High temperature, high pressure, antistatic type impeding level controller

An anti-static, controller technology, applied in liquid level control, non-electric variable control, control/regulation systems, etc., can solve the problems of leakage and pressure resistance of the field and the inner casing of the instrument, and solve the hidden dangers of unsafe, Easy to use and maintain, reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

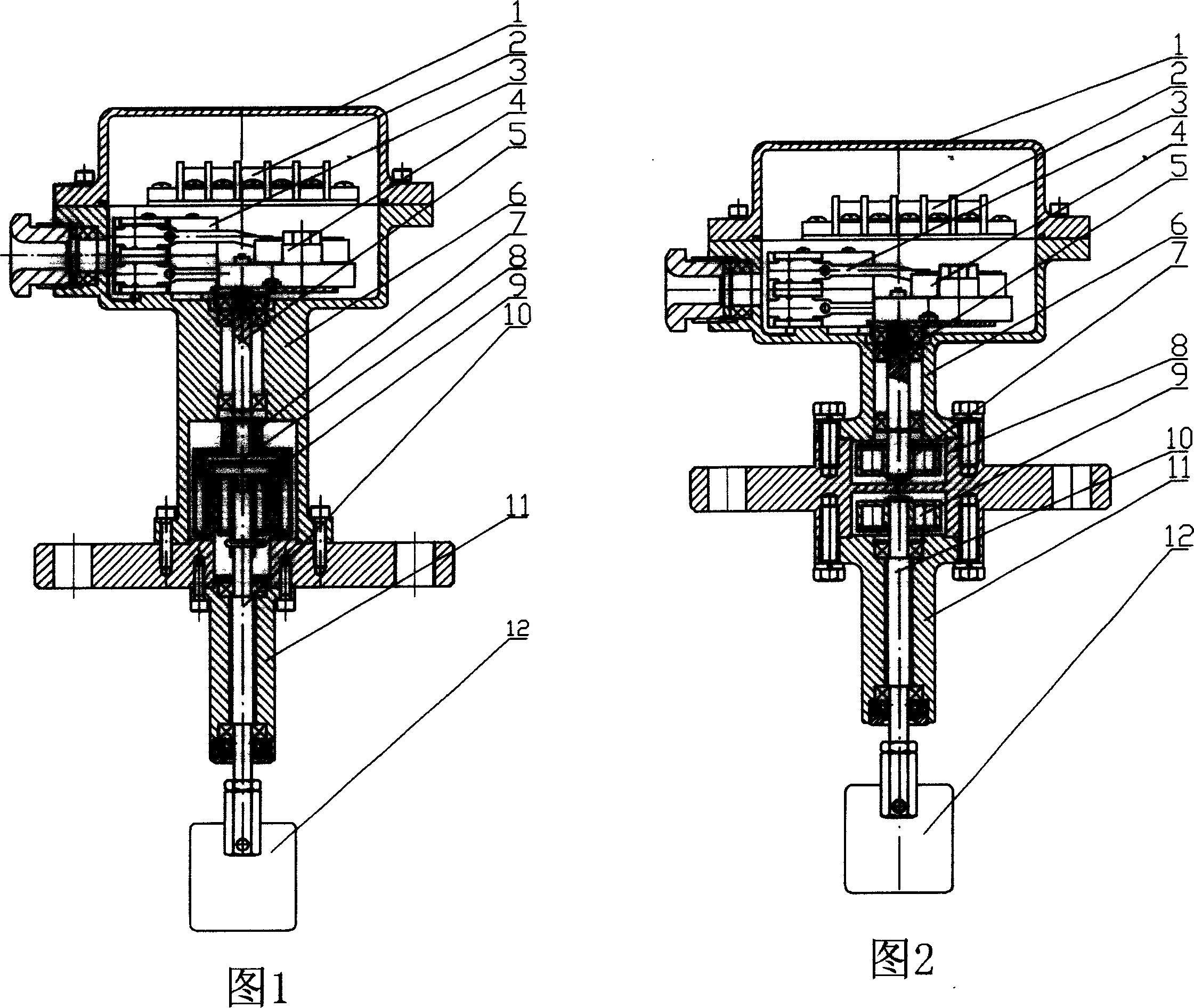

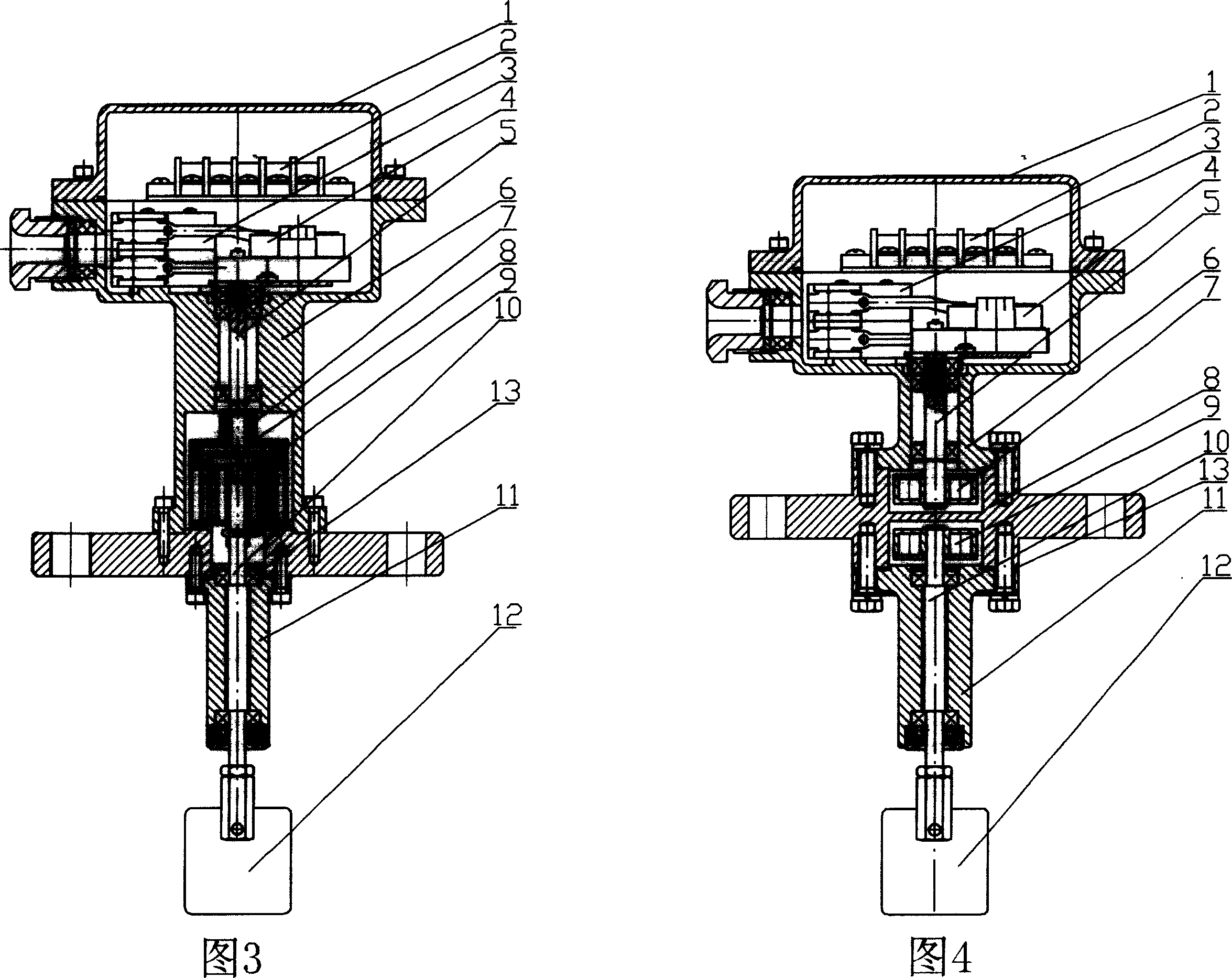

[0019] The two modes of magnetic transmission are cylindrical radial transmission and disc axial transmission. The structures of the material level controllers of the two transmission modes of the present invention are consistent. As shown in the figure, the material level controller includes a cover 1, a terminal 2, a micro switch 3, a motor assembly 4, an axis A5, and a base 6 , drive assembly I7, spacer flange 8, drive assembly II9, shaft B10, shaft cylinder 11, detection board assembly 12, anti-static assembly 13, cover 1 and base 6 are connected by threads, motor assembly 4 is connected with shaft A5, The shaft A5 is installed on the base 6, the motor assembly 4 is connected to the base 6 through a spring, the micro switch 3 is connected to the motor assembly 4, the cover 1 and the base 6 are provided with a terminal 2, and the drive assembly I7 is connected to the other end of the shaft A5 Connected and fixed, the driving component I7 is isolated by the spacer flange 8 a...

Embodiment 2

[0021] As shown in the figure, the structure of the anti-static type is basically the same as that of the material level controller described in Embodiment 1, the difference is that: the anti-static type is provided with an anti-static component between the shaft cylinder 11 and the spacer flange 8 13. The anti-static component is made of polytetrafluorohexene insulating material and the insulating gasket is insulated from the warehouse wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com