A kind of antistatic paint and environmental protection antistatic floor

An anti-static and primer layer technology, used in primers, conductive coatings, anti-corrosion coatings, etc., can solve the problems of fragile service life, poor environmental protection of anti-static paint, and poor surface hardness of anti-static floors, reducing the amount of use. , The effect of improving adhesion and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

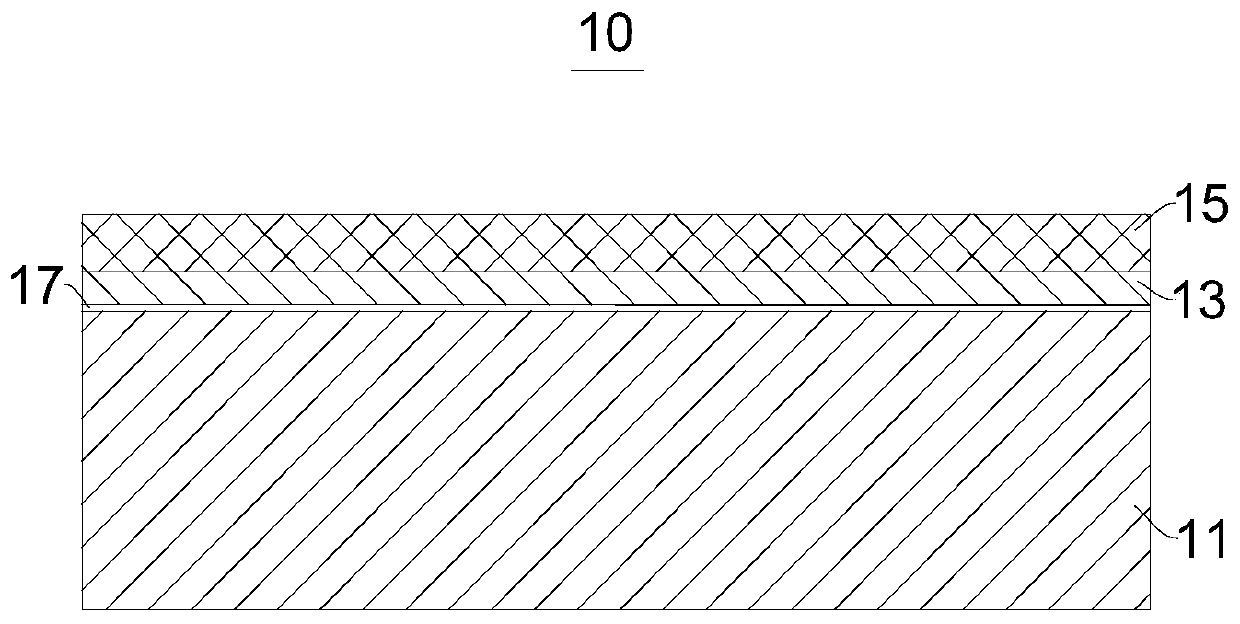

[0048] This embodiment provides an environmentally friendly anti-static floor 10, which includes a concrete base layer 11 with a thickness ratio of 8:1:2, an anti-static primer layer 13 compounded on the concrete base layer 11, and an anti-static primer layer 13 compounded on the anti-static primer layer 13. Antistatic topcoat layer 15.

[0049] Wherein, the antistatic paint used in the antistatic primer layer 13 contains the first raw material and the second raw material in a weight ratio of 20:80. The first raw material contains water-based epoxy curing agent, dispersant, conductive agent and deionized water in a weight ratio of 60:0.1:5.1:34.8. The second raw material includes epoxy resin, reactive diluent and defoamer in a weight ratio of 70:29.8:0.2.

[0050] Among them, the water-based epoxy curing agent adopts an amino-based closed-end epoxy curing agent with a solid content of 47%, a pH value of 6.5, and a viscosity of 1400 MPa·S. The content of active hydrogen in the...

Embodiment 2

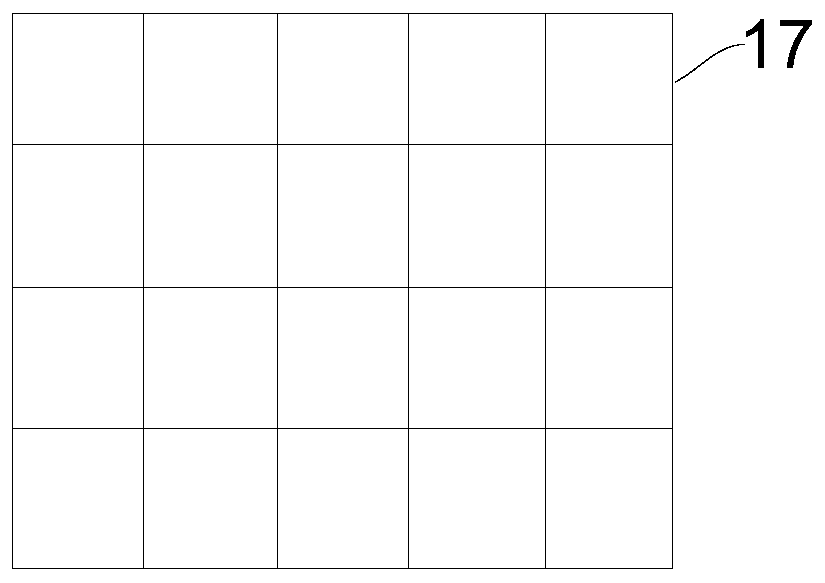

[0053] This embodiment provides an environmentally friendly anti-static floor 10, which includes a concrete base layer 11 with a thickness ratio of 10:1:3, an anti-static primer layer 13 compounded on the concrete base layer 11, and an anti-static primer layer 13 compounded on the anti-static primer layer 13. Antistatic topcoat layer 15. A copper foil layer 17 is arranged between the concrete bottom layer 11 and the antistatic primer layer 13. The copper foil layer 17 is laid horizontally with copper foils with a diameter of 1 cm. Between two adjacent horizontal copper foils or between two adjacent vertical copper foils The spacing between the foils was all 1.5 m.

[0054] Wherein, the antistatic paint used in the antistatic primer layer 13 contains the first raw material and the second raw material in a weight ratio of 30:70. The first raw material contains water-based epoxy curing agent, dispersant, conductive agent and deionized water in a weight ratio of 80:0.5:10.5:9. T...

Embodiment 3

[0058] This embodiment provides an environmentally friendly anti-static floor 10, which includes a concrete base layer 11 with a thickness ratio of 9:1:2.5, an anti-static primer layer 13 compounded on the concrete base layer 11, and an anti-static primer layer 13 compounded on the anti-static primer layer 13. Antistatic topcoat layer 15. A copper foil layer 17 is arranged between the concrete bottom layer 11 and the antistatic primer layer 13. The copper foil layer 17 is laid horizontally with copper foils with a diameter of 2 cm. Between two adjacent horizontal copper foils or adjacent two vertical copper foils The spacing between the foils was all 2.5 m.

[0059] Wherein, the antistatic paint used in the antistatic primer layer 13 contains the first raw material and the second raw material in a weight ratio of 40:60. The first raw material contains water-based epoxy curing agent, dispersant, conductive agent and deionized water in a weight ratio of 70:0.3:7.8:21.9. The se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com