Workbench with better anti-static effect

An anti-static, workbench technology, applied in workbench, static electricity, electrical components and other directions, can solve the problems of poor anti-static effect, single anti-static measures, etc., to achieve good anti-static effect, reasonable and diverse anti-static measures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

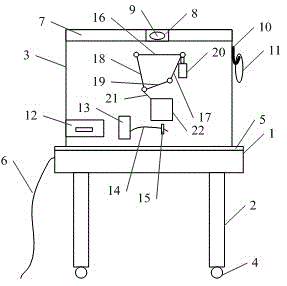

[0024] In Embodiment 1, a workbench with better anti-static effect is provided, please refer to figure 1 , the workbench includes:

[0025] Platen 1, support frame 2, baffle plate 3, hinge four-bar mechanism, the upper end of the support frame is connected with the lower surface of the platen, the lower end of the support frame is provided with a caster with brake 4, and the lower end of the baffle plate is connected with the lower surface of the platen. The side of the platen is connected, the platen is provided with an antistatic rubber table top layer 5, one end of the grounding wire 6 is connected to the platen, and the other end of the grounding wire is grounded; the upper surface of the baffle is provided with The chute 7 is inlaid with a slide block 8, the slide block is fixed with a light 9; the baffle is provided with a hook 10, and the hook is hung with an anti-static bracelet 11; A drawer 12 is fixed on the baffle, and antistatic gloves are housed in the drawer; an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com