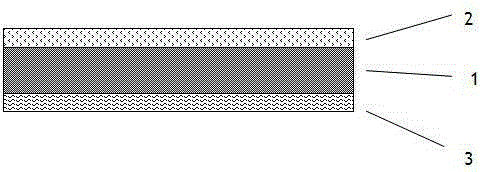

Polyester film base for dry type medical film

A technology of polyester film base and film, applied in the field of medical film, can solve the problems of poor machine performance, lengthy steps, poor smoothness and anti-static effect, etc. Effects of slip properties and antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

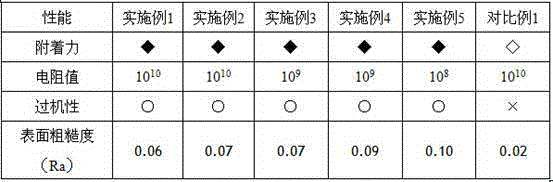

Embodiment 1

[0044] Preparation of bottom coating solution:

[0045]Firstly mix 10g of deionized water and 3g of the first additive (surfactant, the brand is FES-993, Guangzhou Kaishi Chemical Co., Ltd.) to obtain liquid A, and then mix 75g of deionized water with 5g of adhesive (2g Styrene-butadiene latex (brand SD332N, BASF), 2g polyvinyl alcohol (brand 1788, Shanghai Kaidu Industrial Development Co., Ltd.), 1g polyacrylate (brand 941, Guangzhou Shengxin Chemical Technology Co., Ltd.)) pre-mixed to obtain B Finally, slowly add liquid A to liquid B, stir for 10 minutes, add 0.3g of crosslinking agent (brand: LF-8500, Linan Funeng Resin Co., Ltd.), continue stirring for 10 minutes, then add 0.3g of the first wool Surface agent (brand name 14808-60-7, Shanghai Zecheng Chemical Co., Ltd.) was used to prepare the bottom coating solution.

[0046] Preparation of back coating solution:

[0047] First, mix 10g of deionized water and 2g of the second additive (leveling agent, the brand is PE-10...

Embodiment 2

[0050] Preparation of bottom coating solution:

[0051] Firstly mix 10g of deionized water and 3.5g of the first auxiliary agent (surfactant, the brand is FES-993, Guangzhou Kaishi Chemical Co., Ltd.) to obtain liquid A, and then mix 40g of deionized water with 25g of adhesive ( 10g styrene-butadiene latex (brand SD332N, BASF), 10g polyvinyl alcohol (brand 1788, Shanghai Kaidu Industrial Development Co., Ltd.), 5g polyacrylate (brand 941, Guangzhou Shengxin Chemical Technology Co., Ltd.)) pre-mixed to obtain Liquid B, finally slowly add liquid A to liquid B, stir for 10 minutes, add 1.5g of cross-linking agent (brand: LF-8500, Linan Funeng Resin Co., Ltd.), continue stirring for 10 minutes, then add 0.8g of the first Matting agent (brand name 14808-60-7, Shanghai Zecheng Chemical Co., Ltd.) was used to prepare the bottom coating solution.

[0052] Preparation of back coating solution:

[0053] First, mix 10g of deionized water and 4g of the second additive (leveling agent, t...

Embodiment 3

[0056] Preparation of bottom coating solution:

[0057] First, 10g of deionized water and 4g of the first additive (surfactant, the brand is FES-993, Guangzhou Kaishi Chemical Co., Ltd.) are pre-mixed to obtain liquid A, and then 50g of deionized water and 35g of adhesive (14g Styrene-butadiene latex (brand name SD332N, BASF), 14g polyvinyl alcohol (brand name 1788, Shanghai Kaidu Industrial Development Co., Ltd.), 7g polyacrylate (brand name 941, Guangzhou Shengxin Chemical Technology Co., Ltd.)) pre-mixed to obtain B Finally, slowly add liquid A to liquid B, stir for 10 minutes, add 2.0g of crosslinking agent (brand: LF-8500, Linan Funeng Resin Co., Ltd.), continue stirring for 10 minutes, then add 1.2g of the first wool Surface agent (brand name 14808-60-7, Shanghai Zecheng Chemical Co., Ltd.) was used to prepare the bottom coating solution.

[0058] Preparation of back coating solution:

[0059] First, mix 10g of deionized water and 3.5g of the second additive (leveling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com