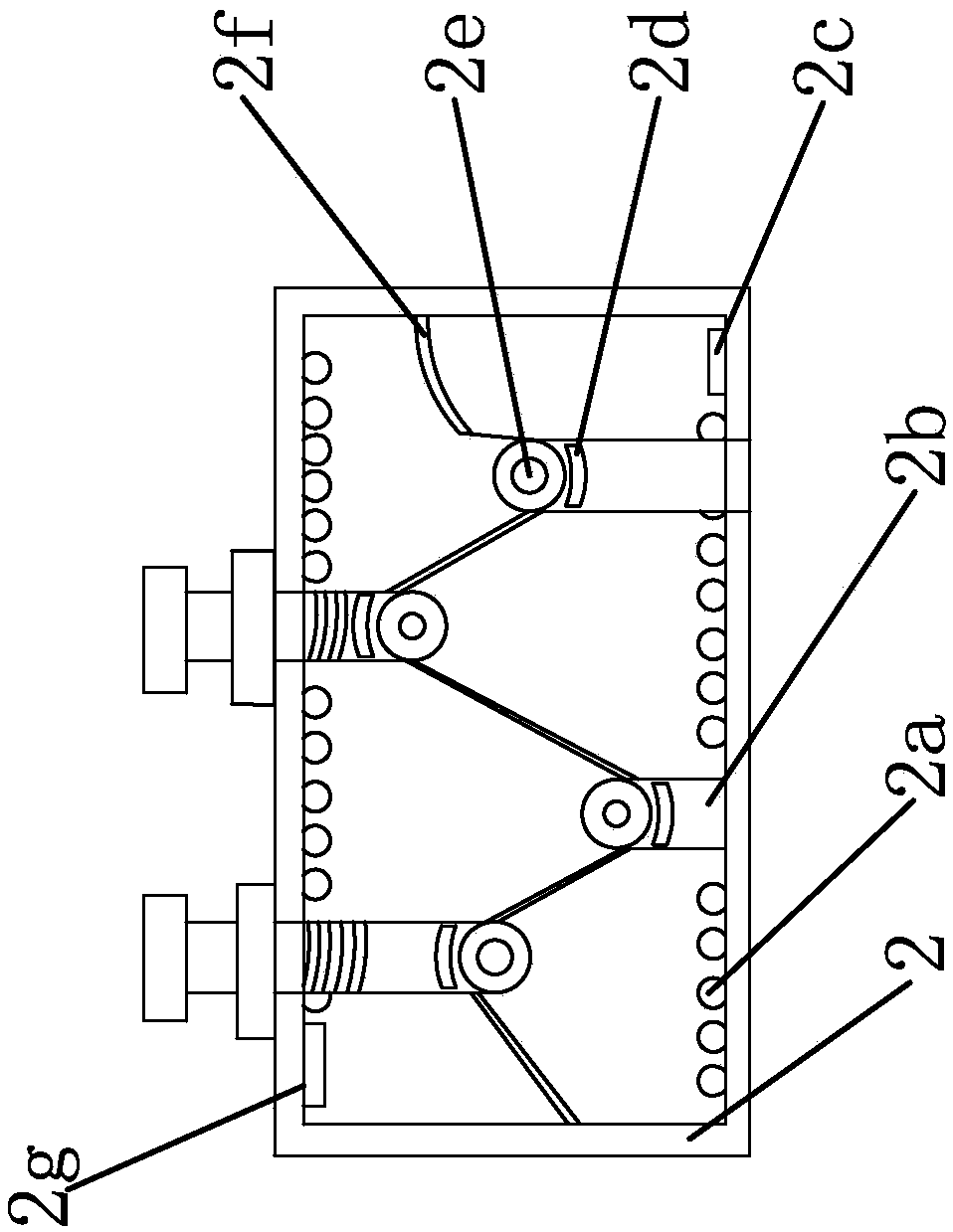

Workbench with better anti-static effect

ActiveCN105619352AImprove anti-static effectSolve the technical problems of single anti-static measures and poor anti-static effectWork benchesElectrostatic chargesEngineeringStatics

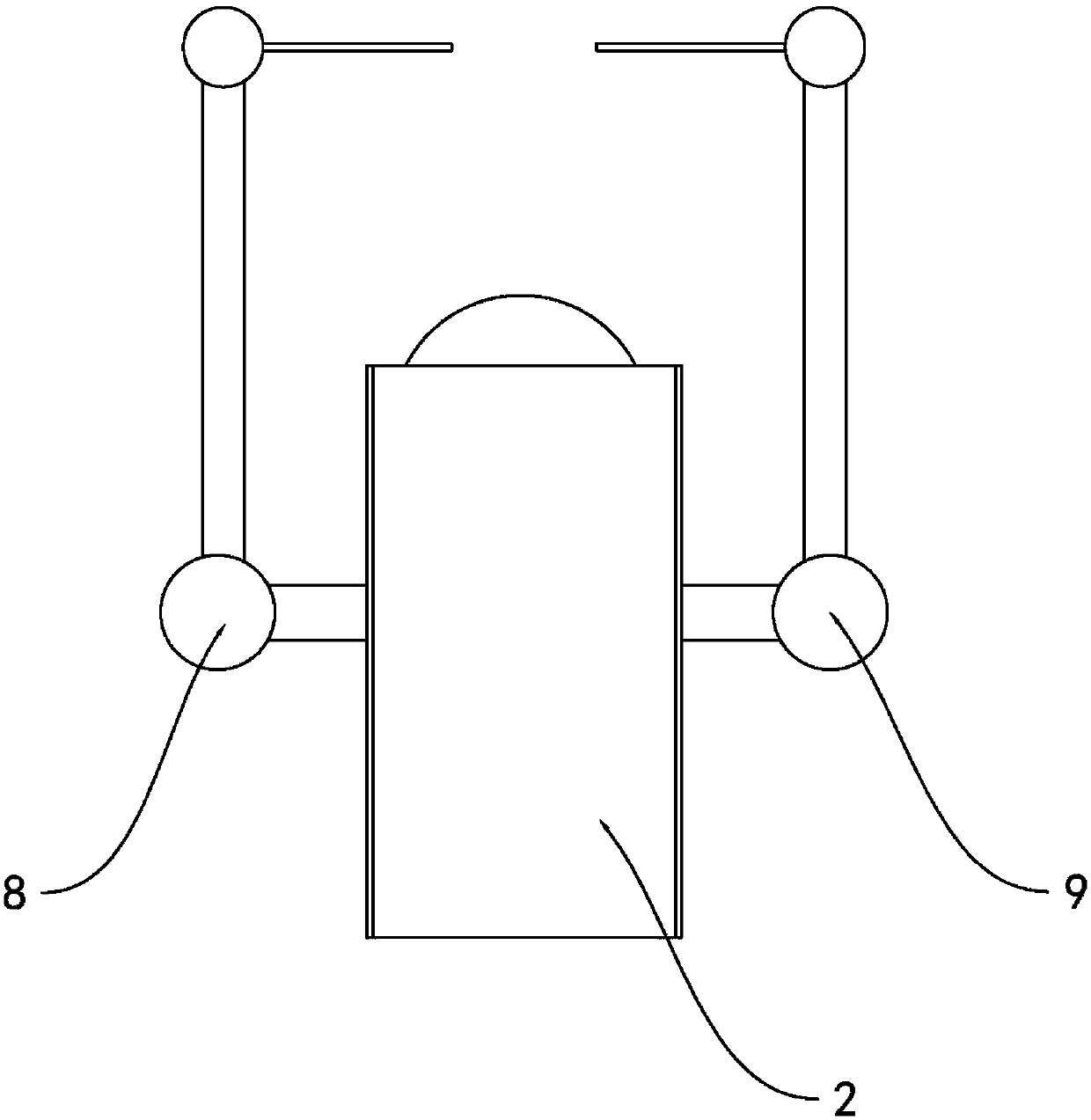

The invention discloses a workbench with a better anti-static effect. The workbench comprises a platen, a supporting frame, a baffle and a hinge four-rod mechanism; the platen is provided with an anti-static rubber table face layer, one end of a ground lead is connected with the platen, and the other end of the ground lead is grounded; a sliding groove is formed in the upper surface of the baffle, a sliding block is inlaid into the sliding groove, and a lighting lamp is fixed to the sliding block; a hook is arranged on the baffle, and an anti-static hand ring is hung on the hook; a drawer is fixed to the baffle, and an anti-static glove is installed in the drawer; an air pump is fixed to the baffle, one end of the air pipe is connected with the air pump, and an air valve is arranged at the other end of the air pipe; and the hinge four-rod mechanism is connected with an ion fan, and the beneficial effects of being reasonable and variable in anti-static precaution of the anti-static workbench and better in anti-static effect are achieved.

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

Multifunctional monitoring device

InactiveCN108156431AReduce wasteEasy to replaceTelevision system detailsColor television detailsEngineeringPulley

The invention discloses a multifunctional monitoring device, belongs to the technical field of monitoring devices, and solves the problems that most of monitoring devices in the prior art monitor onecertain area, are powered by traditional power sources for a long time and consume a large amount of energy; the monitoring devices work in outdoor environments for a long time, the cameras of the monitoring devices are polluted by rainwater and sand wind-blown sand, and the monitoring effect is affected. The multifunctional monitoring device comprises a monitoring device body and is characterizedin that slide rails are arranged on two sides of the camera window of the monitoring device body, a sweeping device is slidably connected to the slide rails, first fixed pulleys are arranged on two sides of the sweeping device, a second fixed pulley and a second fixed pulley are respectively arranged on two sides of the monitoring body in a staggered manner, and a clamp seat is fixedly mounted atthe bottom of the monitoring device body; a linear driver is mounted on a support, a storage battery is connected with output end of a solar panel, a motor and the linear driver, and a steel wire rope sleeves the first fixed pulleys and winds around the second fixed pulley and the third fixed pulley to be connected with the linear driver.

Owner:郑州神盾智能科技有限公司

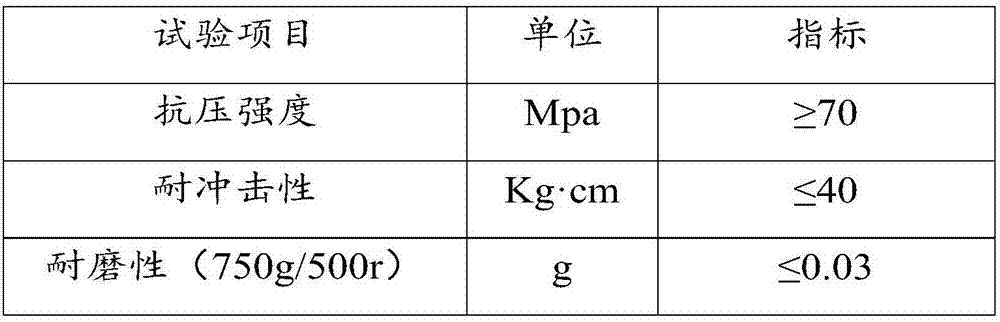

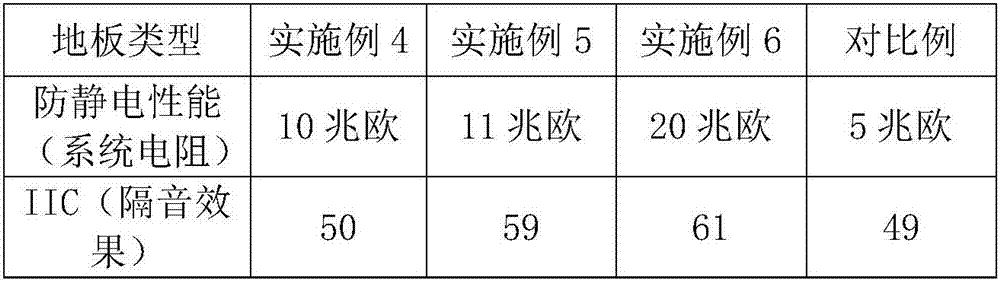

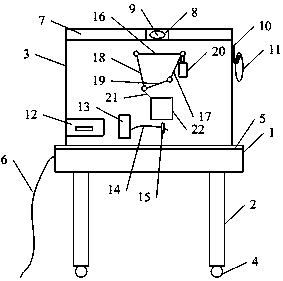

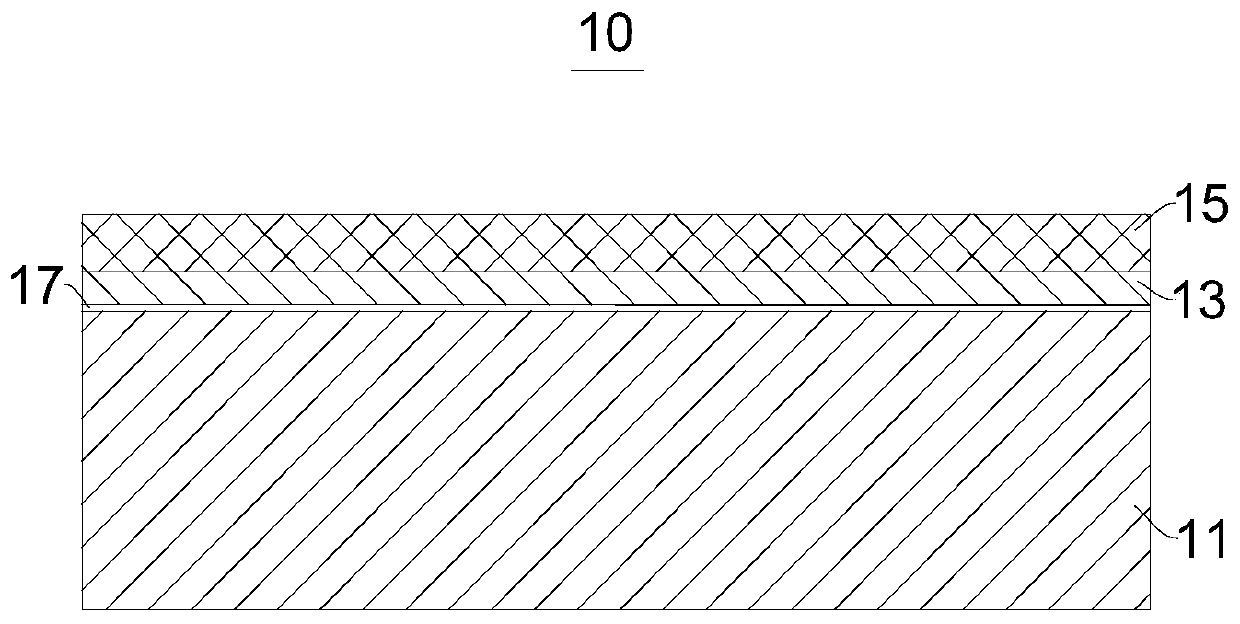

Anti-static non-firing epoxy mortar floor, and construction technology and application thereof

The invention relates to the field of building materials, in particular to an anti-static non-firing epoxy mortar floor, and a construction technology and application thereof. The anti-static non-firing epoxy mortar floor includes a concrete base layer, an epoxy mortar bottom layer, an epoxy mortar middle layer and an epoxy mortar surface layer sequentially laid from bottom to top; a conductive body is arranged on the epoxy mortar bottom layer and connected with a grounding electrode; the epoxy mortar bottom layer, the epoxy mortar middle layer and the epoxy mortar surface layer are mainly prepared from epoxy mortar and conductive powder; the epoxy mortar is mainly prepared from epoxy resin, dolomitic sand, cement, a curing agent and a toughening agent, and the weight ratio of epoxy resinto dolomitic sand to cement to the curing agent to the toughening agent is 100:(150-200):(200-350):(5-10):(12-18). The epoxy mortar floor has the advantages of being antistatic, unfired, dustproof, clean and long in service life.

Owner:杭州电盾装饰材料有限公司

Anti-static and radiation-proof elastic fabric

The invention discloses anti-static and radiation-proof elastic fabric. The elastic fabric comprises elastic warp, anti-static fabric and radiation-proof weft, wherein the elastic warp is prepared from cotton fibers and spandex fibers and accounts for 42%-55% of the weight of the fabric; the anti-static fabric is prepared from colored cotton fibers, bamboo charcoal fibers and polyaniline conductive polyester fibers and accounts for 20%-27% of the weight of the fabric; the radiation-proof weft is prepared from silver fibers and platinum fibers and accounts for 18%-38% of the weight of the fabric. The elastic warp of the fabric has good hygroscopicity and rich elasticity, so that prepared clothes are elastic and comfortable; the anti-static fabric is prepared from the colored cotton fibers, the bamboo charcoal fibers and the polyaniline conductive polyester fibers through blending, the anti-static performance is good, the bamboo charcoal fibers have good air permeability and antibacterial deodorant performance, and the fabric is comfortable to wear; the radiation-proof weft is prepared from the silver fibers and the platinum fibers through blending, has radiation prevention, negative ion and far infrared ray functions and can improve functions of human bodies.

Owner:东莞佛亚铝业有限公司

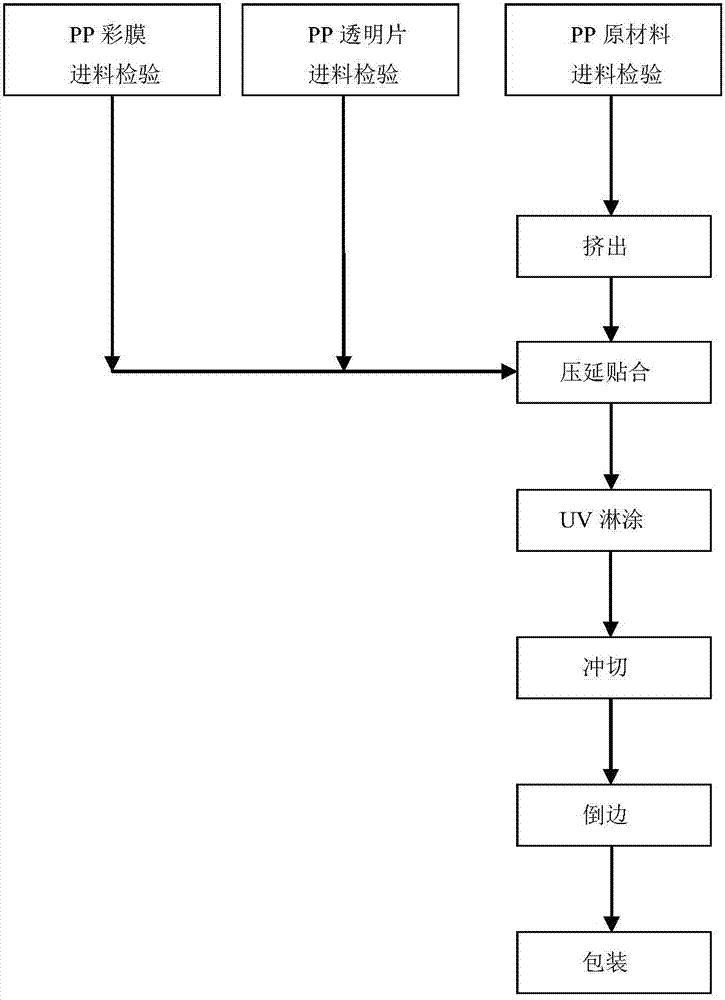

Environment-friendly PP (polypropylene) foam floor board and method for preparing same

InactiveCN107033455AImprove mechanical propertiesImprove flexibilitySynthetic resin layered productsConstructions elementsAntioxidantColor film

The invention discloses an environment-friendly PP (polypropylene) foam floor board and a method for preparing the same. By the aid of the environment-friendly PP foam floor board and the method, the shortcomings of existing PVC (polyvinyl chloride) floor boards can be overcome. The environment-friendly PP foam floor board comprises materials for three layers including PP color films, PP transparent sheets and composite PP foam base sheets which are subjected to composition to form the environment-friendly PP foam floor board. The composite PP foam base sheets are particularly prepared from PP resin, mica, stone powder, solubilizers, epoxidized soybean oil, antioxidants and lubricants according to optimal ratios. The environment-friendly PP foam floor board and the method have the advantages that the environment-friendly PP foam floor board is excellent in mechanical properties and heat-insulation, sound-insulation, antistatic, insulating and flame-retardant properties, stable in chemical properties, easy to degrade and low in carbon and is light and environmentally friendly, materials can be saved, and obvious environment-friendly effects can be realized by the environment-friendly PP foam floor board and the method.

Owner:DECORIA MATERIALS JIANGSU CO LTD

Anti-static silk quilt

The invention provides an anti-static silk quilt, which comprises a quilt cover and a quilt inner which is arranged in the quilt cover and is made of natural silk. The invention is characterized in that the quilt cover is made of carbon fiber anti-static fabric. The proper clean room grade of the carbon fiber anti-static fabric is 100 to 1000. The invention adopts the carbon fiber anti-static fabric to manufacture the quilt cover which is soft, ventilated and comfortable; therefore the level of the silk quilt is improved. The invention has the function of preventing static, dust, ultraviolet radiation and the like and meets the health care requirement of people.

Owner:YANCHENG YALIN HOME TEXTILE

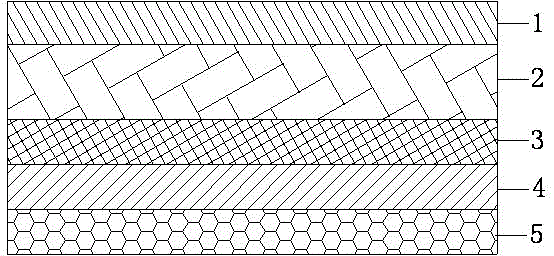

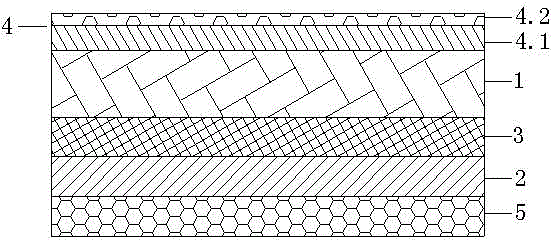

Antiflaming fabric with good dimensional stability

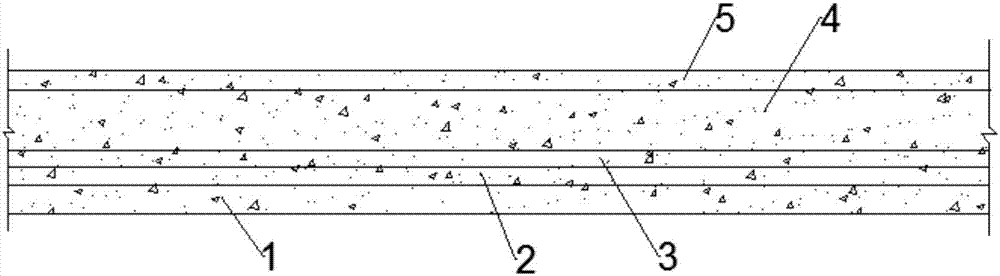

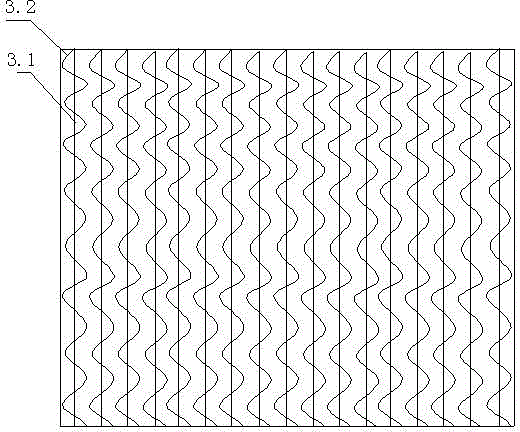

InactiveCN105639791AAnti-static hasSpecial rigiditySynthetic resin layered productsWoven fabricsYarnMetal filament

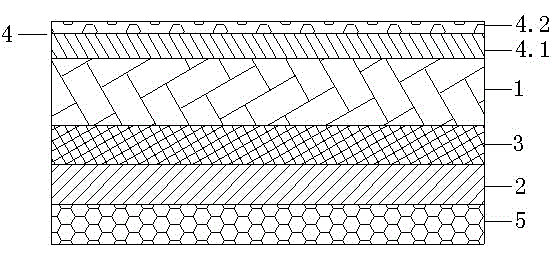

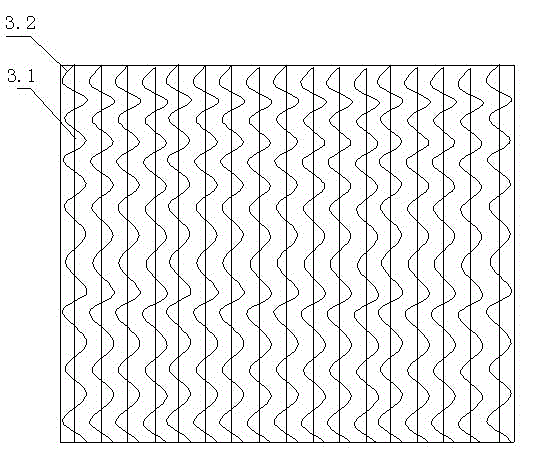

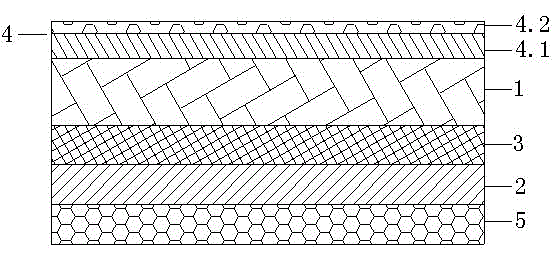

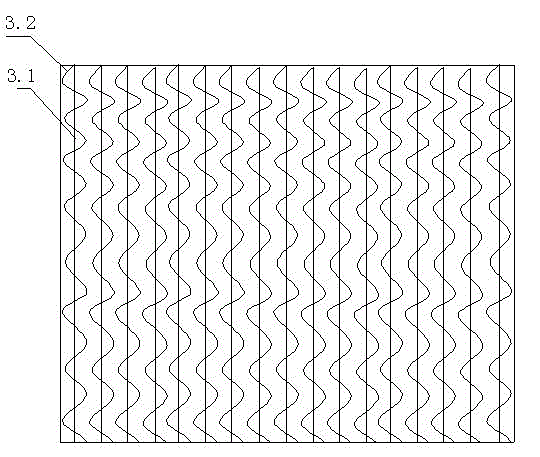

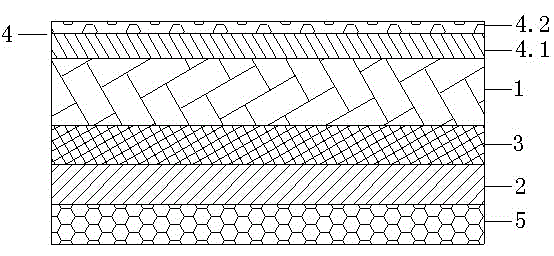

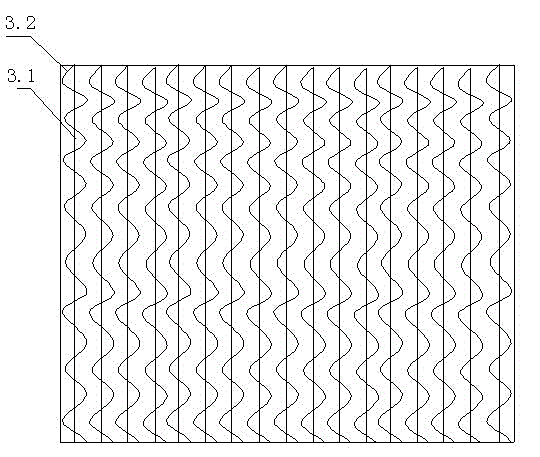

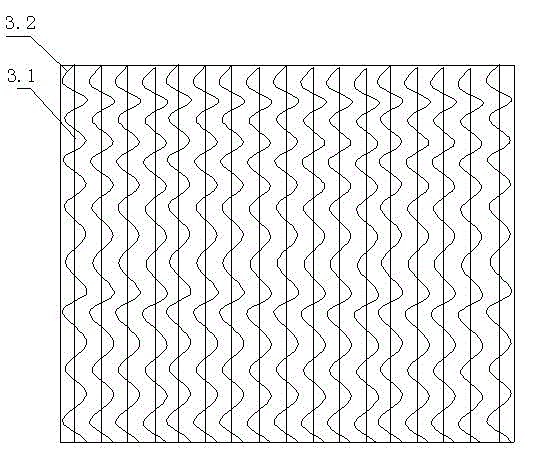

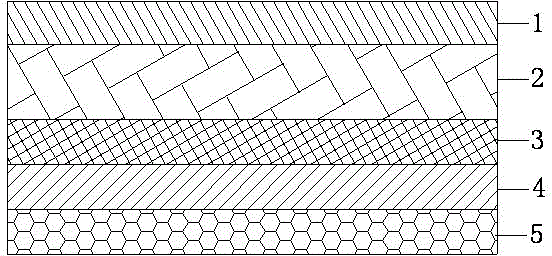

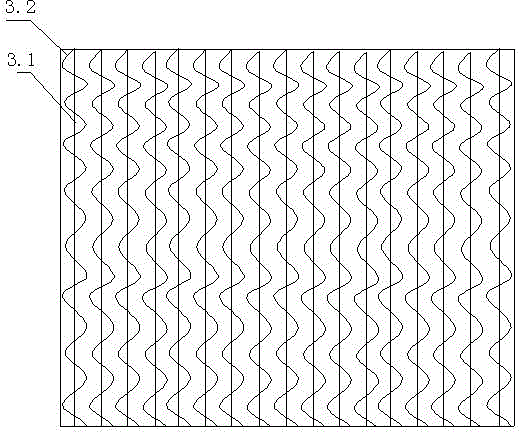

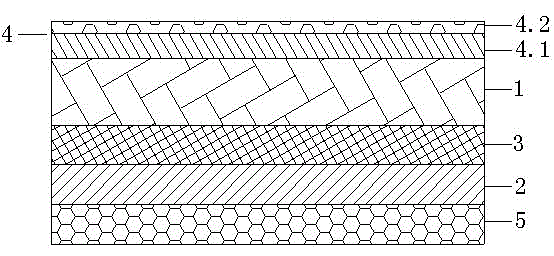

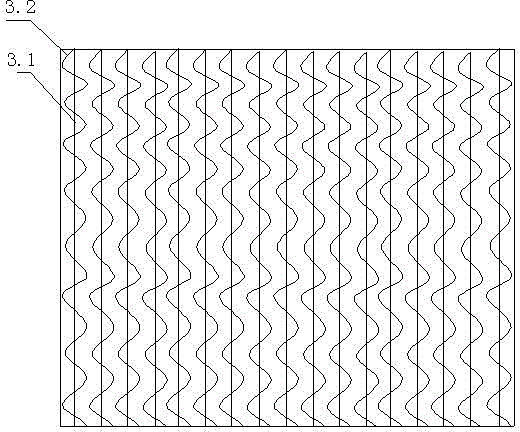

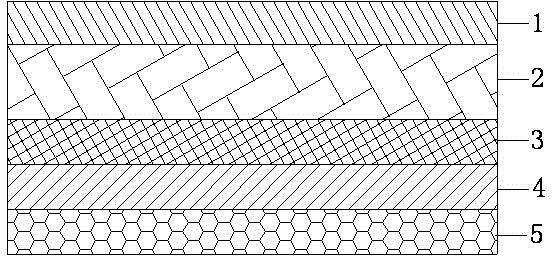

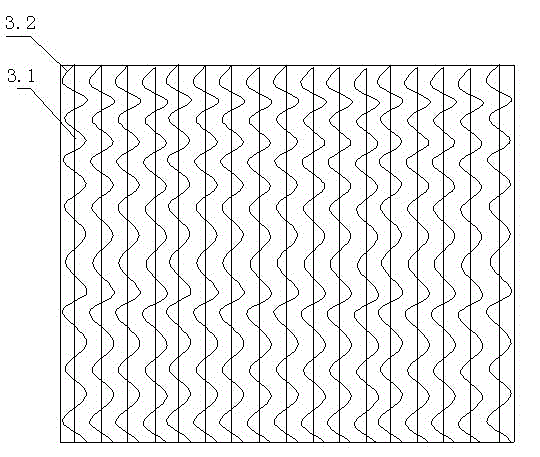

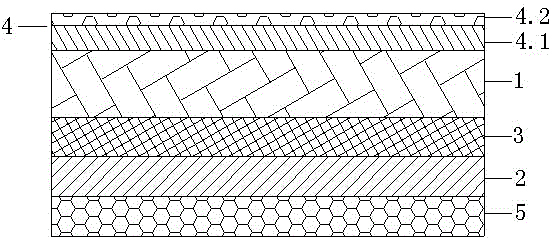

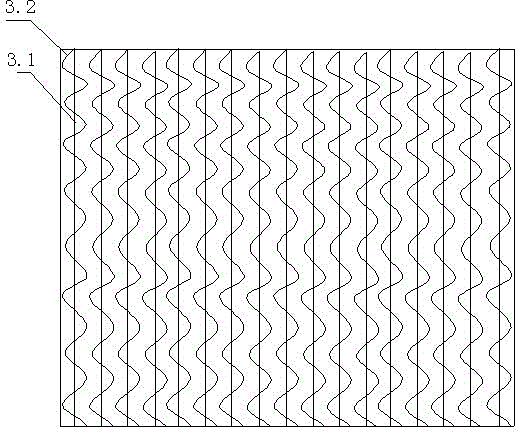

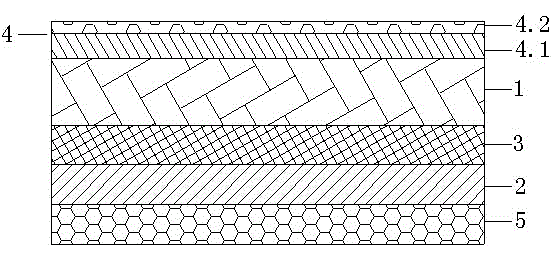

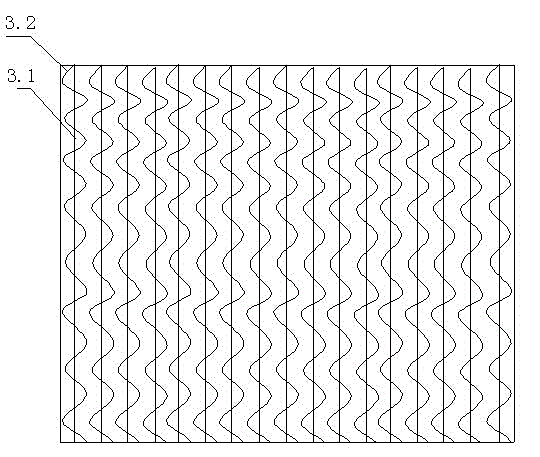

The invention relates to an antiflaming fabric with good dimensional stability; the fabric comprises an upper cotton cloth layer (1) and a lower cotton cloth layer (2); a base layer (5) is composited under the lower cotton cloth layer; an anti-static layer (3) is arranged between the upper and lower cotton cloth layers, and formed by core spun silk fibers comprising yarns (3.1) and metal filaments (3.2), wherein the metal filament wind on the yarn; the surface of the upper cotton cloth layer is coated with an antiflaming coating (4) comprising a bottom antiflaming polyurethane layer (4.1) and a top organic silicon oil layer (4.2). The base layer is formed by a cloth, and the cloth is obtained by mutually interlacing warp yarns with filling yarns, wherein the warp yarns and filling yarns are arranged in a two-up two-down mode; the warp yarn is 50D / 72F terylene low stretch yarn; the filling yarn is 50D / 36F terylene low stretch yarn, and the warp yarn and the filling yarn are in a twill weave structure. The antiflaming fabric with good dimensional stability is low in cost, variable in bending, and good in dimensional stability.

Owner:JIANGYIN YONGTAI PLASTICS CO LTD

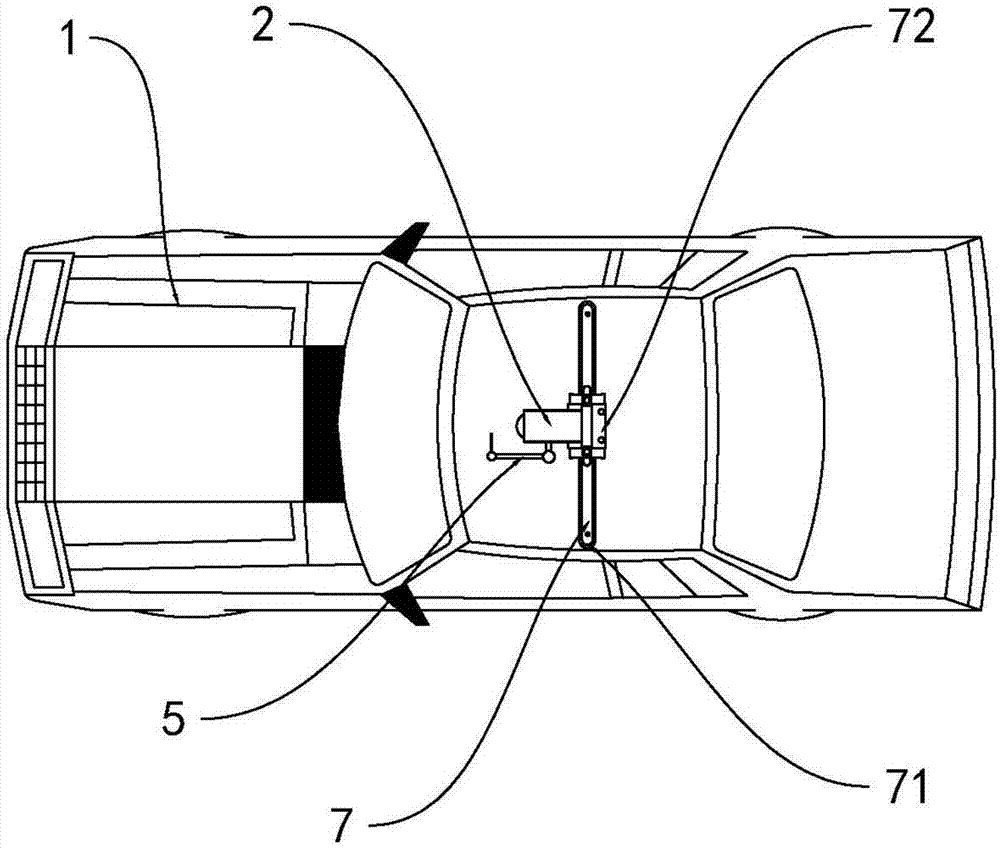

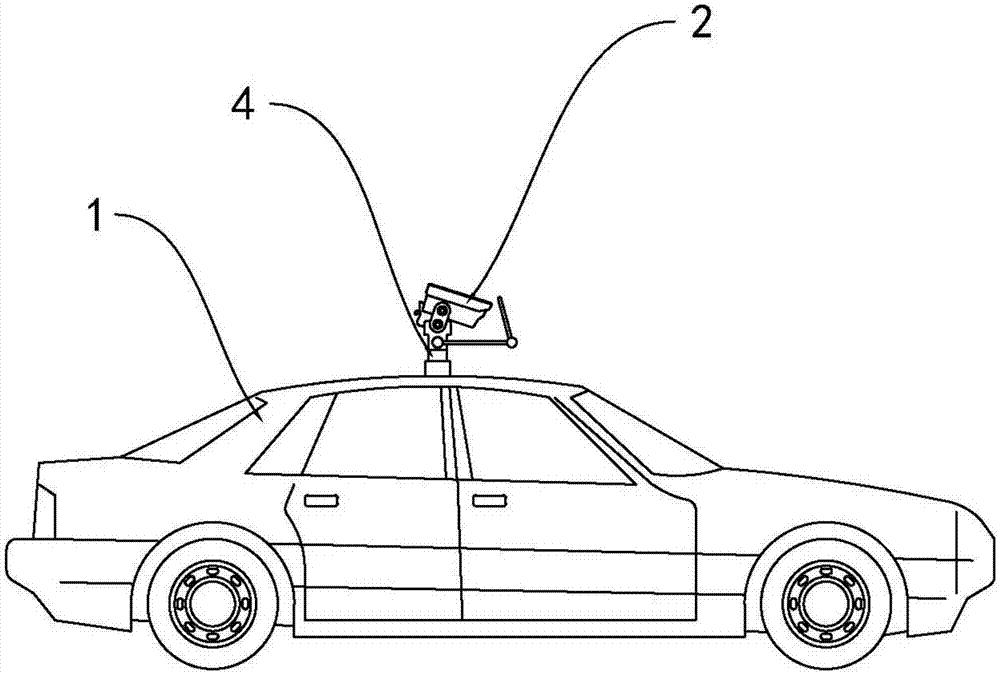

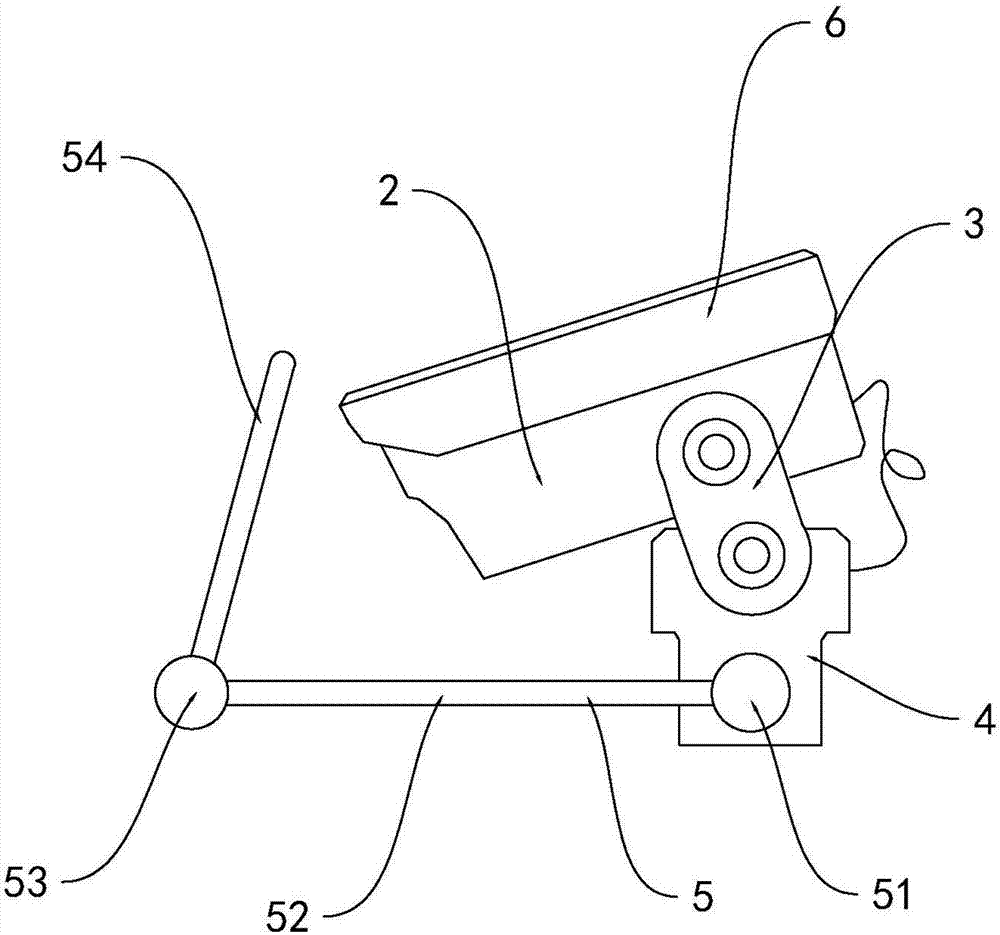

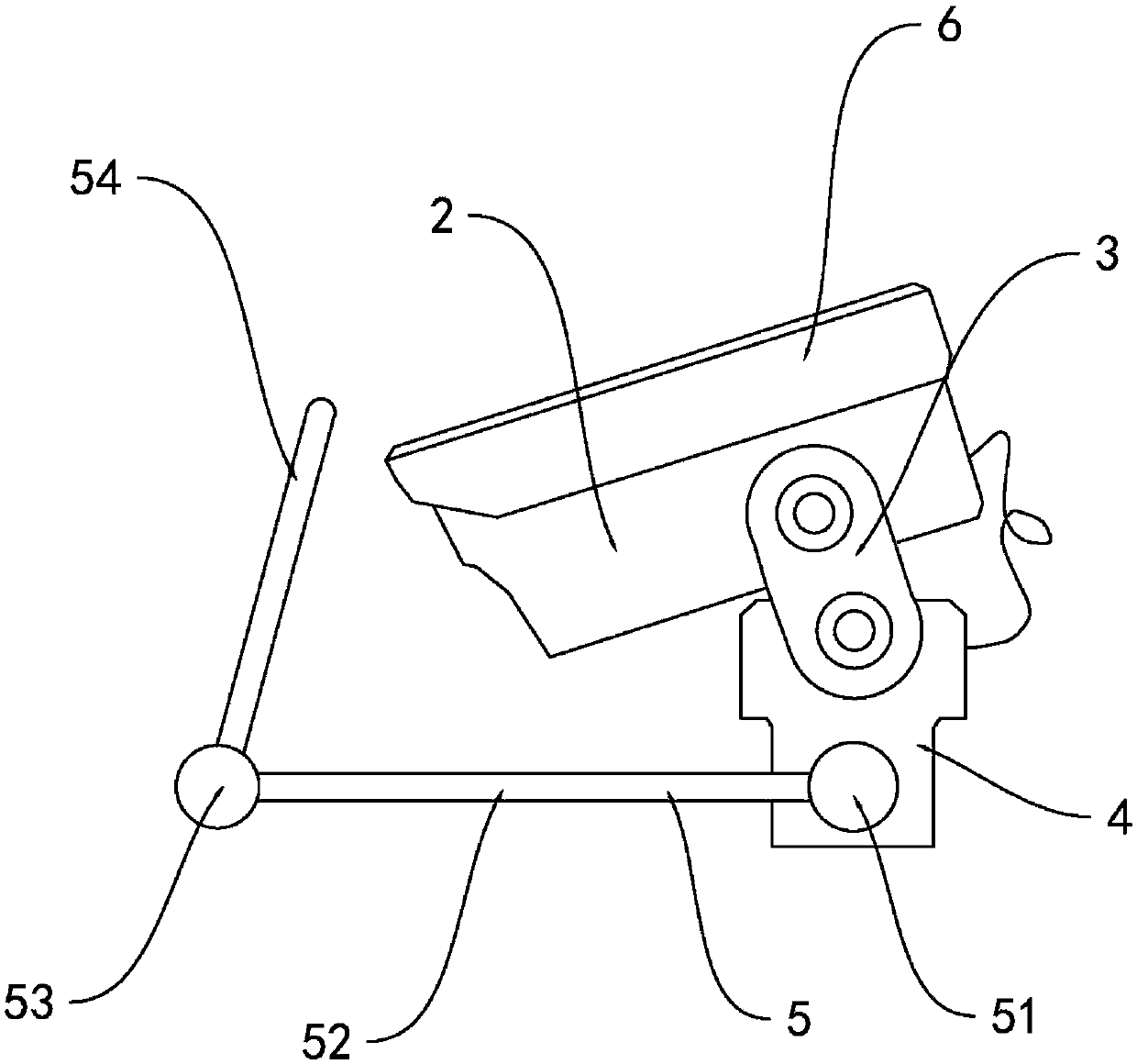

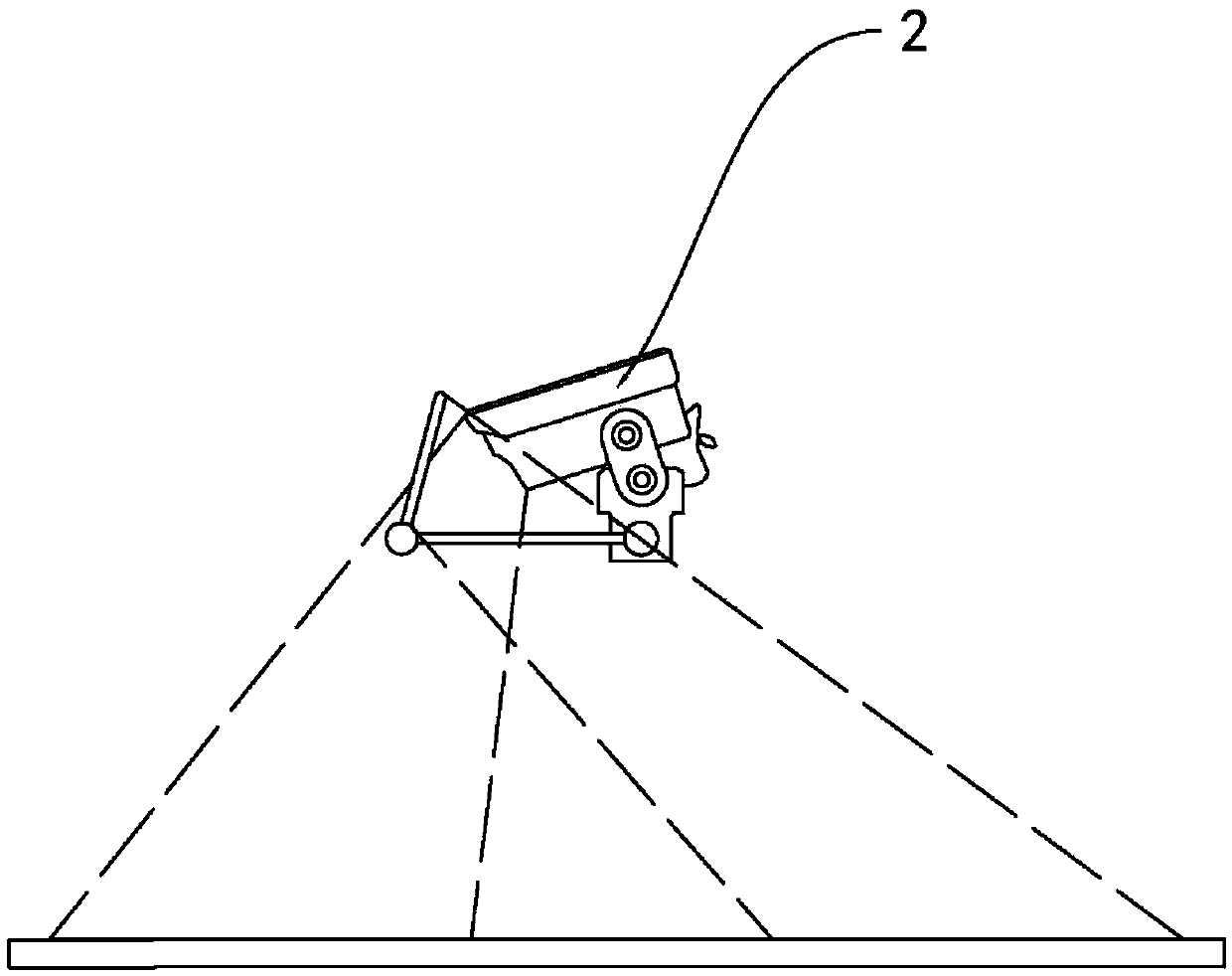

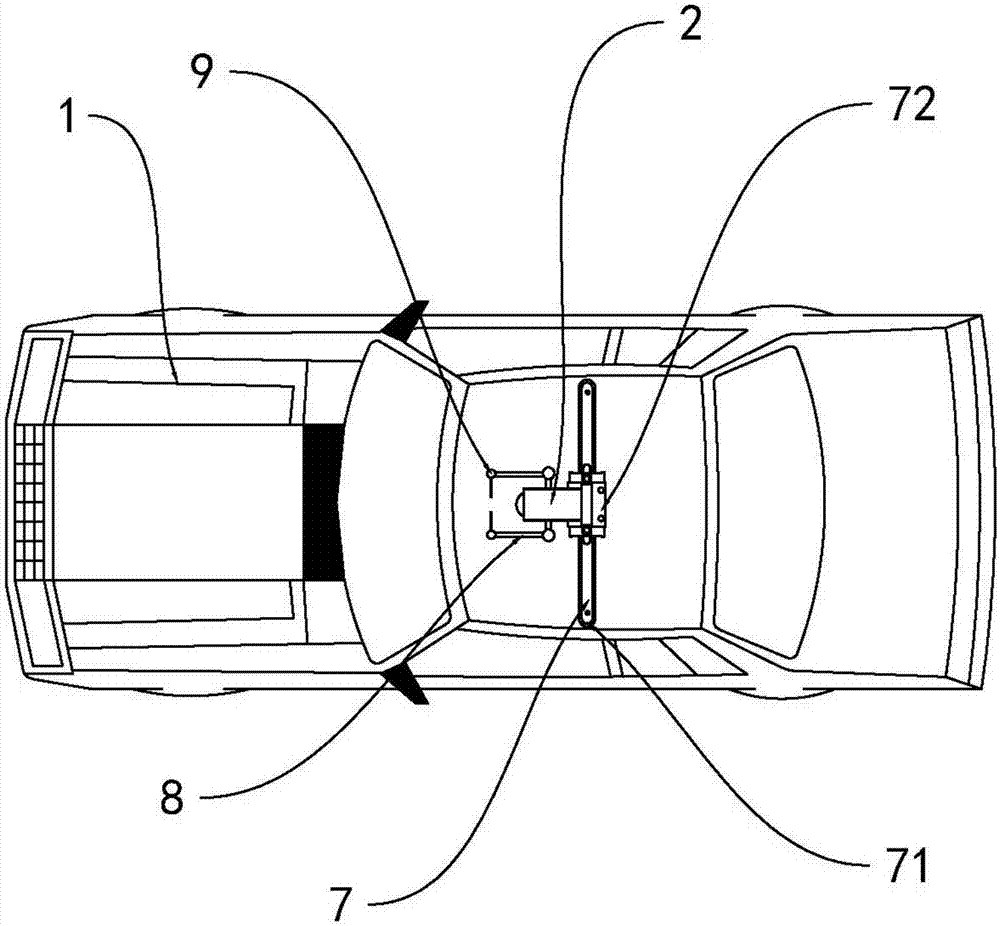

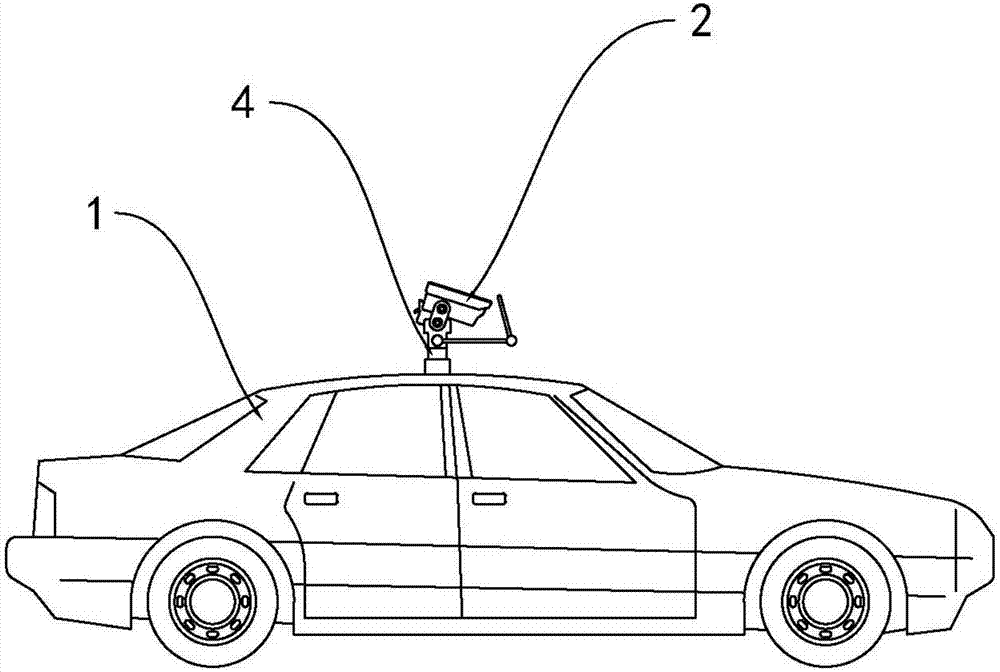

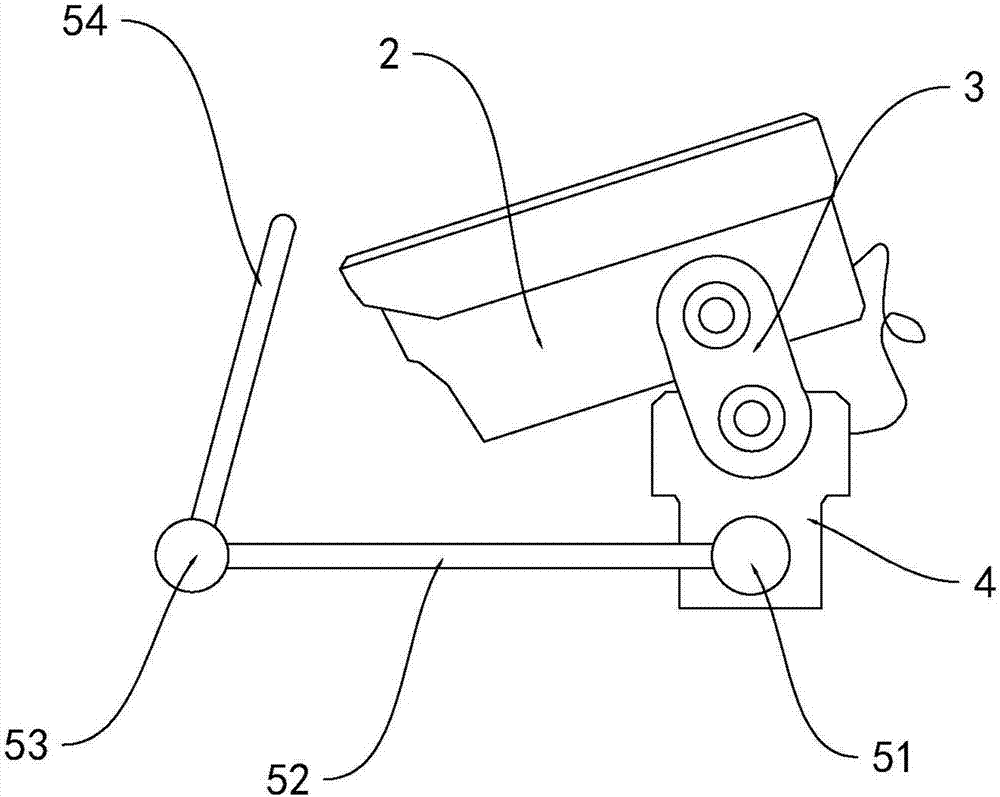

Portable mobile detection vehicle

InactiveCN107959830AImprove running stabilityExpand the detection rangeTelevision system detailsColor television detailsControl theoryMechanical engineering

The invention discloses a portable motion detection vehicle, and relates to the technical field of detection devices. The vehicle comprises a vehicle body, a camera, an angle adjustment rotating shaft, a support seat, and a reflection mechanism for expanding the monitoring range. The support seat is disposed at the top of the vehicle body, the camera is disposed on the support seat through the angle adjustment shaft, and the reflection mechanism is installed at one side of the camera. The reflection mechanism comprises a primary damping rotating shaft, a worm, a secondary damping rotating shaft, and a reflector. One end of the worm is connected with the support seat through the primary damping rotating shaft, and the reflector is connected with the worm through the secondary damping rotating shaft. The reflector is disposed in front of a side of the camera. The vehicle can achieve the bidirectional detection, and saves the cost.

Owner:SICHUAN GUANTENG TECH CO LTD

Portable wide angle bidirectional monitoring device

InactiveCN107835395AMonitoring blind area is largeExpand coverageTelevision system detailsColor television detailsEngineeringMonitor equipment

Owner:SICHUAN GUANTENG TECH CO LTD

Flame-retardant fabric with good ventilation effect

InactiveCN104799461AAnti-static hasSpecial rigidityCellulosic plastic layered productsWoven fabricsYarnViscose

The invention relates to a flame-retardant fabric with a good ventilation effect. The flame-retardant fabric comprises an upper cotton cloth layer (1) and a lower cotton cloth layer (2); a base layer (5) is compounded on the lower surface of the lower cotton cloth layer; an anti-static layer (3) is further arranged between the upper cotton cloth layer (1) and the lower cotton cloth layer (2); the anti-static layer is made from core spun silk fiber; the fiber comprises yarns (3.1) and metal wires (3.2); the metal wires wind the yarns; the surface of the upper cotton cloth layer is covered by a flame-retardant coating layer (4); the flame-retardant coating layer comprises a flame-retardant polyurethane layer (4.1) at the bottom and an organic silicone oil layer (4.2) on the top; the base layer is made from textile; the textile is formed by plainly weaving viscose silks and natural silks at a ratio of 1:1; the monofilament diameter of the viscose silk is 0.8-1.5 microns. The flame-retardant fabric with the good ventilation effect is relatively low in cost, variable in bending, and good in ventilation effect.

Owner:JIANGYIN GUORUN TEXTILE RAW MATERIALS SALES

Flame-retarding anti-stain breathable fabric

InactiveCN105584177ANot easy to stainWith breathable effectSynthetic resin layered productsMetal layered productsYarnEngineering

The invention relates to a flame-retarding anti-stain breathable fabric which includes an upper cotton cloth layer (1) and a lower cotton cloth layer (2). A base layer is laminated under the lower cotton cloth layer. An antistatic layer (3) is disposed between the upper cotton cloth layer and the lower cotton cloth layer and is made from core spun silk fibers. The core spun silk fiber includes a yarn (3.1) and a metal wire (3.2), wherein the metal wire twines the yarn. A flame-retarding coating layer (4) coats the surface of the upper cotton cloth layer and includes a flame-retarding polyurethane layer (4.1) in the bottom and an organic silicon oil layer (4.2) on the top. The base layer is made of a fabric, wherein a fluorine monomer aqueous polyurethane coating layer coats the surface of the fabric. The flame-retarding anti-stain breathable fabric is low in cost and is flexible and bendable. By coating the fabric with the fluorine monomer aqueous polyurethane coating layer, the fabric is anti-stain, and has waterproofing and breathable effects.

Owner:刘正华

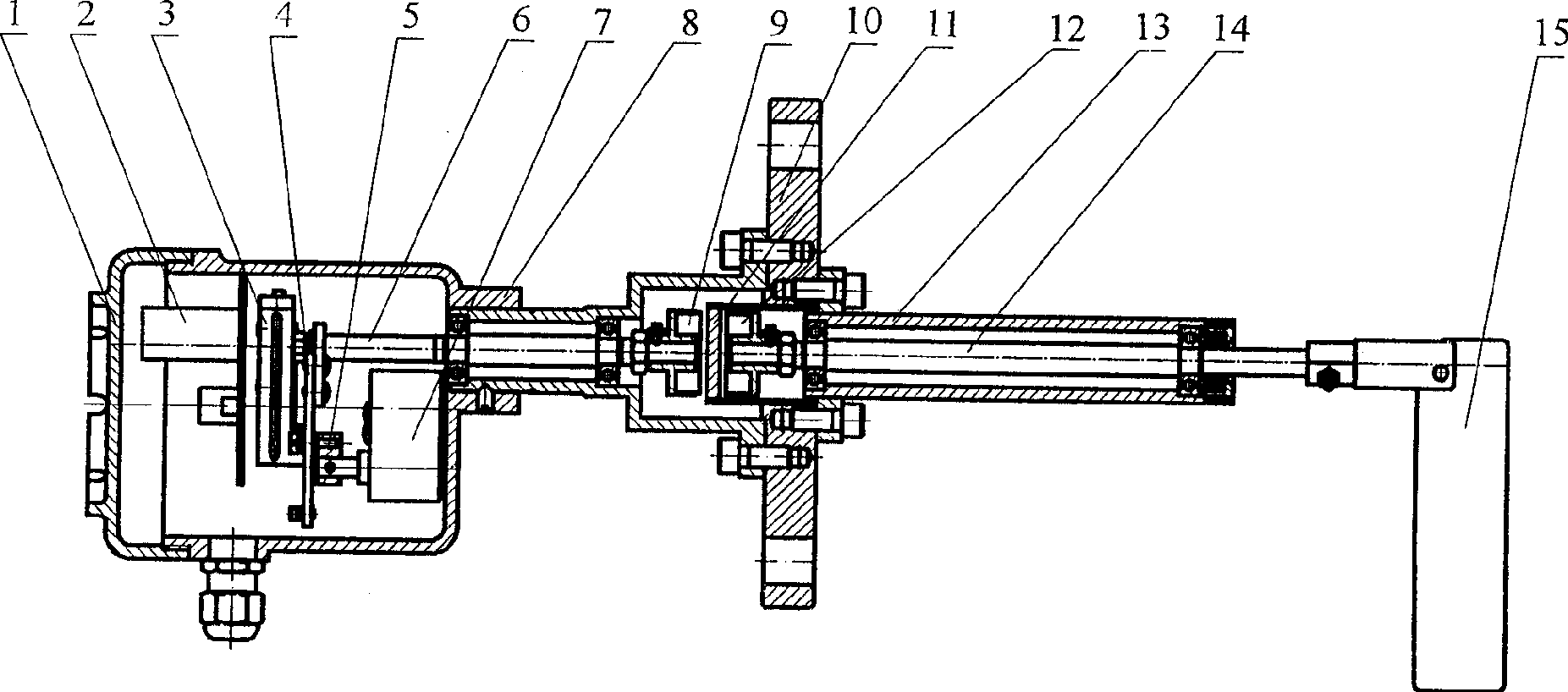

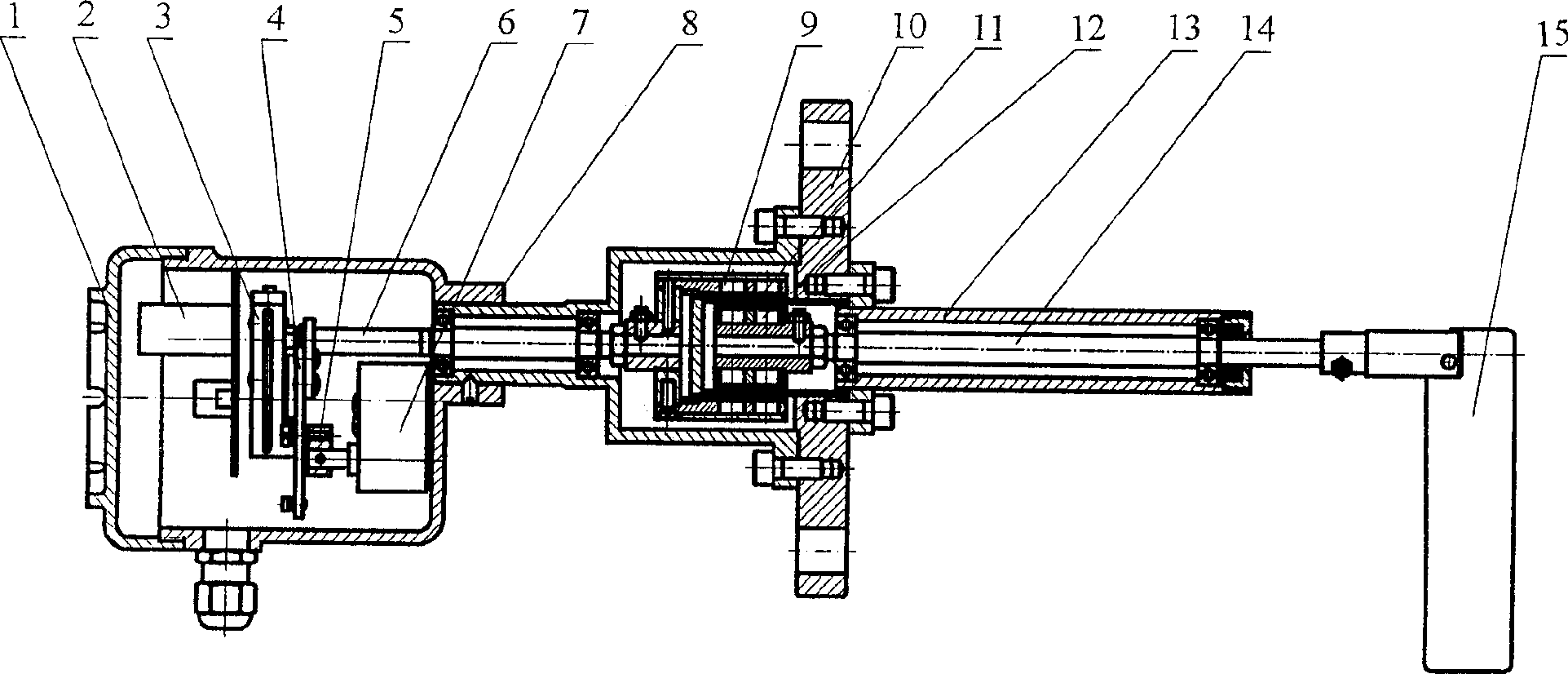

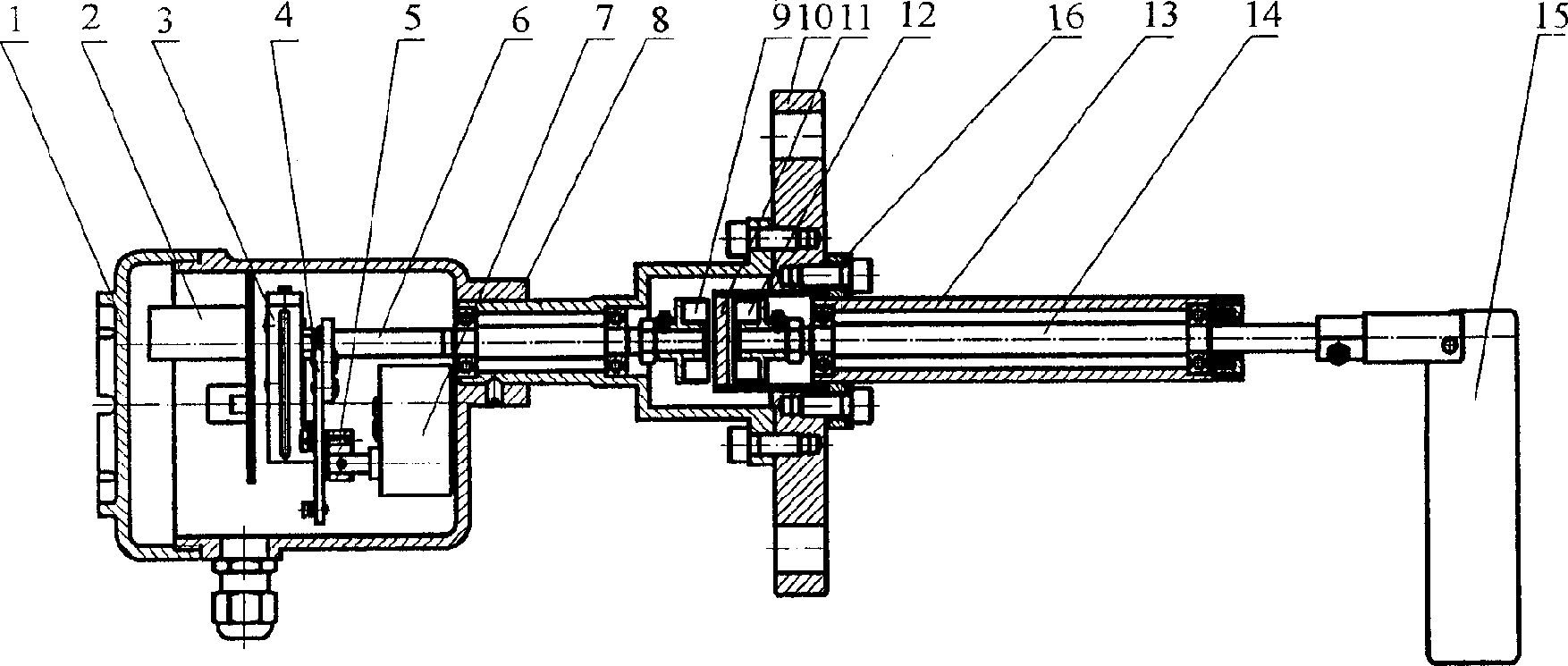

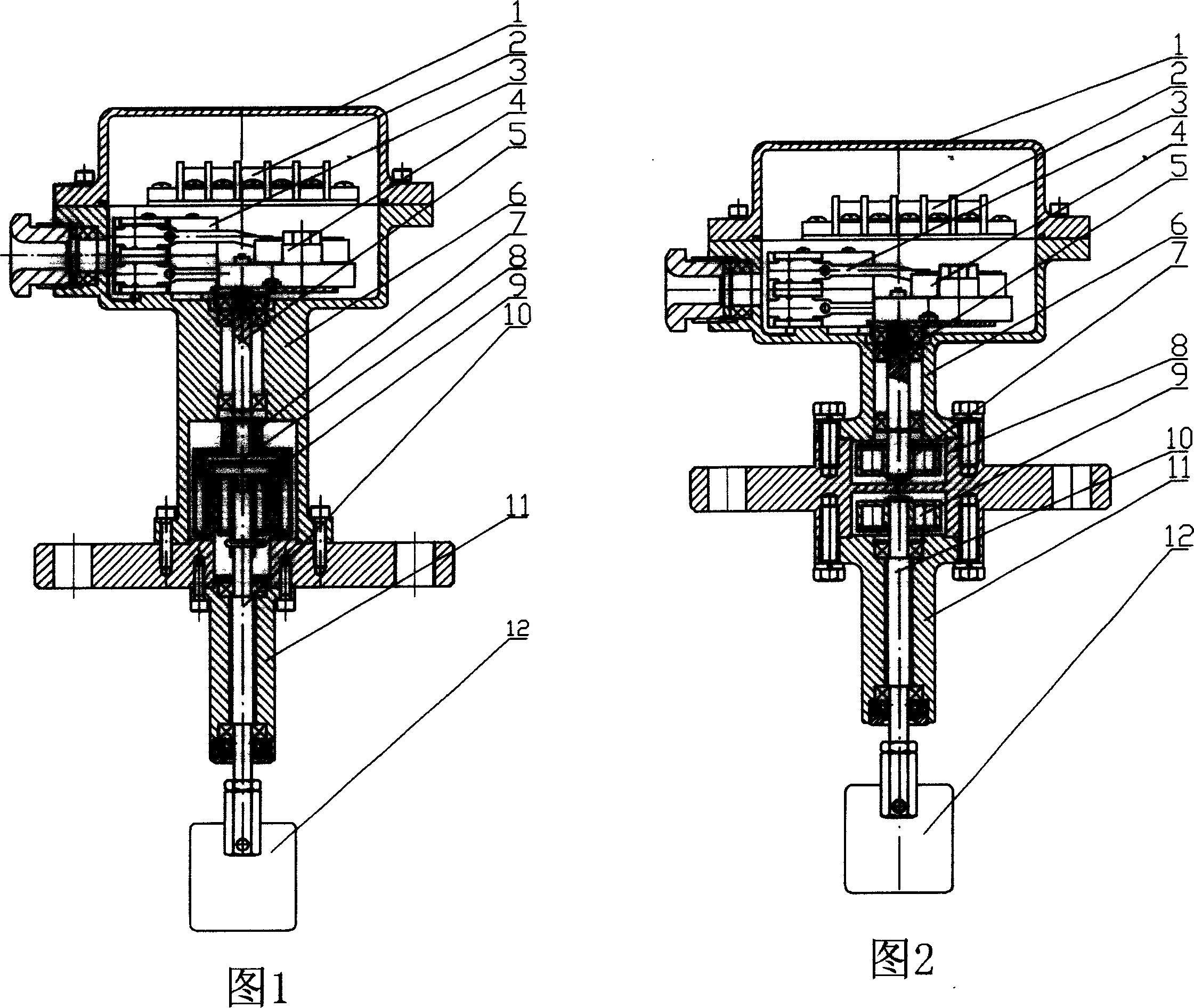

High-temperature high-pressure antistatic oscillating charge level controller

InactiveCN1908837ASolve the phenomenon that is prone to leakageWith high pressureLevel controlLower limitHigh pressure

The high-temperature high-pressure static-proof swing material position controller made from magnetic material comprises: a cover connected with a base by thread, a motor fixed on base, a fork assembly connected with one end of the shaft, a drive assembly I connected with one end of the shaft to drive a drive assembly II arranged on shaft cylinder assembly, the flange, an isolation sleeve, a checkup shaft / board, and a static-proof assembly between the cylinder assembly and flange. This invention has wide application.

Owner:张明

High temperature, high pressure, antistatic type impeding level controller

High-pressure, high-temperature anti-static resistance rotating material level controller relates to a material level controller, and the material level controller includes the cover, the electrical component, the axis A, the base, the drive component I, the separated set flange, the drive component II, the axis B, the axis cylinder, the detection plate component, and the antistatic component. Its cover connects with the base by thread, the electrical component connecting with the end of the axis A, and the drive component I connecting with the other end of the axis A to be fixed, and the drive component I drives the drive component II after the isolation of the separated set flange, the drive component II connecting with the end of the axis B to be fixed, and the axis cylinder is fixed on the separated set flange through bolt, the other end of the axis B connecting with the detection plate component, and between the axis cylinder and the separated set flange, there is the antistatic component. The invention is suitable for upper and lower threshold alarm of silo or dust clean equipment in the metallurgical, chemical, mining, power, road, food and environmental industries, with the characteristics of resisting high-temperature, high-pressure and antistatic.

Owner:张明

Anti-static workbench

ActiveCN105619352BAnti-static hasHigh temperature resistanceWork benchesElectrostatic chargesAir pumpEngineering

The invention discloses a workbench with a better anti-static effect. The workbench comprises a platen, a supporting frame, a baffle and a hinge four-rod mechanism; the platen is provided with an anti-static rubber table face layer, one end of a ground lead is connected with the platen, and the other end of the ground lead is grounded; a sliding groove is formed in the upper surface of the baffle, a sliding block is inlaid into the sliding groove, and a lighting lamp is fixed to the sliding block; a hook is arranged on the baffle, and an anti-static hand ring is hung on the hook; a drawer is fixed to the baffle, and an anti-static glove is installed in the drawer; an air pump is fixed to the baffle, one end of the air pipe is connected with the air pump, and an air valve is arranged at the other end of the air pipe; and the hinge four-rod mechanism is connected with an ion fan, and the beneficial effects of being reasonable and variable in anti-static precaution of the anti-static workbench and better in anti-static effect are achieved.

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

Mixed fabric with good usability

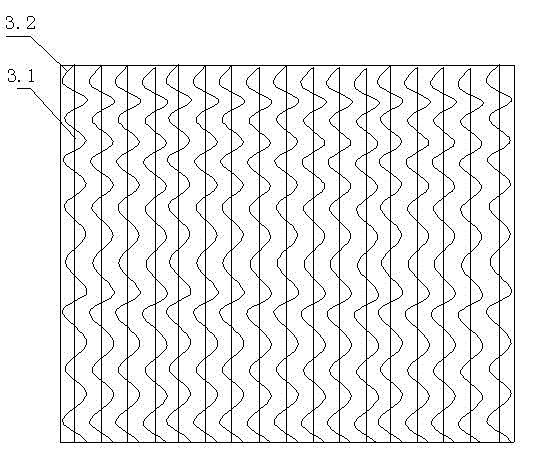

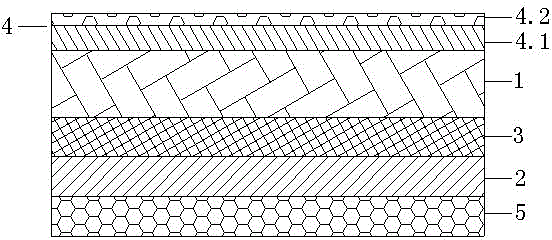

InactiveCN104786566AReasonable structureEasy to useWoven fabricsMetal layered productsYarnBiochemical engineering

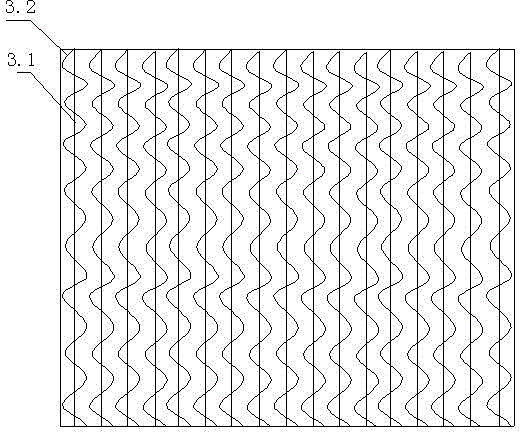

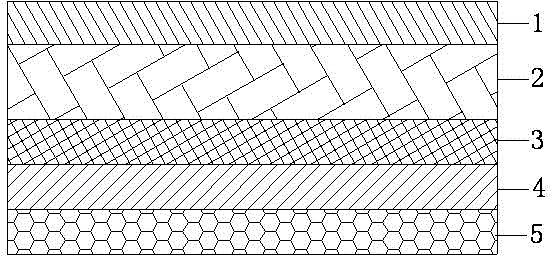

The invention relates to a mixed fabric with good usability. The mixed fabric comprises a pure cotton fabric (1); a bamboo charcoal fiber layer (2) is arranged on the lower surface of the pure cotton fabric (1); an anti-static layer (3) is arranged on the lower surface of the bamboo charcoal fiber layer (2), and is made of core spun silk fibers; the core spun silk fibers comprise yarns (3.1) and metal wires (3.2); the metal wire (3.2) are wound on the yarns (3.1); the bottom of the anti-static layer (3) is coated with a layer of blended fabric (4) which is formed by blending of soybean fibers and pure cotton fibers; a base layer (5) is compounded on the lower surface of the blended fabric (4), and is made of a textile; the warps and the wefts of the textile adopt wool fibers and coconut fibers respectively; the diameter of the wool fibers is 9 [mu]m; the diameter of the coconut fibers is 10 [mu]m; the warp density of the textile is 26.6 threads / cm; the weft density of the textile is 31.3 threads / cm. The mixed fabric has low probabilities of shrinkage and crinkle; the adopted fabric construction is reasonable; the service performance is good.

Owner:JIANGYIN HANXIN TEXTILE

Blended fabric with lasting elasticity

The invention relates to blended fabric with lasting elasticity. The blended fabric comprises pure cotton fabric (1), wherein a bamboo charcoal fiber layer (2) is arranged under the pure cotton fabric (1); an anti-static layer (3) is arranged under the bamboo charcoal fiber layer (2), and made of core spun silk fibers; the core spun silk fibers comprise yarn (3.1) and metal silk (3.2); the metal silk (3.2) is wound on the yarn (3.1); a blended fabric layer (4) covers the bottom of the anti-static layer (3), and is formed by blending soybean fibers and pure cotton fibers; a substrate (5) is arranged under the blended fabric layer (4) in a blended manner, and made of fabric; the fabric is formed by interweaving warp silk and tram silk ups and downs; the warp silk is inelastic yarn; the tram silk is elastic yarn, and comprises first warp silk and second warp silk. The blended fabric is lasting in fabric elasticity and particularly good in anti-crease effect.

Owner:JIANGYIN DONGFA GARMENT MAKING

Mixed fabric capable of effectively preventing electromagnetic wave

InactiveCN104786571AAvoid harmGood radiation protectionCellulosic plastic layered productsMetal layered productsYarnEngineering

The invention relates to a mixed fabric capable of effectively preventing an electromagnetic wave. The mixed fabric comprises a pure cotton fabric (1), wherein a bamboo charcoal fiber layer (2) is arranged below the pure cotton fabric (1); an anti-static layer (3) is arranged below the bamboo charcoal fiber layer (2); the anti-static layer (3) is prepared from core-spun yarn fiber; the core-spun yarn fiber comprises yarns (3.1) and metal wires (3.2); the yarns (3.1) are wound by the metal wires (3.2); a layer of blended fabric (4) covers the bottom of the anti-static layer (3); the blended fabric (4) is formed by blending soybean fiber with pure cotton fiber; a basic layer (5) is compounded below the blended fabric (4); the basic layer is prepared from a fabric; the fabric is formed by interweaving warps and wefts; the warps are prepared from nanometer metallic shield fiber yarns, and the wefts are prepared from tencel fiber yarns. The mixed fabric disclosed by the invention is low in possibility of shrinkage and ruffle, good in anti-radiation performance, and capable of effectively preventing a human body from being hurt by the electromagnetic wave.

Owner:JIANGYIN YASHUN GARMENT

Flame-retardant multi-color fabric

InactiveCN104783379AMeet different needsAnti-static hasFibre treatmentWoven fabricsEngineeringCotton cloth

The invention relates to a flame-retardant multi-color fabric. The flame-retardant multi-color fabric comprises an upper cotton cloth layer (1) and a lower cotton cloth layer (2). A base player (5) is combined to the lower face of the lower cotton cloth layer (2). An anti-static layer (3) is further arranged between the upper cotton cloth layer (1) and the lower cotton cloth layer (2) and is made of core spun silk fibers. The fibers comprise yarns (3.1) and metal wires (3.2). The metal wires (3.2) are wound around the yarns (3.1). The surface of the upper cotton cloth layer (1) is covered with a flame-retardant coating (4). The flame-retardant coating (4) comprises a flame-retardant polyurethane layer (4.1) at the bottom and an organic silicon oil layer (4.2) at the top. The base layer (5) is made of a fabric. The fabric comprises first weft yarns, second weft yarns and warp yarns. The first weft yarns are wound around the warp yarns from the left side, the second weft yarns are wound around the warp yarns from the right side with the same latitude, and the first weft yarns and the second weft yarns share one of the warp yarns and are different. The flame-retardant multi-color fabric is low in cost, bendable and deformable, and has multiple colors.

Owner:JIANGYIN HONGWEI QINGSHAN SPINNING

Anti-static epoxy ester modified styrene-acrylic resin anti-corrosion coating

InactiveCN110591492ASolve the problem of insufficient compactnessImprove anti-corrosion performanceAnti-corrosive paintsElectrically-conductive paintsEpoxyBenzoyl peroxide

The invention relates to the technical field of anti-corrosion and anti-static coating, and discloses an anti-static epoxy ester modified styrene-acrylic resin anti-corrosion coating, which comprisesthe following raw materials in parts by weight: epoxy ester modified styrene-acrylic resin, modified styrene-acrylic resin curing agent, catalyst, distilled water, filler, cosolvent and 0.1-0.3 partsof organic silicone defoamer, wherein the modified styrene-acrylic resin curing agent is hydrophilic polyamide curing agent and the catalyst is benzoyl peroxide. According to the antistatic epoxy ester modified styrene-acrylic resin anticorrosive coating, the epoxy ester modified styrene-acrylic resin is formed by using epoxy resin and gamma-linoleic acid as raw material to synthesize styrene-acrylic emulsion and in the process of emulsion film formation, it can be further crosslinked and cured, which can solve the problem of insufficient compactness of the coating film and improve the anti-corrosion performance. The catalyst is benzoyl peroxide, and a small amount of polyacyl ester benzene methyl acrylate polymer is generated to form a network conductive network, so that the emulsion hasstable conductive performance, thus the coating has anti-static function.

Owner:厦门珉瑶贸易有限公司

Flame-retardant and fluorescent luminescent fabric

InactiveCN104890314AEasy to manufactureLight structureSynthetic resin layered productsMetal layered productsYarnFluorescence

The invention relates to a flame-retardant and fluorescent luminescent fabric, which comprises an upper cotton cloth layer (1) and a lower cotton cloth layer (2). A basement layer (5) is compounded onto the lower surface of the lower cotton cloth layer. An anti-static layer (3) is arranged between the upper cotton cloth layer (1) and the lower cotton cloth layer (2). The anti-static layer is prepared by core-spun silk fibers. The fibers are composed of yarns (3.1) and metal wires (3.2). The metal wires are wound around the yarns. A flame-retardant coating (4) is covered onto the surface of the upper cotton cloth layer. The flame-retardant coating comprises a bottom flame-retardant polyurethane layer (4.1) and a top organic silicon oil layer (4.2). The basement layer is prepared by the fabric. The fabric comprises a fabric body, an intermediate layer and a light-emitting body, wherein the intermediate layer and the light-emitting body are disposed on the fabric body successively. The back surface of the light-emitting body is provided with a bonding layer. The front surface of the light-emitting body is provided with a fluorescent surface layer. The flame-retardant and fluorescent luminescent fabric is low in cost, bendable and variable. Meanwhile, the fabric is capable of emitting light, and is simple in structure, light in weight, convenient and flexible to use, easy to manufacture and long in service life. The fabric can be freely arranged according to requirements.

Owner:JIANGYIN FANRONG YARN DYE FABRIC

Blended fabric with better dimensional stability

InactiveCN105615081ABig spaceIncrease elasticitySynthetic resin layered productsWoven fabricsPolyesterMetal filament

The invention relates to blended fabric with better dimensional stability. The blended fabric comprises pure cotton fabric (1), wherein a bamboo charcoal fiber layer (2) is arranged under the pure cotton fabric (1); an anti-static layer (3) is arranged under the bamboo charcoal fiber layer (2) and is made of core spun silk fibers, the core spun silk fibers comprise yarn (3.1) and metal filaments (3.2), and the yarn (3.1) is wound with the metal filaments (3.2); the bottom of the anti-static layer (3) is covered with a blended cloth layer (4) which is prepared from soybean fibers and pure cotton fibers through blending, and a base layer (5) is compounded under the blended cloth layer (4). The base layer is made of fabric, the fabric is formed through interweaving of warp yarn and weft yarn, the warp yarn and the weft yarn are arranged in a two-up and two-down mode, and the warp yarn adopts 50D / 72F polyester drawn textured yarn; the blended yarn is not prone to shrinking and creasing and has the better dimensional stability.

Owner:JIANGYIN FANGLONG FINERY HANDICRAFT

Flame-retarding ceramic-particle-exposed textile fabric

InactiveCN105584160AAnti-static hasSpecial rigiditySynthetic resin layered productsCeramic layered productsYarnSurface layer

The invention relates to a flame-retarding ceramic-particle-exposed textile fabric which includes an upper cotton cloth layer (1) and a lower cotton cloth layer (2). A base layer is laminated under the lower cotton cloth layer. An antistatic layer (3) is disposed between the upper cotton cloth layer and the lower cotton cloth layer and is made from core spun silk fibers. The core spun silk fiber includes a yarn (3.1) and a metal wire (3.2), wherein the metal wire twines the yarn. A flame-retarding coating layer (4) covers the surface of the upper cotton cloth layer and includes a flame-retarding polyurethane layer (4.1) in the bottom and an organic silicon oil layer (4.2) on the top. The base layer is made of a fabric which is composed of a base layer, a middle layer and a surface layer, wherein the base layer is integrated with the surface layer through the middle layer. Among the base layer and the surface layer, at least the surface layer is mesh cloth. The textile fabric is low in cost and is flexible and bendable. The textile fabric has excellent health-caring effects and has a cool feel since some of the ceramic particles are exposed.

Owner:JIANGYIN YONGLONG PLASTICS

Mobile detection device with adjustable angle

InactiveCN108012120AImprove running stabilityExpand the detection rangeTelevision system detailsColor television detailsEngineeringLarge range

Owner:SICHUAN GUANTENG TECH CO LTD

Flame retardant composite textile fabric

InactiveCN105644046AAnti-static hasSpecial rigiditySynthetic resin layered productsMetal layered productsFiberYarn

The present invention relates to a flame retardant composite textile fabric including an upper cotton cloth layer (1) and a lower cotton cloth layer (2), a base layer (5) is compounded under the lower cotton cloth layer, an anti-static layer(3) is arranged between the upper cotton cloth layer (1) and the lower cotton cloth layer (2), the anti-static layer(3) is made from core-spun yarn fiber, the core-spun yarn fiber includes a yarn (3.1) and a metal wire (3.2), the metal wire winds the yarn, the surface of the upper cotton cloth layer (1) is covered with a layer of fire-retardant coating (4), and the fire-retardant coating (4) comprises a bottom fire-retardant polyurethane layer (4.1) and a top silicone oil layer (4.2). The base layer is made of a fabric, the fabric comprises a machine-woven fabric and a knitted fabric, the machine-woven fabric and the knitted fabric are bonded together by an adhesive. The flame retardant composite textile fabric is low in cost and bending-variable. One side of the flame retardant composite textile fabric is the machine-woven fabric, and the other side of the flame retardant composite textile fabric is the knitted fabric, so that garments prepared from the flame retardant composite textile fabric can be used in both sides, and are different in styles, novel and unique.

Owner:吴建平

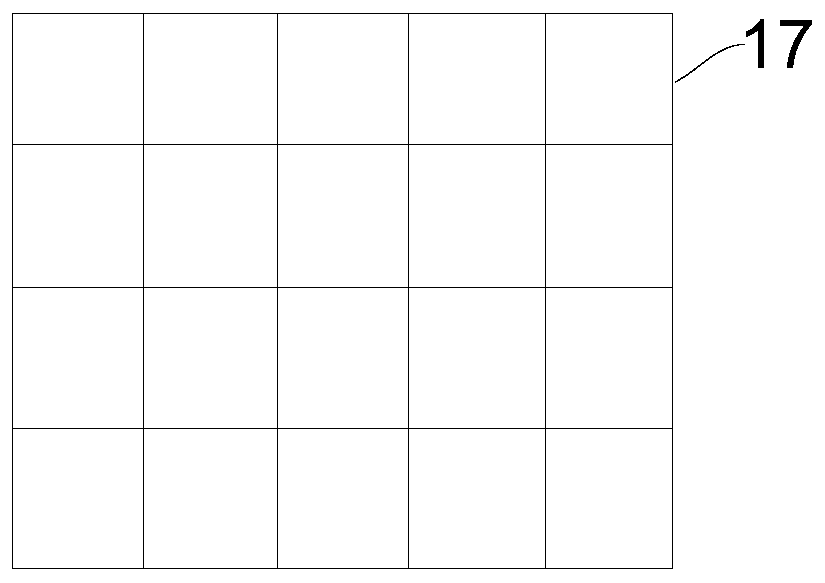

A kind of antistatic paint and environmental protection antistatic floor

ActiveCN107964326BImprove stabilityImprove adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsFirming agentPolymer chemistry

Belonging to the building field, the invention relates to an antistatic paint and an environment-friendly antistatic terrace. The antistatic paint comprises the a first raw material and a second raw material in a weight ratio of 20-40:60-80, wherein the first raw material comprises a waterborne epoxy curing agent, a dispersant, a conductive agent and deionized water in a weight ratio of 60-80:0.1-0.5:5.1-10.5:9-34.8, and the second raw material includes epoxy resin, an active diluent and a defoamer in a weight ratio of 70-90:9.2-29.8:0.2-0.8. The antistatic paint has excellent electrical conductivity, hardness and antistatic effect. The environment-friendly antistatic terrace includes a concrete base layer, an antistatic primer layer compounded on the concrete base layer, and an antistaticfinishing paint layer compounded on the antistatic primer layer, and the primer used by the antistatic primer layer is the antistatic paint. The environment-friendly antistatic terrace provided by the invention has the characteristics of antistatic properties, strong surface hardness and long service life.

Owner:上海牧桔新型材料有限公司

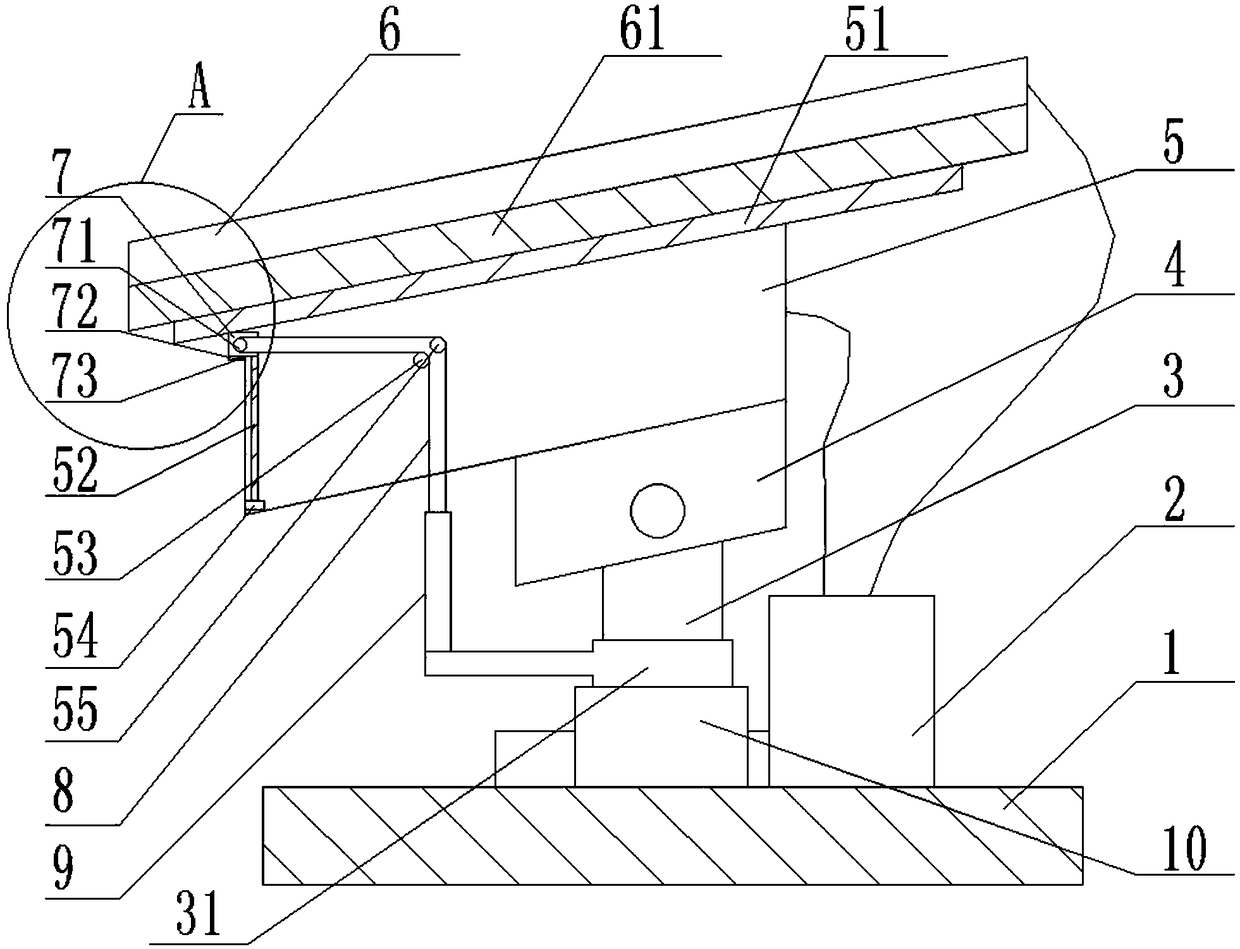

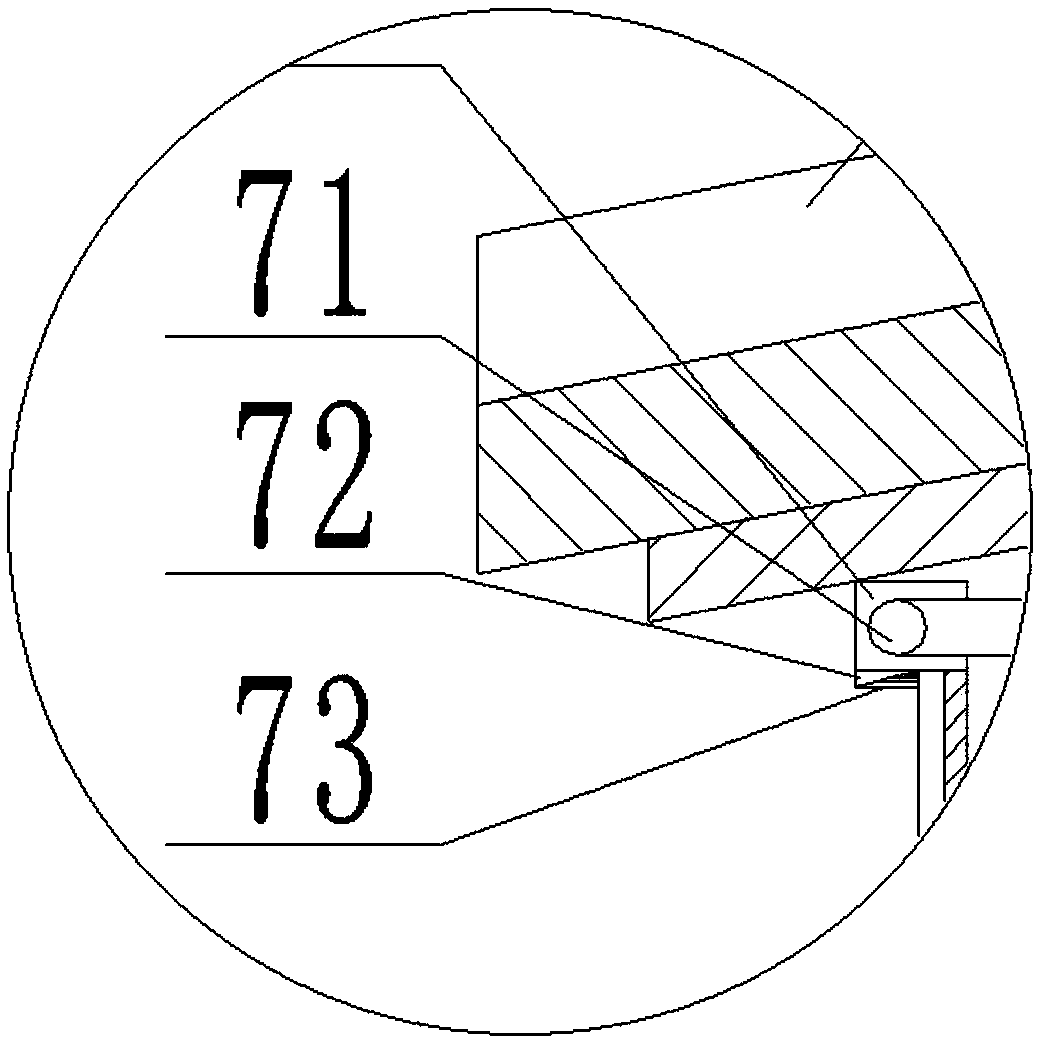

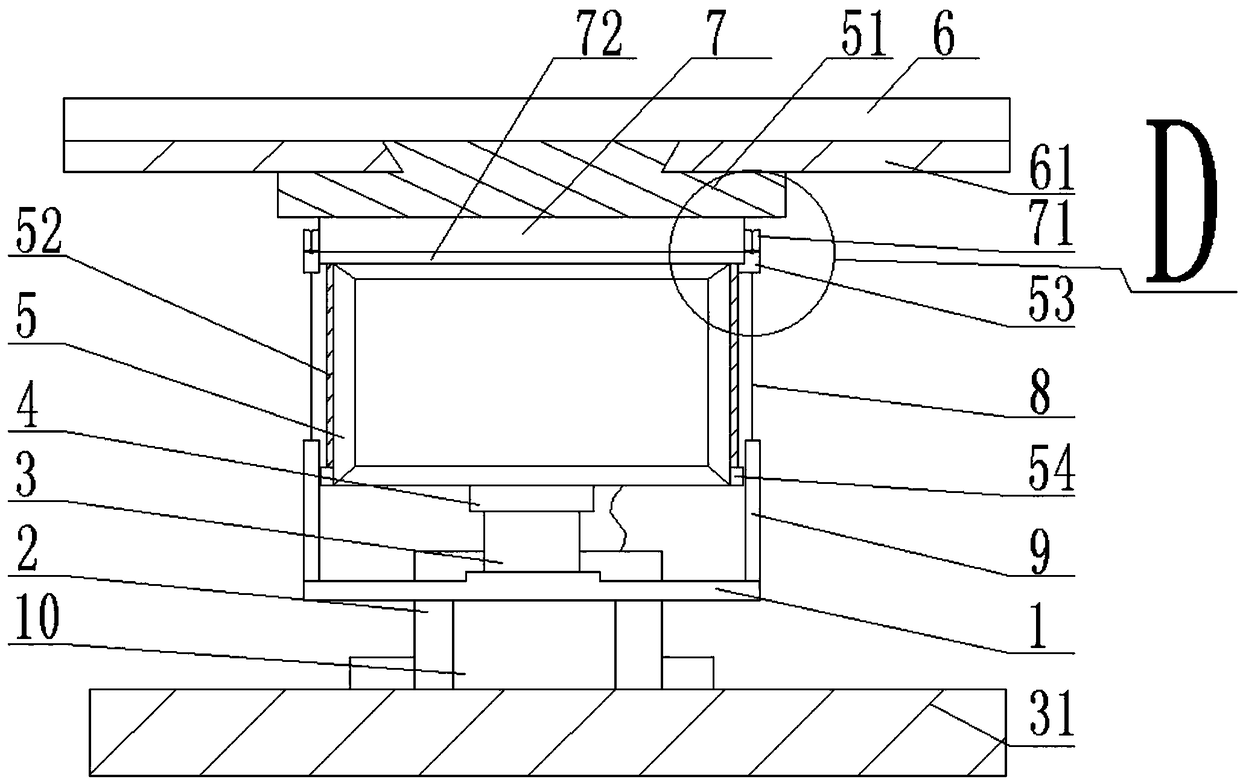

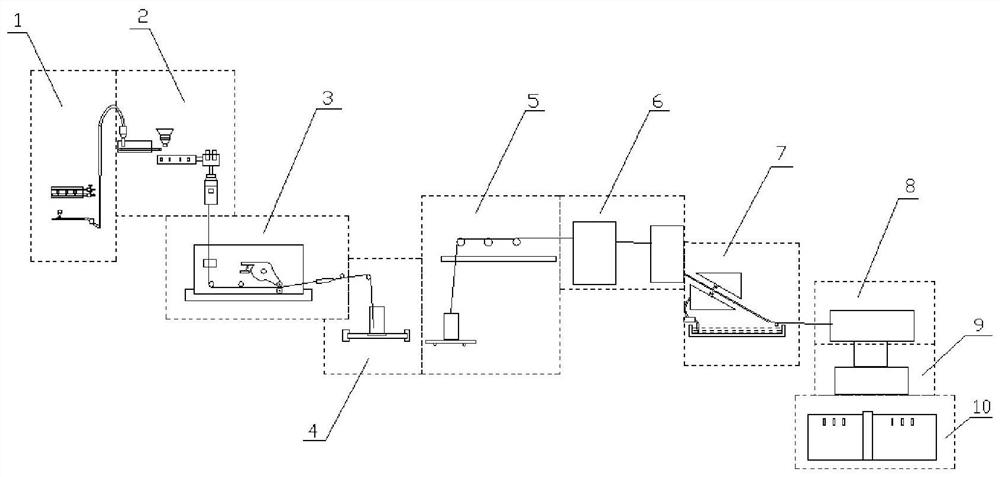

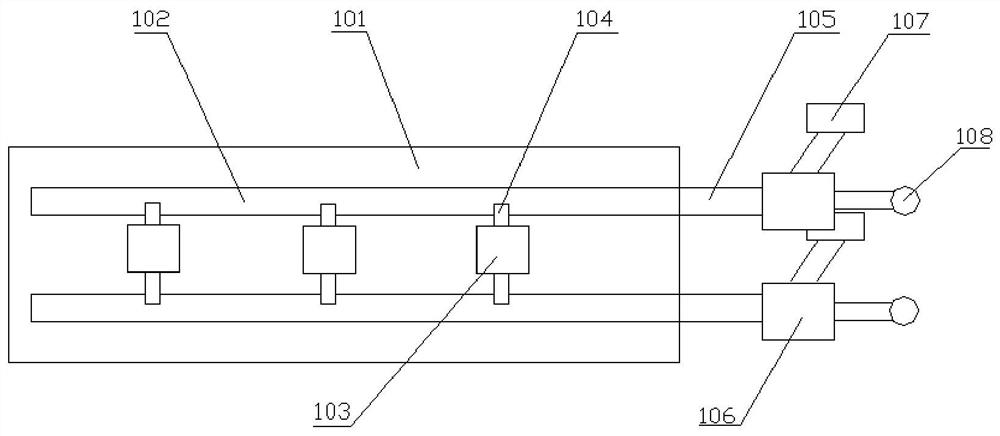

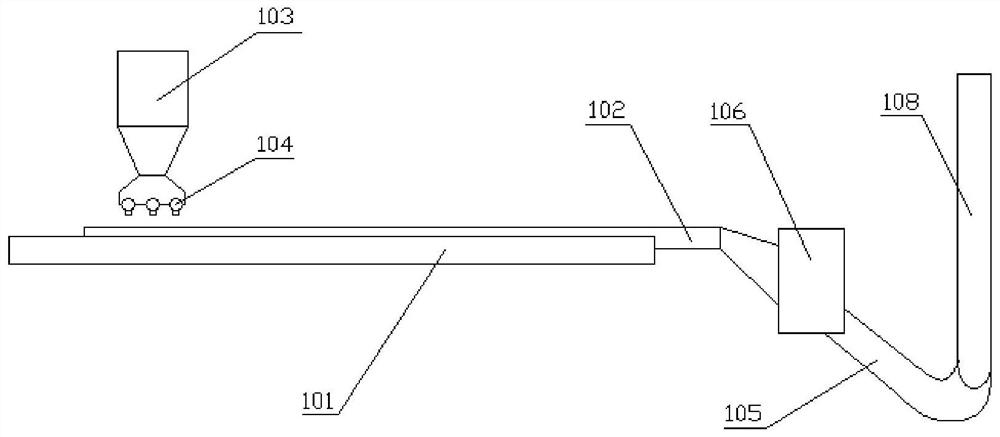

A kind of fibril preparation process and the pet fiber that this process makes

ActiveCN108977905BImprove the ratio accuracyHigh precisionSpinning solution de-aeratingNew-spun product collectionFiberPolymer science

The invention relates to filament preparation technology and PET fibers acquired by the technology. The technology comprises following steps: step 1, mixing raw material through a material mixing mechanism and then pouring the material to an extrusion mechanism; step 2, heating and melting raw material by the extrusion mechanism and performing filament drawing operation; step 3, oiling drawn silkthreads through a drawing and picking mechanism and conveying the threads to a material collecting mechanism; step 4, guiding the silk threads by the material collecting mechanism to a bundling drum;step 5, moving the bundling drum besides a bundling mechanism and guiding silk threads in the bundling drum to an extending mechanism to extend the threads; step 6, oiling the drawn and extended silkthreads through a curling oil-spray mechanism; step 7, cutting some of the oiled silk threads by a cutting mechanism to be short fibers; step 8, precisely weighing short fibers through a discharge mechanism so that the fibers drop down to a packing mechanism; step 9, packing short fibers by the packing mechanism. The filament preparation technology and PET fibers acquired by the technology are high in production efficiency, excellent in production quality and good in antibacterial effect.

Owner:TAKAYASU IND JIANGYIN CO LTD

Anti-flaming anti-static audio/video wire

InactiveCN108892896AAnti-static hasImprove flame retardant performancePlastic/resin/waxes insulatorsFiberCarbon fibers

The invention discloses an anti-flaming anti-static audio / video wire which is made from polyvinyl chloride, fire retardant, anti-static agent, dispersing agent, filling agent and plasticizer, whereinmagnesium hydroxide is served as the fire retardant; fatty alcohol-polyoxyethylene ether is served as the anti-static agent; an ethylene-vinyl acetate copolymer is served as the dispersing agent; a carbon fiber is served as the filling agent; triethylene glycol dibenzoate is served as plasticizer; the weight parts of the components of the anti-flaming anti-static audio / video wire are as follows: 68-79 parts of polyvinyl chloride, 4-9 parts of magnesium hydroxide, 2-7 parts of fatty alcohol-polyoxyethylene ether, 1-6 parts of ethylene-vinyl acetate copolymer, 21-27 parts of carbon fiber and 3-8parts of triethylene glycol dibenzoate. The anti-flaming anti-static audio / video wire has the characteristics of excellent fire resistance, anti-static property, high strength, excellent abrasive resistance, processing convenience and high safety.

Owner:苏州兆能精密弹簧五金有限公司

Anti-static guide mechanism of insulated paper board laminating machine

The invention relates to an anti-static guide mechanism of an insulated paper board laminating machine, which comprises a guide frame base plate, a corner bracket and a guide pad. The guide frame base plate is arranged outside a moving table, the outer end of the guide frame base plate is fixedly connected with an external frame plate by socket head screws, the inner end of the guide frame base plate is connected with the corner bracket, and the guide pad is arranged on the lower part of the corner bracket; inner corners of the corner bracket are connected with the moving table by socket head screws with spring washers, and a cylindrical pin is arranged between the corner bracket and the moving table. By using the guide pad and the guide base plate which are formed by grinding special materials, the anti-static guide mechanism achieves good lubricating condition and has the effects of static and dust prevention.

Owner:王荣伟

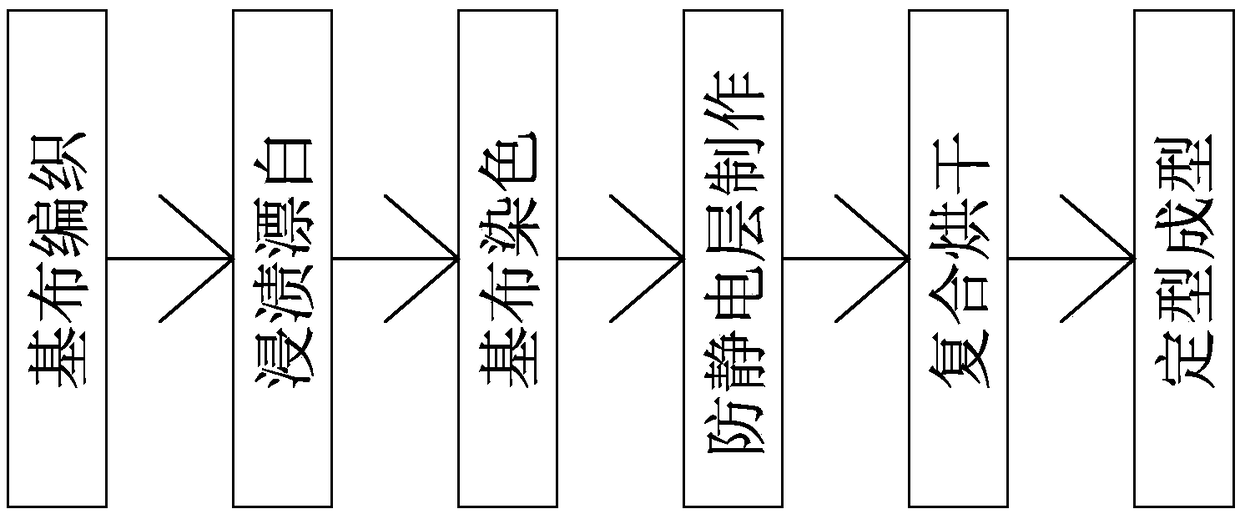

Manufacturing process of anti-static lace composite fabric

InactiveCN108340644AAnti-static hasAvoid situations where you cannot connect to each otherLamination ancillary operationsWeft knittingYarnWhitening Agents

The invention provides a manufacturing process of an anti-static lace composite fabric, and belongs to the technical field of fabrics. The invention solves the problem of low production quality in theprior art. The manufacturing process of the anti-static lace composite fabric comprises the following steps: S1, weaving a base cloth: weaving the base cloth by using bottom-comb yarns and pattern-comb yarns through a knitter, wherein the bottom-comb yarns and the pattern-comb yarns are both made of mulberry silk; S2, carrying out dipping and bleaching: putting the base cloth obtained in the S1 into a dipping cylinder for dipping, and adding a whitening agent, wherein the weight of the whitening agent is 2% of the weight of the base cloth, and the soaking time is 1-2 hours; S3, dyeing the base cloth: putting the base cloth obtained in S2 into a dyeing cylinder for dyeing, wherein the dyeing time is 5-6 hours; and S4, manufacturing the anti-static layer: weaving the anti-static layer by using warps and wefts, wherein the warps and wefts are both cotton threads. The manufacturing process provided by the invention has the advantages of improving production quality.

Owner:海宁市金义服饰有限公司

Flame retardant fabric material with patterns

InactiveCN104859212AAnti-static hasSpecial rigiditySynthetic resin layered productsMetal layered productsYarnEngineering

The invention relates to a flame retardant fabric material with patterns. The flame retardant fabric material with the patterns comprises an upper cotton cloth layer (1) and a lower cotton cloth layer (2), a base layer (5) is arranged under the lower cotton cloth layer in a composite mode, an anti-static layer (3) is disposed between the upper cotton cloth layer and the lower cotton cloth layer, the anti-static layer is made of core spun silk fibers, the fibers comprise yarns (3.1) and metal silks (3.2), the metal silks wind the yarns, a flame retardant coating (4) cover surface of the upper cotton cloth layer, and the flame retardant coating comprises a flame retardant polyurethane layer (4.1) at the bottom and an organic silicone oil layer (4.2) at the top. The base layer is made of fabrics which are formed by interweaving of warps and wefts, the structure of the fabrics is a 3 / 1 interweaving twill weave structure, the warps are 800D dacron super bright FDY, the wefts are 800D dacron super bright FDY, the warp density is 25 / cm, the weft density is 16 / cm, and spinning twists of the warps are 180 / m. The flame retardant fabric material with the patterns has the advantages that the costs are low, and the material can be bent and changed. The patterns of the fabrics are formed through change of the fabric woven structure, and dyeing is not required after weaving is finished.

Owner:JIANGYIN BETTER TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com