Flame-retardant and fluorescent luminescent fabric

A kind of fabric and fluorescent technology, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve the problems of complex process, poor rigidity and bending of fabrics, easy to wrinkle, etc., and achieve long service life and convenient use Flexible, simple and lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

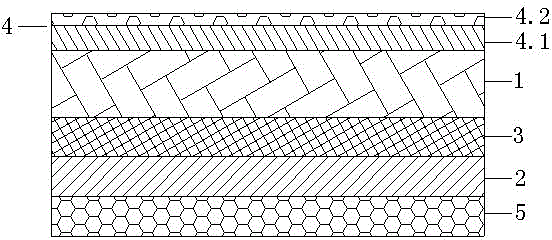

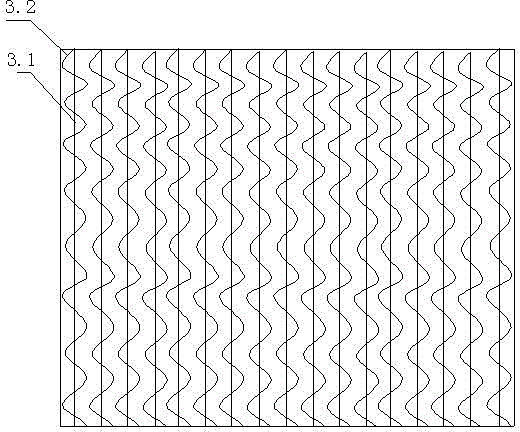

[0013] see figure 1 and figure 2 , the present invention relates to a flame-retardant fluorescent luminescent fabric, which comprises an upper cotton layer 1 and a lower cotton layer 2, a base layer 5 is compounded under the lower cotton layer 2, and there is a gap between the upper cotton layer 1 and the lower cotton layer 2 An antistatic layer 3 is provided, and the antistatic layer 3 is made of core-spun silk fibers, and the fibers include yarns 3.1 and metal wires 3.2, and the metal wires 3.2 are wound on the yarns 3.1, and the upper cotton layer 1 The surface is covered with a layer of flame-retardant coating 4, which includes a flame-retardant polyurethane layer 4.1 at the bottom and an organic silicone oil layer 4.2 at the top. The flame-retardant polyurethane layer 4.1 has good flame-retardant performance and is suitable for applications with high flame-retardant requirements. In the use of occasions, the silicone oil layer 4.2 makes the surface of the fabric smooth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com