Biodegradable anti-static macromolecule composite material and preparation method of the same

A technology of biodegradation and composite materials, which is applied in the field of antistatic polymer composite materials and their preparation, and polymer composite materials, can solve the problems of not having the advantages of general promotion, narrow application range, and inability to produce large-scale production, and achieve good results. Anti-static performance and mechanical properties, good molding performance, suitable for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

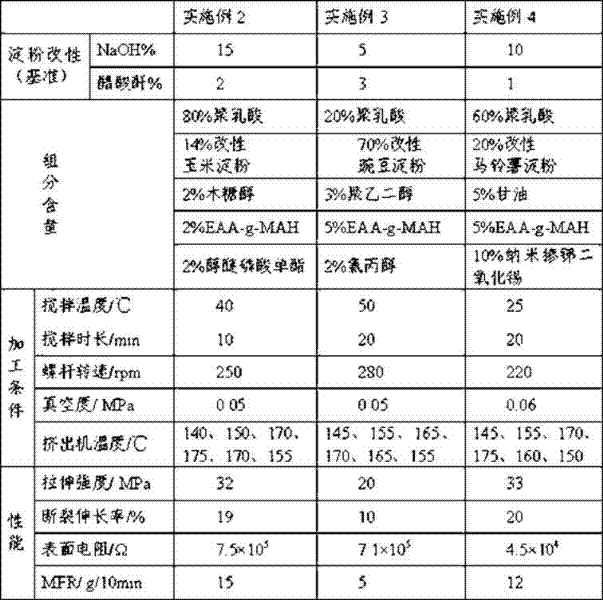

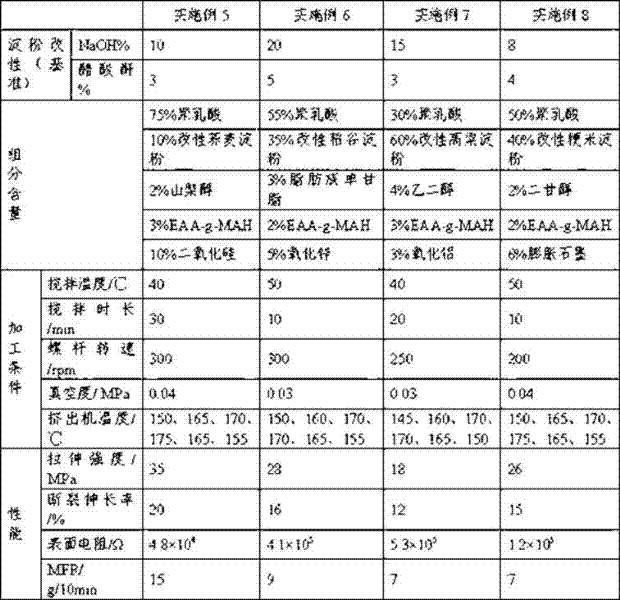

Examples

Embodiment 1

[0032] 1) Mix tapioca starch, 10% by weight relative to tapioca starch, and 10% NaOH solution in a beaker, then move the mixed material into a reaction flask, and install the flask into a MAS-I atmospheric pressure microwave In the auxiliary synthesis reactor, after stirring at 75°C and 250r / min for 3 minutes, add 3% acetic anhydride relative to the weight of tapioca starch into the separatory funnel, keep the temperature and rotation speed constant, and carry out the esterification reaction inside. After the end, wash the reaction product repeatedly with distilled water to pH 6-7. After cooling down and discharging the material, dry it at room temperature to constant weight. Grind the dried sample into powder to obtain modified tapioca starch for use (in this step, react The temperature should not be too high or too low, the side reaction will be accelerated if the temperature is too high, and the starch esterification reaction will be insufficient if the temperature is too lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com