A kind of composite negative electrode material of high-capacity lithium-ion battery and preparation method thereof

A technology of lithium-ion batteries and negative electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of good cycle performance and stability, large capacitance of composite negative electrode materials, and low charge-discharge specific capacity to achieve cycle performance Good stability, low requirements for reaction conditions, and large capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

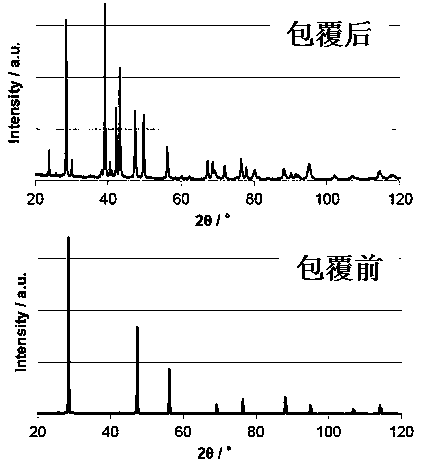

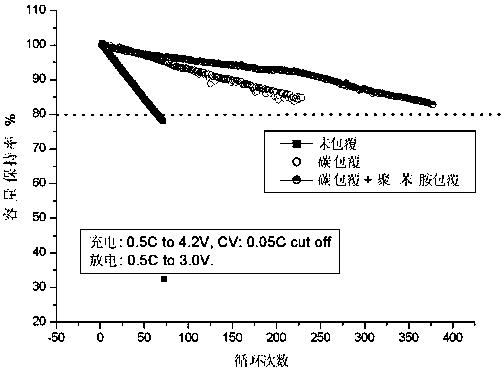

Image

Examples

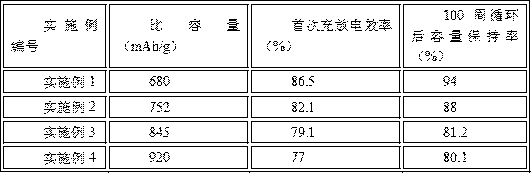

Embodiment 1

[0037] A composite negative electrode material for a high-capacity lithium-ion battery, the preparation method of which is as follows:

[0038] (1) Weigh 200g of silicon powder and 800g of natural graphite, mix and stir the silicon and graphite to form a silicon-carbon composite powder. The particle size of the silicon powder is 100nm-1μm, and the particle size of the graphite is between 4μm-26μm. The high-energy ball mill is used for dry mixing, and the mixture is evenly mixed at 150rpm for 30min;

[0039] (2) Mix 1000g of silicon-carbon composite powder obtained in step (1) with 100g of asphalt. The specific method: disperse the silicon-carbon composite powder in tetrahydrofuran / acetone solution dissolved with coal tar pitch, put it into a mixer, and stir at 160rpm for 30min to make it even. In the tetrahydrofuran / acetone solution of coal tar pitch, coal tar pitch 100g, tetrahydrofuran 400g, acetone 500g;

[0040] (3) After drying in a blast oven at 150oC for 2 hours to eva...

Embodiment 2

[0051] A composite negative electrode material for a high-capacity lithium-ion battery, the preparation method of which is as follows:

[0052] (1) Weigh 250g of silicon powder and 750g of natural graphite, mix and stir the silicon and graphite to form a silicon-carbon composite powder. The particle size of the silicon powder is 100nm - 1μm, and the particle size of the graphite is between 4μm - 26μm. The high-energy ball mill is used for dry mixing, and the mixture is uniformly mixed at 150rpm for 30min.

[0053] (2) Mix 1000g of silicon-carbon composite powder obtained in step (1) with 100g of asphalt. The specific method: disperse the silicon-carbon composite powder in tetrahydrofuran / acetone solution dissolved with coal tar pitch, put it into a mixer, and stir at 160rpm for 30min to make it even. In the tetrahydrofuran / acetone solution of coal tar pitch, 100 g of coal tar pitch, 400 g of tetrahydrofuran, and 500 g of acetone.

[0054] (3) After drying in a blast oven at 1...

Embodiment 3

[0064] A composite negative electrode material for a high-capacity lithium-ion battery, the preparation method of which is as follows:

[0065] (1) Weigh 300g of silicon powder and 700g of natural graphite, mix and stir the silicon and graphite to form a silicon-carbon composite powder. The particle size of the silicon powder is 100nm - 1μm, and the particle size of the graphite is between 4μm - 26μm. The high-energy ball mill is used for dry mixing, and the mixture is uniformly mixed at 150rpm for 30min.

[0066] (2) Mix 1000g of silicon-carbon composite powder obtained in step (1) with 100g of asphalt. The specific method: disperse the silicon-carbon composite powder in tetrahydrofuran / acetone solution dissolved with coal tar pitch, put it into a mixer, and stir at 160rpm for 30min to make it even. In the tetrahydrofuran / acetone solution of coal tar pitch, 100 g of coal tar pitch, 400 g of tetrahydrofuran, and 500 g of acetone.

[0067] (3) After drying in a blast oven at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com