Patents

Literature

54results about How to "Inhibition of reduction reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrolyte solution for negative lithium titanate battery, lithium ion battery and preparation method thereof

ActiveCN103117414AWide variety of sourcesEasy to operateFinal product manufactureElectrolyte accumulators manufactureSolventCarbonate

The invention discloses an electrolyte solution for a negative lithium titanate battery, a lithium ion battery and a preparation method thereof. The electrolyte solution is characterized in that lithium hexafluorophosphate is adopted as electrolyte, ethylene carbonate, methyl ethyl carbonate, diethyl carbonate and propylene carbonate are adopted as solvents, and one or more of fluoroethylene carbonate, double oxalate ithium borate, 1,3-propanesultone or vinylene carbonate are adopted as a film-formation additive.

Owner:CALB CO LTD +1

Method of palliating degradation degree in polypropylene fusion graft process

The invention discloses a method to reducing degree of degradation under polypropylene melting grafted process, which is comprises the following steps: 1. adding grafted monomer, secondary monomer, trigger, anti-oxidant and polypropylene to high-velocity dispersion machine and mixing evenly; the usage of grafted monomer is 0.5%-15% of polypropylene total quantity; the usage of secondary monomer is 0.1%-10% of polypropylene total quantity; the usage of trigger is 0.1%-15% of anti-oxidant; the usage of anti-oxidant is 0.1%-1.5% of polypropylene total quantity; 2. adding the mixture of first step into bi-bolt force out machine; melting; squeezing grafted reaction; 3. cooling and dicing squeezing material of the second step get graft modified polypropylene of degraded to a less extent, graft ratio increased.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

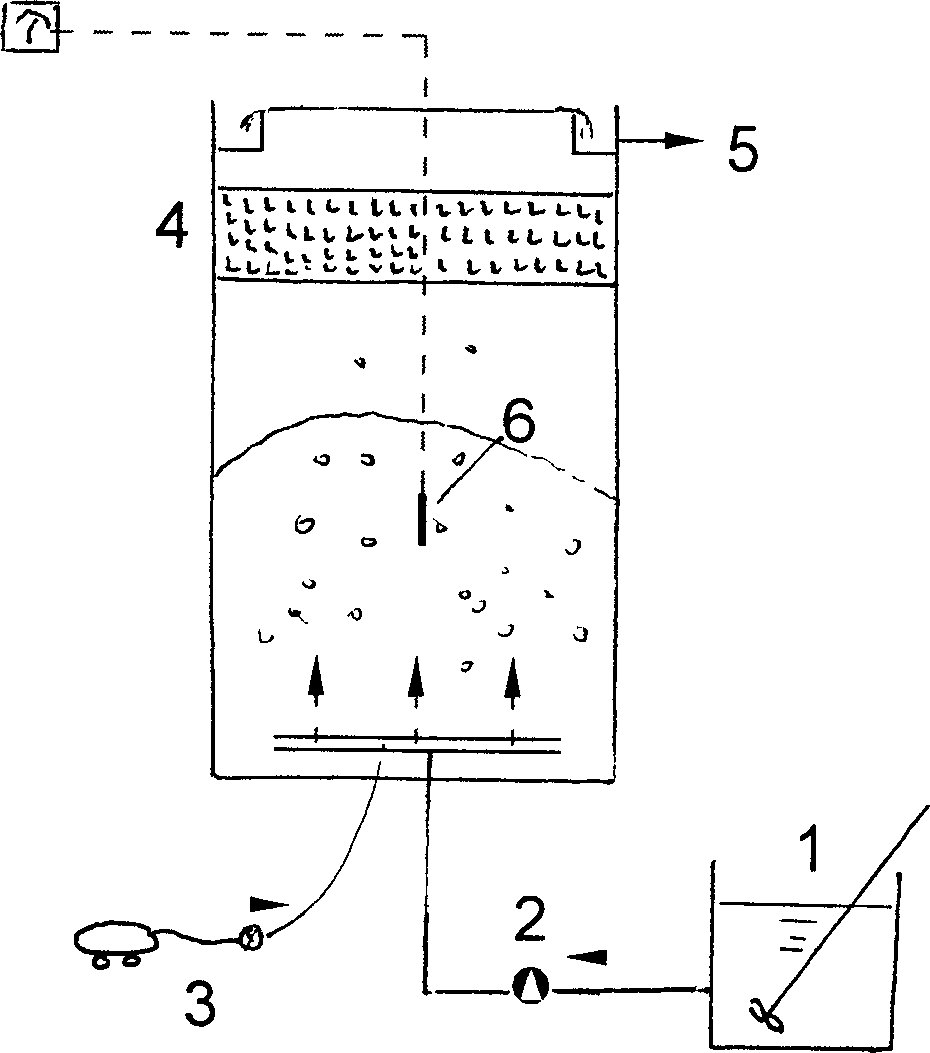

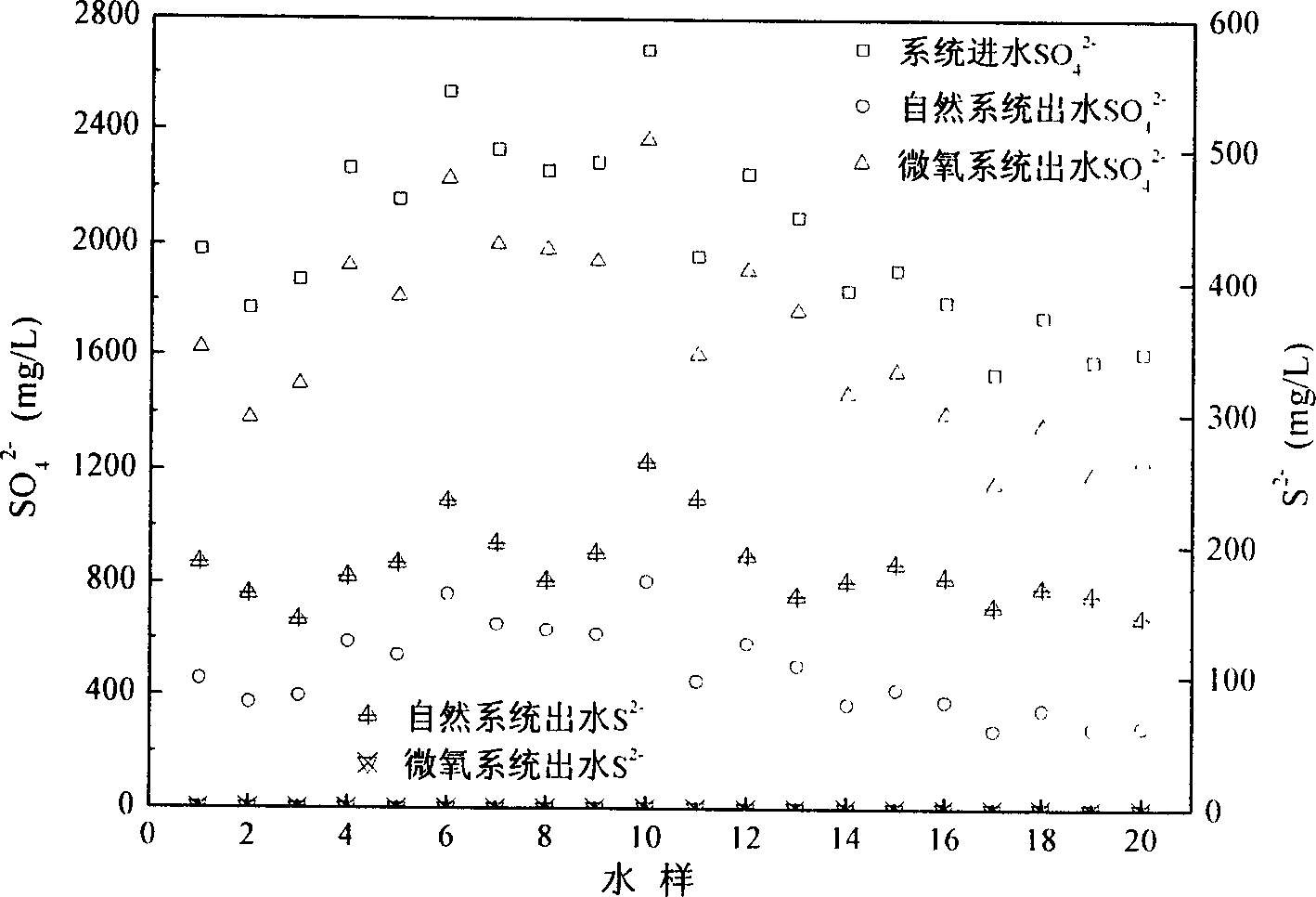

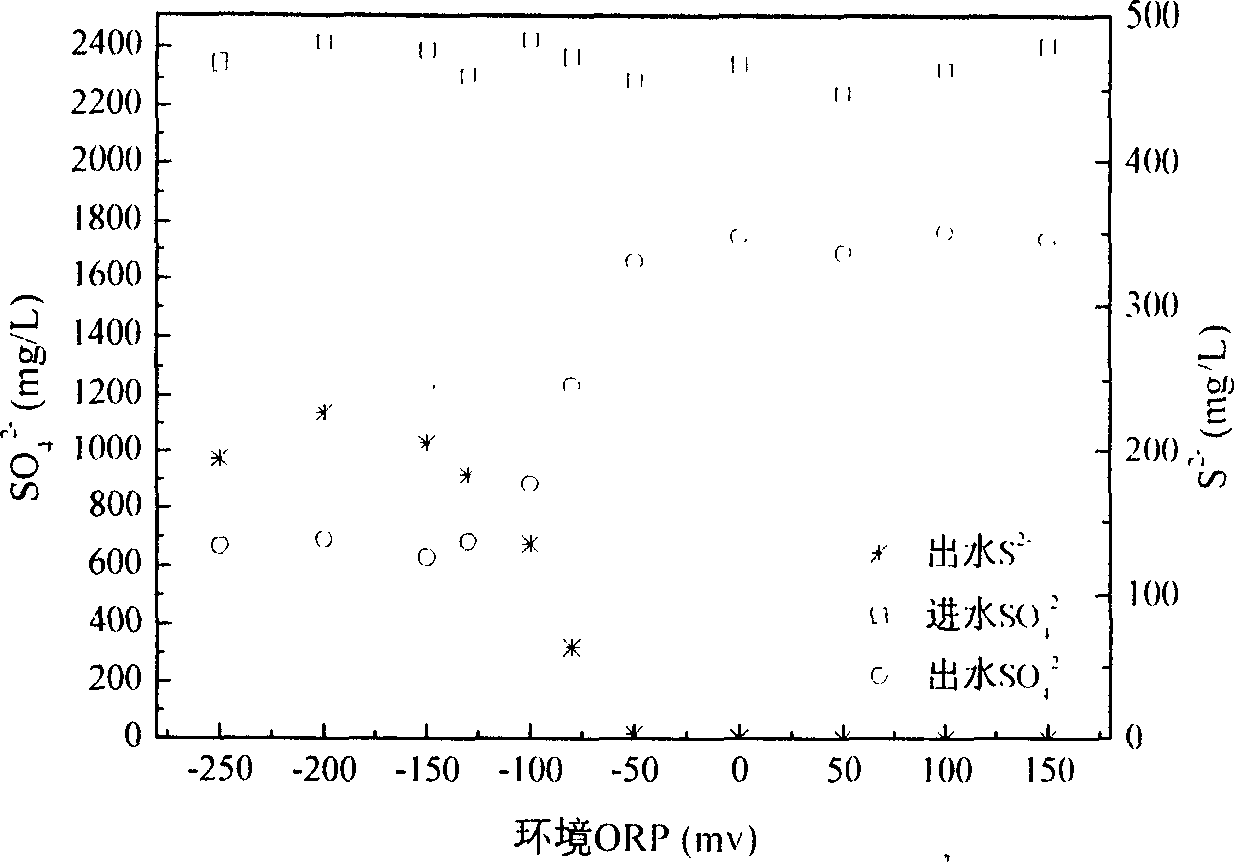

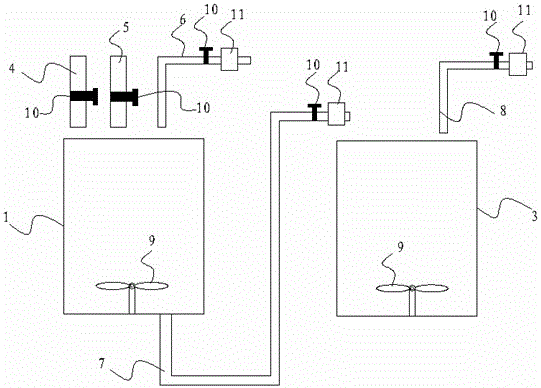

Method for pretreatment of sulphate-contained high concentration organic wastewater by micro-aerobic hydrolysis and acidification

InactiveCN1803670AEnhance physiological metabolic functionInhibition of reduction reactionWater contaminantsTreatment with aerobic and anaerobic processesHigh concentrationPretreatment method

The pretreatment method for high-concentration organic sewage contained sulfate by micro-oxygen hydrolyzing and acidifying comprises: on micro-oxygen condition, controlling the hydrolysis and acidification by aeration during anaerobic treatment process. Compared with prior art, this invention improves system treatment efficiency and yield of methane, and eliminates the effect to biological treatment from sulfide.

Owner:NANJING UNIV

Method for inhibiting offensive odor of riverway water body and bottom mud

InactiveCN101209868AHigh in ironInhibition of sulfate reduction reactionSludge treatmentWater/sewage treatmentEnvironmental chemistryRiver water

The invention provides a method for eliminating odor emitting by the water and bottom sludge in a river. The method is characterized in that: ferric oxide and sodium humate complex preparation is added into river water with the dosage of 10-30g per cubic meter. The weight percentage ratio of the ferric oxide and the sodium humate complex preparation is 50-70 percent of ferric oxide and 30-50 percent of sodium humate. The method of the invention can obviously inhibit water and bottom sludge in a river emitting odor, so as to avoid disturbing people.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

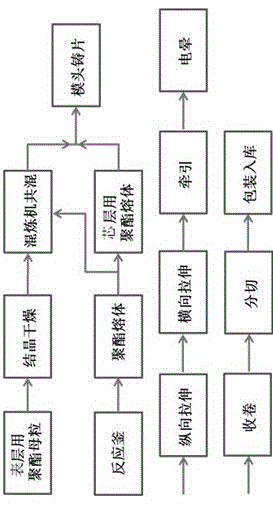

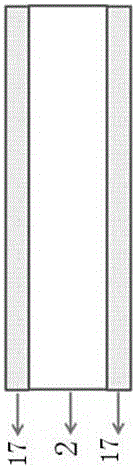

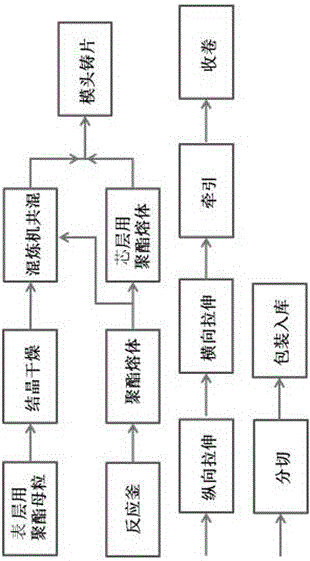

PET aluminum-plated base membrane and preparation method thereof

InactiveCN106427149AHigh light transmittanceIncrease surface tensionSynthetic resin layered productsFlat articlesPolyesterAnti-Adhesion Agent

The invention discloses a PET aluminum-plated base membrane and a preparation method thereof. The PET aluminum-plated base membrane comprises a core layer in the middle and surface layers arranged on the two surfaces of the core layer. The surface layers and the core layer are integrally formed through co-extrusion and two-way stretching. The core layer is a PET layer, and the surface layers are PET layers mixed with anti-adhesion agents. The preparation method includes the steps of polyester synthesis, mixing, co-extrusion, sheet casting through a die, longitudinal stretching, transverse stretching, traction and trimming, corona treatment, coiling, cutting and obtaining of a finished product. The PET aluminum-plated base membrane can be prepared through the preparation method, and has excellent light transmittance and surface tension. The light transmittance can reach 89%, the glossiness is 130, the surface tension can reach 58 dyne, and the light transmittance, the glossiness and the surface tension can keep for a long time and do not weaken. Aluminum-plated membranes meeting different packaging requirements can be produced, and the produced aluminum-plated membranes are uniform and high in aluminum layer bonding force.

Owner:江苏三房巷薄膜股份有限公司

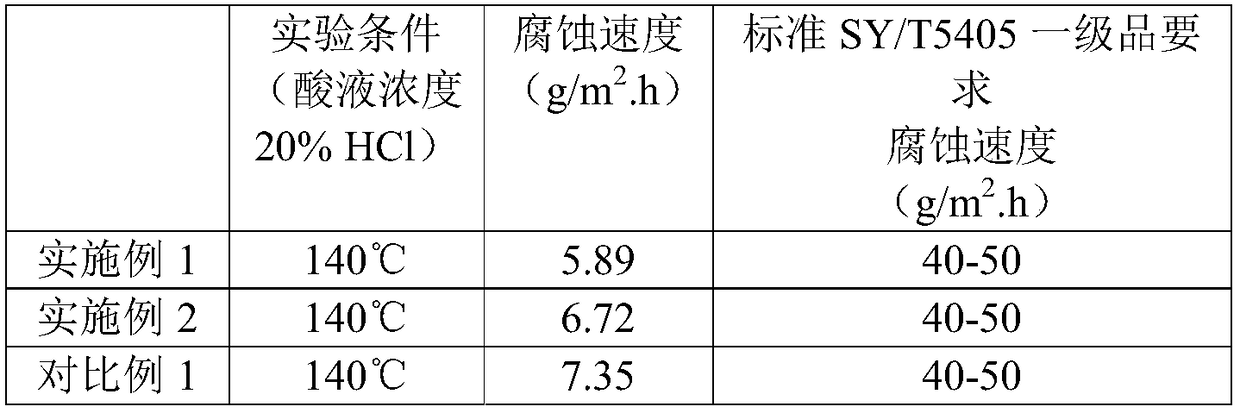

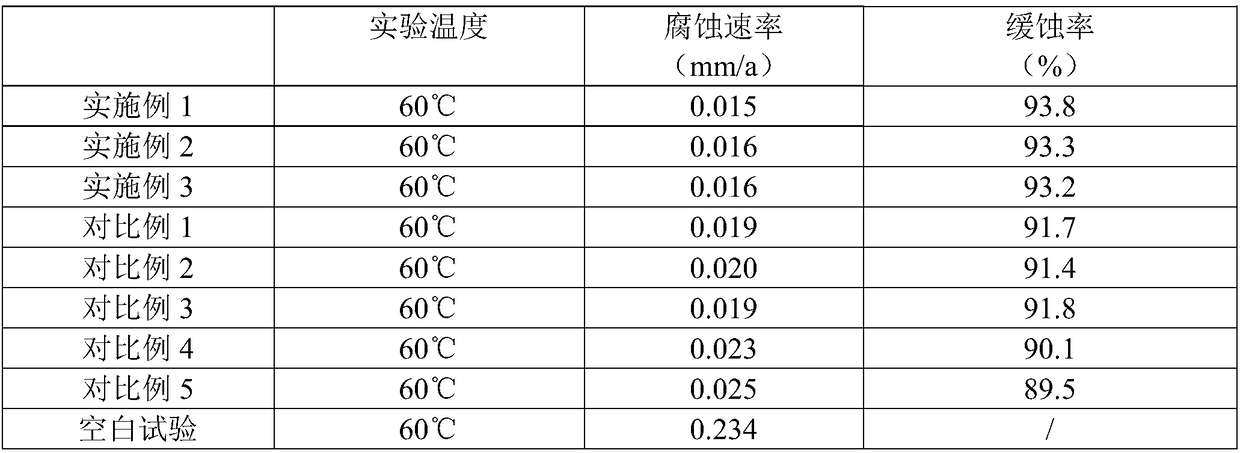

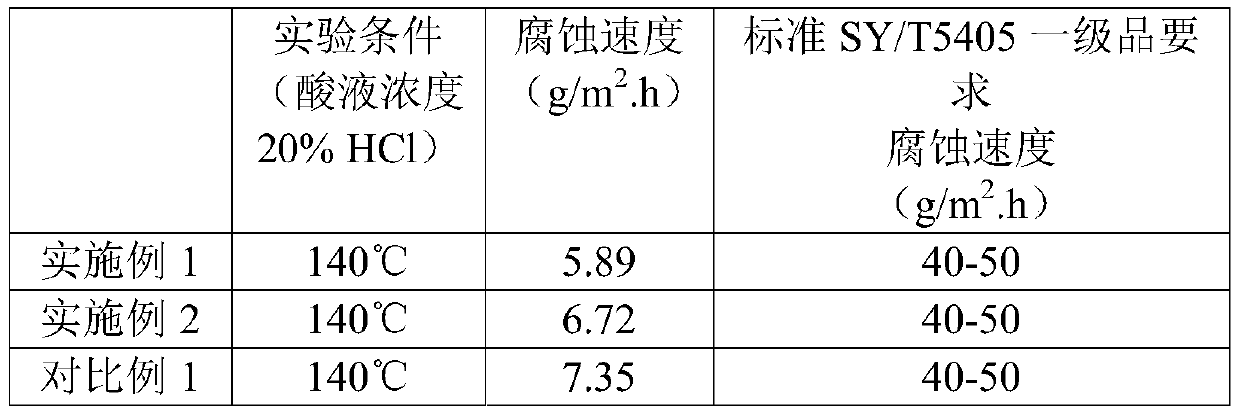

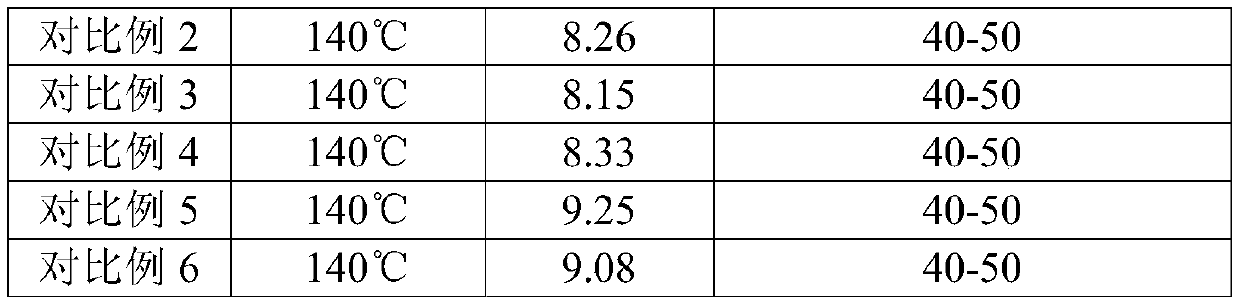

Environment-friendly high-temperature acidizing resistant corrosion inhibitor and preparation method thereof

The invention provides an environment-friendly high-temperature acidizing resistant corrosion inhibitor and a preparation method thereof. The environment-friendly high-temperature acidizing resistantcorrosion inhibitor comprises the components of, by weight, 10-50 parts of corrosion inhibitor primary agents, 1-10 parts of synergists, 0.5-1.5 parts of surfactants, 40-60 parts of solvents and 5-10parts of mercaptan acid; the corrosion inhibitor primary agent comprises 5-15 parts of polyquinoline quaternary ammonium salt, 5-10 parts of imidazolium quaternary ammonium salt, 10-25 parts of Mannich base; and the synergist comprises 1-5 parts of organic alkynol and 1-10 parts of plant extracts, wherein plant extract comprises one or more of a stephania tetrandra extract, a rhizoma corydalis extract, a sophora flower bud extract and a roxburgh rose extract. The environment-friendly high-temperature acidizing resistant corrosion inhibitor has the excellent performance of environmental protection, high temperature resistance, low damage and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Electrolyte and lithium ion battery containing same

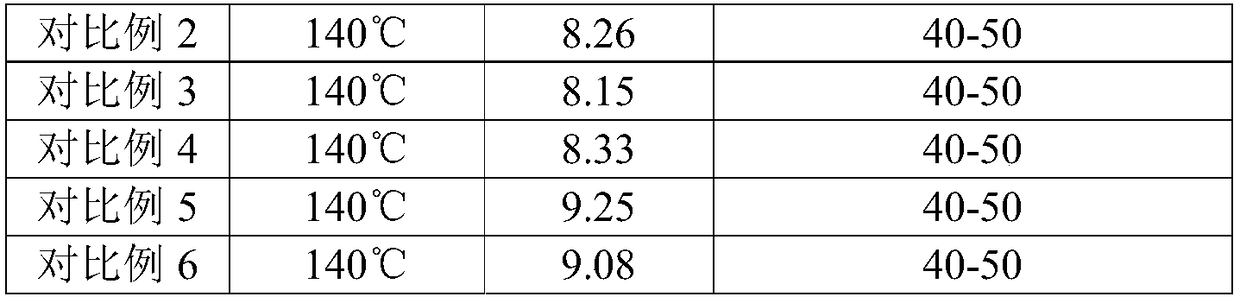

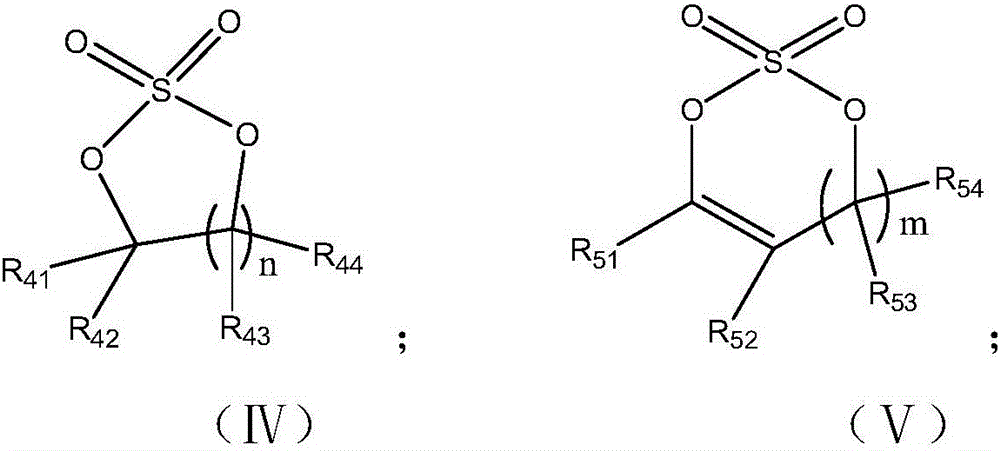

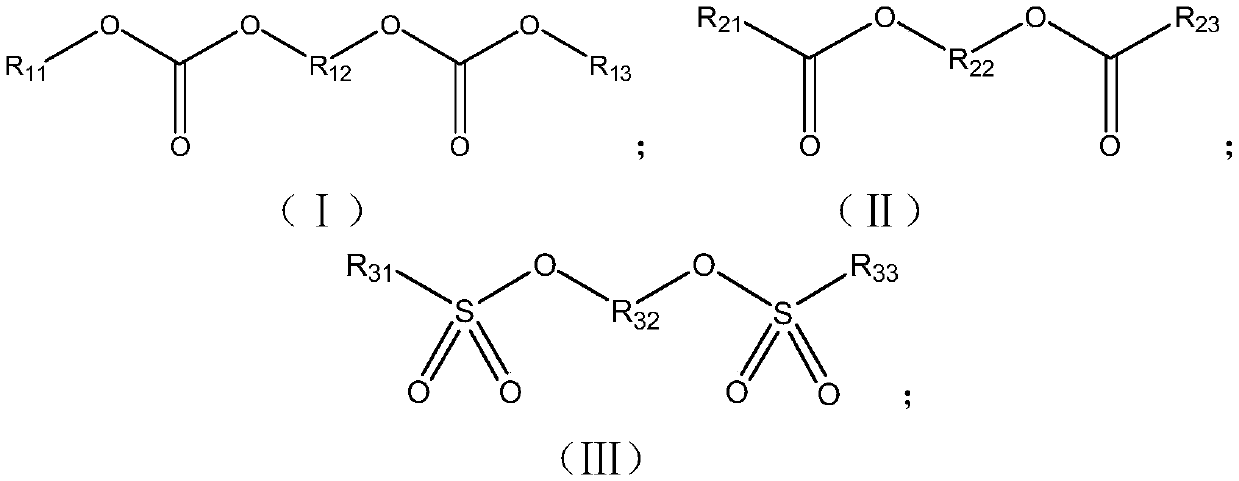

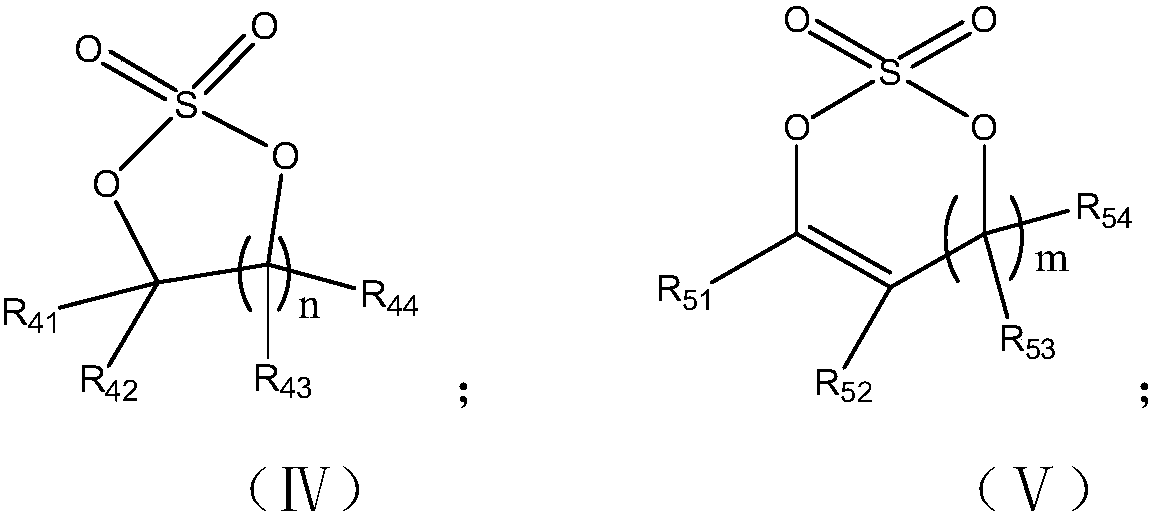

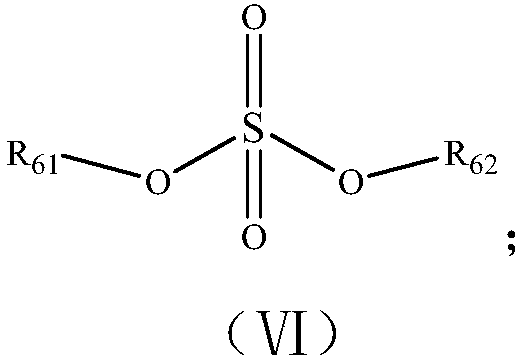

ActiveCN106410273AInhibition of reduction reactionInhibit positive oxidationFinal product manufactureElectrolyte accumulators manufactureOrganic solventBiopolymer

The invention relates to the technical field of a lithium ion battery, in particular to an electrolyte and a lithium ion battery containing the same. The electrolyte disclosed by the invention comprises a lithium salt, an organic solvent and an additive, wherein the additive contains a bipolyester compound and a sulphate compound, the bipolyester compound comprises a carbonic bipolymer, a carboxylic biopolymer and a sultone biopolymer, and the sulphate compound comprises an annular sulphate compound and a straight-chain or branch-chain sulphate compound. The bipolyester compound can be used for effectively forming a film at a positive electrode and preventing an electrolyte from being oxidized at the positive electrode, so that the high-temperature performance and the cycle performance of the battery are effectively improved; and the sulphate compound can be used for preventing the bipolyester compound from being reduced at a negative electrode, so that the battery acquire favorable low-temperature charge-discharge performance and rate performance, and the cycle performance of the battery can also be improved.

Owner:NINGDE AMPEREX TECH

PET transfer basement film and preparation method thereof

InactiveCN106626677AWith zoom featureGood shrink resistanceFlexible coversWrappersPolyesterSurface layer

The invention discloses a PET transfer basement film and a preparation method thereof. The PET transfer basement film comprises a core layer and surface layers, wherein the core layer is positioned in the middle of the PET transfer basement film; the surface layers are arranged on the two surfaces of the core layer; the surface layers and the core layers are integrally formed by co-extrusion and bidirectional stretching; the core layer is a PET layer; and each surface layer is a PET layer mixed with an anti-blocking agent. The preparation method comprises the following steps: polyester synthesizing, blending, co-extruding, die head casting, longitudinal stretching, transverse stretching, traction and edge cutting, rolling, slitting and finished product obtaining. The thickness is 12-20 mu m, the breadth is 8,700 mm, the heat resistance temperature exceeds 120 DEG C, the tensile strength is greater than or equal to 220 MPa, the heat shrinkage rate is less than or equal to 3.5%, and the friction coefficient of the surface of the basement film is less than or equal to 0.55. Compared with the conventional transfer basement film, the PET transfer basement film has excellent shrinkage preventing property. The transfer basement film has excellent heat stability and high tensile strength, and can meet requirements of clients. Transfer films which do not deform at high temperature, are complete in transfer and full and clear in image-texts are produced.

Owner:江苏三房巷薄膜股份有限公司

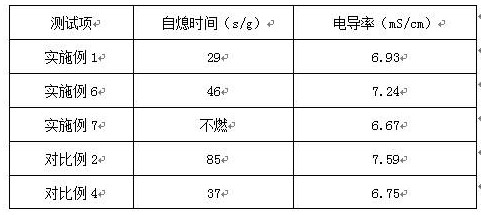

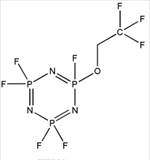

Electrolyte adaptive to high-nickel ternary positive electrode material

InactiveCN112599856AReduced hydrofluoric acid (HF) contentImprove Interface StabilitySecondary cellsOrganic electrolytesElectrolytic agentElectrical battery

The invention relates to an electrolyte adaptive to a high-nickel ternary positive electrode material. The electrolyte comprises an electrolyte lithium salt, a non-aqueous organic solvent and additives, the additives comprise a positive electrode film-forming additive, a negative electrode film-forming additive and a flame-retardant additive, the positive electrode film-forming additive is sodiumdihydrogen phosphate, the negative electrode film-forming additive is p-toluenesulfonyl isocyanate, and the flame-retardant additive is (trifluoroethoxy) pentafluorocyclotriphosphazene. According to the electrolyte adaptive to the high-nickel ternary positive electrode material, the normal-temperature / high-temperature circulation, high-temperature storage and safety performance of a high-nickel ternary positive electrode material battery under high voltage are effectively improved through a synergistic effect generated by combined use of multiple additives.

Owner:新乡华锐锂电新能源股份有限公司 +2

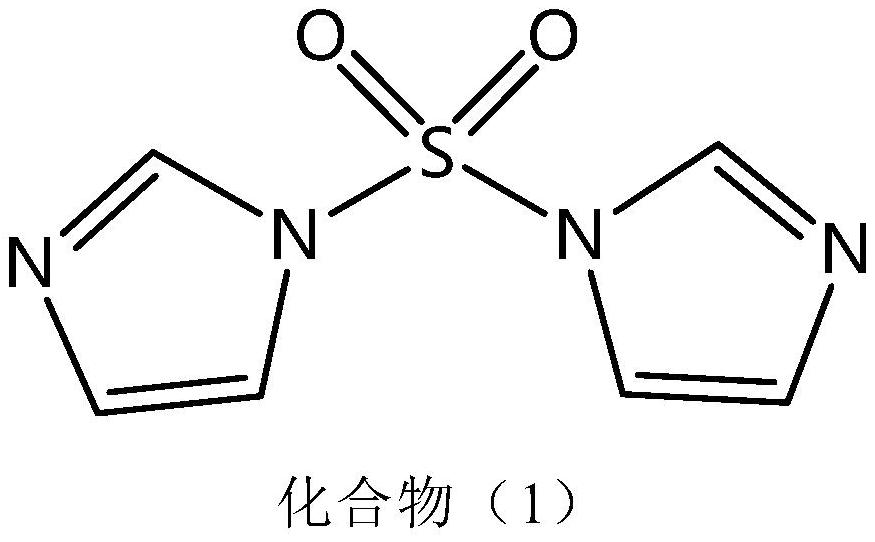

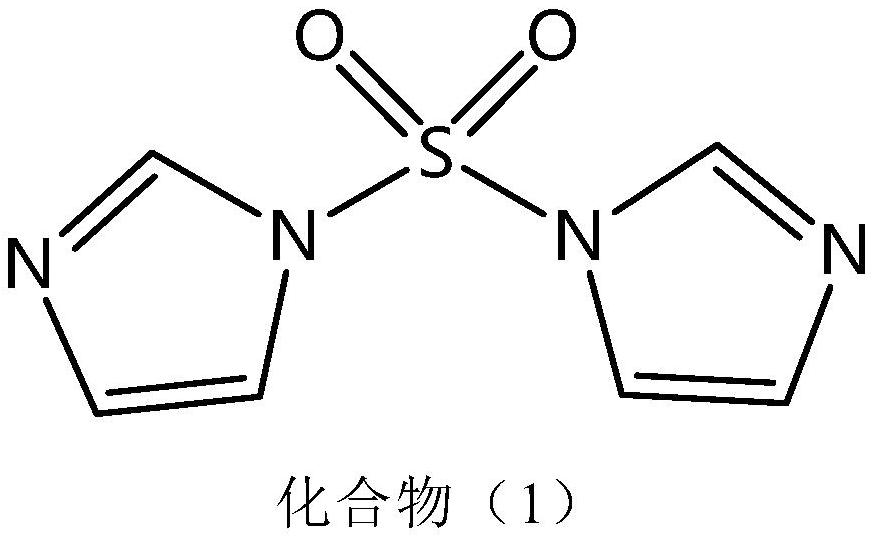

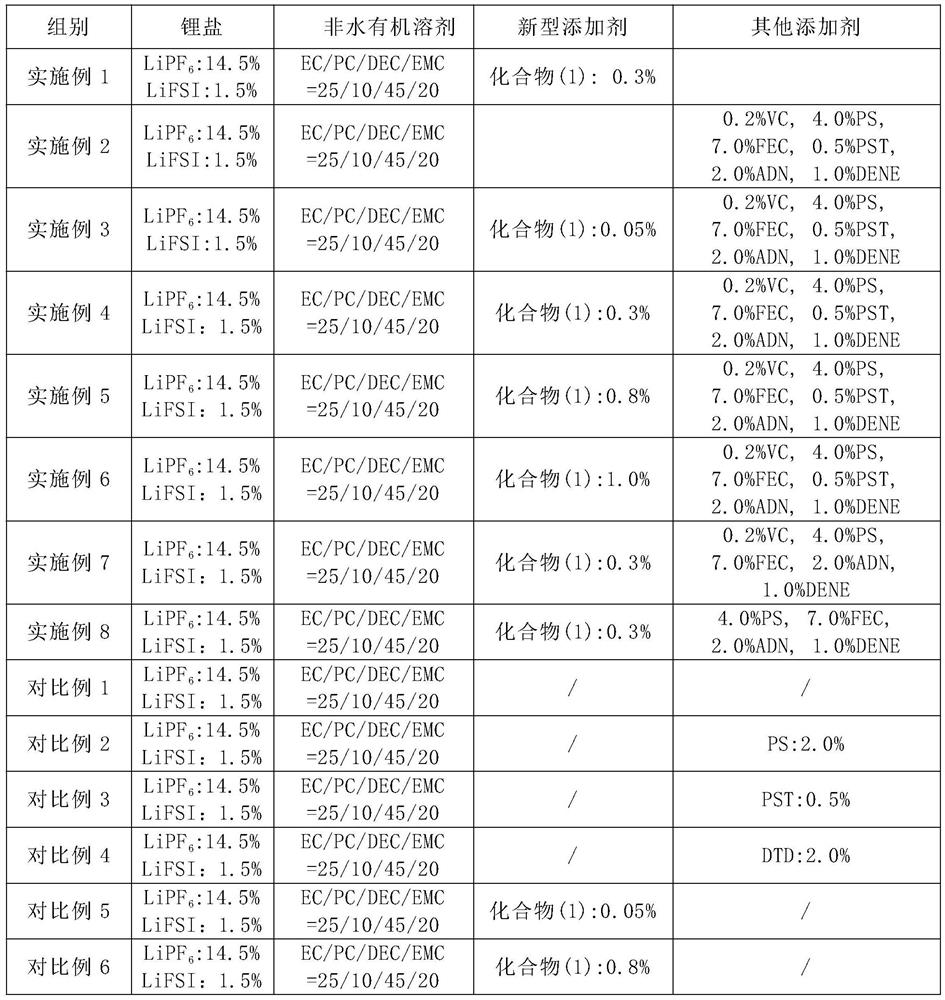

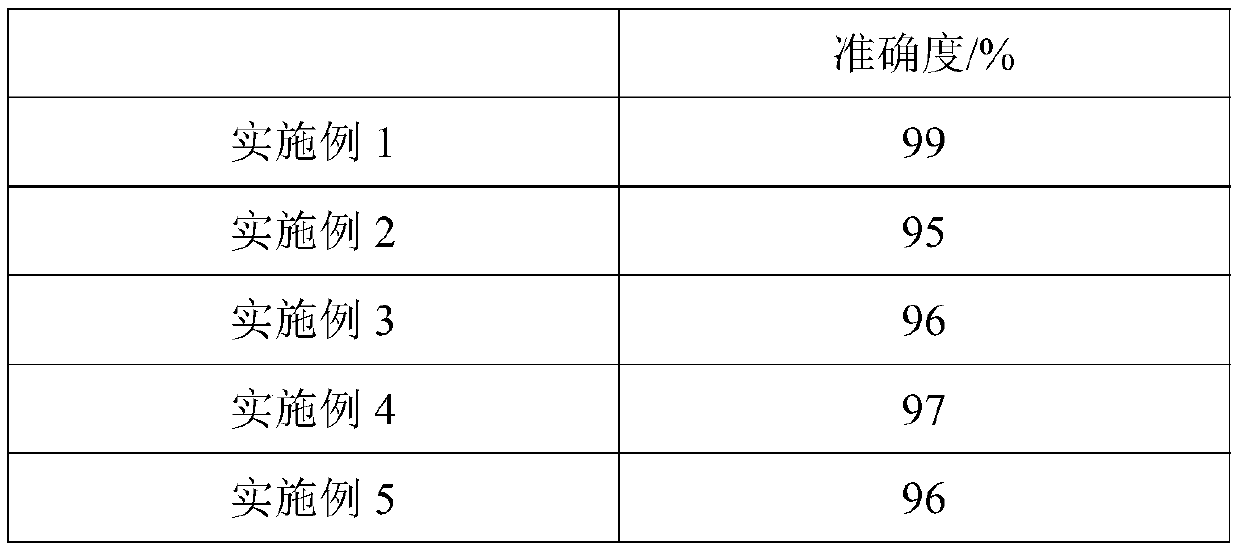

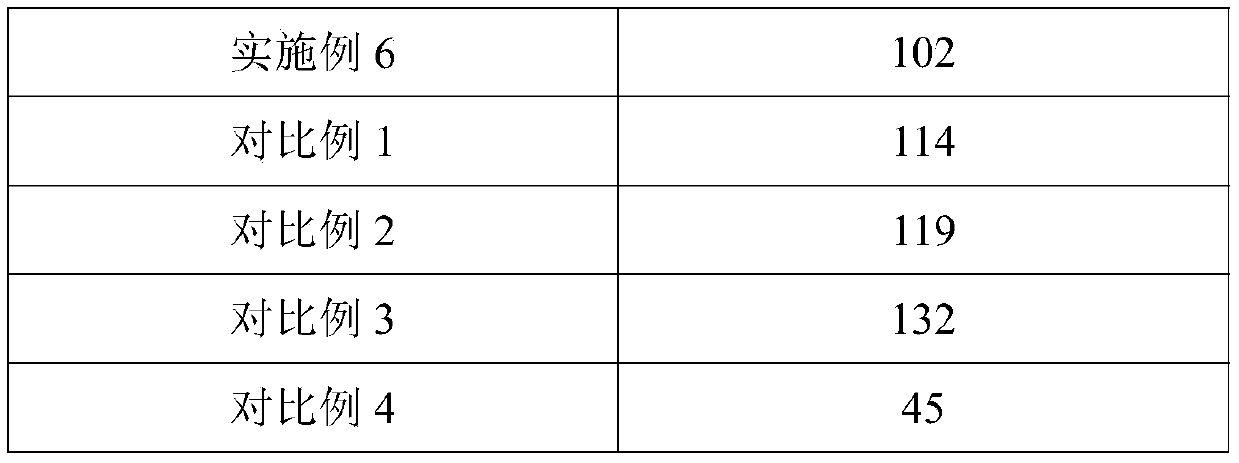

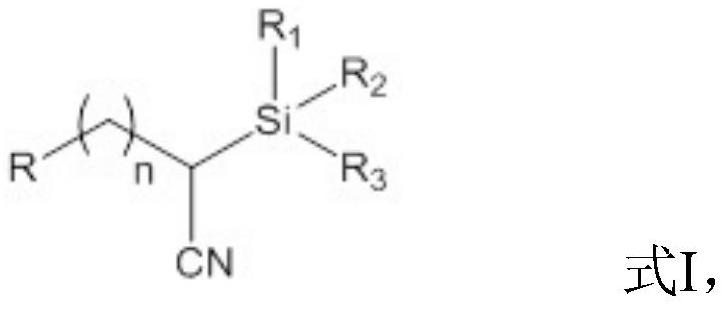

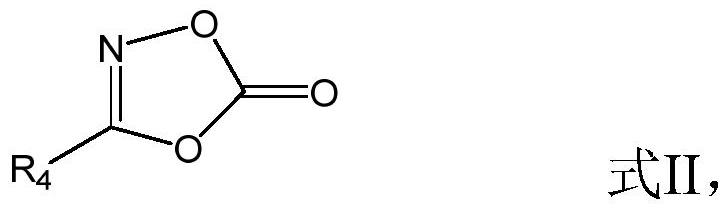

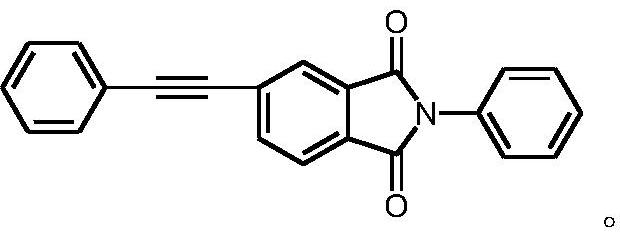

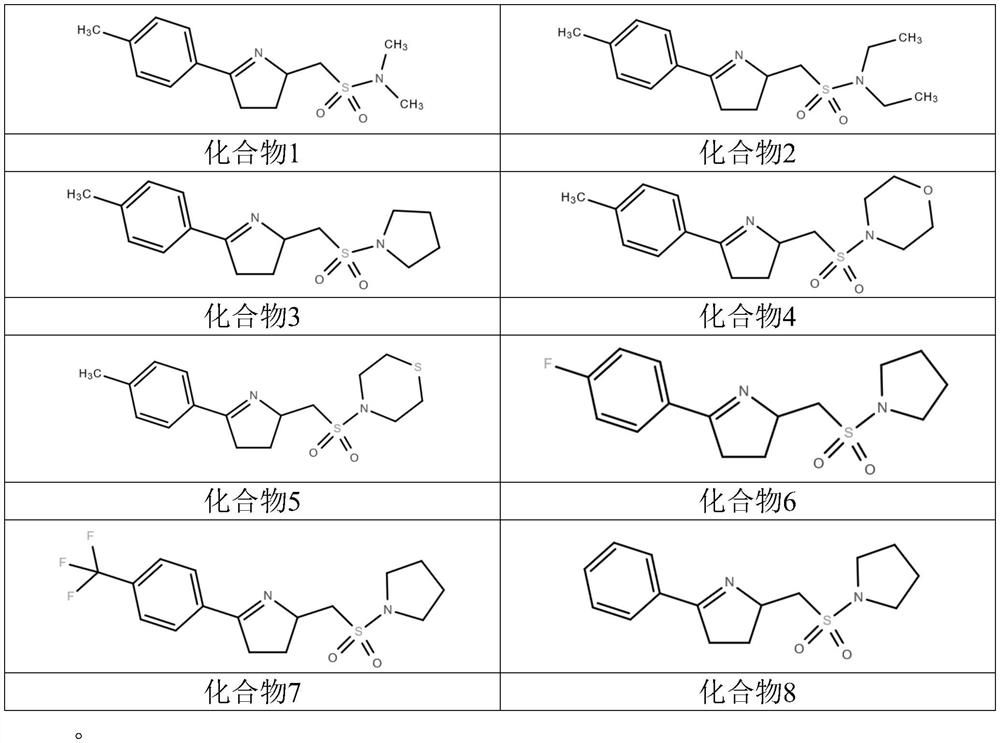

High-voltage-resistant lithium ion battery non-aqueous electrolyte and ternary high-voltage lithium ion battery

InactiveCN112467203AReduce reactivityImprove cycle performanceCell electrodesSecondary cellsElectrolytic agentOrganic solvent

The invention belongs to the technical field of lithium ion batteries, and discloses a high-voltage-resistant lithium ion battery non-aqueous electrolyte and a ternary high-voltage lithium ion battery. The high-voltage-resistant non-aqueous electrolyte of the lithium ion battery comprises a non-aqueous organic solvent, an electrolyte lithium salt and an additive, wherein the additive comprises a conventional additive and an additive as shown in a compound (1). Compared with the prior art, through the combined action of the combined conventional additive and the additive with the structure shown in the formula (I), a film can be formed on the surface of the positive electrode material, generation of cracks in particles of the positive electrode material in the circulation process is inhibited, dissolution of transition metal elements at high temperature is reduced, and an SEI film can be formed on the surface of the negative electrode material; and meanwhile, the interface impedance canbe reduced, so that the cycle performance, the rate capability and the low-temperature performance of the ternary high-voltage lithium ion battery are effectively improved.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

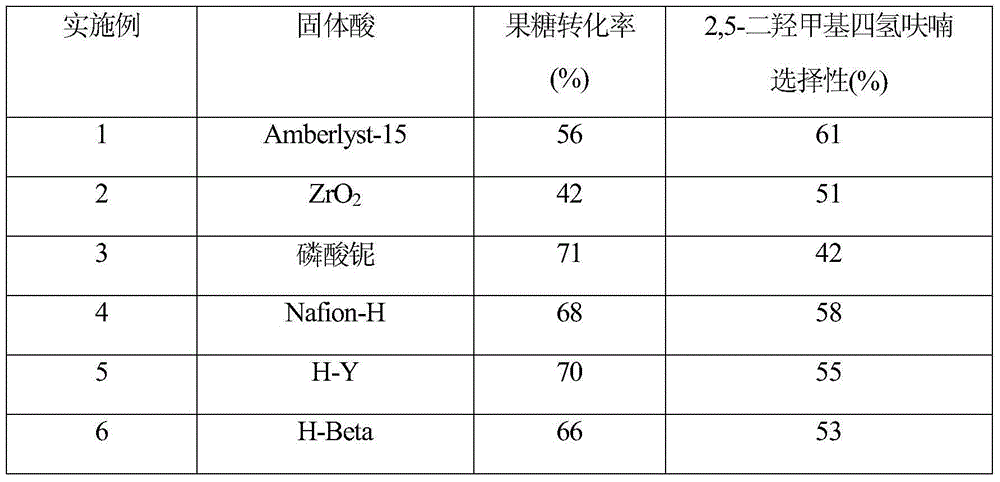

Method for directly preparing 2,5-dihydroxymethyl tetrahydrofuran from fructose

ActiveCN104672186AReduce concentrationInhibition of reduction reactionOrganic chemistryFructoseTetrahydrofuran

The invention relates to a method for directly preparing 2,5-dihydroxymethyl tetrahydrofuran from fructose, which comprises the following step: in a water / oil two-phase system, directly converting fructose into the 2,5-dihydroxymethyl tetrahydrofuran by one step under the conditions of 0.5-10 MPa H2 and 80-180 DEG C under the action of a catalyst for 0.5-16 hours. The maximum selectivity of the 2,5-dihydroxymethyl tetrahydrofuran is 72%, and the maximum yield is 56%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Agglomerate modifier and using method thereof

InactiveCN1584071AReduce the pulverization rate of low temperature reductionRestorability has no effectIron(III) chlorideBlast furnace

A agglomerate modifier for blasting iron-smelting and utilizing method are disclosed. The agglomerate consists of calcium chloride 80-90wt%, ferric chloride 10-20wt%, the purity of calcium chloride is up to 93%. The agglomerate modifier is added by water and prepared into modifier solution with 1-4% concentration, and sprayed on the surface of agglomerate by streaming volume of agglomerate 1-3wt%. Its advantages include low cost, to decrease low-temperature reducing pulverizing rate and improve reducing strength index.

Owner:ANYANG IRON & STEEL GRP

Method for detecting hexavalent chromium in soil

ActiveCN111077091AAccurate Hexavalent Chromium ConcentrationReduce distractionsMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationChromium contaminationSoil science

The invention, which belongs to the technical field of hexavalent chromium detection methods, particularly relates to a method for detecting the content of hexavalent chromium in soil. The method canbe used for detecting hexavalent chromium in a soil sample containing a large number of reducing agents after ventilation, heating and other pretreatment. Ferric oxide and sulfur reducing agents are used in the method, trivalent chromium is not oxidized, and the oxidation environment can be kept under a certain air flow to inhibit the reduction reaction. Therefore, the interference of a reducing agent on an alkali digestion result is reduced and the digested hexavalent chromium is protected to the greatest extent, so that the concentration of the hexavalent chromium in the solution is rapidlyand accurately measured. The Cr<6+> detection method provided by the invention is simple and convenient to operate, rapid in detection and low in cost and is suitable for chromium-contaminated site repair, acceptance and detection. The method has the broad application value.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

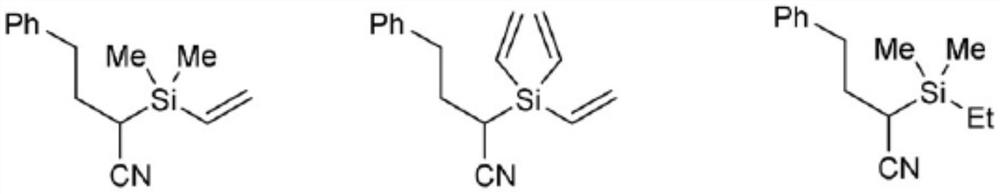

Non-aqueous electrolyte and lithium ion battery containing the non-aqueous electrolyte

PendingCN113823837AAvoid direct contactReduce dissolutionSecondary cellsOrganic electrolytesHigh temperature storageElectrolytic agent

The invention provides a non-aqueous electrolyte and a lithium ion battery containing the non-aqueous electrolyte. The non-aqueous electrolyte comprises a solvent, a lithium salt, an additive A and an additive B, wherein the additive A is an organic silicon nitrile compound, and the additive B is an oxazolone compound. Through the combined action of the additive A organic silicon nitrile compound and the additive B oxazolone compound, the cycle performance, the high-temperature storage performance and the low-temperature performance of the high-voltage lithium ion battery, especially the ternary high-voltage lithium ion battery, are effectively improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

Environment-friendly oxygen-resistant corrosion inhibitor for oilfield surface gathering pipelines and preparation method thereof

The invention discloses an environment-friendly oxygen-resistant corrosion inhibitor for oilfield surface gathering pipelines and a preparation method thereof. The environment-friendly oxygen-resistant corrosion inhibitor for oilfield surface gathering pipelines at least includes 10-50 parts of a corrosion inhibitor main agent, 1-10 parts of a synergist, 0.5-1.5 parts of a surfactant, 40-60 partsof a solvent, 5-25 parts of amino acid, and 2-10 parts of a deoxidant. The corrosion inhibitor main agent comprises: 5-20 parts of an imidazole quaternary ammonium salt, and 10-25 parts of Mannich base. The synergist comprises 1-5 parts of organic alkynol, and 1-10 parts of a plant extract. Specifically, the plant extract includes one or more of a radix stephaniae tetrandrae extract, a banyan leafextract, an artemisia argyi extract, a lettuce extract and a roxburgh rose extract. The environment-friendly oxygen-resistant corrosion inhibitor for oilfield surface gathering pipelines provided bythe invention has the excellent performance of environmental protection and low damage.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

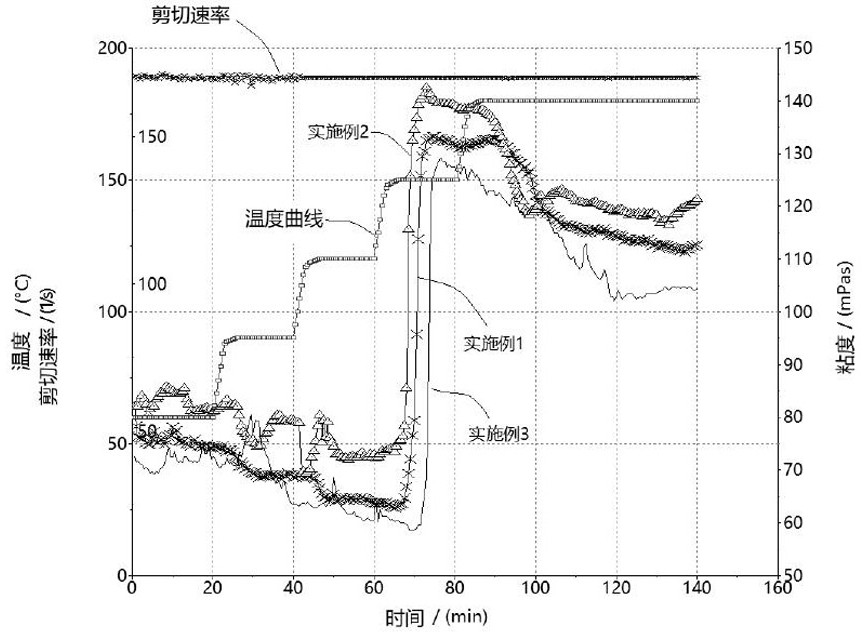

Water-in-oil type nano-emulsion, nano-emulsion composite response type variable-viscosity acid thickening agent and preparation methods of water-in-oil type nano-emulsion and nano-emulsion composite response type variable-viscosity acid thickening agent

ActiveCN113372485AHigh viscosityInhibition of reduction reactionDrilling compositionPolymer scienceMorpholine

The invention relates to the technical field of oil and gas field development, and provides a water-in-oil nano-emulsion, a nano-emulsion composite response type variable-viscosity acid thickening agent and preparation methods of the water-in-oil type nano-emulsion and the nano-emulsion composite response type variable-viscosity acid thickening agent. The nano-emulsion composite response type variable-viscosity acid thickening agent is composed of the following components in parts by weight: 200-350 parts of thickening agent ultrafine powder, 15-20 parts of a coating agent, 5-10 parts of an activating agent, 135-235 parts of white oil, and 390-650 parts of the water-in-oil type nano-emulsion. According to the thickening agent, ultrafine powder is used as a core, a suspension system is used as a middle layer, and the nano-emulsion is used as an outer layer; the nano-emulsion comprises a water phase, an oil phase and a phase inversion agent, and is a copolymer of acrylamide, acryloylmorpholine, a tackifying monomer, dimethyl diallyl ammonium chloride and a hydrophobic monomer; the ultrafine powder is a copolymer of acrylamide, acryloyl morpholine, a cationic monomer and a response monomer; the suspension system is a coating system composed of a coating agent, an activating agent and white oil, and is suitable for acidification construction operation of oil and gas fields of deep wells and ultra-deep wells.

Owner:SHANDONG NUOER BIOLOGICAL TECH

Chemically processed steel sheet improved in corrosion resistance

InactiveUS6544666B2Inhibition of dissolutionEfficient implementationAnodisationMetallic material coating processesChromium CompoundsChemical treatment

A new processed steel sheet comprising of a steel base coated with a Zn or its alloy plating layer and a converted layer, which contains both of at least an insoluble or scarcely-soluble metal compound and at least a soluble metal compound. The insoluble or scarcely-soluble compound may be one or more of valve metal oxides or hydroxides, and the soluble compound may be one or more of valve metal fluorides. The converted layer may be also composed of one or more of complex compounds of Mn and Ti. The insoluble or scarcely-soluble compound acts as a barrier for insulation of a steel base from an atmosphere, while the soluble compound exhibits a self-repairing faculty to repair defective parts of the converted layer. Due to the converted layer, the processed steel sheet is remarkably improved in corrosion resistance, without the presence of chromium compounds which would put harmful influences on the environment.

Owner:NISSHIN STEEL CO LTD

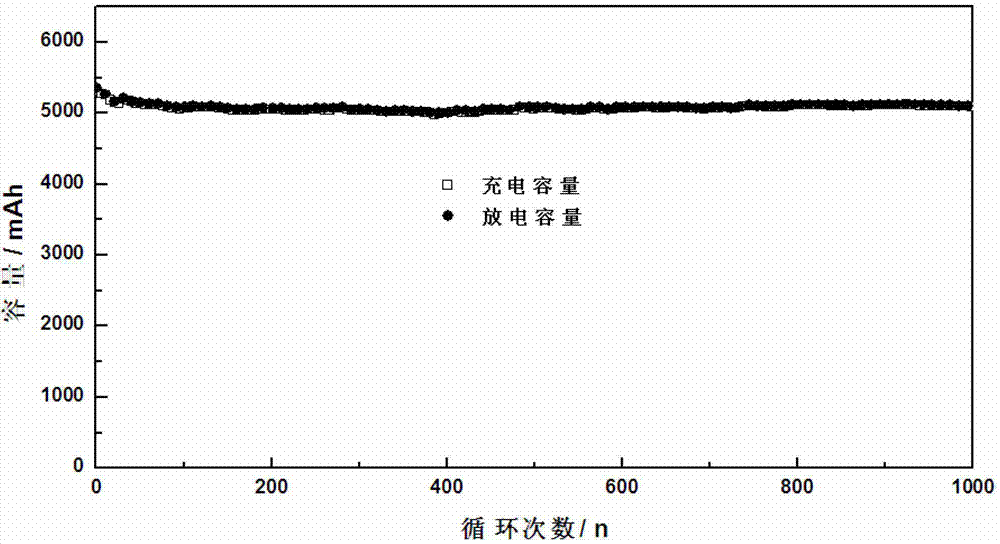

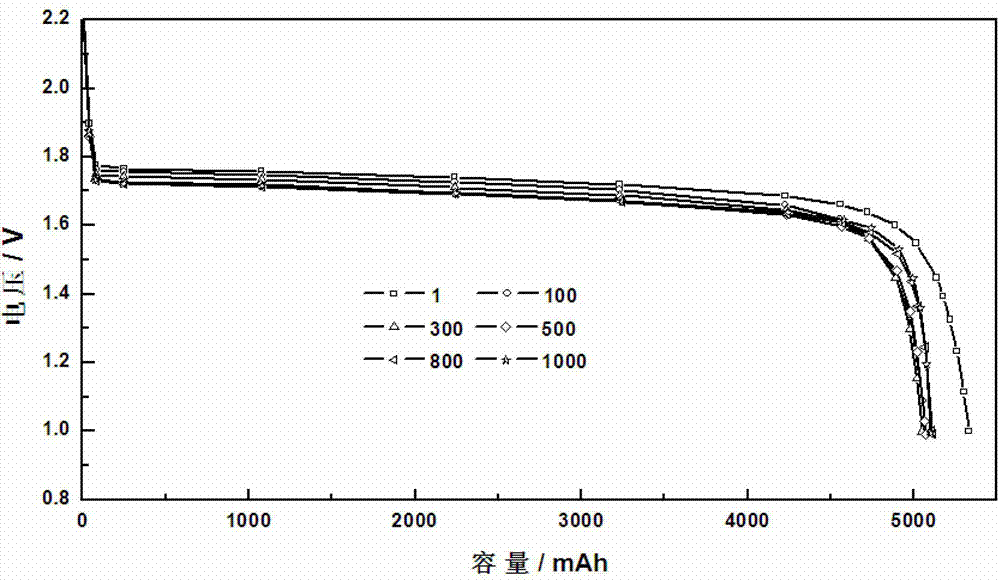

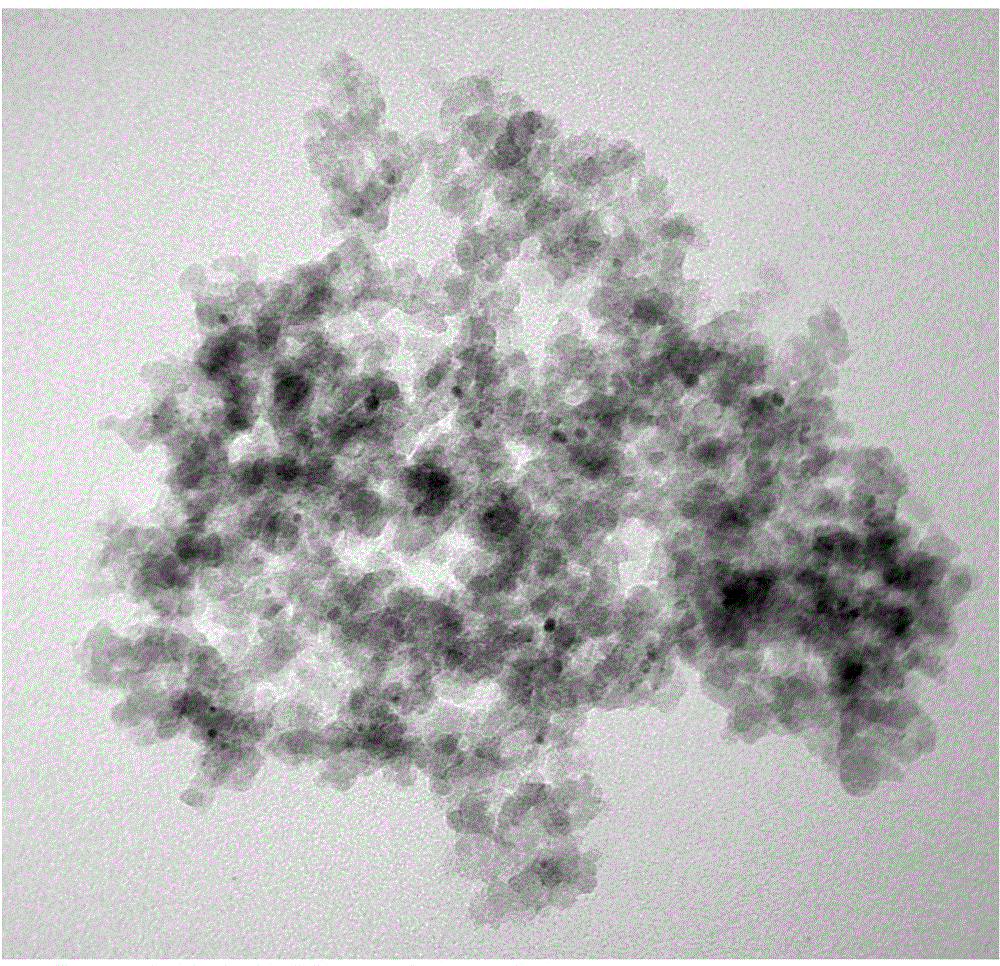

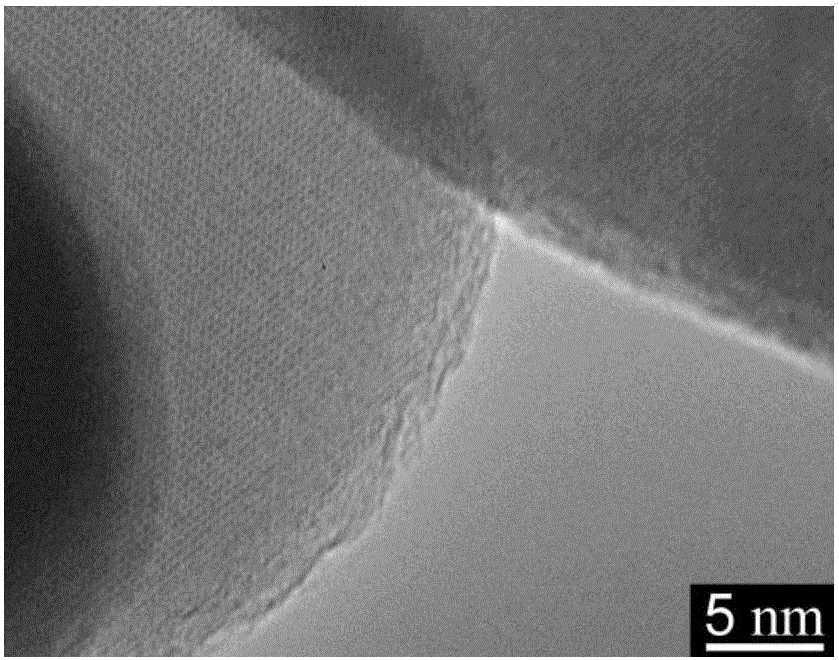

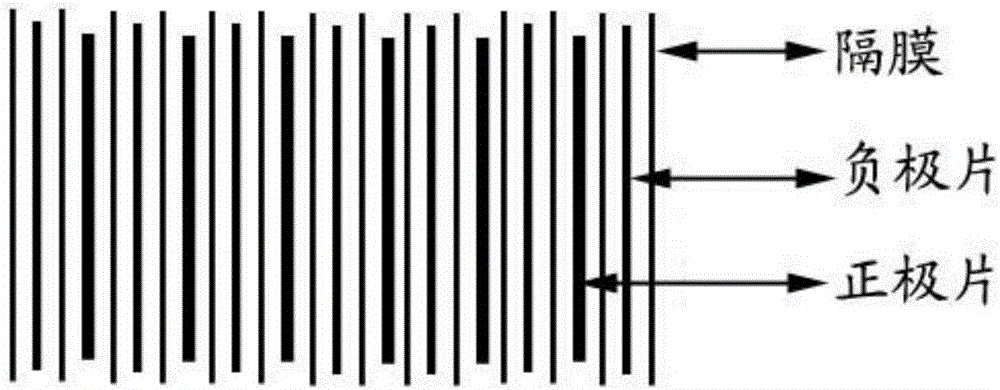

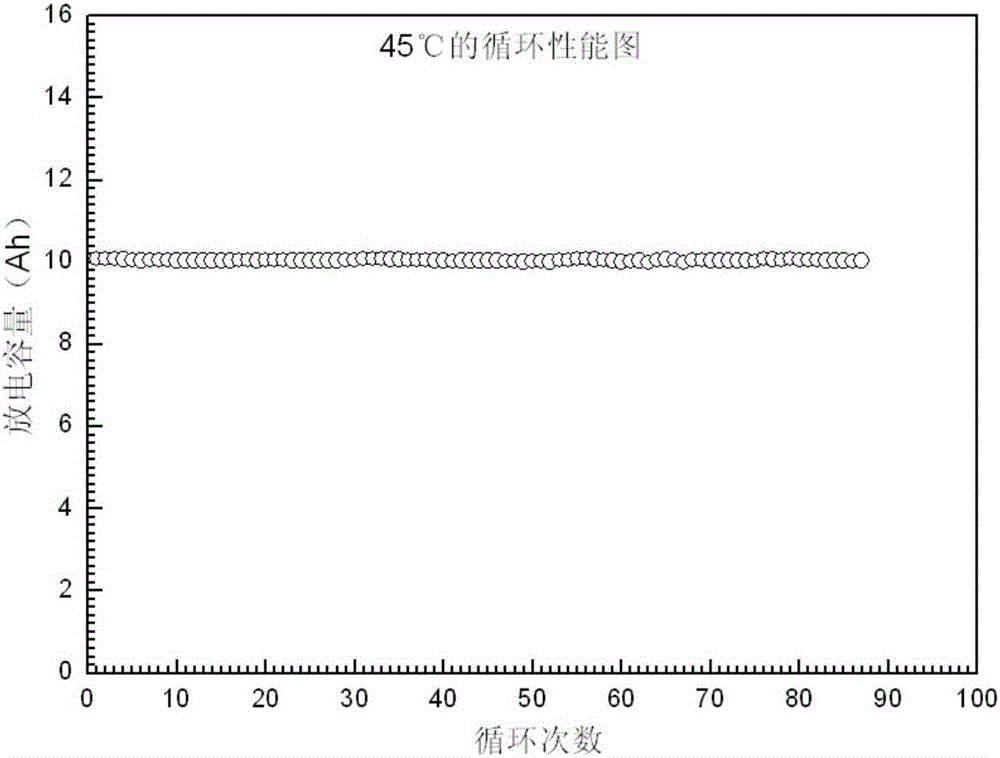

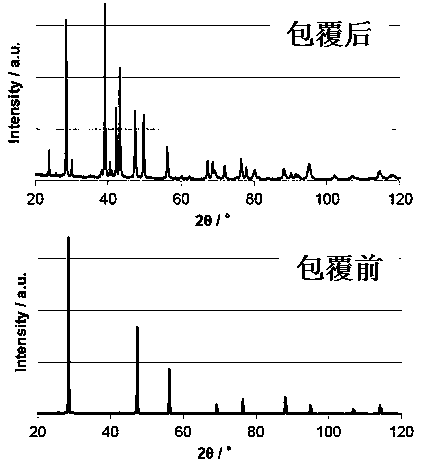

Li4Ti5O12 negative material and lithium titanate battery prepared from same

ActiveCN106532031AStable structureImprove conductivityCell electrodesSecondary cellsSubstance useCarbon layer

The invention relates to an Li4Ti5O12 negative material and a lithium titanate battery prepared the Li4Ti5O12 negative material. The Li4Ti5O12 negative material disclosed by the invention is of a multilayer core-shell structure, and is prepared from an Li4Ti5O12 material in the center, an Li1+2xM2yTi(2-x-y)P3O12-x layer in the middle and a conducting carbon layer on the surface, wherein x and y are in the range of 0 to 0.2. The lithium titanate battery is prepared from an active substance using the Li4Ti5O12 material as a negative plate. The Li4Ti5O12 negative material and the lithium titanate battery disclosed by the invention have excellent electrochemical performance, cycling stability and safety, and are expected to be widely applied in the fields of new energy automobiles and energy storage.

Owner:四川国创成电池材料有限公司

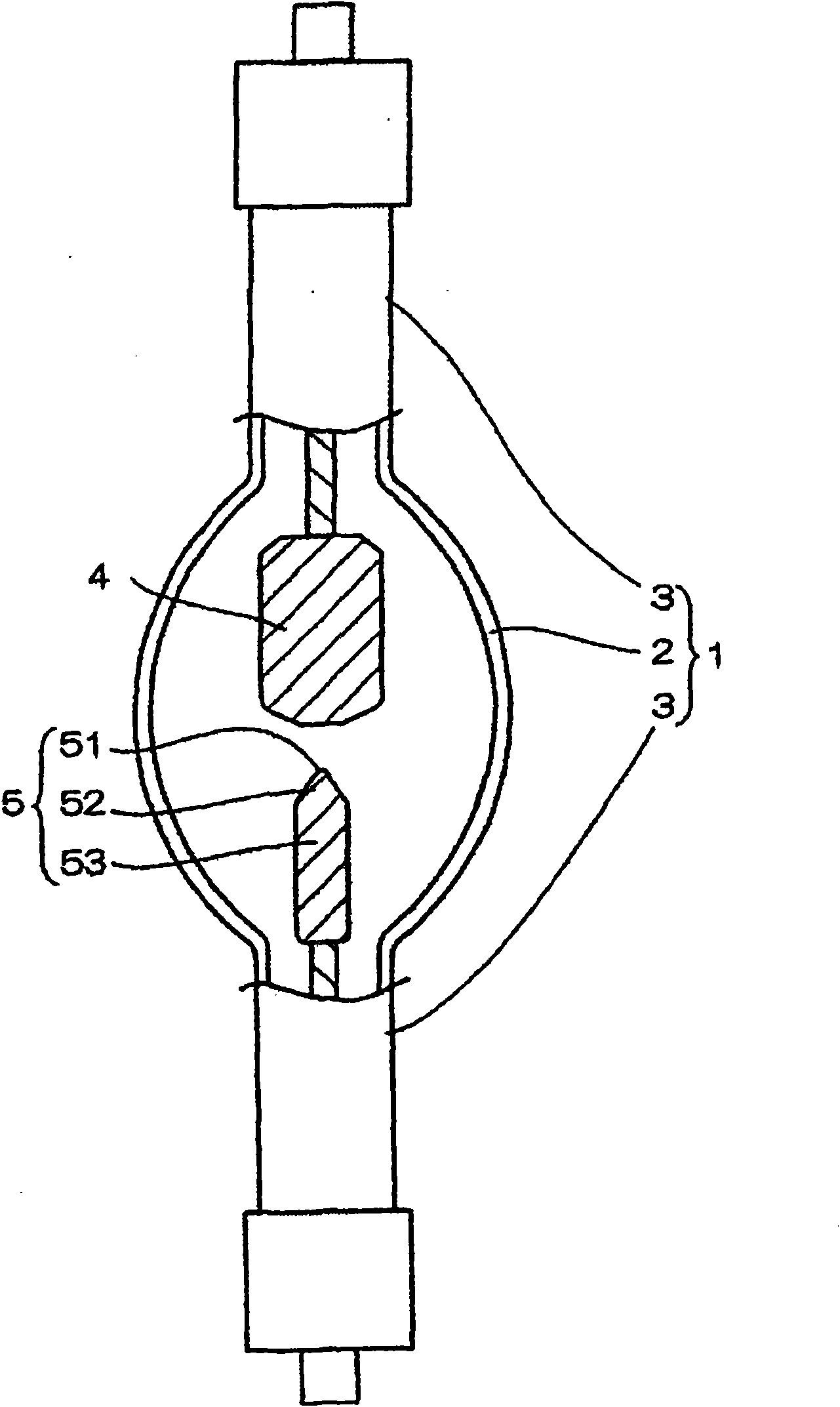

Discharge lamp

ActiveCN101794704APromote reductionIncrease supplyGas discharge lamp detailsGas-discharge lampEngineering

Owner:USHIO DENKI KK

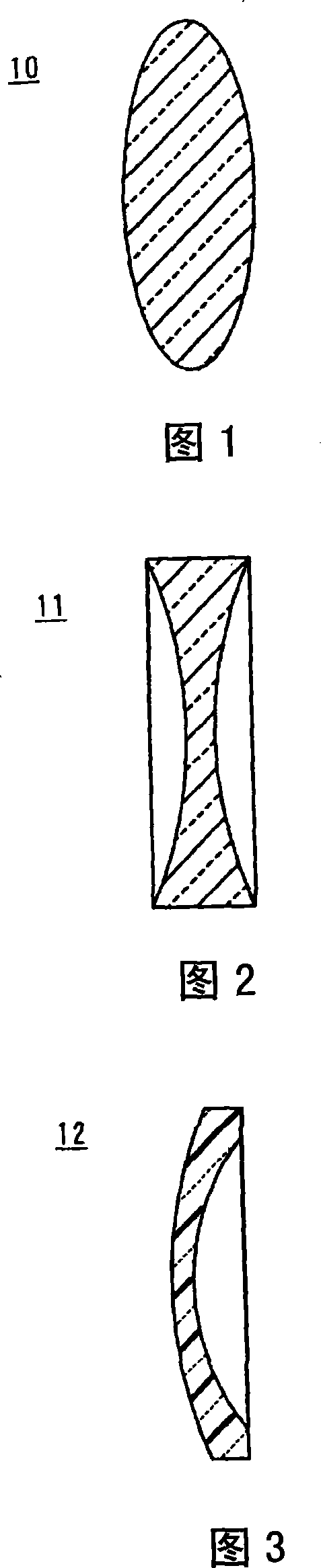

Translucent ceramic, method for manufacturing the same, optical component, and optical device

InactiveCN101163649AReduce porosityHigh light transmittanceRecord information storageOptical beam guiding meansOptical pickupChemical composition

Disclosed is a light-transmitting ceramic having high light transmittance. Specifically disclosed is a light-transmitting ceramic mainly containing a perovskite compound having a chemical composition represented by the following general formula: (Ba1-s-tSrsCat)(MxB1yB2z)vOw (wherein M includes at least one of Sn, Zr and Hf; B1 represents at least one of Mg, Zn, Y and In; B2 represents at least one of Ta and Nb; 0 = s = 0.99; 0.01 = t = 0.45; x + y + z = 1; 0 < x = 0.9; 1.00 = z / y = 2.40; 0.97 = v = 1.05; and w represents a positive number required for maintaining electroneutrality). This light-transmitting ceramic can be advantageously used as an objective lens (2) for an optical pickup (9).

Owner:MURATA MFG CO LTD

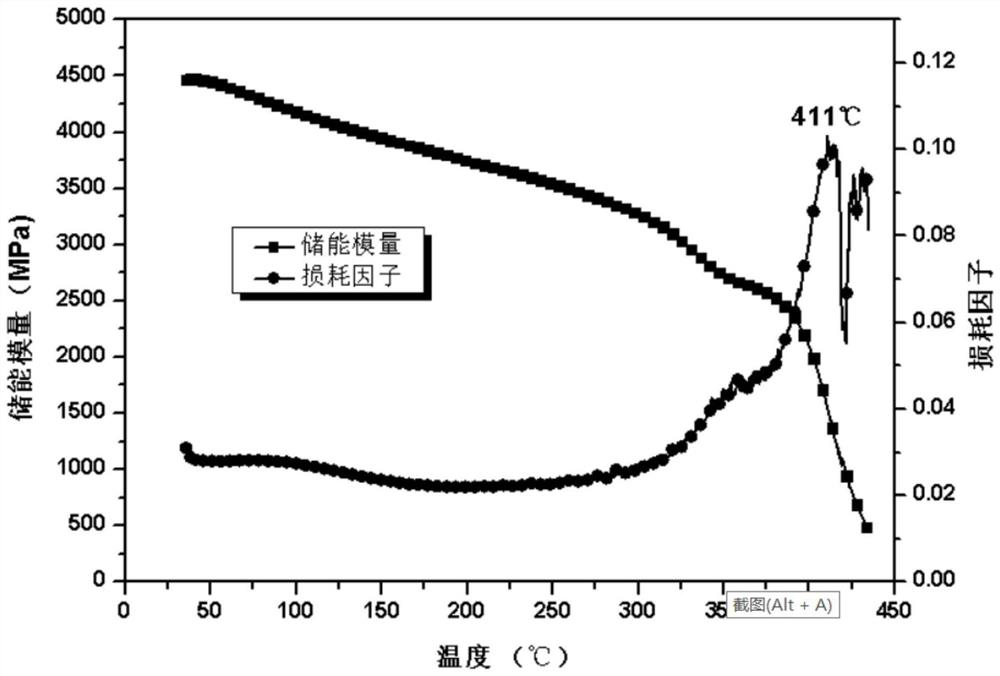

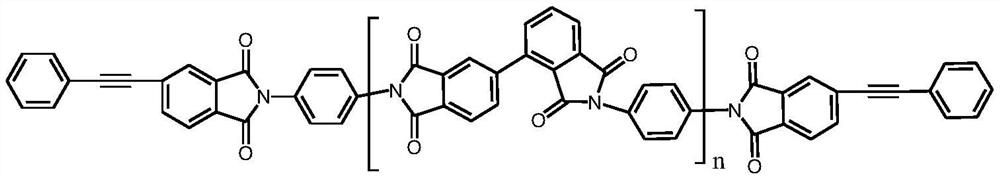

Ultrahigh-temperature polyimide heat-conducting insulating material and preparation method thereof

PendingCN113930073AExcellent high temperature thermal oxygen/thermal stabilityGood mechanical propertiesThermal dilatationPolymer science

The invention discloses an ultrahigh-temperature polyimide heat-conducting insulating material and a preparation method thereof, and belongs to the field of high polymer materials. The ultrahigh-temperature polyimide heat-conducting insulating material comprises the following raw materials in parts by mass: 100 parts of reactive polyimide resin, 5-20 parts of a heat-conducting filler, 3-5 parts of a repairing agent, 0.5-3 parts of an anti-aging agent, and 1-10 parts of a reactive diluent. According to the preparation method of the ultrahigh-temperature polyimide heat-conducting insulating material, reactive polyimide resin is taken as a base material, the heat-conducting filler, the repairing agent, the anti-aging agent and the reactive diluent are added, a modified resin system is prepared by adopting a melt blending process, an insulating material system with the glass transition temperature being greater than 350 DEG C, the initial thermal decomposition temperature being greater than 500 DEG C, the heat conductivity coefficient being greater than 0.3 W / m.K, the electric breakdown strength being greater than 80kV / mm and the thermal expansion coefficient being less than 40PPM / DEG C is obtained by means of program temperature controlled curing, the excellent performance of the insulating material system meets the use requirements of sealing and insulation of special motor stator electromagnetic wire windings, and the material has a wide application prospect in the technical field of heavy oil thermal recovery.

Owner:辽宁鲸苇科技有限公司

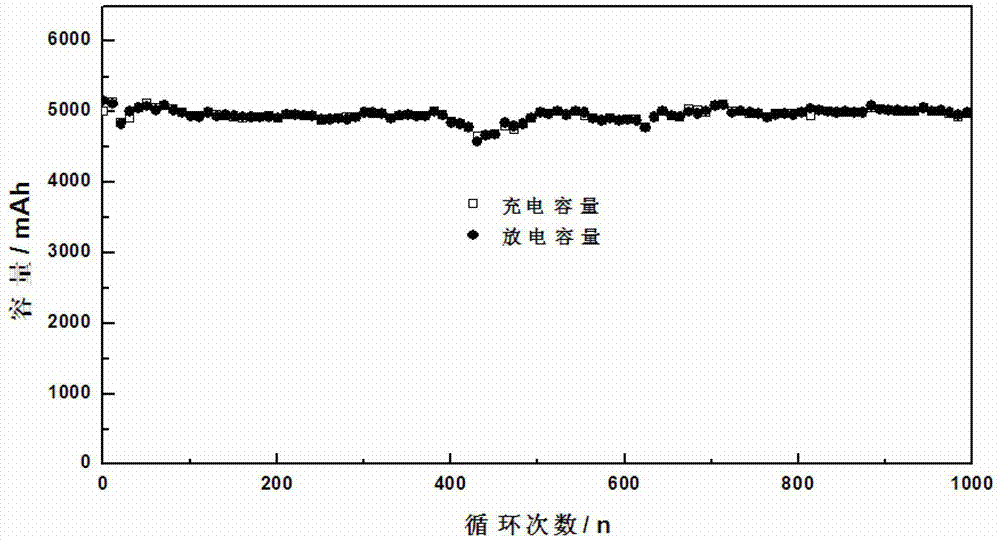

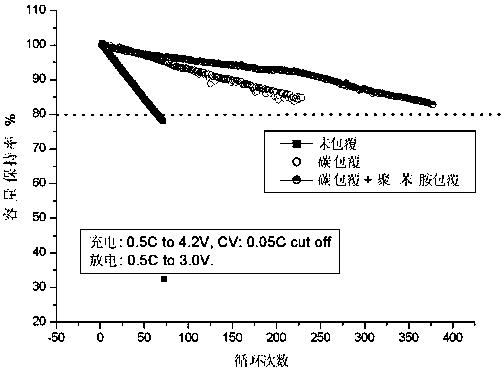

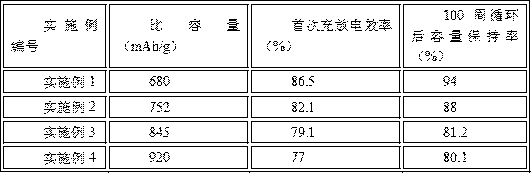

A kind of composite negative electrode material of high-capacity lithium-ion battery and preparation method thereof

The invention relates to the technical field of a lithium ion battery, in particular to a composite negative electrode material of a high-capacity lithium ion battery and a preparation method of the composite negative electrode material. The constituents of the composite negative electrode material are silicon powder and graphite which are arranged at an inner layer and a dual-layer coating object arranged at an outer layer, a first layer of the dual-layer coating object is a coating carbon layer, the coating object is amorphous carbon, a second layer of the dual-layer coating object is a coating polymer, the coating object is polyaniline, the composite negative electrode material is a powder material, the grain size of the powder material is 0.5 to 40 micrometers, the mass ratio of the silicon powder to the graphite is 1:99 to 1:1, the mass percentage of the coating carbon layer accounts for 3-15%, and the mass percentage of the coating polymer layer accounts for 3-15%. With the composite negative electrode material, the problems of low charging and discharging specific capacity and poor cycle performance of the conventional carbon material serving as the negative electrode material of a power lithium ion battery are solved, and the composite negative electrode material is high in capacitance and has favorable cycle performance and stability performance.

Owner:WANXIANG 123 CO LTD

A kind of electrolytic solution and lithium ion battery containing the electrolytic solution

ActiveCN106410273BInhibition of reduction reactionInhibit positive oxidationFinal product manufactureElectrolyte accumulators manufactureOrganic solventSulfate

The present application relates to the technical field of lithium-ion batteries, in particular, to an electrolyte and a lithium-ion battery containing the electrolyte. The electrolytic solution of the present application includes lithium salt, organic solvent and additive, contains diester compound and sulfuric acid ester compound in the additive, and diester compound includes carbonate dimer, carboxylate dimer and sultone Dimer; sulfate ester compounds include cyclic sulfate ester compounds and linear or branched chain sulfate ester compounds. The diester compound can effectively form a film on the positive electrode, inhibit the oxidation of the electrolyte on the positive electrode, and effectively improve the high temperature performance and cycle performance of the battery; the sulfuric acid ester compound can inhibit the reduction reaction of the diester compound on the negative electrode, so that the battery can obtain good Excellent low-temperature charge-discharge performance and rate performance, and can improve the cycle performance of the battery.

Owner:NINGDE AMPEREX TECH

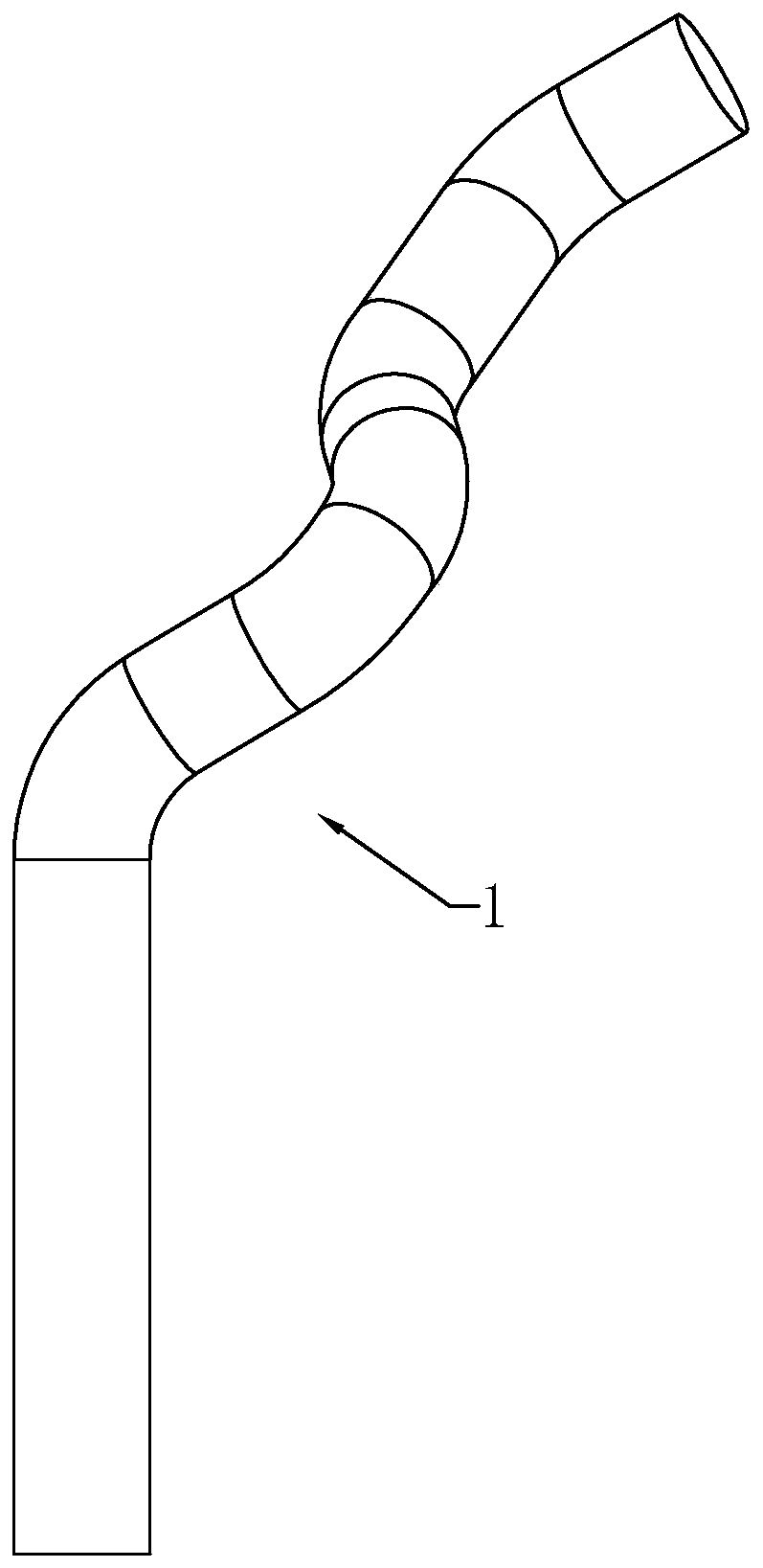

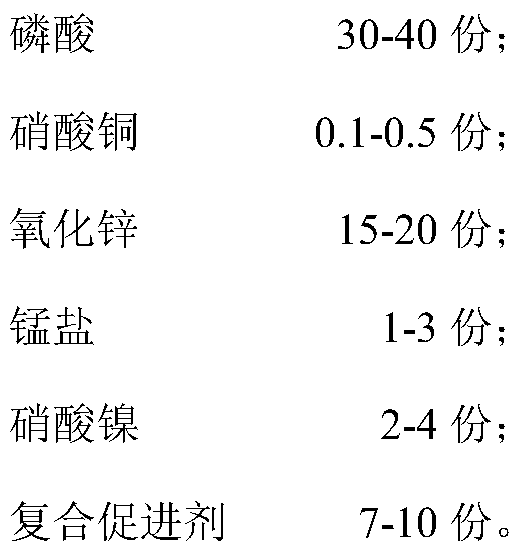

Car trunk hinge part and production process thereof

InactiveCN109706440AEffective complexationIncrease active pointMetallic material coating processesElectrode potentialElectrochemical response

The invention discloses a car trunk hinge part. The outer surface of the hinge part is treated with a phosphating solution to form a phosphating film, wherein the phosphating solution comprises the following components in parts by weight: 30-40 parts of phosphoric acid, 0.1-0.5 part of copper nitrate, 15-20 parts of zinc oxide, 1-3 parts of manganese salt, 2-4 parts of nickel nitrate, and 7-10 parts of a compound accelerant. The car trunk hinge part has the advantages that: phosphoric acid and zinc oxide are taken as main film-forming substances, so that a continuous and uniform phosphating film is formed on a treated metal surface. Meanwhile, the compound accelerant further can be added to increase film-forming speed of the phosphating film and improve film-forming quality of the phosphating film. Besides, electrode potential of copper is positive than that of iron, and copper ions are reduced for being deposited on the surface of a phosphated hinge body, so that a cathode region of the surface is increased, electrochemical reaction of phosphating is further promoted, formation of a phosphating crystal nucleus is accelerated, and crystalline grains are refined, and therefore, thephosphating film is compact and uniform, phosphating speed is reduced, and the phosphating film has the advantages of being tight in film-forming and strong in adhesive force.

Owner:温州疆昊汽车部件有限公司

High-temperature and high-voltage electrolyte and battery containing same

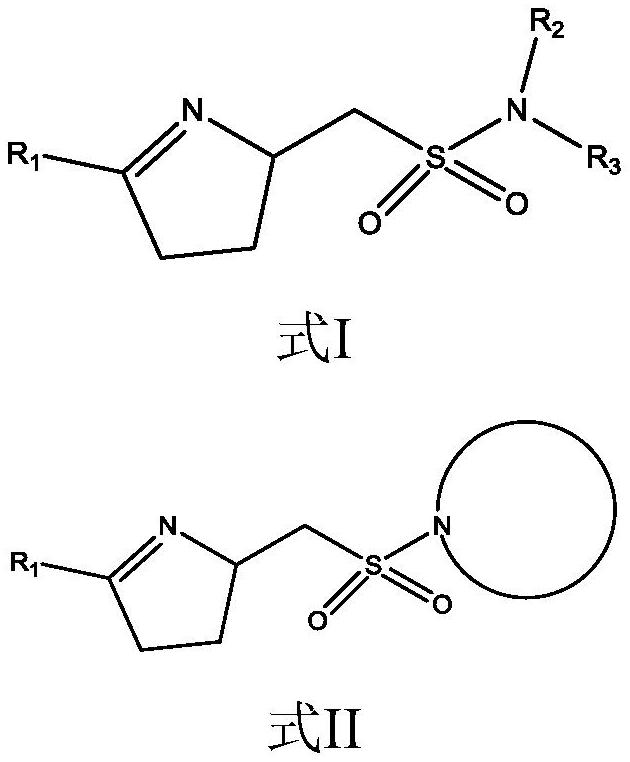

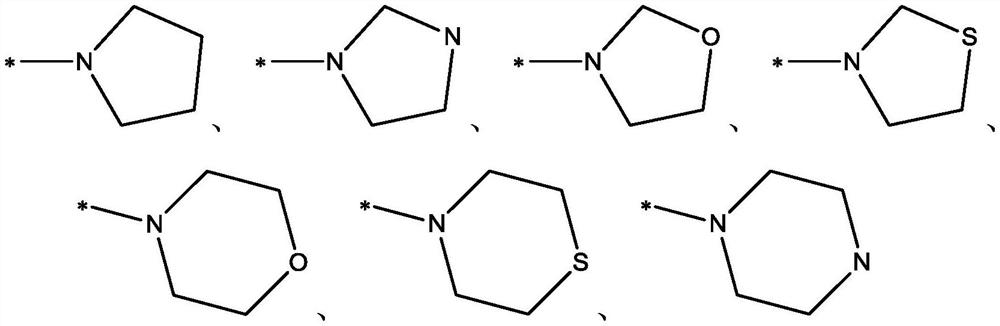

ActiveCN114497738AImprove normal temperature cycle performanceInhibition of reduction reactionLi-accumulatorsOrganic electrolytesElectrolytic agentOrganic solvent

The invention provides a high-temperature and high-voltage electrolyte and a battery containing the electrolyte, the electrolyte comprises an electrolyte salt, an organic solvent and an additive, and the additive comprises a first additive and a second additive; the first additive is selected from sulfonamide compounds, and the second additive is selected from oxazolone compounds. Through the synergistic effect of the first additive and the second additive, a film can be formed on the surface of a positive electrode, direct contact between an electrode material and an electrolyte is avoided, the microstructure of the electrode material is stabilized, dissolution of transition metal elements at high temperature is reduced, and an SEI film can be formed on the surface of a negative electrode material; and meanwhile, the interface impedance can be reduced, so that the high-temperature storage performance and the high-temperature cycle performance of the battery at high temperature and high voltage are effectively improved, and meanwhile, the normal-temperature cycle performance of the battery can be further improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

PET gold stamping base film and preparation method thereof

InactiveCN106427150AExcellent shrink resistanceGood thermal stabilityLamination ancillary operationsSynthetic resin layered productsPolyesterSurface friction

The invention discloses a PET gold stamping base film and a preparation method thereof. The PET gold stamping base film comprises a core layer located in the middle and surface layers arranged on two surfaces of the core layer, wherein the surface layers and the core layer are integrally molded through co-extrusion and biaxial stretching; the core layer is a PET layer; each surface layer is a PET layer mixed with an anti-blocking agent; the preparation method comprises the steps of synthesizing a polyester, commixing, co-extruding, casting a piece on a die head, carrying out longitudinal stretching, carrying out transverse stretching, drawing and trimming, winding and slitting to obtain a finished product, wherein the thickness is 10mu m to 36mu m, the width is 8700mm, the heat-resistance temperature exceeds 120 DEG C, the tensile strength is more than or equal to 220MPa, the heat shrinkage rate is smaller than or equal to 3.5 percent, and the surface friction coefficient of the base film is smaller than or equal to 0.55. Compared with a conventional transferring base film, the PET gold stamping base film provided by the invention has excellent shrinkage-proof performance; the gold stamping base film has excellent thermal stability and great tensile strength, and can meet the requirements of customers to produce gold stamping films which are not deformed at a high temperature, are completely subjected to gold stamping and have complete and clear patterns and texts.

Owner:江苏三房巷薄膜股份有限公司

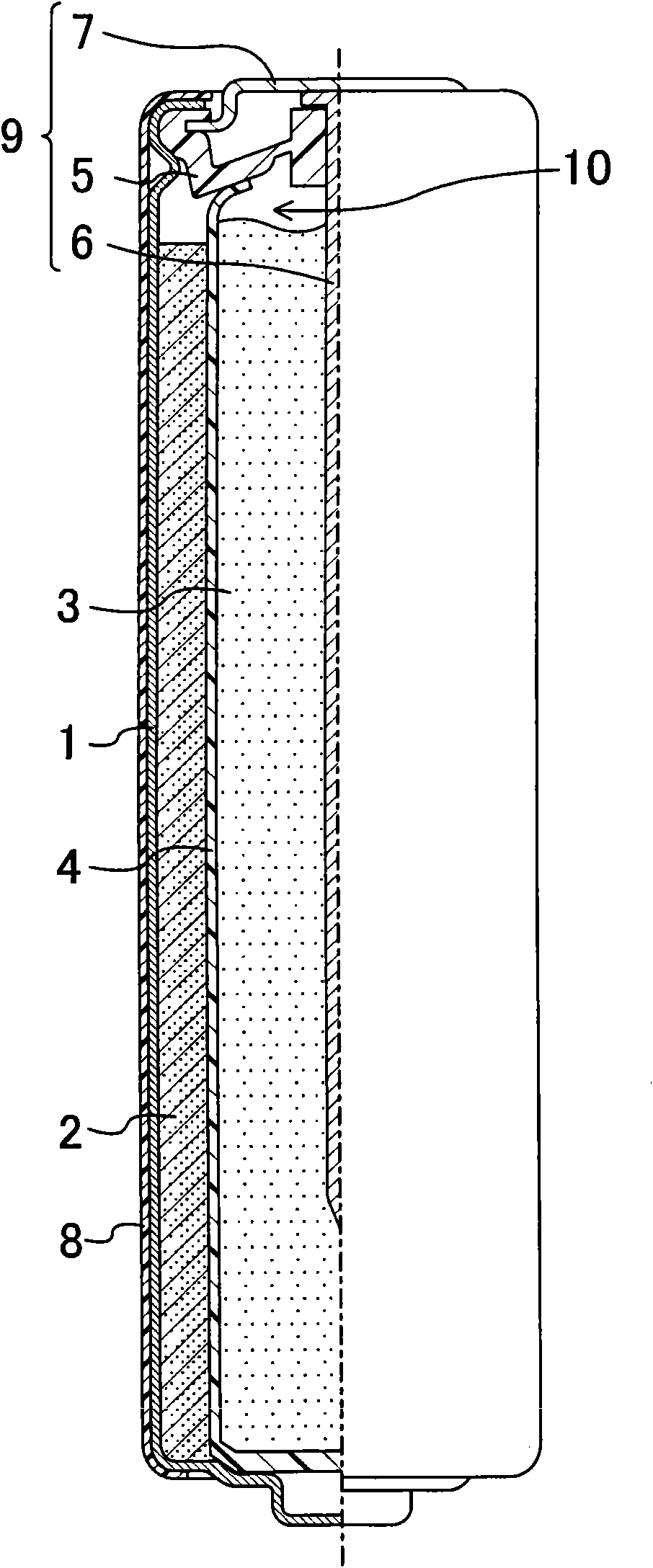

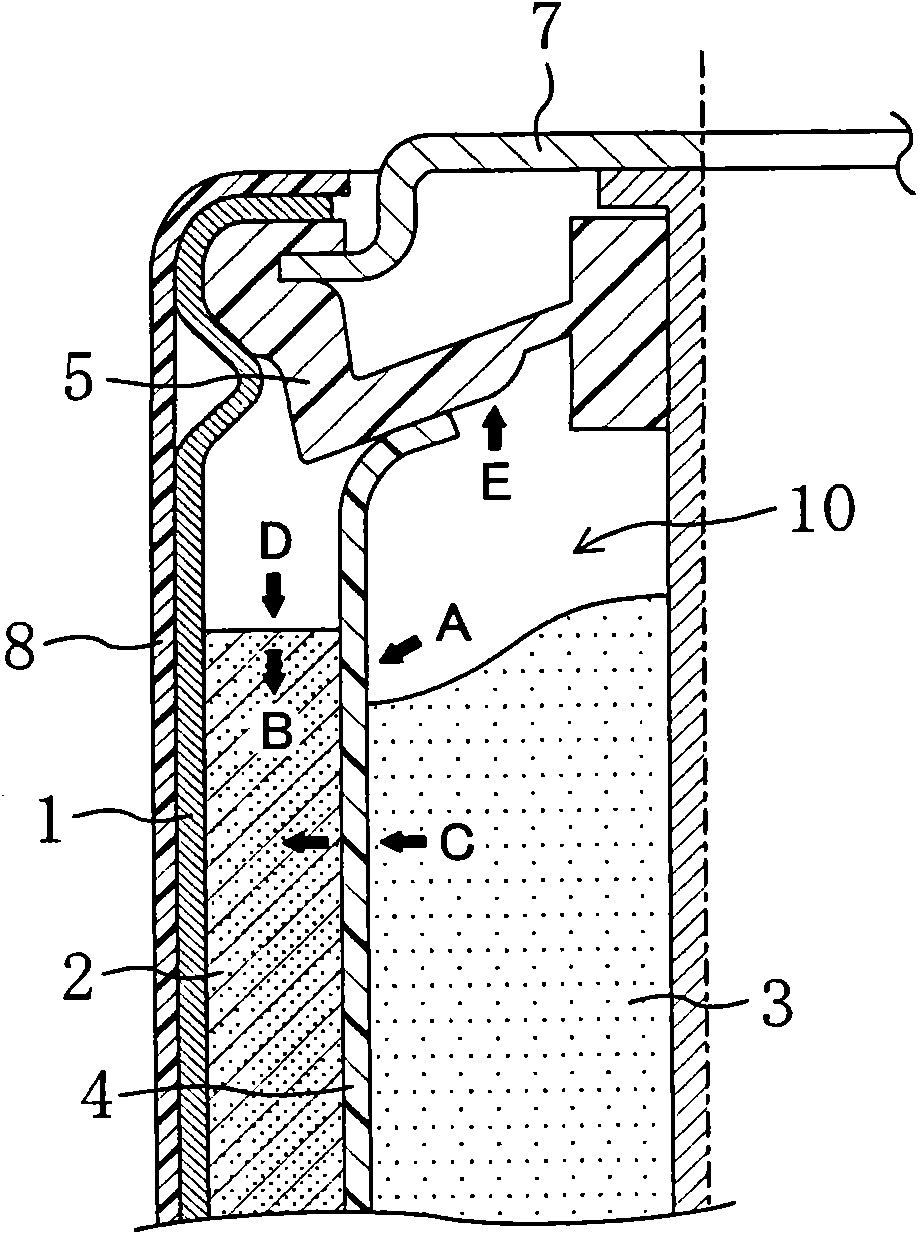

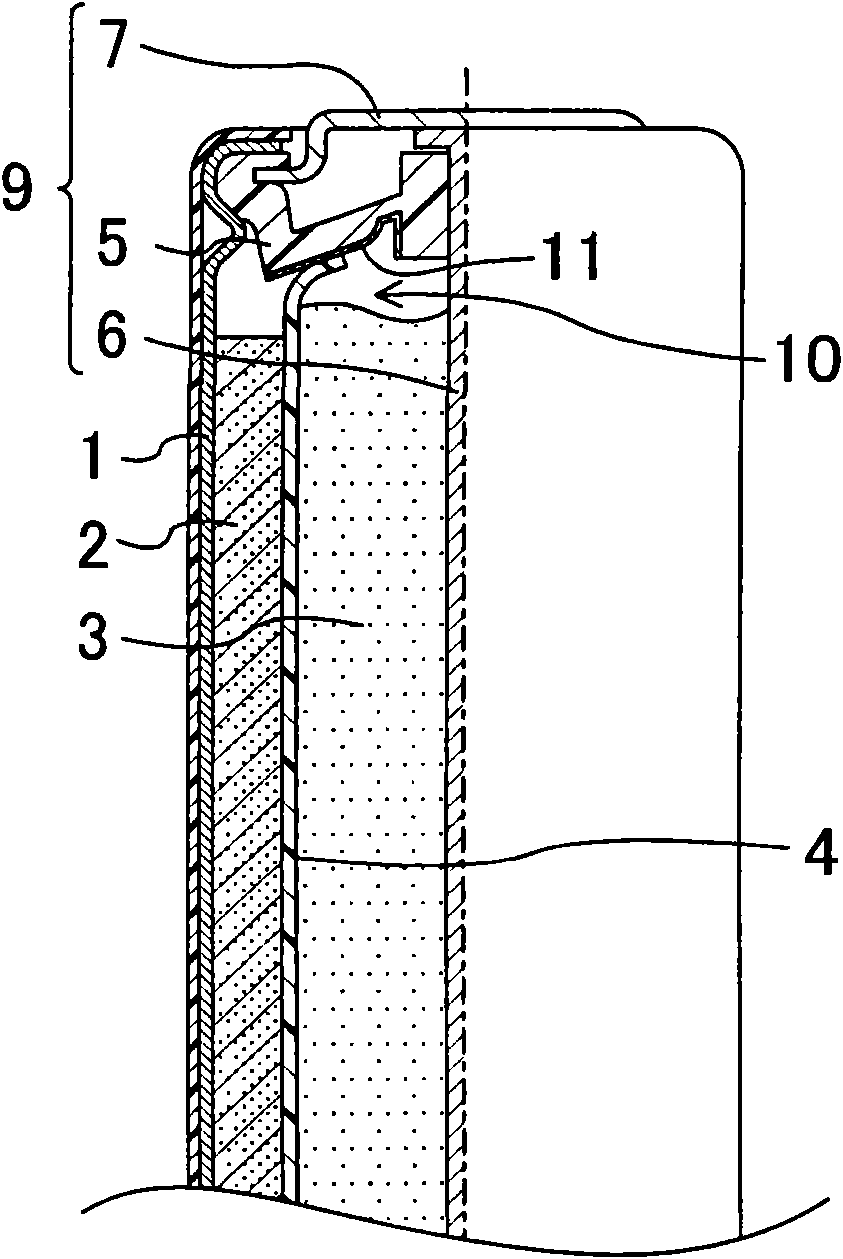

Alkali battery

ActiveCN101803083AInhibition of reduction reactionSmall volumeCell seperators/membranes/diaphragms/spacersFinal product manufactureElectrolysisElectric potential

The invention relates to an alkali battery. The opening part of a battery case (1) is sealed by a sealing plate (7) with a gasket (5) interposed, and the electrical potential of electrolytic manganese dioxide which is the active material on the positive electrode is in the range of 275-320 mV, and the capacity of a closed space (10) which is formed between the positive electrode (2) and negative electrode (3) inside the battery case (1), on the one hand, and the gasket (5), on the other, is in the range of 2.0-6.0% of the capacity of the battery interior which is formed by the battery case (1) and the sealing plate (7).

Owner:PANASONIC CORP

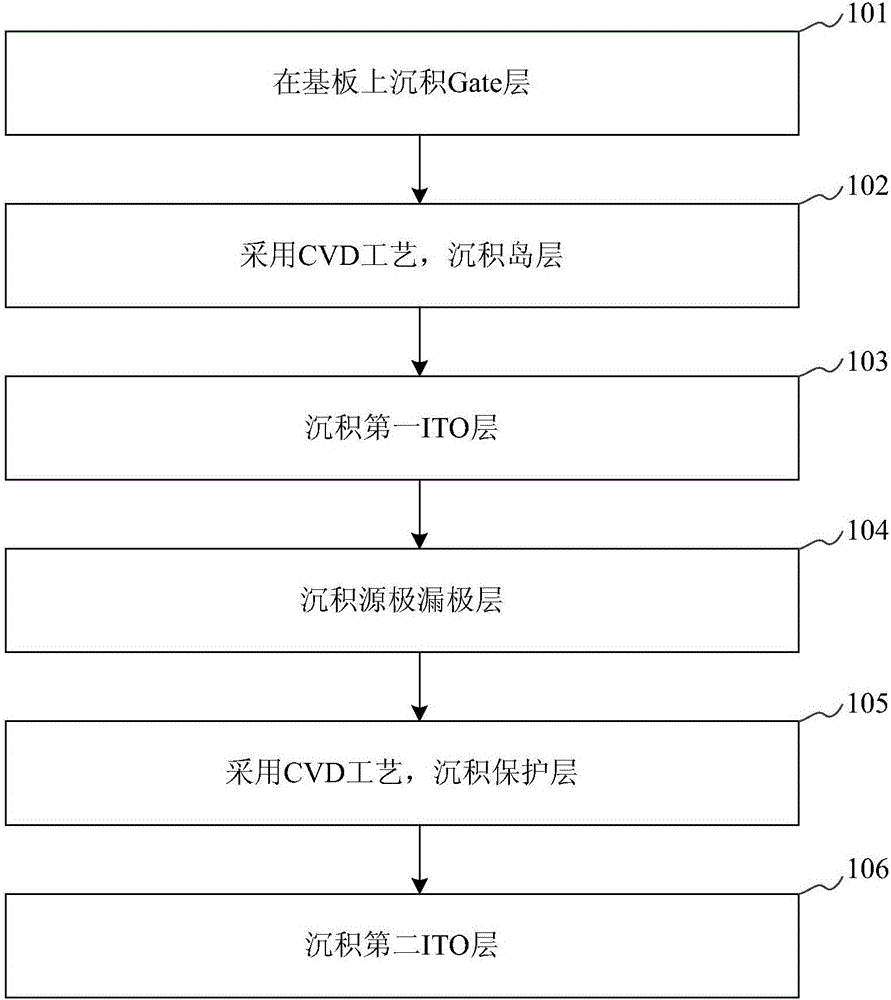

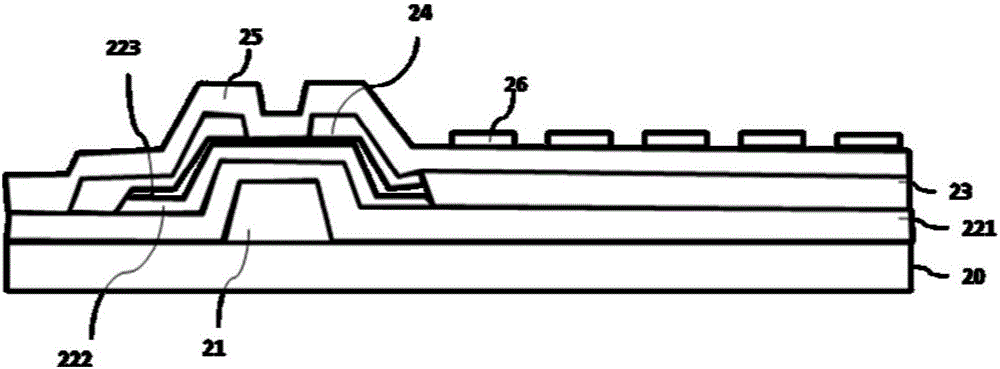

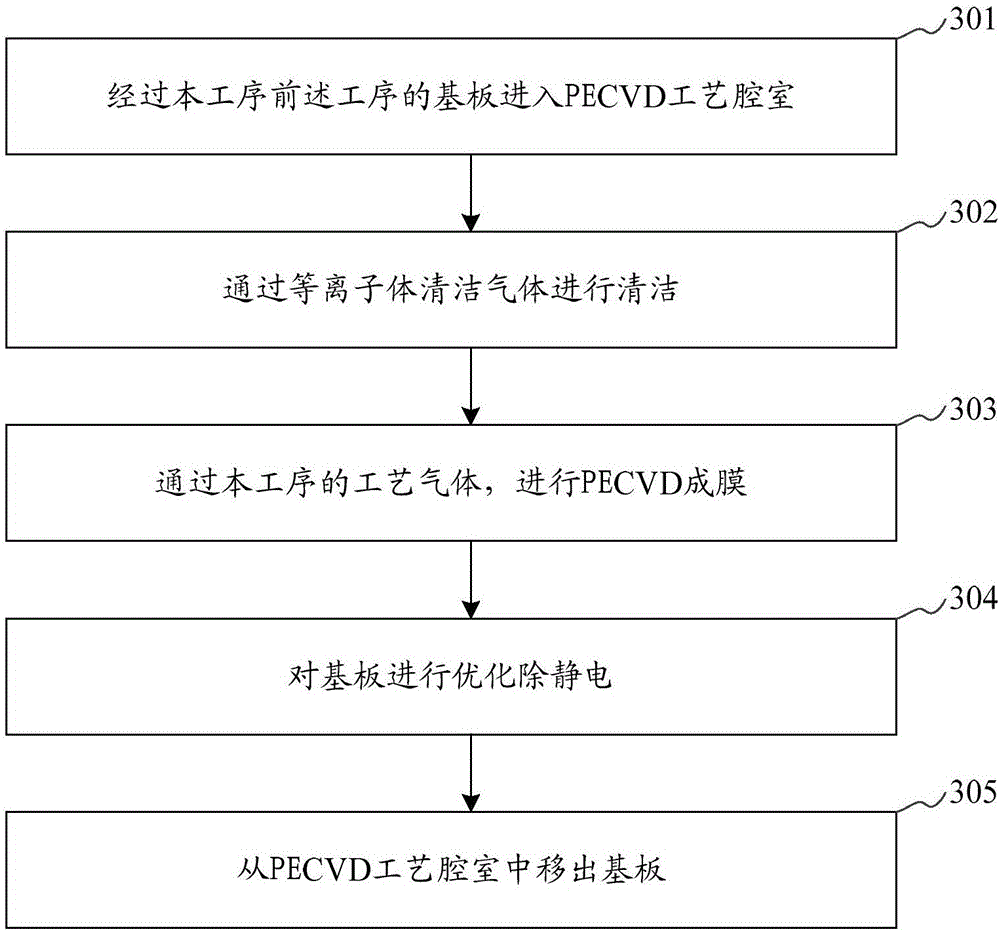

Wide visual angle mode TFT substrate manufacturing method

InactiveCN106098617AImprove yieldSave energySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceTransmittance

The invention discloses a wide visual angle mode TFT substrate manufacturing method. The method includes the steps of depositing a Gate layer on a substrate, depositing an island layer by employing CVD technology, depositing a first ITO layer, depositing a source-drain electrode layer, depositing a PA layer by employing PECVD technology, and depositing a second ITO layer, wherein the step of depositing a PA layer by employing PECVD technology includes dissociating the process gas in the step with relative low power into plasma, reacting to deposit a first PA layer, and dissociating the process gas in the step with relative high power into plasma and reacting to deposit a second PA layer. In the manufacturing process, reduction of the first ITO layer can be prevented, and the electric and optical performance of the first ITO layer can be protected. The transmittance of the TFT substrate can be improved, and the power consumption of a TFT display is reduced.

Owner:TRULY HUIZHOU SMART DISPLAY

Preparation method of high melt strength polypropylene by solid phase reaction

The invention relates to a preparation method of high melt strength polypropylene by solid phase reaction. The purpose of the invention is to solve the problems that universal polypropylene is low instrength and is hard to be applied to the fields such as foaming, hollow molding. A formula of the high melt strength polypropylene comprises the following materials in parts by weight: 100 parts of powdery or granular polypropylene, 1 to 4 parts of grafted monomer, 0.2 to 4 parts of an antioxidant, the preparation method comprises the following steps: weighing and uniformly mixingpowdery or granular polypropylene, grafted monomer and the antioxidant, enabling the three to react for 5 to 40 mins at the temperature of 120 to 130 DEG C in air, after reaction, adding 0.1 to 0.4 parts by weight ofthe antioxidant and uniformly stirring (used for stabilization of subsequent processing and forming), thus obtaining high melt strength polypropylene. The invention provides a method for preparing high melt strength polypropylene with simple process, flexible operation, low cost, good environmental protection, good color and luster with large scale industrial implementation prospect, branched structure and a small amount of cross-linking structure.

Owner:XUZHOU COLLEGE OF INDAL TECH +1

A kind of environmentally friendly high-temperature acidification corrosion inhibitor and preparation method thereof

The invention provides an environment-friendly high-temperature acidizing resistant corrosion inhibitor and a preparation method thereof. The environment-friendly high-temperature acidizing resistantcorrosion inhibitor comprises the components of, by weight, 10-50 parts of corrosion inhibitor primary agents, 1-10 parts of synergists, 0.5-1.5 parts of surfactants, 40-60 parts of solvents and 5-10parts of mercaptan acid; the corrosion inhibitor primary agent comprises 5-15 parts of polyquinoline quaternary ammonium salt, 5-10 parts of imidazolium quaternary ammonium salt, 10-25 parts of Mannich base; and the synergist comprises 1-5 parts of organic alkynol and 1-10 parts of plant extracts, wherein plant extract comprises one or more of a stephania tetrandra extract, a rhizoma corydalis extract, a sophora flower bud extract and a roxburgh rose extract. The environment-friendly high-temperature acidizing resistant corrosion inhibitor has the excellent performance of environmental protection, high temperature resistance, low damage and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com