Halogen-free flame-retardant highly-temperature-resistant polytetramethylene adipamide composite material and preparation method thereof

A technology of polybutylene adipamide and composite materials, which is applied in the field of preparation of polymer composite materials, can solve problems such as difficult processing and poor fluidity, and achieve the effects of low economic cost, broad market prospects and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

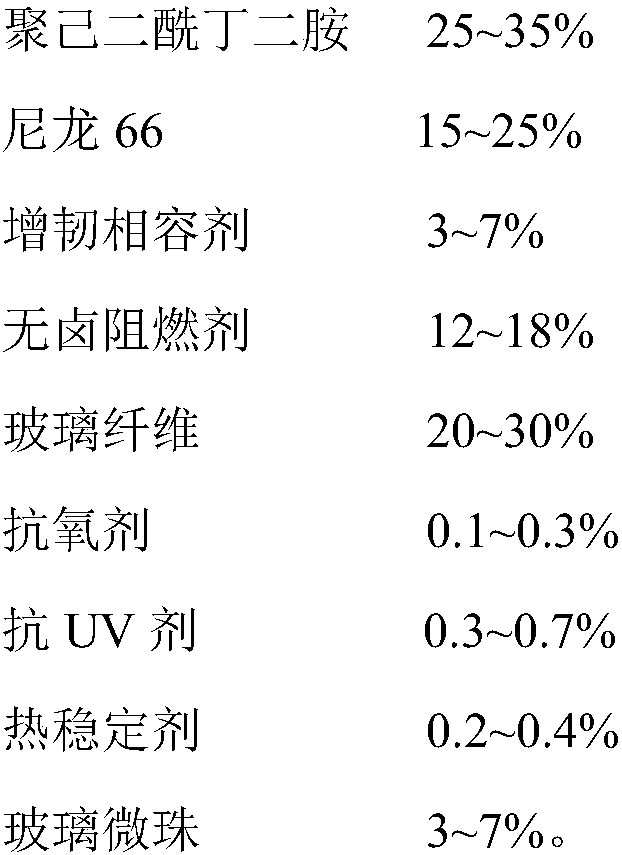

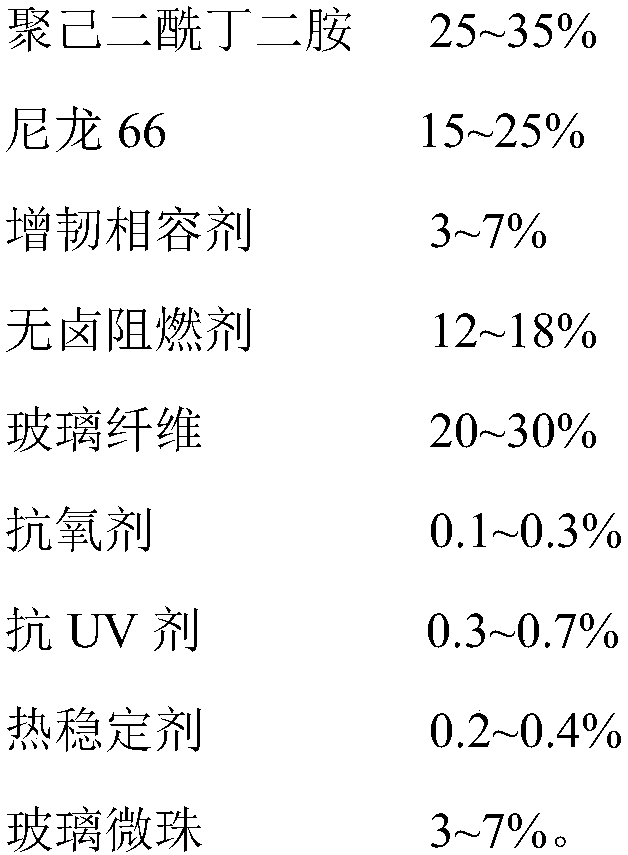

[0024] A high-wear-resistant and high-temperature-resistant polybutylene adipamide composite material is made of the following components by weight percentage:

[0025] 35% polybutylene adipamide;

[0026] 18% Nylon 66;

[0027] 5% toughening compatibilizer (polyethylene octene copolymer elastomer-maleic anhydride copolymer, EPDM rubber-maleic anhydride copolymer, polystyrene-ethylene-butylene-polystyrene-maleic anhydride copolymer, the mass ratio is 1:1:1);

[0028] 14% halogen-free flame retardant (phosphinate, tricresyl phosphate, red phosphorus, the mass ratio is 1:1:1);

[0029] 23% glass fiber (round glass fiber, non-round glass fiber, the mass ratio is 2:1);

[0030] 0.3% antioxidant (N, N'-hexamethylene-1.6-bis[(3,5-di-tert-butyl-4-hydroxyphenyl)propionamide], tetrakis[β-(3,5-di-tert-butyl Base-4-hydroxyphenyl)propionic acid]pentaerythritol ester, tris(2,4-di-tert-butylphenyl)phosphite, bis(2,4-di-tert-butylphenyl)pentaerythritol diphosphite, The mass ratio is 1:1...

Embodiment 2

[0036] A high-wear-resistant and high-temperature-resistant polybutylene adipamide composite material is made of the following components by weight percentage:

[0037] 25% polybutylene adipamide;

[0038] 20% Nylon 66;

[0039] 7% toughening compatibilizer (polyethylene octene copolymer elastomer-maleic anhydride copolymer);

[0040] 16% halogen-free flame retardant (phosphinate);

[0041] 26% glass fiber (round glass fiber);

[0042] 0.2% antioxidant (N,N'-hexamethylene-1.6-bis[(3,5-di-tert-butyl-4-hydroxyphenyl)propionamide]);

[0043] 0.5% anti-UV agent (subjected to histamine),

[0044] 0.3% heat stabilizer (PolyAd HS 02);

[0045] 5% glass microspheres (hollow glass microspheres).

[0046] First dry polybutylene adipamide resin (moisture content 1‰), nylon 66 resin (moisture content 1‰), 3kg polyethylene octene copolymer elastomer-maleic anhydride copolymer, N, N'- Hexyl-1.6-bis[(3,5-di-tert-butyl-4-hydroxyphenyl) propionamide], histamine are added to the high-spe...

Embodiment 3

[0048] A high-wear-resistant and high-temperature-resistant polybutylene adipamide composite material is made of the following components by weight percentage:

[0049] 28% polybutylene adipamide;

[0050] 20% Nylon 66;

[0051] 6% toughening compatibilizer (polyethylene octene copolymer elastomer-maleic anhydride copolymer, EPDM rubber-maleic anhydride copolymer, mass ratio is 1:1);

[0052] 14% halogen-free flame retardant (phosphinate, tricresyl phosphate, mass ratio is 1:1);

[0053] 25% glass fiber (non-round glass fiber);

[0054]0.15% antioxidant (N, N'-hexamethylene-1.6-bis[(3,5-di-tert-butyl-4-hydroxyphenyl)propionamide], tetrakis[β-(3,5-di-tert-butyl Base-4-hydroxyphenyl) propionate] pentaerythritol ester, the mass ratio is 1:1);

[0055] 0.55% anti-UV agent (subject to histamine, hydroxybenzophenone, mass ratio is 1:1),

[0056] 0.3% heat stabilizer (PolyAd HS 02);

[0057] 6% glass microspheres (hollow glass microspheres).

[0058] After drying, polybutylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com