Patents

Literature

33results about How to "Prevent co-embedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

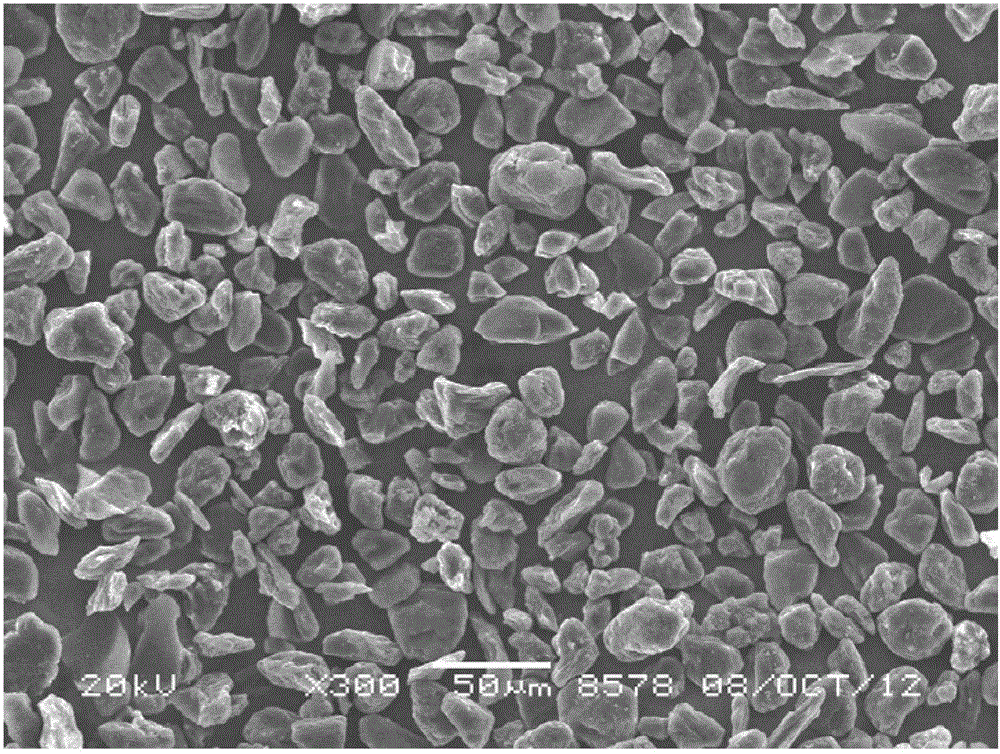

Coke powder-based cathode material of lithium ion power battery and preparation method thereof

ActiveCN103066243AShort processReduce manufacturing costCarbon compoundsCell electrodesSolid carbonPower battery

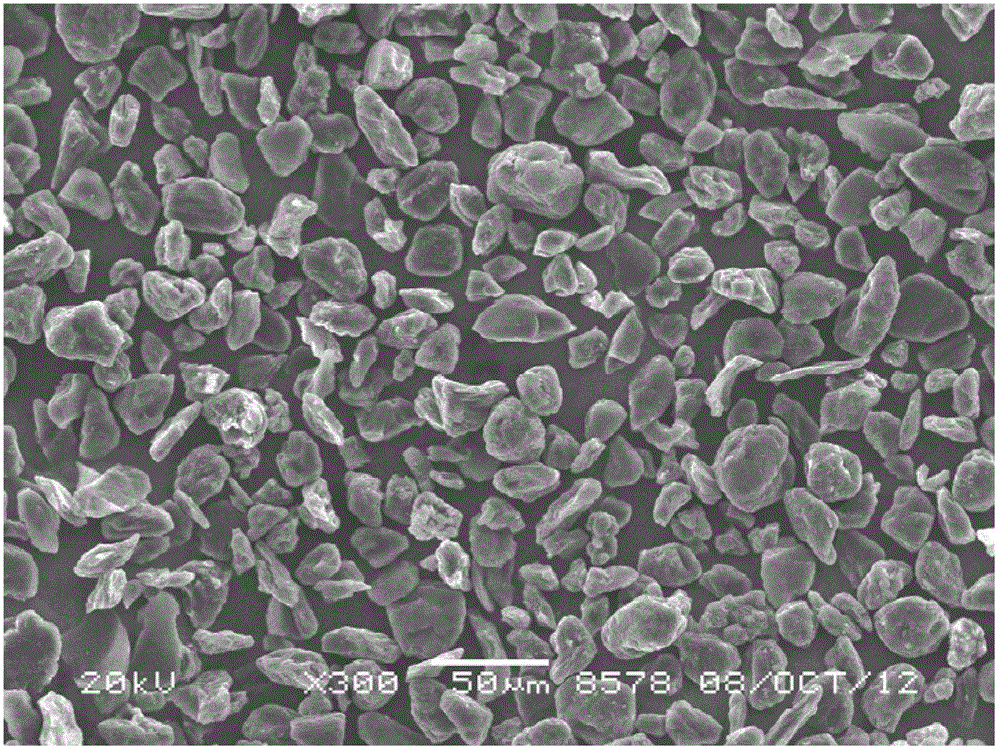

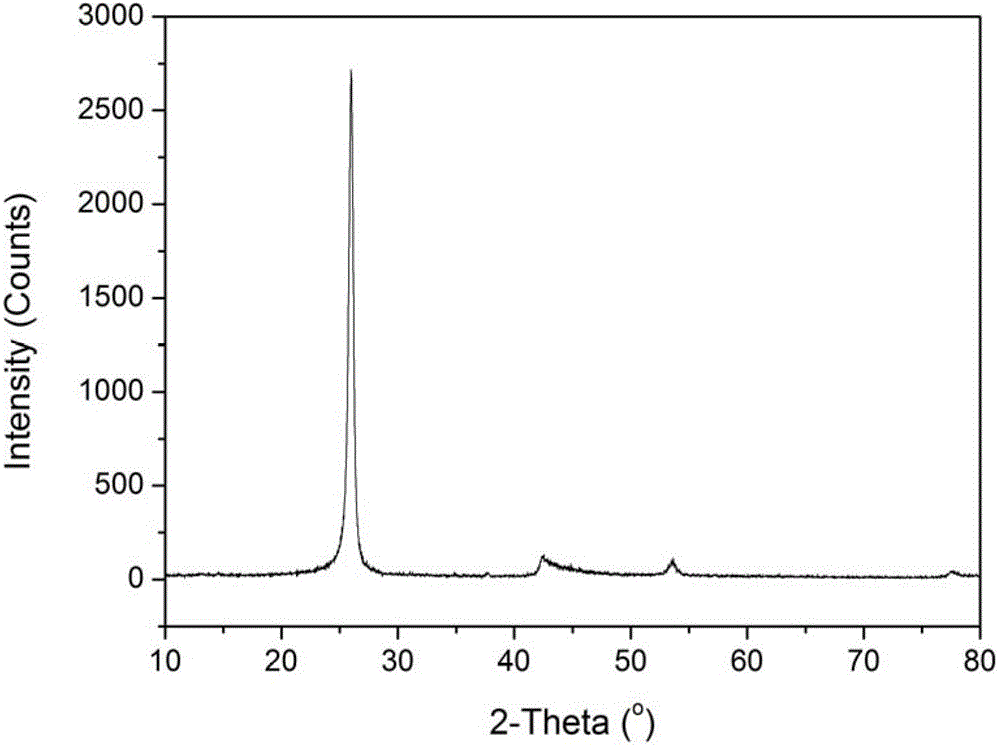

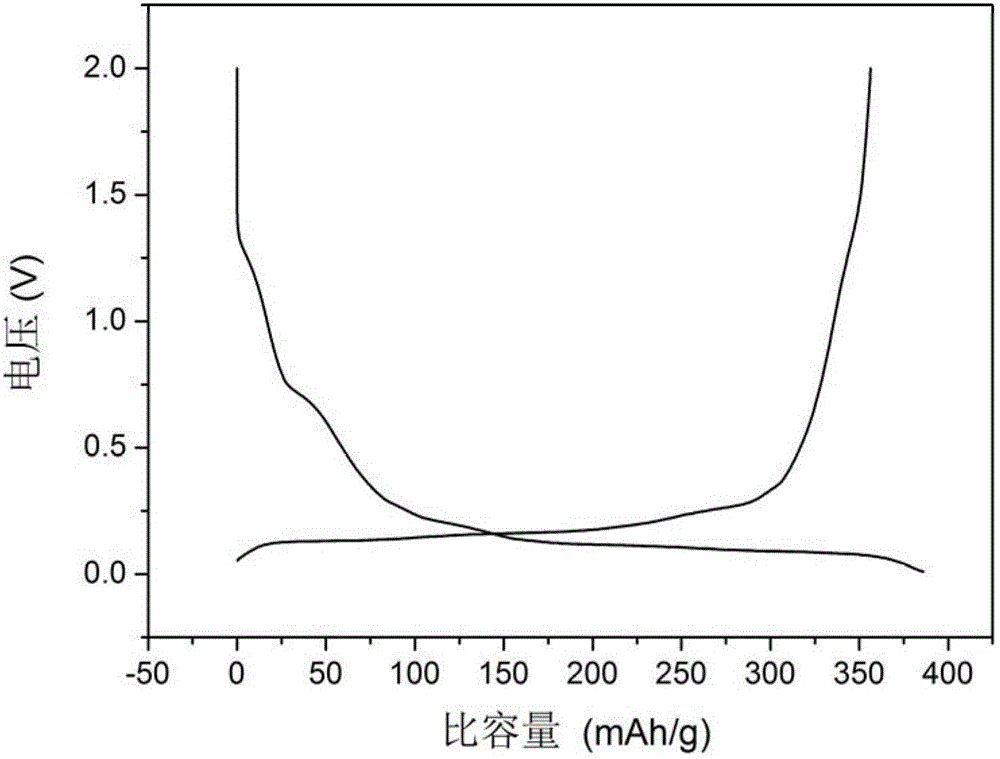

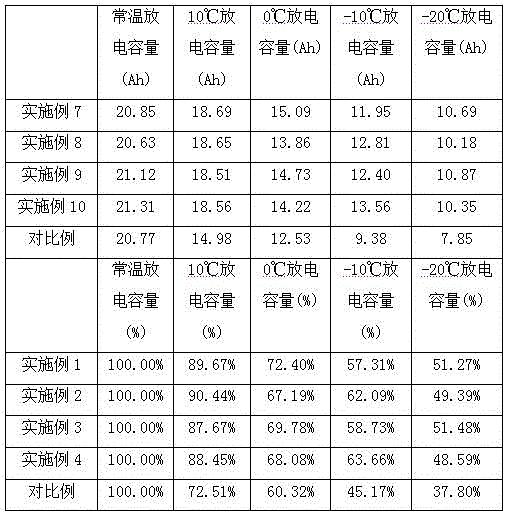

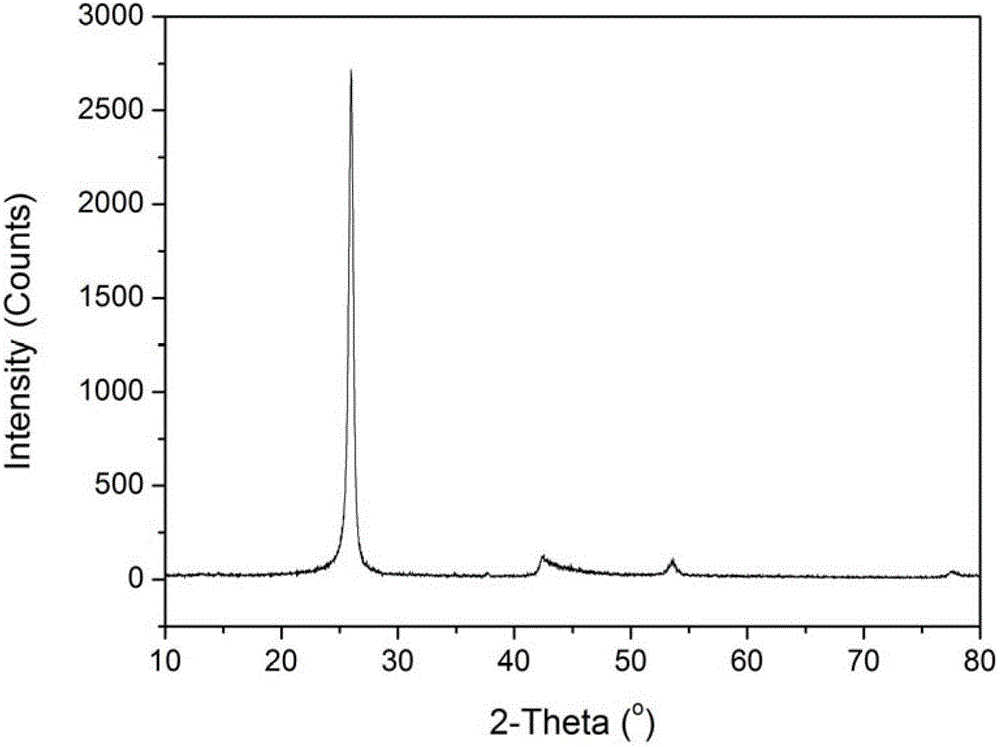

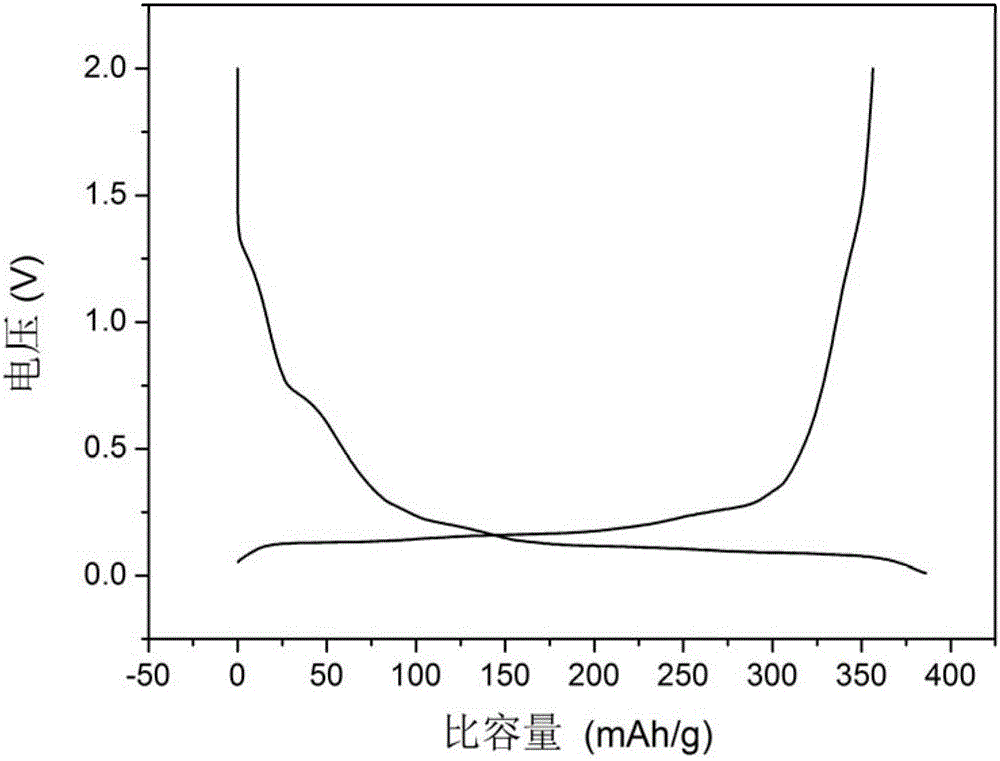

The invention discloses a coke powder-based cathode material of a lithium ion power battery and a preparation method thereof. The cathode material has a D50 of 10-30 [mu]m, a minimum granularity of 5 [mu]m, a maximum granularity of 30 [mu]m, and a tap density of 1.1-1.5 g / cm<3>. The cathode material has a core-shell structure, wherein a core is graphitized coke powder, and a shell is composed of coal pitch pyrolytic carbon and metal particles. The cathode material contains 95.00-99.00 % of solid carbon and 1-5 % of metal or metal oxide particles by mass percent. The preparation method comprises crushing, grading and purifying the coke powder, cladding coal pitch on the coke powder particles, graphitizing under a high temperature, attaching metal or metal oxide on the particles, etc. The cathode material is excellent in rate performance, good in high-temperature and low-temperature performances, low in manufacture cost and suitable for large-scale industrialization.

Owner:CENT SOUTH UNIV +1

Graphite cathode material modified by epoxy resin and its preparation method

InactiveCN103647055AImprove the defect of poor cycle stabilityImprove discharge capacityCell electrodesEpoxyPolymer science

The invention provides a graphite cathode material modified by epoxy resin and its preparation method, which belong to the chemical cell field. According to the invention, an organosilicon modification epoxy resin and natural graphite are performed with processes of grinding, solidifying, charing and crushing to obtain the graphite cathode material modified by epoxy resin. An epoxy resin carbon membrane coated on the surface of graphite can prevent co-intercalation of large volume solvent molecules, so that a graphite layer can expand and contract in a reversible mode in a small scope, rapid collapse can not be generated, and thereby the cycle life of the graphite cathode is prolonged.

Owner:成都兴能新材料股份有限公司

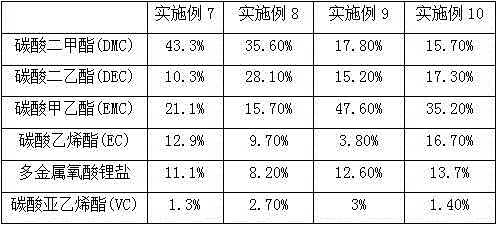

Low-temperature electrolyte for LiFePO4 (lithium iron phosphate) lithium-ion batteries

InactiveCN102983362AIncrease migration rateGood low temperature characteristicsSecondary cellsElectrolytic agentPhosphomolybdic acid

The invention relates to a low-temperature electrolyte for LiFePO4 (lithium iron phosphate) lithium-ion batteries, belonging to the technical field of low-temperature electrolytes for lithium batteries. The electrolyte comprises dimethyl carbonate, diethyl carbonate, ethyl methyl carbonate, ethylene carbonate, a film-forming additive and lithium polyoxometallate, wherein the lithium polyoxometallate refers to lithium phosphomolybdate Li3PMo12O40, lithium phosphotungstate Li3PW12O40, lithium silicotungstate Li4SiW12O40 or lithium silicomolybdenate Li4SiMo12O40. For solving the problems that in the prior art, the lithium ion transport of an electrolyte is blocked, slow in speed and low in efficiency and the electrolyte is poor in low-temperature performance, the invention provides a novel fluoride-free low-temperature electrolyte for LiFePO4 lithium-ion batteries; and by taking the non-fluoride lithium polyoxometallate with a three-dimensional skeleton structure as an electrolytic lithium salt and selectively adopting a low-viscosity carbonate solvent, through optimized proportioning, the migration rate of lithium ions is increased, and the low temperature properties of LiFePO4 batteries can be significantly improved.

Owner:中国东方电气集团有限公司

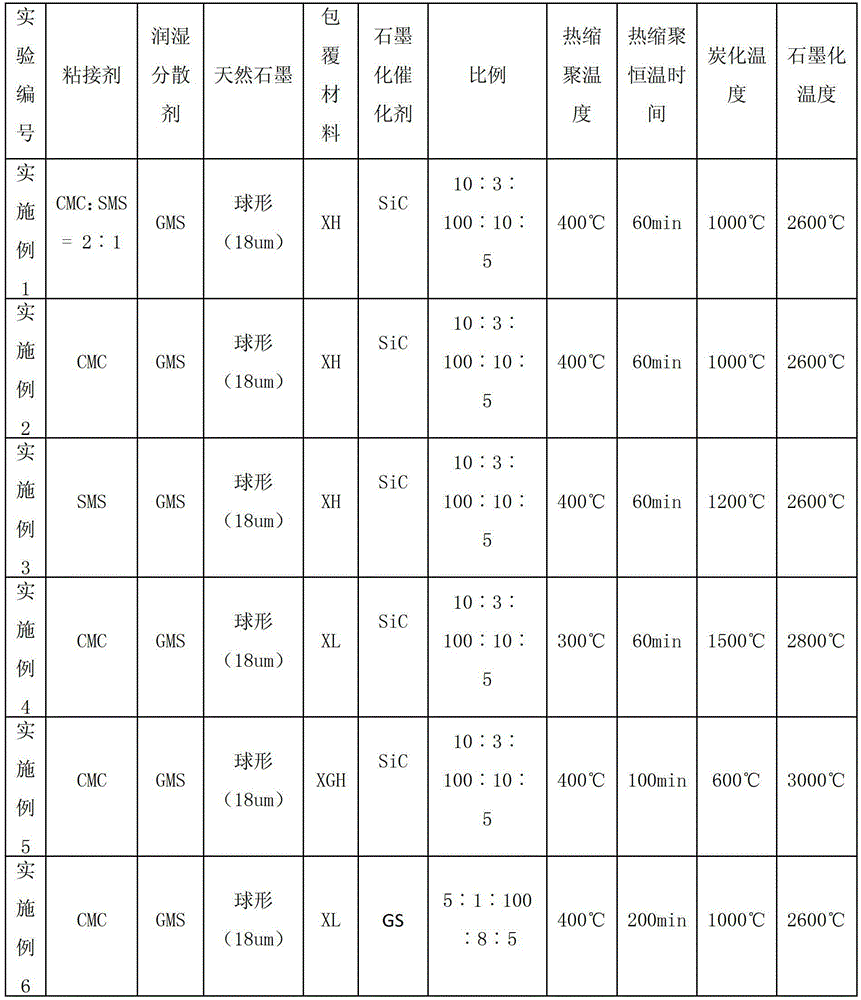

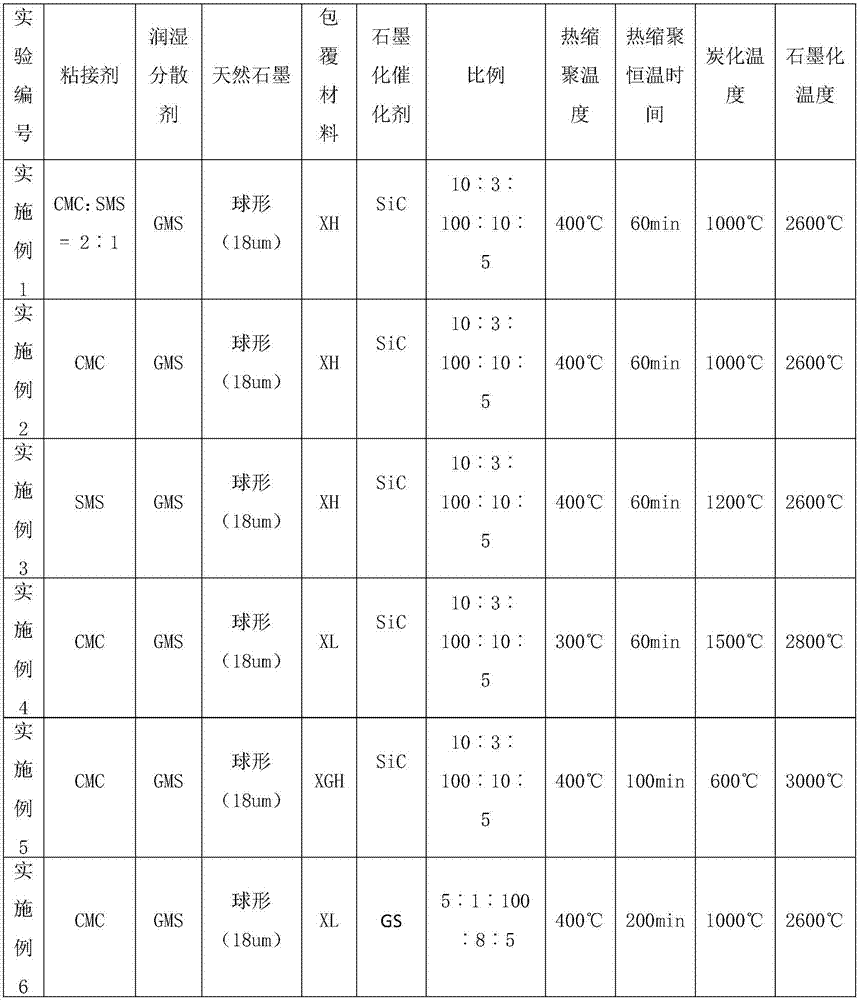

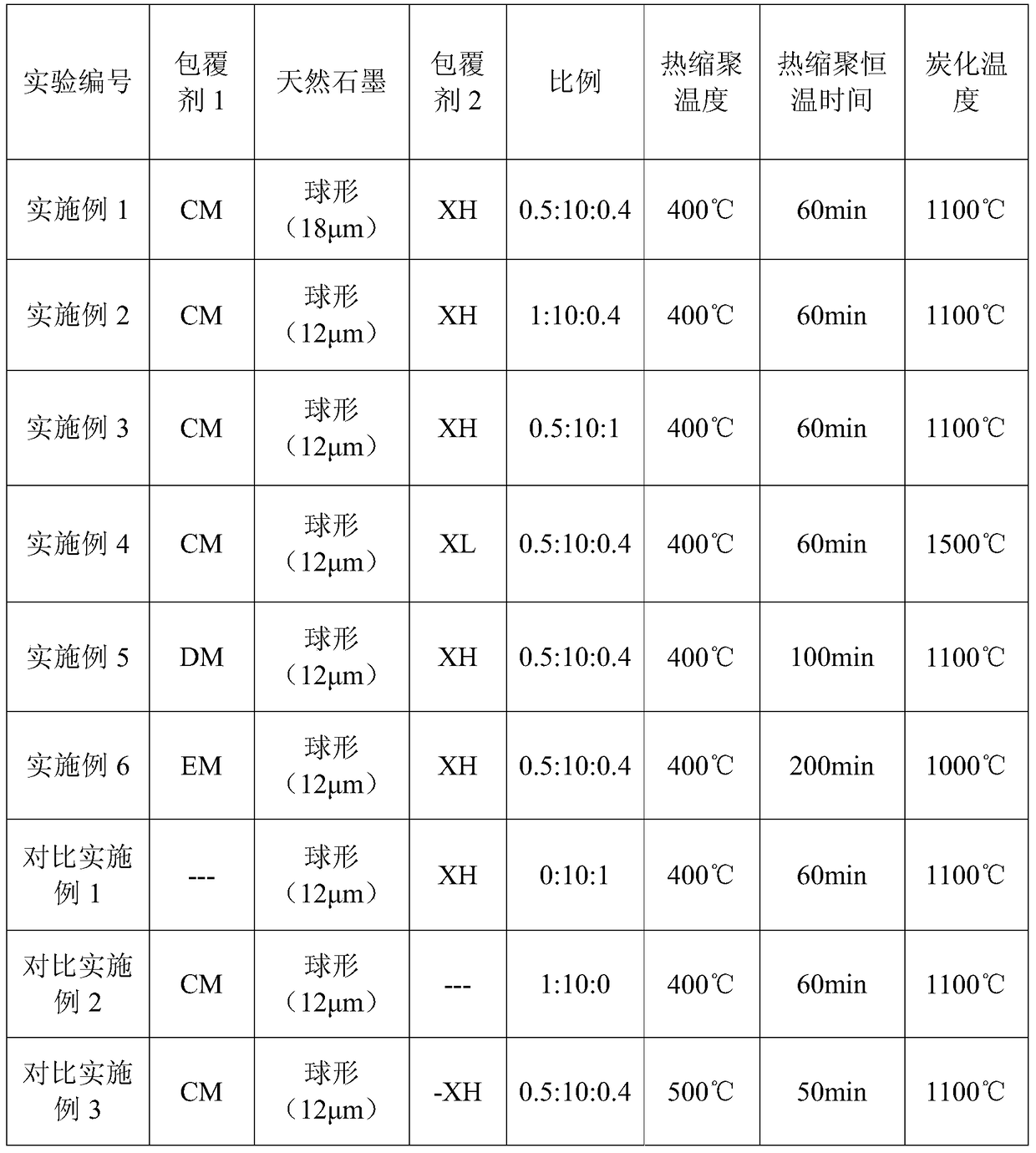

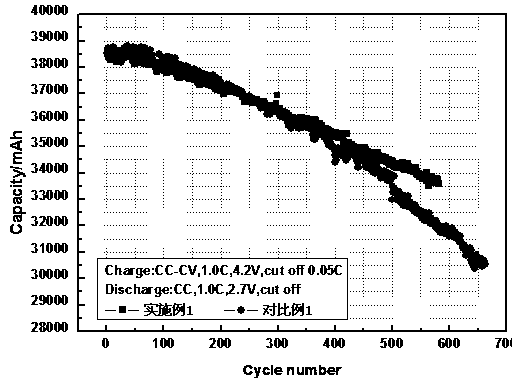

Modified natural graphite and preparation method thereof

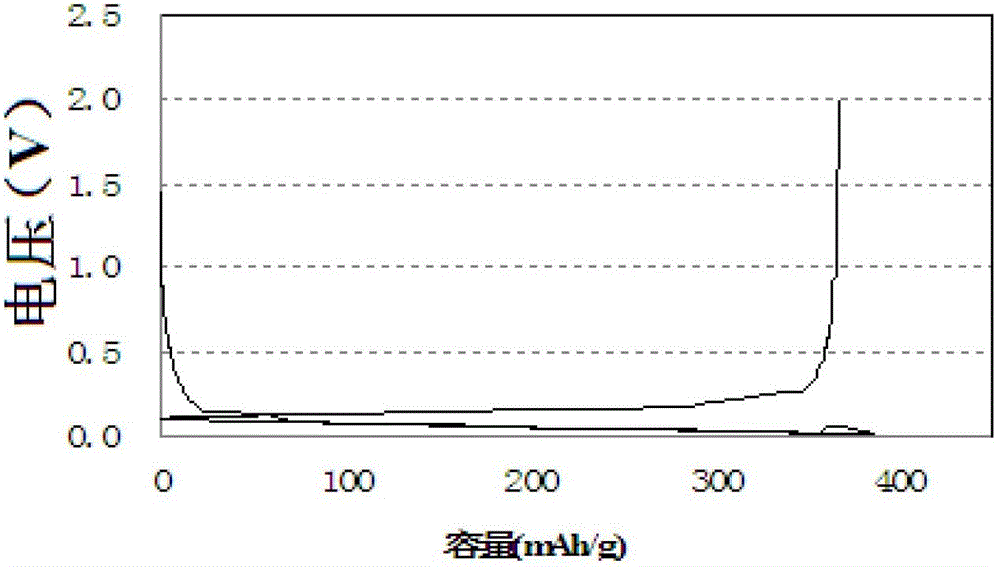

ActiveCN104037417AImprove bindingImprove cycle performanceCell electrodesSecondary cellsLithium-ion batteryLithium electrode

The invention discloses modified natural graphite and a preparation method thereof. The preparation method comprises the following steps: (1) adding a wetting dispersant and a bonding agent in a weight ratio of 1: 10 to 3: 10 into water and carrying out full mixing so as to prepare a mixed solution with a mass concentration of 30 to 60%; (2) adding natural graphite into the mixed solution prepared in the step (1) and successively carrying out mixing and drying; (3) fully mixing a substance obtained in the step (2) with an amorphous carbon precursor and a graphitization catalyst in a cladding kettle, carrying out heating to 300 to 400 DEG C and then carrying out thermal condensation polymerization at a constant temperature; (4) subjecting a substance obtained in the step (3) to compression molding and then carrying out hot isostatic pressing; and (5) subjecting a substance obtained in the step (4) to carbonizing treatment at first and graphitization treatment next under the protection of inert gas. A lithium ion battery negative electrode material prepared from the modified natural graphite has high initial charge and discharge efficiency, long cycle performance and good application prospects.

Owner:SHANGHAI SHANSHAN TECH CO LTD

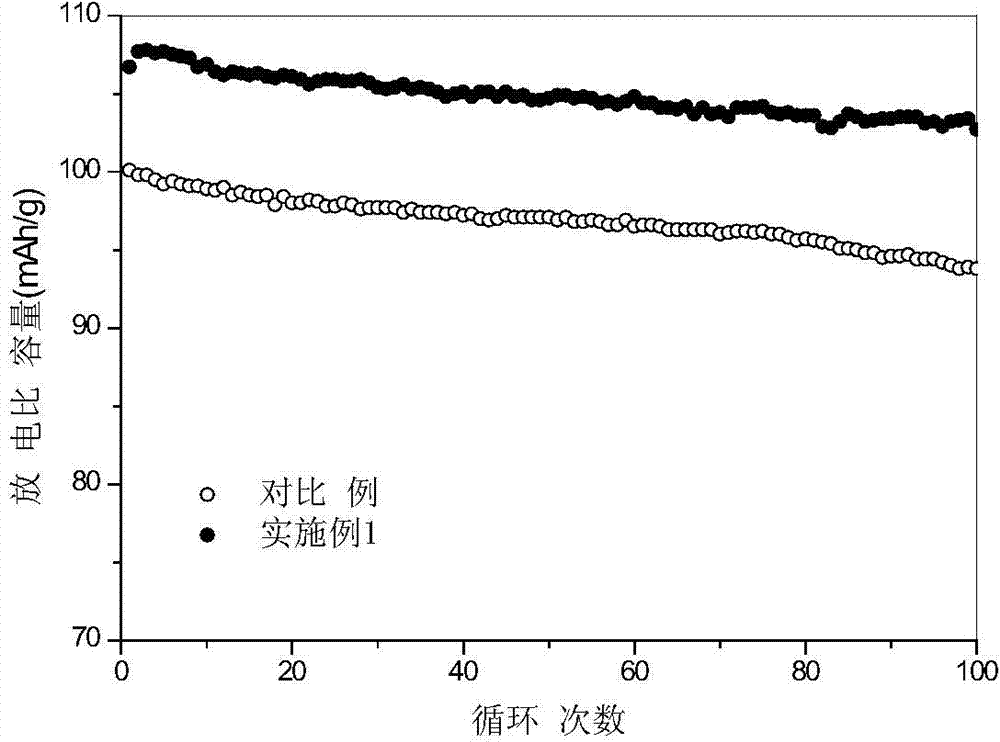

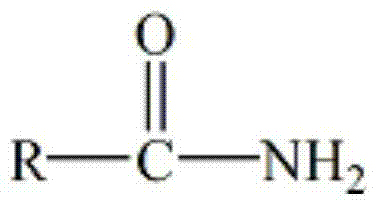

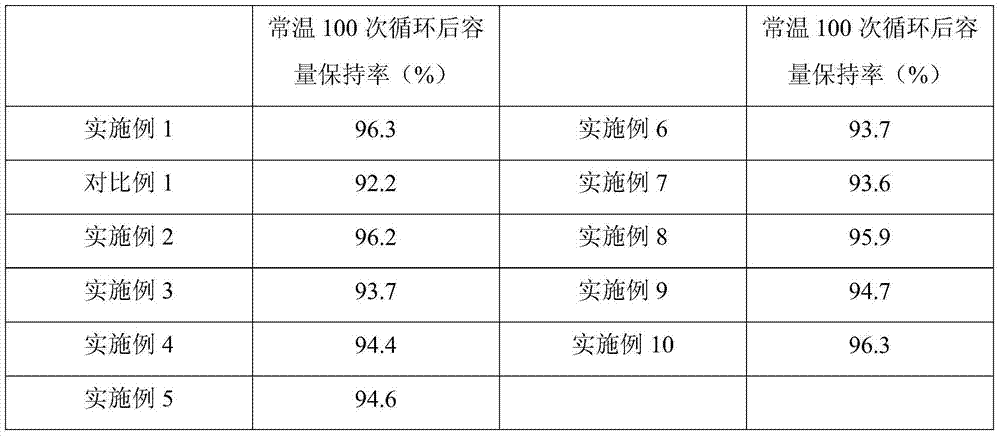

Lithium ion battery amide-type additive having film-forming and stabilizing functions and electrolyte containing same

InactiveCN104518239AImprove charge and discharge efficiencyImprove cycle lifeSecondary cellsOrganic electrolytesPyridazinePyrazine

The invention discloses a lithium ion battery amide-type additive having film-forming and stabilizing functions and electrolyte containing the same. The invention relates to an amide-type additive, which is suitable for lithium ion battery and has the film-forming and stabilizing functions. The additive can prominently promote the forming of SEI membrane and at the same time can control water content of electrolyte, and thus the cycle performance and safety of lithium ion battery are improved. The structure of the amide-type additive is shown in the description, wherein the R represents a five-membered or six-membered nitrogen-containing heterocyclic group, such as pyrrole, imidazole, pyridine, pyridazine, pyrimidine, pyrazine, and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

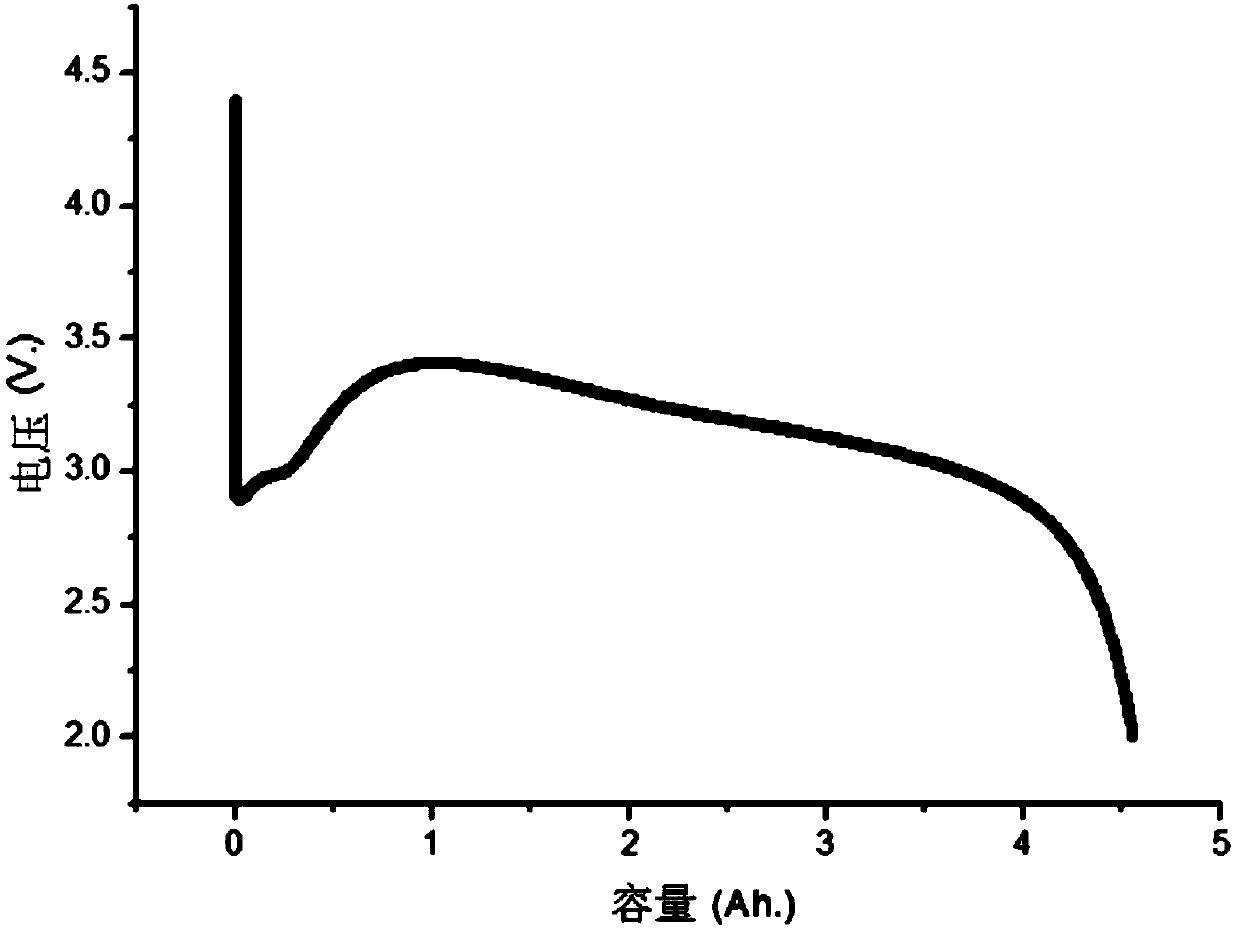

Lithium ion battery system with high specific energy and ultra-low-temperature rate discharge

InactiveCN107910483AIncrease the charge cut-off voltageIncrease design capacityCell electrodesSecondary cellsCyclic processPolyolefin

The invention discloses a lithium ion battery system with high specific energy and ultra-low-temperature rate discharge. The lithium ion battery system comprises a positive electrode active material,a negative electrode active material, an electrolyte and a diaphragm; the positive electrode active material of the lithium ion battery system is a high-voltage lithium cobalt oxide material, and thecharging cut-off voltage is 4.3-4.5V; and the negative electrode active material is graphite. By selecting small-particle high-voltage lithium cobalt oxide positive electrode material, high specific energy is ensured while rate capability is improved; by adoption of soft carbon or hard carbon-coated artificial graphite, the low-temperature advantage can be played while co-embedding of an electrolyte solvent can be prevented; and a carbonic ester solvent combination capable of improving the low-temperature performance, a low-temperature synergistic additive and a high-voltage-resistant cyclingstabilizer are introduced to the electrolyte formula. The ceramic diaphragm disclosed in the invention adopts a dry method polyolefin film as the base material; and the single surface is coated with ananometer ceramic coating layer, so that the synergistic effects lies in keeping dry film high ventilation degree while improving retention rate of the electrolyte in the cycle process.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

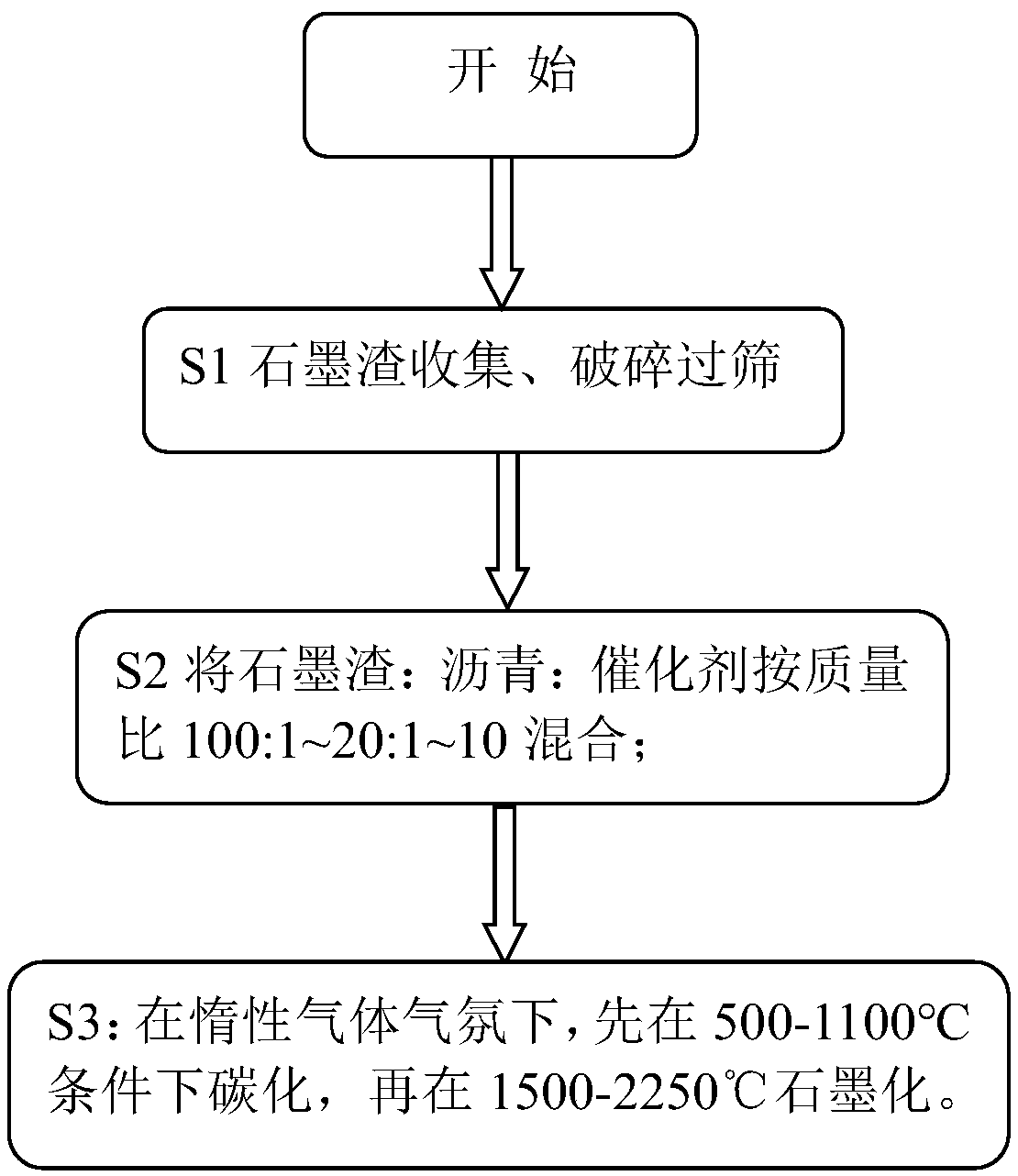

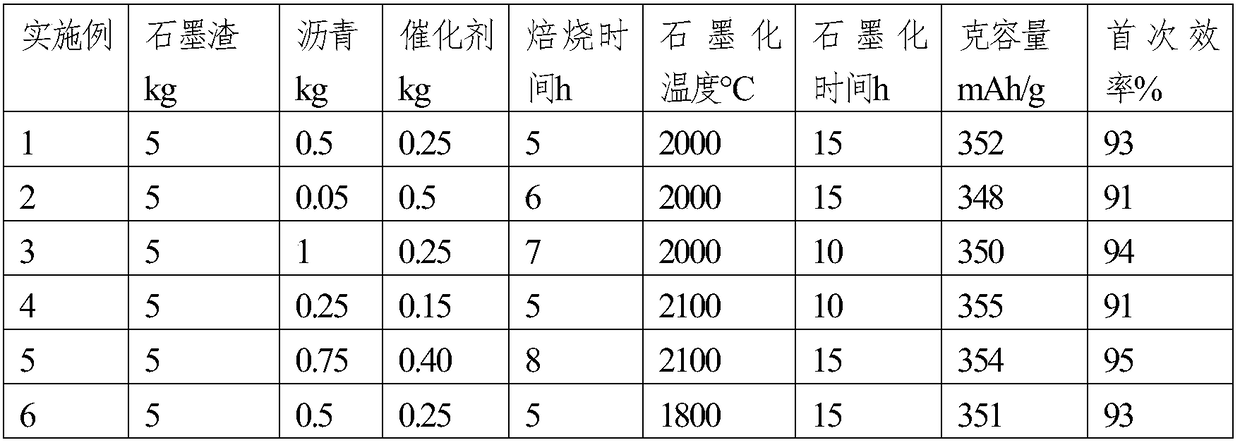

Method for recovering a lithium ion battery anode material

ActiveCN108879014AAvoid negative effectsImprove consistencyWaste accumulators reclaimingBattery recyclingElectrical batterySlag

The invention relates to a method for recovering a lithium ion battery anode material. The method comprises the following steps: S1: collecting, crushing and sifting the graphite slag left after recovering metal of the lithium ion battery to obtain finer and more uniform graphite slag; S2: mixing graphite slag: asphalt: catalyst at a mass ratio of 100:1-20:1-10 to obtain a mixture; S3: under the protection of an inert gas atmosphere, carbonizing the graphite slag mixture at 500-1100 DEG C for 2-20 hours; then at 1500 DEG C-2250 DEG C graphitizating for 10-35 hours to obtain a graphite material. The method can obtain graphite anode material with excellent performance by using less asphalt, lower graphitization temperature and shorter graphitization time, and the performance of the obtainedgraphite anode material can directly meet the requirements for manufacturing a new lithium ion battery anode.

Owner:SOUNDON NEW ENERGY TECH CO LTD

Lithium ion battery electrolyte and preparation method thereof

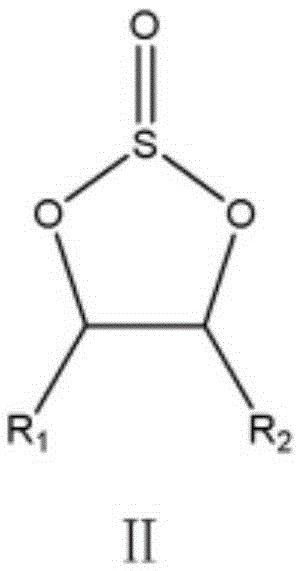

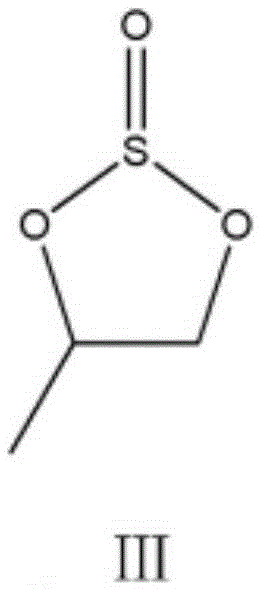

InactiveCN105355977AThe group ratio is reasonableIncrease capacitySecondary cellsElectrolytesOrganic solventPhysical chemistry

The invention provides a lithium ion battery electrolyte and belongs to the technical field of lithium secondary batteries. The lithium ion battery electrolyte is composed of organic solvents, additives and lithium salt. The organic solvents are composed of a solvent A and a solvent B. According to the principle that the total mass of the organic solvents and the additives is 100%, the lithium ion battery electrolyte is prepared from, by mass, 20-30% of the solvent A, 30-69.5% of the solvent B and 0.5-50% of the additives. The solvent A is ethylene carbonate. The solvent B is one or more of methyl ethyl carbonate, dimethyl carbonate and diethyl carbonate, The additives are sulfite organic solvents. The concentration of the mass of lithium salt in the electrolyte is 0.6-1.5 mol / L. The invention further provides a preparation method of the lithium ion battery electrolyte and a lithium secondary battery. The compatible characteristic between the lithium ion battery electrolyte and electrode materials is good, the temperature adaption characteristic of the electrolyte materials is widened, and by means of the lithium ion battery electrolyte, the circulation performance, the rate performance and the temperature adaptability of the lithium secondary battery can be effectively improved.

Owner:百顺松涛(天津)动力电池科技发展有限公司

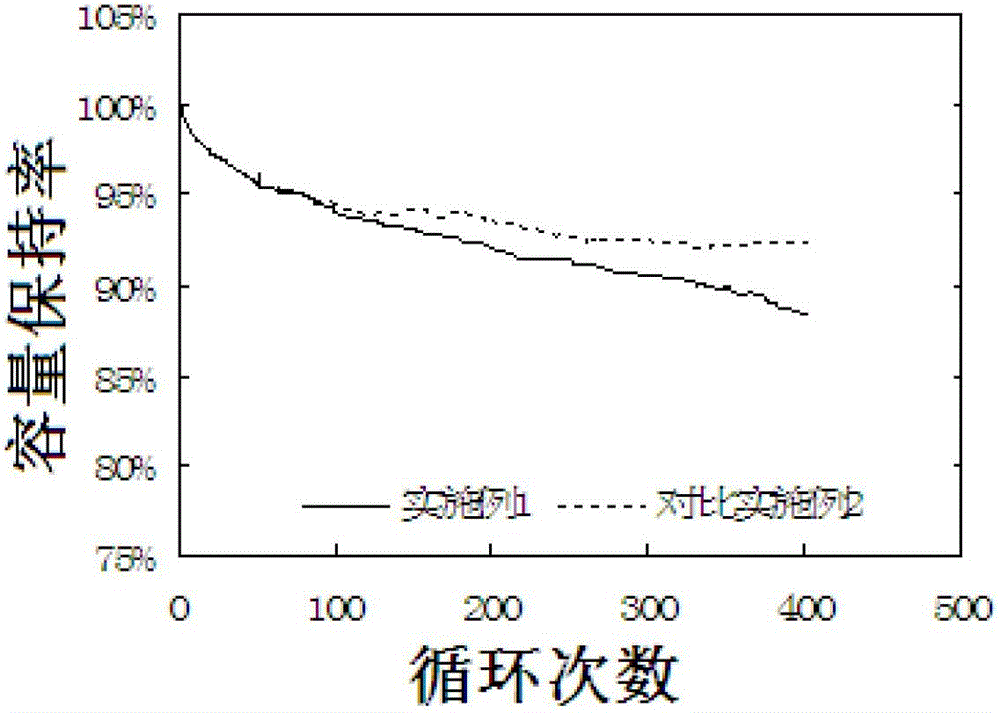

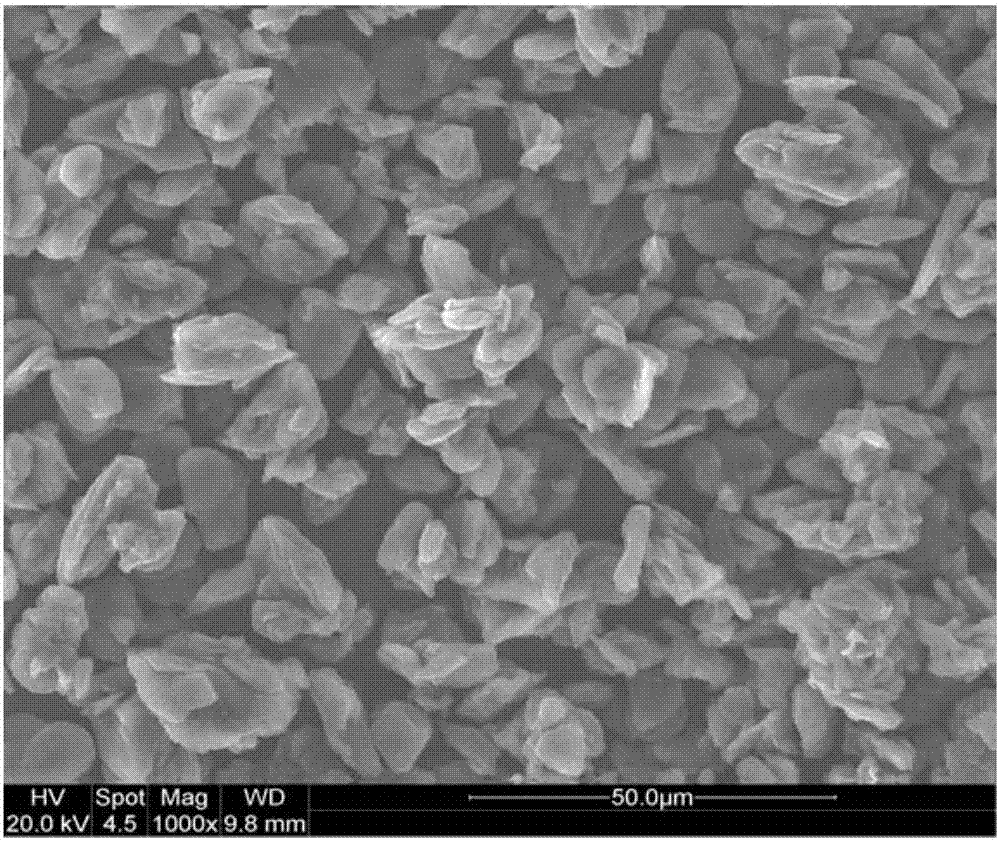

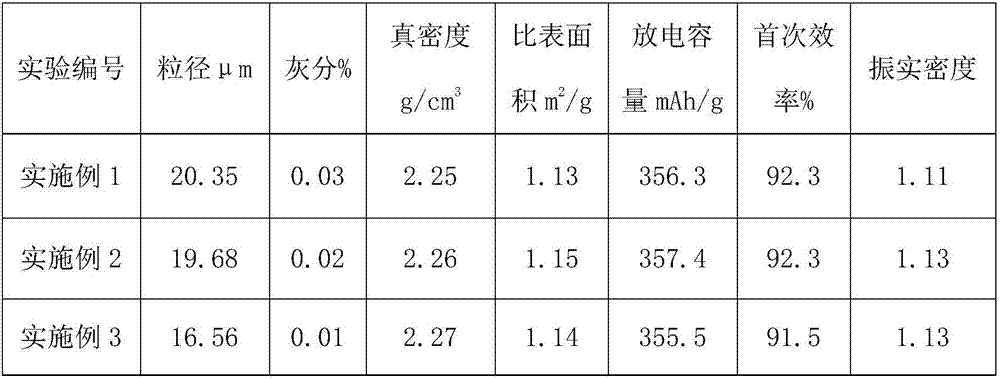

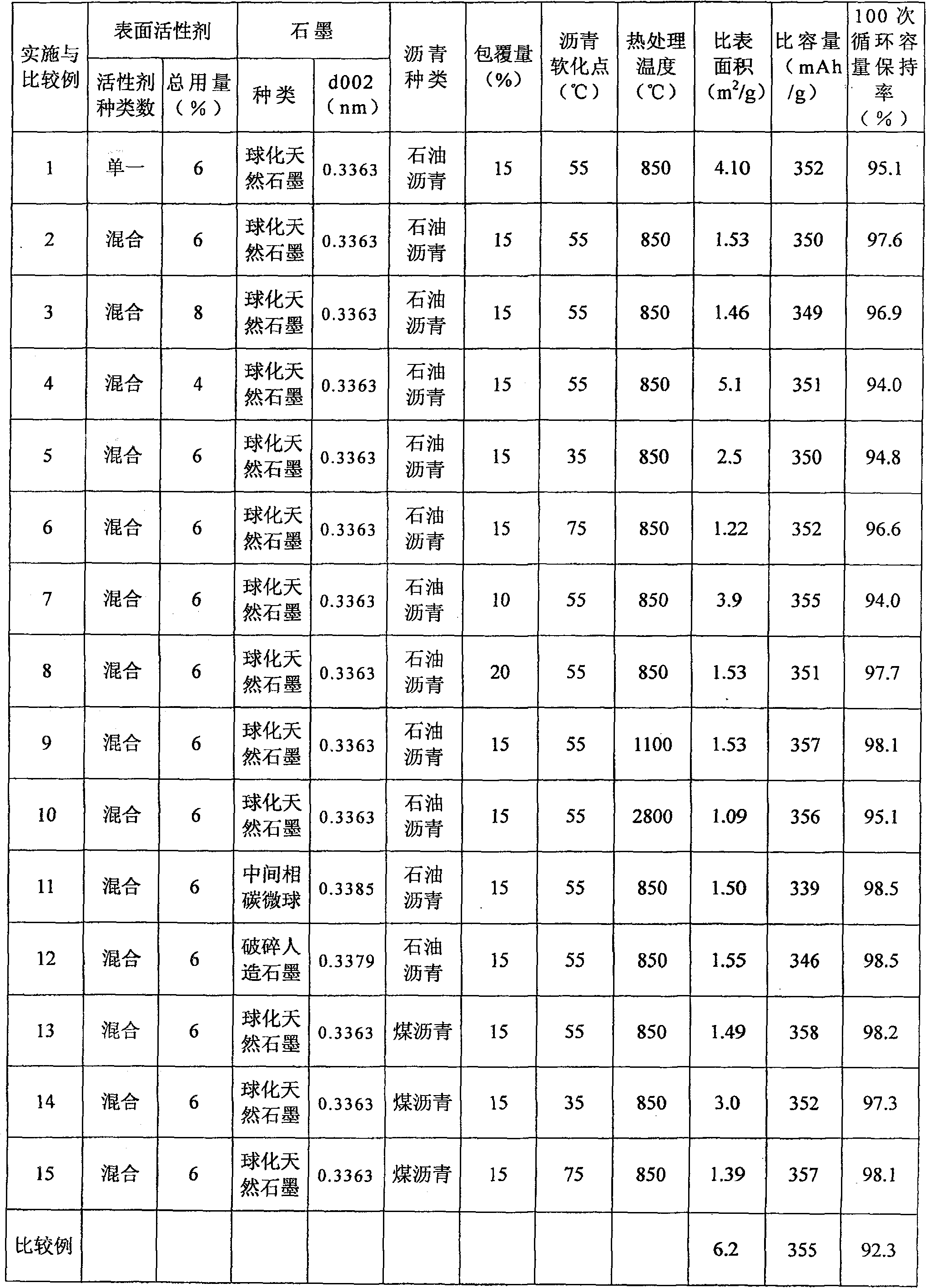

Composite graphite negative electrode material for lithium ion batteries and preparation method thereof

InactiveCN107316983AHigh tap densityRegular particle shapeCell electrodesSecondary cellsGramSurface modification

The invention discloses a composite graphite negative electrode material for lithium ion batteries and a preparation method thereof. The preparation method comprises the following steps: mixing a synthetic graphite raw material, a natural graphite raw material and an adhesive in a mass proportion of 100: (55 to 65): (3 to 7); under inert gas shielding, putting the mixed materials into a low-temperature surface modification reaction kettle, warming and stirring to obtain a cladding body; carrying out carbonizing treatment on the cladding body; enabling the cladding body through carbonizing treatment to enter into a fusing machine for normal temperature modification to prepare a fusing body, and carrying out graphitization treatment on the fusing body in inert gas to prepare the negative electrode material for lithium ion batteries. According to the graphite negative electrode material for lithium ion batteries disclosed by the invention, the specific capacity is not smaller than 355 mAh / g, and the first charging and discharging efficiency is more than 91.0%; and the graphite negative electrode material has relatively high gram volume, is extremely high in rate capacity and cycle performance and stable in performance, and can be widely applied to negative electrode materials of the lithium ion batteries.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

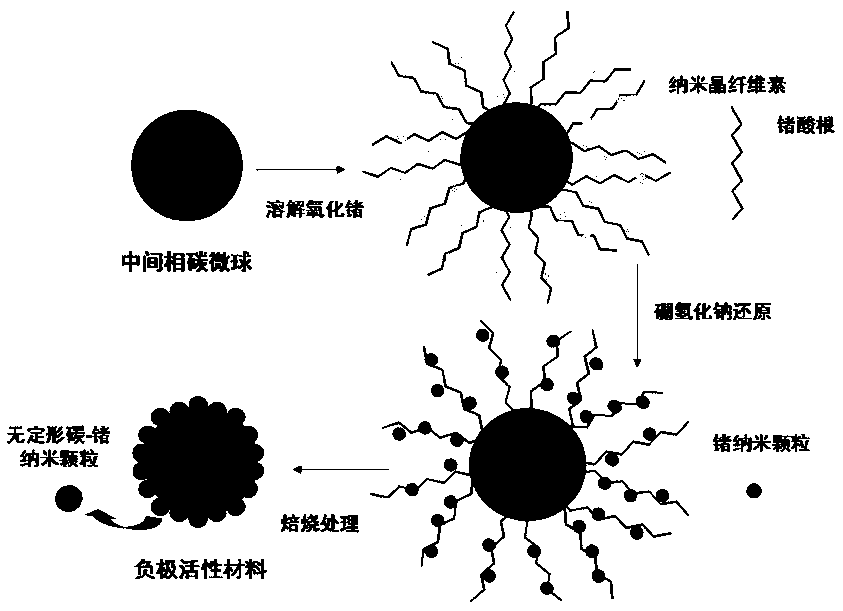

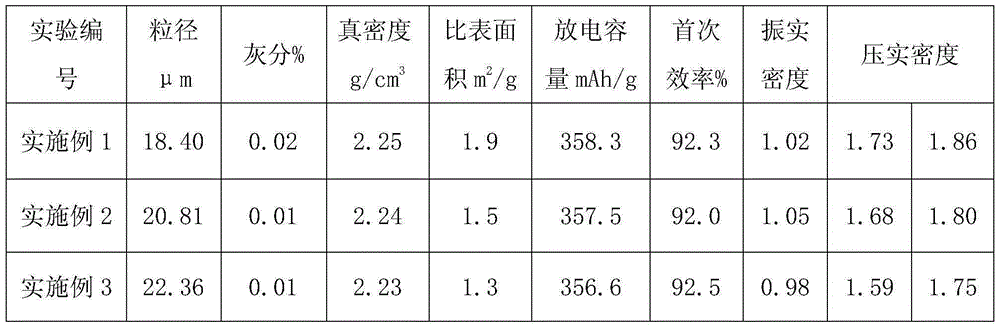

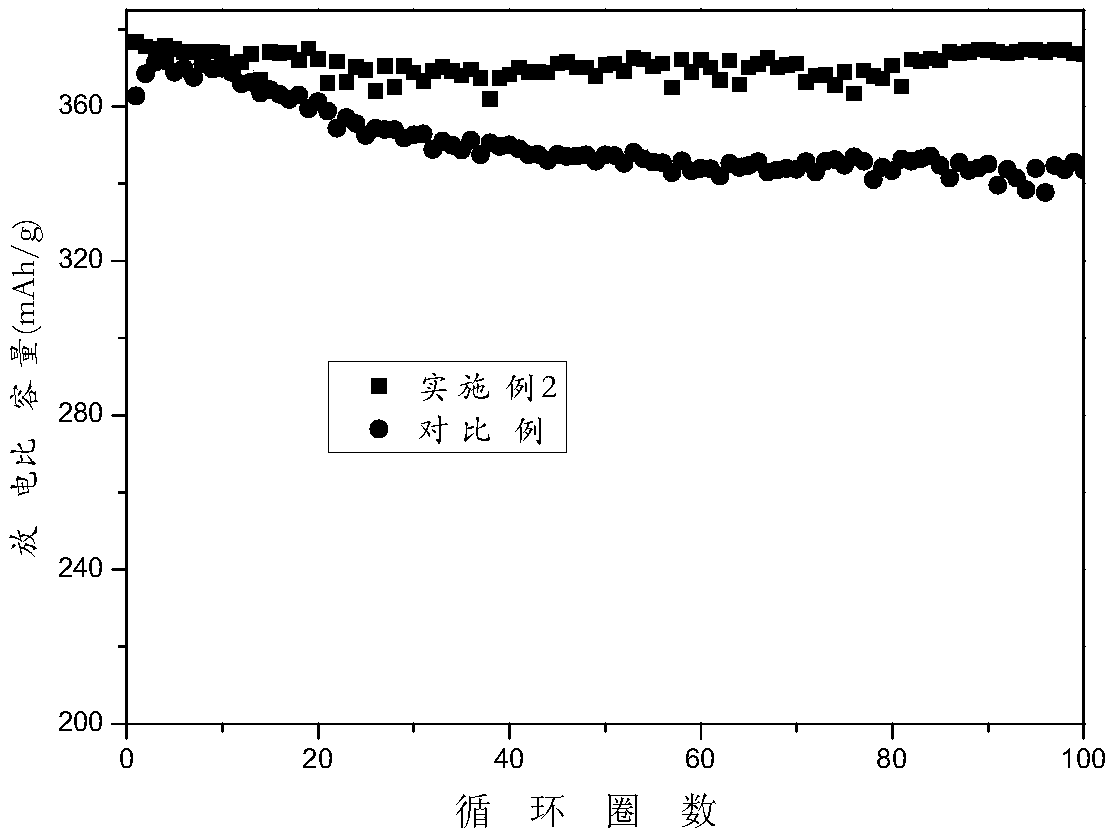

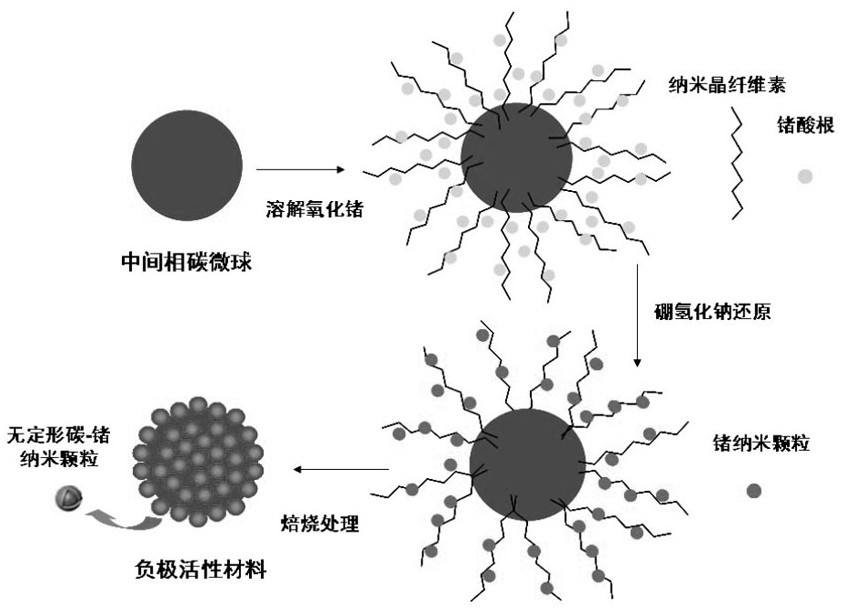

Lithium-ion battery germanium/carbon composite negative electrode material and preparation method and application thereof

ActiveCN110085847AImprove cycle stabilityAvoid reunionNegative electrodesSecondary cellsCelluloseCarbon composites

The invention discloses a lithium-ion battery germanium / carbon composite negative electrode material and a preparation method and an application thereof. The composite negative electrode material includes germanium nanoparticles, mesocarbon microbeads and amorphous carbon. The preparation method comprises the steps of (1) dissolving GeO2 in an alkaline solution, adding nanocrystalline cellulose, adjusting the pH-value of the obtained first suspension, adding the mesocarbon microbeads and stirring to form a second suspension, and transferring the second suspension to a water bath; (2) preparingan NaBH4 solution, adding the heated second suspension, stirring for reaction in the water bath, washing wafer vacuum filtration, then carrying out vacuum drying, roasting the dried solid in an inertgas or reducing atmosphere to obtain the product. The composite negative electrode material disclosed by the invention has high mass capacity and volume specific capacity, can effectively alleviate the volume change and pulverization of germanium, is high in cycle stability and good in compatibility with a propylene carbonate containing electrolyte, has the advantages of good low-temperature electrochemical performance and the like and can be applied to lithium-ion batteries.

Owner:NAT UNIV OF DEFENSE TECH

Graphite negative electrode material of lithium-ion battery and preparation method of graphite negative electrode material

InactiveCN106505198AHigh tap densityEasy to chargeCell electrodesSecondary cellsMass ratioElectric capacity

The invention discloses a graphite negative electrode material of a lithium-ion battery and a preparation method of the graphite negative electrode material. The method comprises the steps of mixing an artificial graphite raw material with a binder and a catalyst SiC (the content is greater than 92%) at the mass ratio of 100:(6-12):(3-8) during preparation, putting the evenly mixed materials into a low-temperature surface modification reaction kettle in an inert gas and carrying out warming and stirring to obtain a coated body; carrying out graphitization treatment on the coated body; and fusing the coated body subjected to graphitization treatment and the binder at the mass ratio of 100:(2-6) to prepare a fusion body and carrying out carbonizing treatment on the fusion body in the inert gas to obtain the graphite negative electrode material of the lithium-ion battery. According to the prepared graphite negative electrode material of the lithium-ion battery, the initial discharge capacity is not smaller than 355mAh / g; the initial charge-discharge efficiency is greater than 92.0%; the graphite negative electrode material has the advantages of high electric capacity, low irreversible capacity and very good and stable battery cycle performance, especially has great advantages in a low-temperature cycle, and is used as the negative electrode material of the lithium-ion battery and the like.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

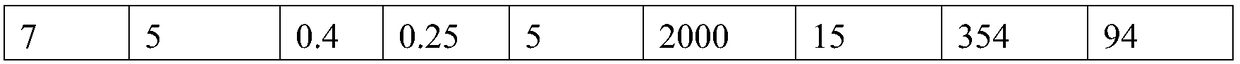

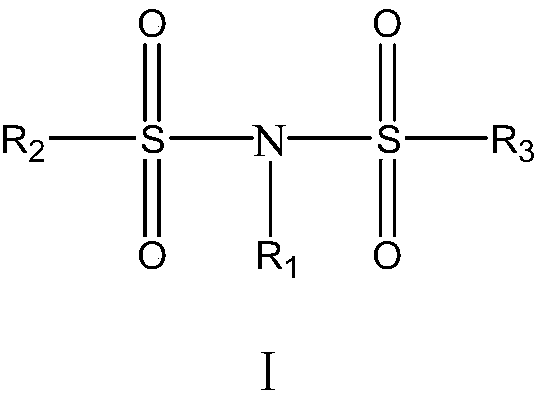

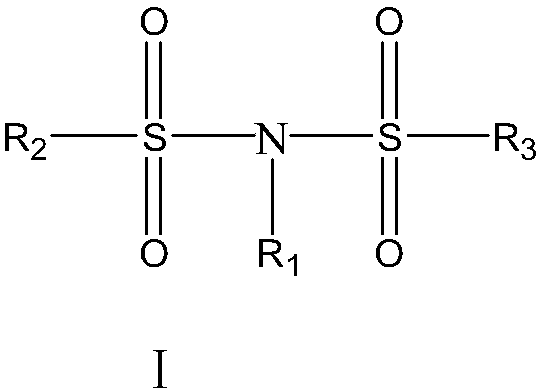

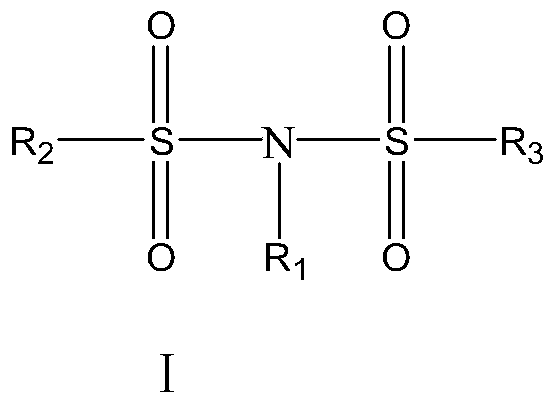

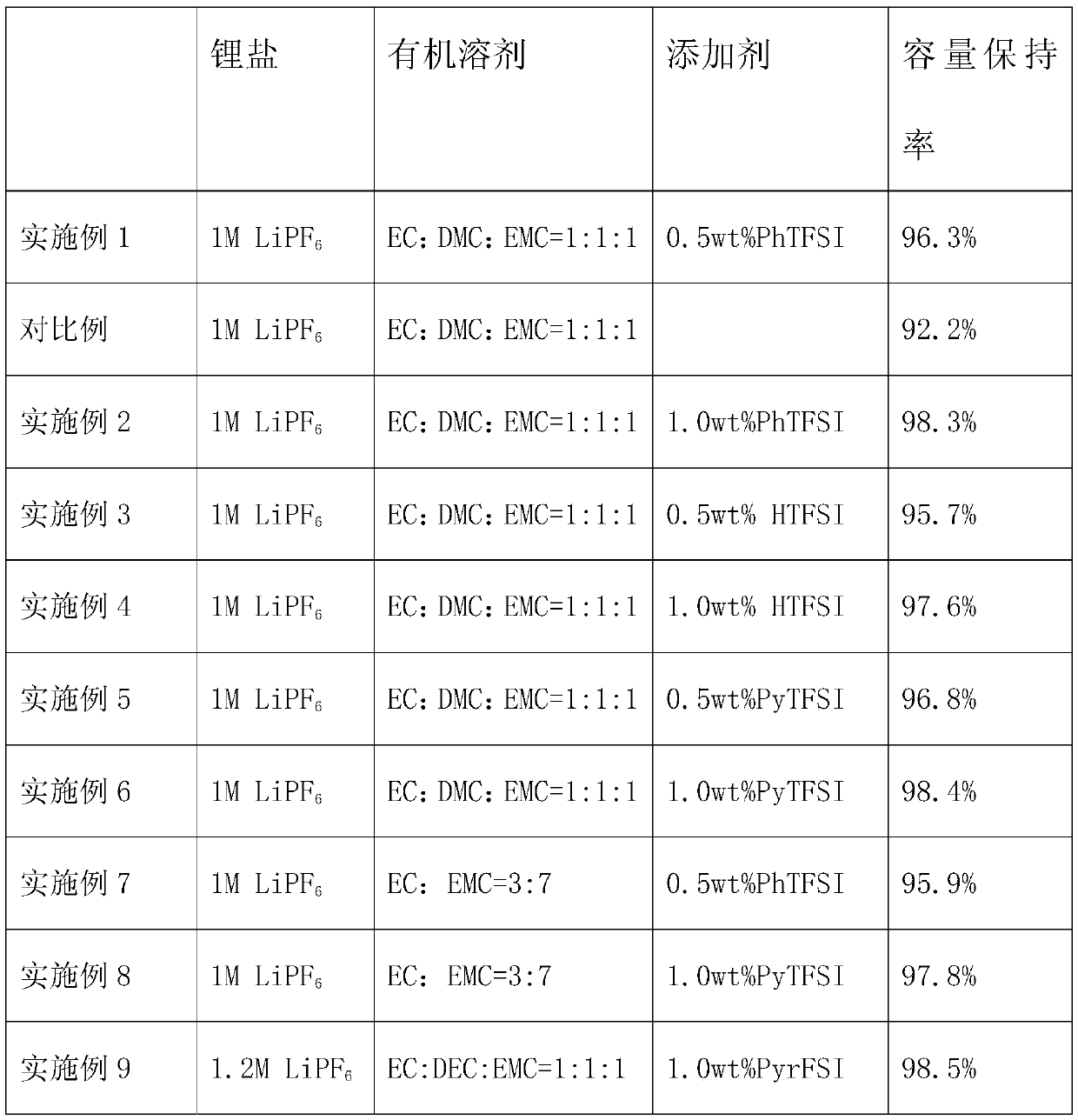

Fluoro-alkyl sulfonamide additive for promoting film formation of graphite carbon anode and electrolyte containing fluoro-alkyl sulfonamide additive

ActiveCN107706454APrevent co-embeddingInhibition of continuous reductive decompositionSecondary cells servicing/maintenancePyrrolePyrimidine

The invention discloses a fluoro-alkyl sulfonamide additive, with a structural formula as shown in a formula I, for a lithium-ion battery electrolyte for promoting film formation of a graphite carbonanode; the formula I is as shown in the specification, wherein R1 is hydrogen, a benzene ring and a pentabasic or hexahydric heterocyclic group; the pentabasic or hexahydric heterocyclic group is selected from furan, thiophene, pyrrole, thiazole, imidazole, pyridine, pyrazine, pyrimidine and pyridazine; and R2 and R3 are F atoms or fluorinated alkyl of which 1-3 hydrogen atoms in methyl, ethyl andpropyl are substituted by F. The performance of an SEI film formed by the fluoro-alkyl sulfonamide additive is superior to that of an SEI film formed by VC, the cycling stability of the graphite carbon anode is better improved, the safety performance of a lithium-ion battery is improved and the fluoro-alkyl sulfonamide additive has good practicability and economic value.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

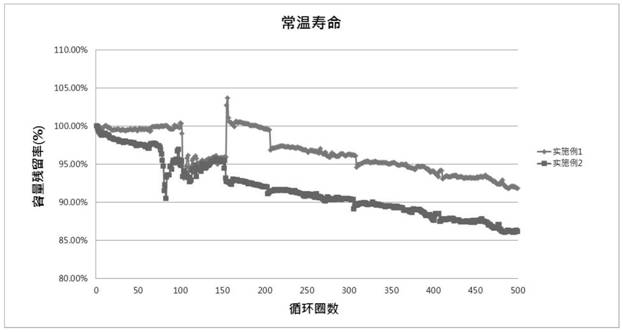

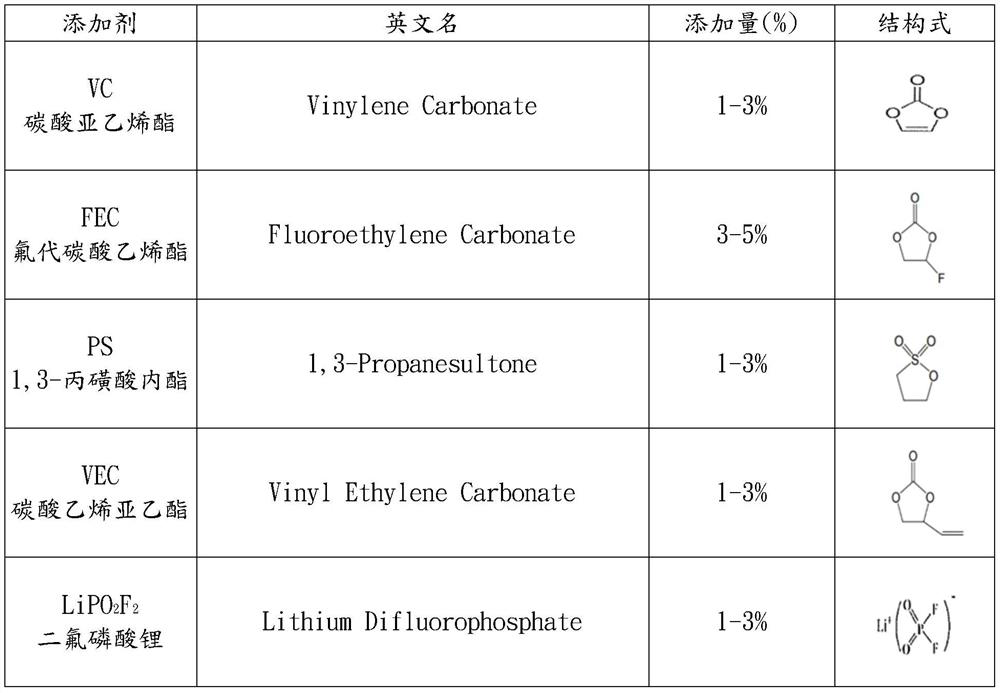

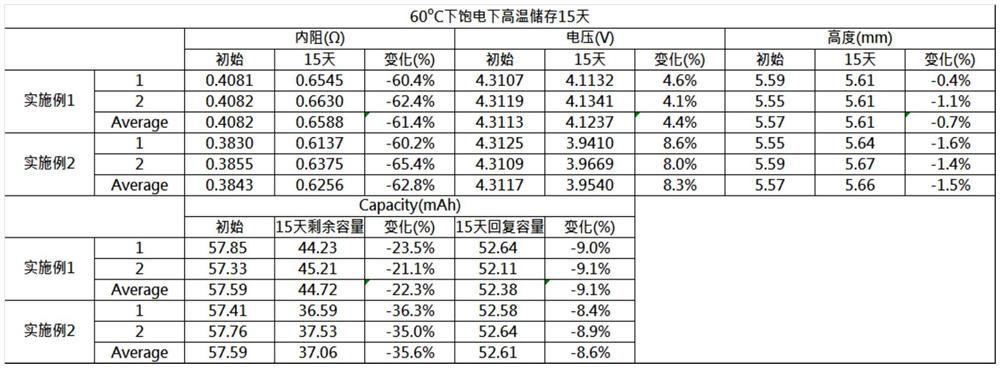

Non-aqueous electrolyte for lithium ion battery with ternary positive electrode material and negative silicon-oxygen-carbon composite negative electrode material

PendingCN113299996AReduce viscosityLow melting point propertiesSecondary cells servicing/maintenanceOrganic electrolytesElectrolytic agentCarbon composites

The invention belongs to the field of lithium ion batteries, and discloses a non-aqueous electrolyte for a lithium ion battery with a ternary positive electrode material and a negative silicon-oxygen-carbon composite negative electrode material, which comprises a non-aqueous organic solvent, an electrolyte lithium salt and an electrolyte additive; the non-aqueous organic solvent comprises ethylene carbonate and methyl ethyl carbonate; and the electrolyte additives comprise vinylene carbonate, fluoroethylene carbonate, 1, 3-propane sultone, vinylethylene carbonate and lithium difluorophosphate. The non-aqueous electrolyte contains cyclic carbonate, a negative electrode film-forming agent, a positive electrode film-forming agent and three lithium salts. The lithium ion non-aqueous electrolyte can be applied to improvement of high-temperature and normal-temperature cycle performance.

Owner:KUNSHAN SYNERGY SCIENTECH CO LTD

Lithium ion battery electrolyte considering high and low temperature performances and battery

ActiveCN110931870AInhibition of continuous reductive decompositionReduce consumptionSecondary cellsOrganic electrolytesElectrolytic agentLithium-ion battery

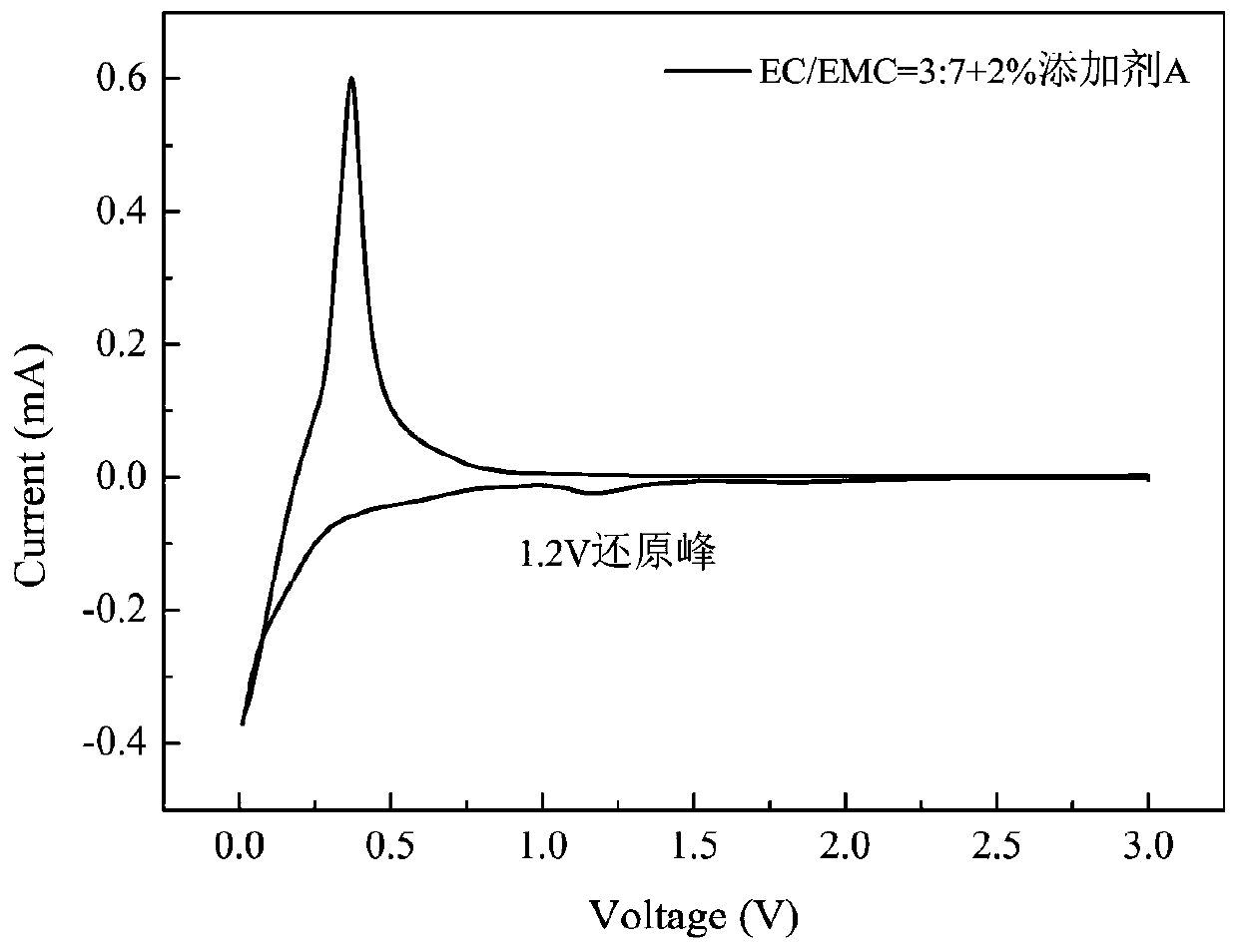

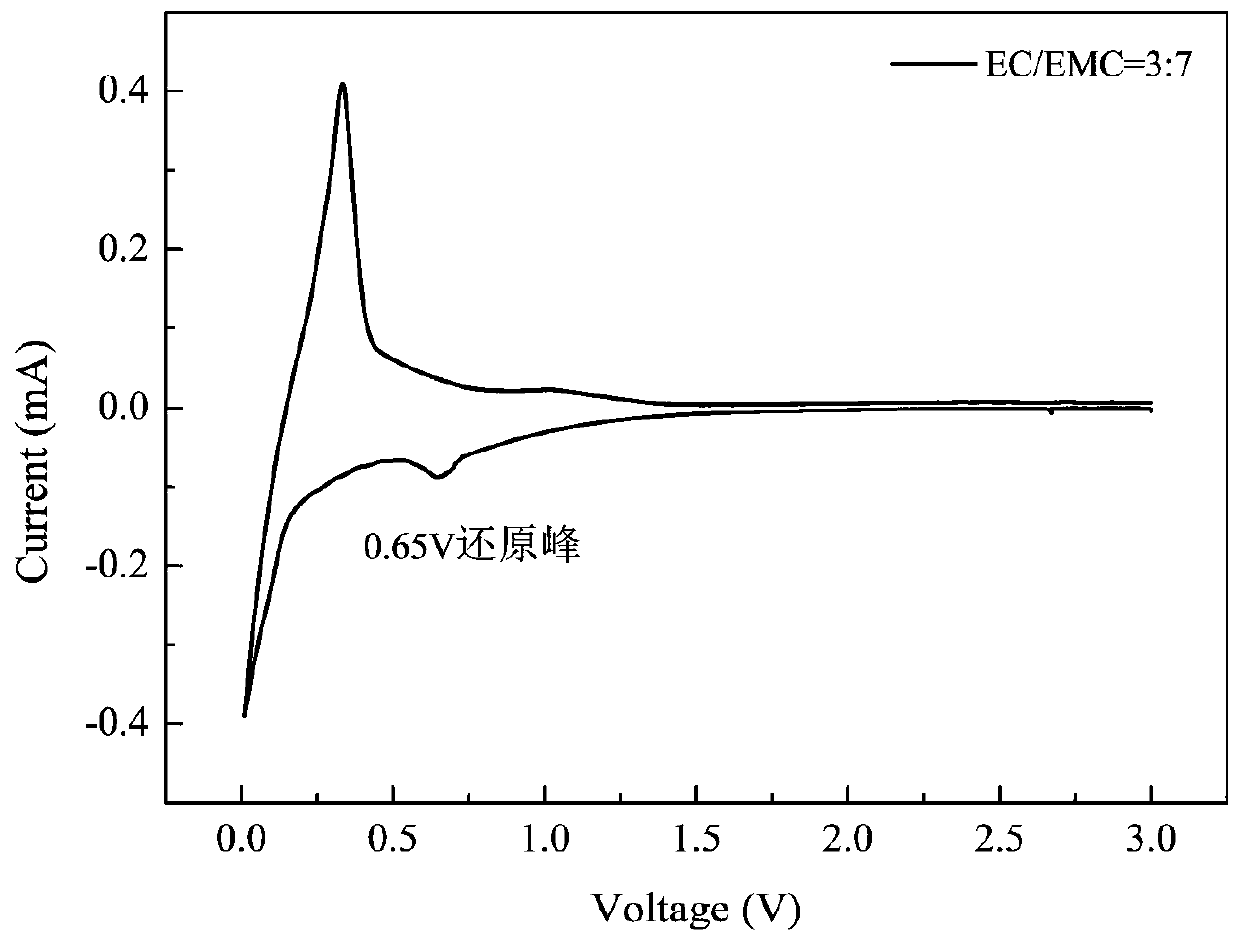

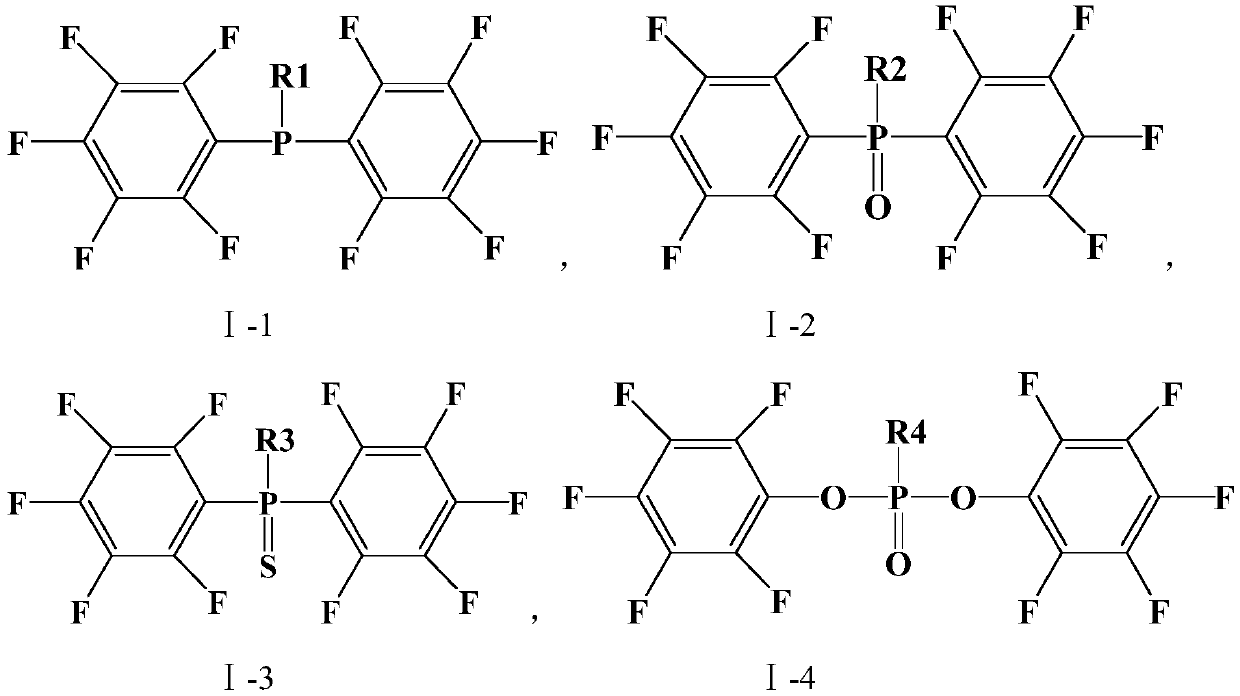

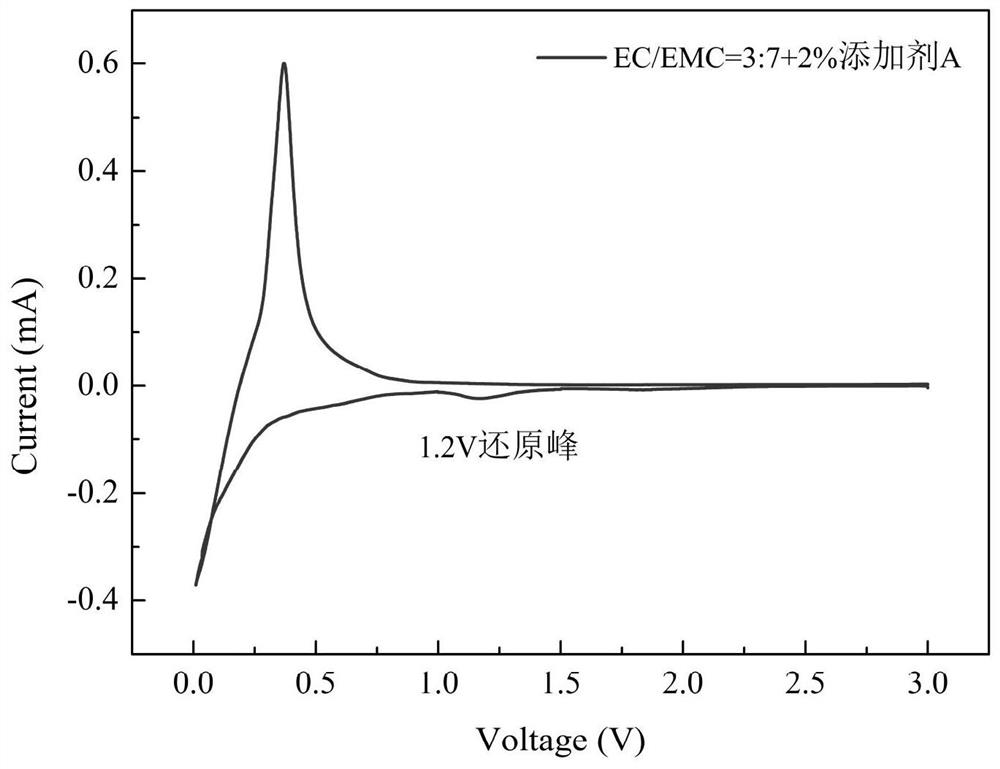

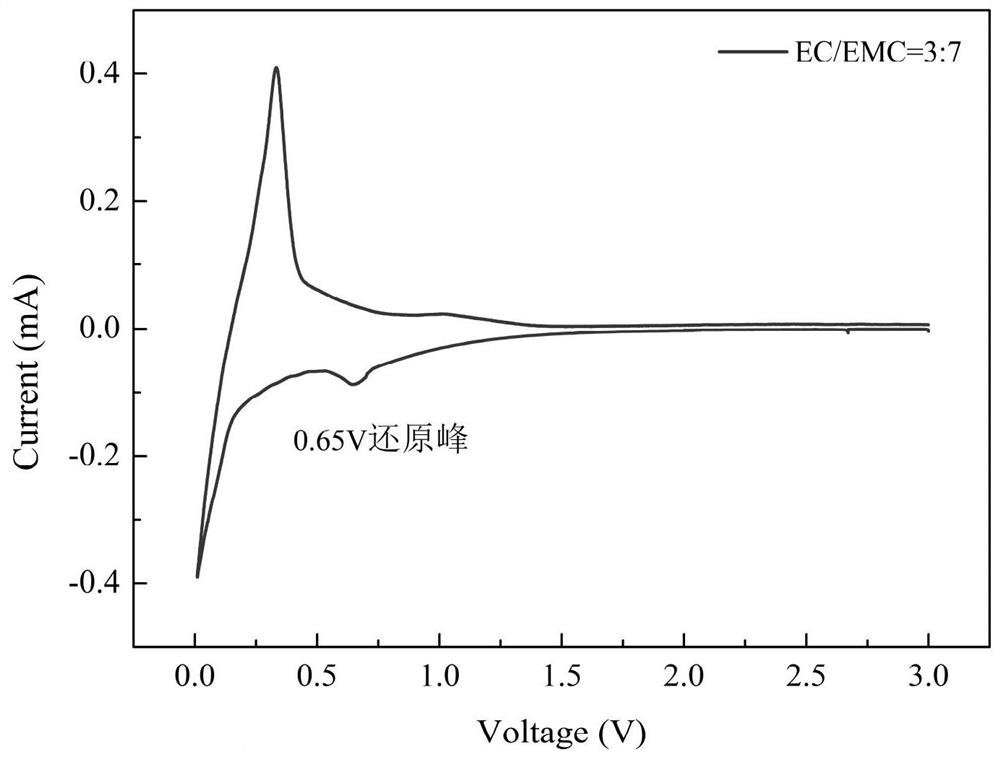

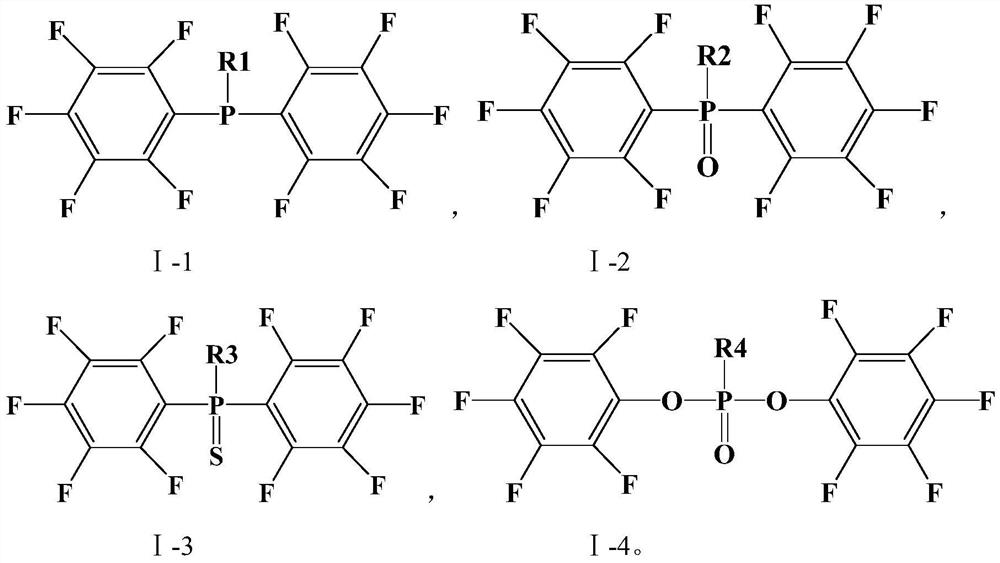

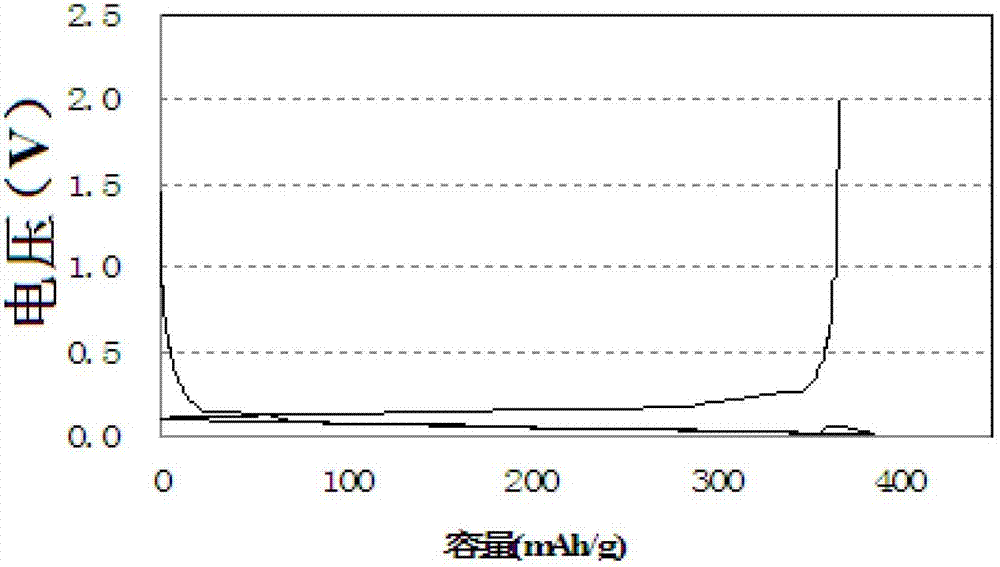

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a lithium ion battery electrolyte considering high and low temperature performances and a battery. Byadding the bis-pentafluorophenylphosphino compound into the electrolyte, a reduction reaction is performed on a negative electrode material prior to a solvent to form an SEI film with excellent performance, so that the co-intercalation of solvent molecules is prevented, the interface stability of the negative electrode is improved, and the low-temperature performance of a lithium ion battery is improved; and by complexing with HF in the electrolyte at a high temperature, the corrosion of HF in the electrolyte to a positive electrode material under the high-temperature and high-pressure conditions is avoided, and the high-temperature performance of the lithium ion battery is improved.

Owner:GUANGZHOU TINCI MATERIALS TECH

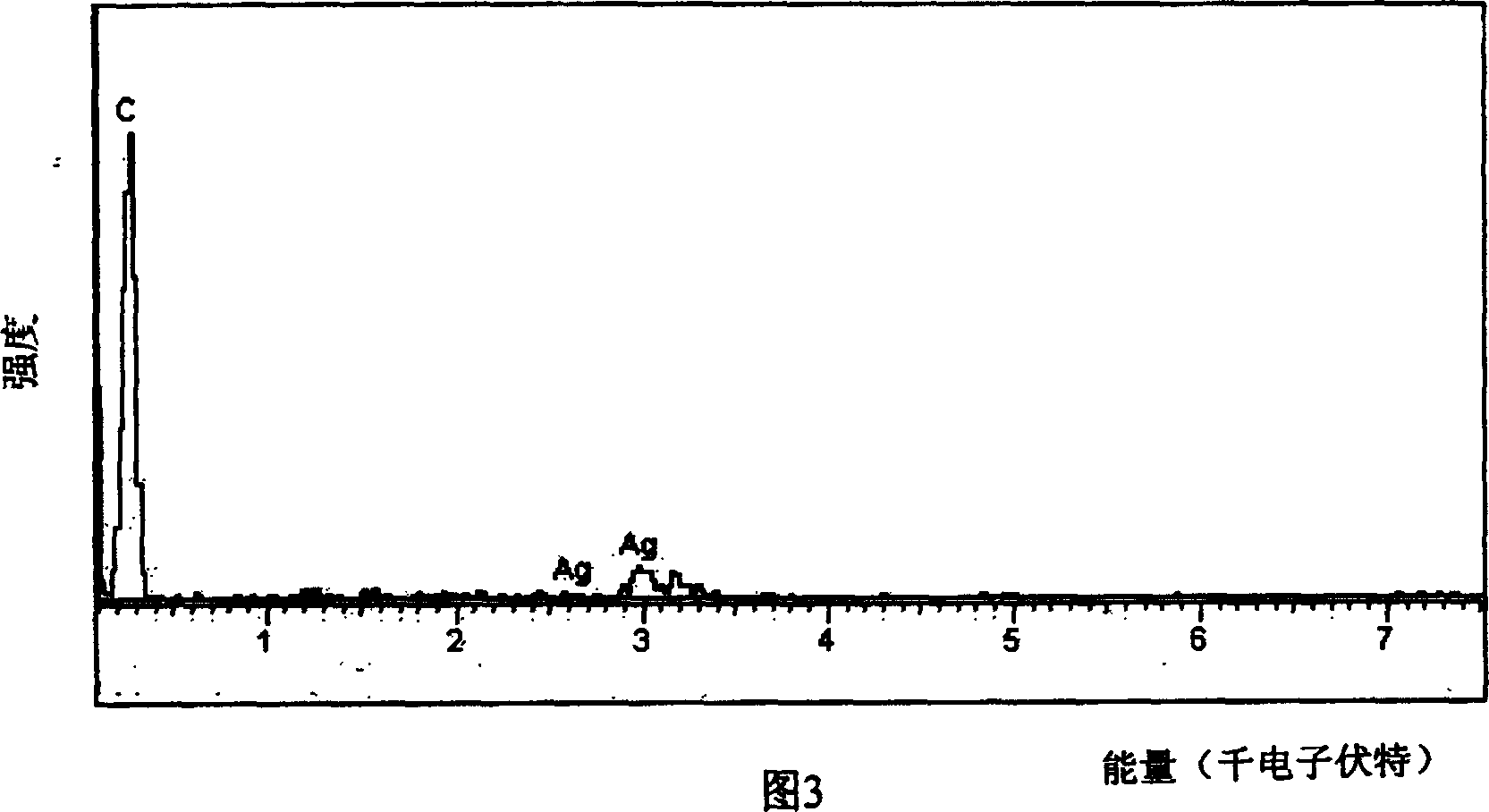

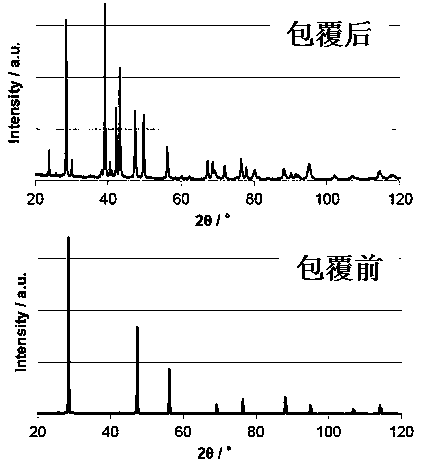

Coke powder-based cathode material of lithium ion power battery and preparation method thereof

ActiveCN103066243BShort processReduce manufacturing costCarbon compoundsCell electrodesSolid carbonPower battery

The invention discloses a coke powder-based cathode material of a lithium ion power battery and a preparation method thereof. The cathode material has a D50 of 10-30 [mu]m, a minimum granularity of 5 [mu]m, a maximum granularity of 30 [mu]m, and a tap density of 1.1-1.5 g / cm<3>. The cathode material has a core-shell structure, wherein a core is graphitized coke powder, and a shell is composed of coal pitch pyrolytic carbon and metal particles. The cathode material contains 95.00-99.00 % of solid carbon and 1-5 % of metal or metal oxide particles by mass percent. The preparation method comprises crushing, grading and purifying the coke powder, cladding coal pitch on the coke powder particles, graphitizing under a high temperature, attaching metal or metal oxide on the particles, etc. The cathode material is excellent in rate performance, good in high-temperature and low-temperature performances, low in manufacture cost and suitable for large-scale industrialization.

Owner:CENT SOUTH UNIV +1

Nanometer metal or alloy composite material and preparation and usage thereof

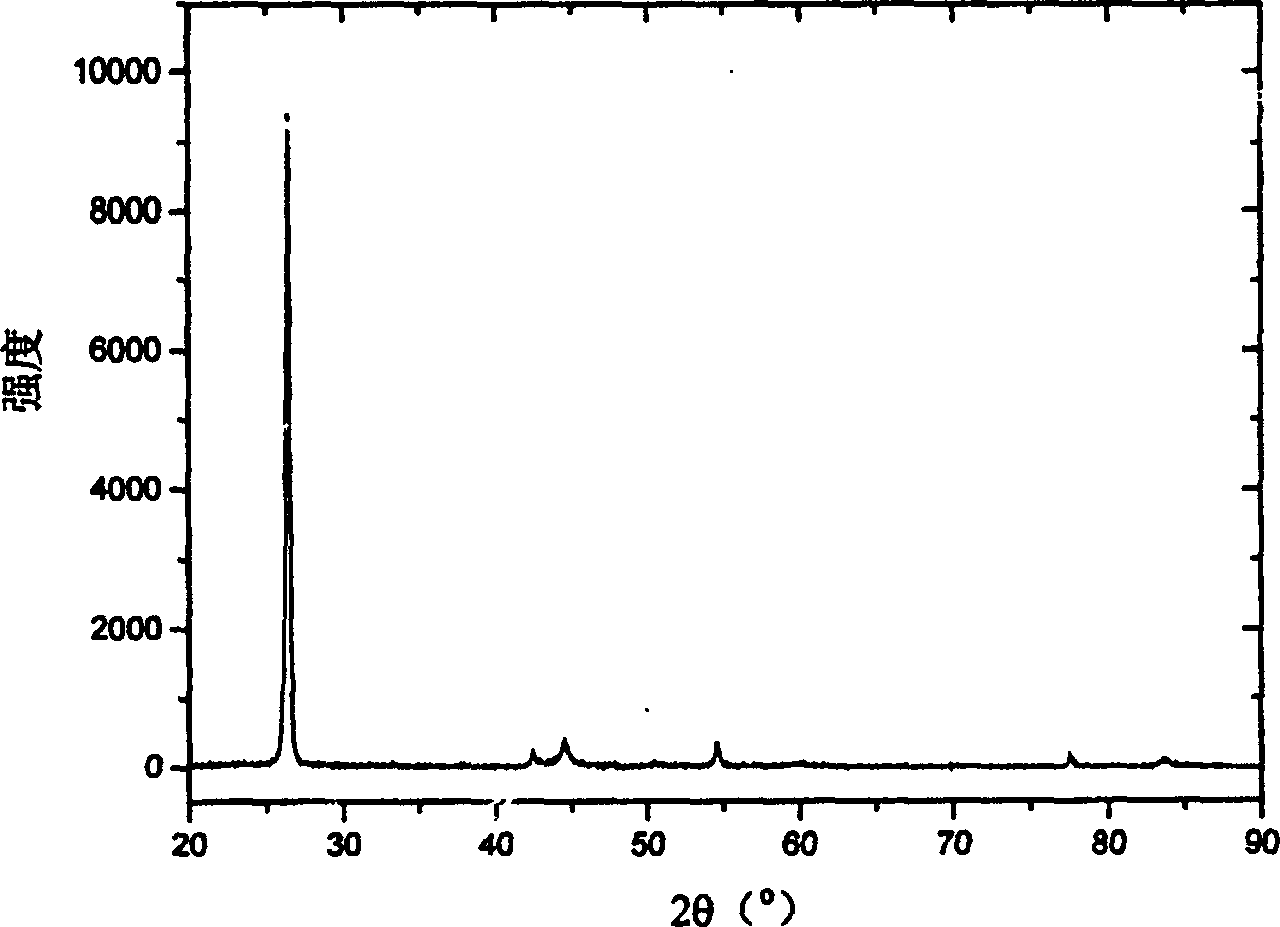

InactiveCN1269243CImprove cycle performanceImprove ionic conductivityAlkaline accumulatorsElectrode manufacturing processesHigh energyAlloy composite

The invention relates to a compound material of millimicron metal or alloy / electrode active substance, comprising: millimicron metal or alloy and electrode active substance; millimicron metal or particle of alloy takes up 0.02~30 wt% of electrode active substance. The compound material is negative electrode active material of secondary lithium battery, cooperating with of metal oxide containing lithium, organic electrolyte solution, diaphragm, battery shell, and afflux agent and lead, to form secondary lithium battery. The electrode active substance of compound material supplies rigid skeleton structure and center for inlaying lithium, helps the formation of solid electrolyte layer on the surface of electrode active substance which has excellent ion conducting power; can avoid destruction to lamellar structure of graphite, stop unit of millimicron material effectively and increase periodicity and capacity of discharge and discharge with large current. The a secondary lithium battery has excellent abilities of circulation and safety, suitable for the place needing fairly high energy density.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

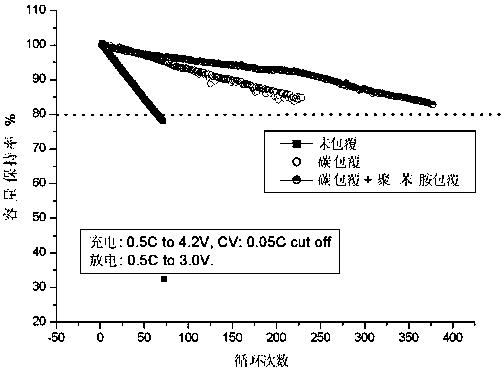

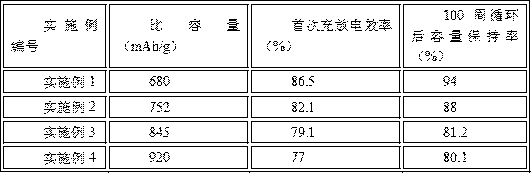

A kind of composite negative electrode material of high-capacity lithium-ion battery and preparation method thereof

The invention relates to the technical field of a lithium ion battery, in particular to a composite negative electrode material of a high-capacity lithium ion battery and a preparation method of the composite negative electrode material. The constituents of the composite negative electrode material are silicon powder and graphite which are arranged at an inner layer and a dual-layer coating object arranged at an outer layer, a first layer of the dual-layer coating object is a coating carbon layer, the coating object is amorphous carbon, a second layer of the dual-layer coating object is a coating polymer, the coating object is polyaniline, the composite negative electrode material is a powder material, the grain size of the powder material is 0.5 to 40 micrometers, the mass ratio of the silicon powder to the graphite is 1:99 to 1:1, the mass percentage of the coating carbon layer accounts for 3-15%, and the mass percentage of the coating polymer layer accounts for 3-15%. With the composite negative electrode material, the problems of low charging and discharging specific capacity and poor cycle performance of the conventional carbon material serving as the negative electrode material of a power lithium ion battery are solved, and the composite negative electrode material is high in capacitance and has favorable cycle performance and stability performance.

Owner:WANXIANG 123 CO LTD

High-rate electrolyte suitable for lithium battery of unmanned aerial vehicle

ActiveCN113991181AImprove lithium ion conductivityLow viscosityFinal product manufactureSecondary cells servicing/maintenancePropanoic acidLithium hexafluorophosphate

The invention provides a high-rate electrolyte suitable for a lithium battery of an unmanned aerial vehicle. The high-rate electrolyte comprises a lithium salt, an organic solvent and a functional additive. The organic solvent is a common carbonic ester solvent and linear carboxylic ester, and comprises ethylene carbonate, diethyl carbonate, methyl ethyl carbonate, propylene carbonate, ethyl propionate, methyl acetate and gamma-butyrolactone. The lithium salt is lithium hexafluorophosphate, lithium difluoro (oxalato) borate, lithium tetrafluoroborate and lithium bis (fluorosulfonyl) imide. The additives are vinylene carbonate, difluoroethylene carbonate and diethylene glycol dibenzoate. The method of mixing and matching the ethylene carbonate-based solvent and the propylene carbonate-based solvent is adopted, the solvent composition of the electrolyte is optimized, the solvation effect of lithium ions is improved, the impedance of a solid electrolyte interface formed by the electrolyte on the surface of an electrode material is greatly reduced by using the additive, and the electrolyte is more suitable for high-rate charging and discharging of a battery.

Owner:郑州中科新兴产业技术研究院

A kind of modification method of lithium ion battery graphite negative electrode material

ActiveCN105514394BImprove the first Coulombic efficiencyReduce irreversible capacityCell electrodesSecondary cellsCyclic processGraphite

The invention relates to a modification method for a lithium-ion battery graphite cathode material. The method comprises the following steps that a, graphite and a maleate water solution are mixed to obtain a mixed solution; b, the mixed solution is heated to be dry on the constant-stirring condition. Due to the existence of a wrapping layer, the effect of an artificial SEI membrane is achieved, the reversible capacity of the material is effectively lowered, and the first-time coulombic efficiency of a lithium-ion battery is improved. In addition, the wrapping layer can be better attached to the surface of the graphite, cointercalation of solvation lithium ions can be resisted to a certain extent, the effect of the SEI membrane is achieved, and the stability of a graphite structure is protected; in addition, lithium consumption can be resisted in the electrode cyclic process, and therefore long-term cyclic stability of the graphite material is better protected.

Owner:JIANGSU DAOYING TECH CO LTD

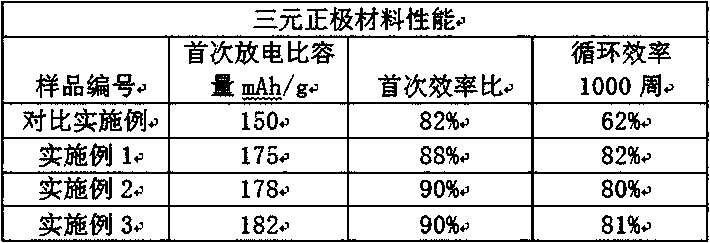

Preparation method of modified ternary anode material

InactiveCN108807978AImprove the defect of poor cycle stabilityReversible expansion and contractionMaterial nanotechnologyCell electrodesMetallurgyCycle efficiency

The invention relates to a preparation method of a modified ternary anode material. According to the anode material, a ternary anode material is coated with polyvinylpyrrolidone resin to form an amorphous carbon coating layer on the surface of the ternary anode material; polyvinylpyrrolidone is organic silicon modified polyvinylpyrrolidone; the ternary anode material is LiNixCoyMnzO2, wherein x ismore than or equal to 0.3 and less than or equal to 1, y is more than or equal to 0 and less than or equal to 0.5, and z is more than or equal to 0 and less than or equal to 0.5, and x+ y+ z=1. The preparation method specifically comprises the following steps: mixing the polyvinylpyrrolidone and the ternary anode material in ethanol, then stirring and filtering the mixture, heating the mixture tocarbonize the mixture, and finally cooling and smashing the product. The preparation method disclosed by the invention has the advantages that the modified polyvinylpyrrolidone and the ternary anodematerial are treated to prepare the modified ternary anode material, and the initial efficiency of the modified ternary anode material is 13 percent higher than that of a non-modified material; the initial efficiency of a ternary anode material coated sample is higher than that of a non-modified ternary material, and the later cycle efficiency of the sample is also 60 percent higher than that of the non-modified material; the defect of low cycle stability of the ternary anode material can be effectively improved.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

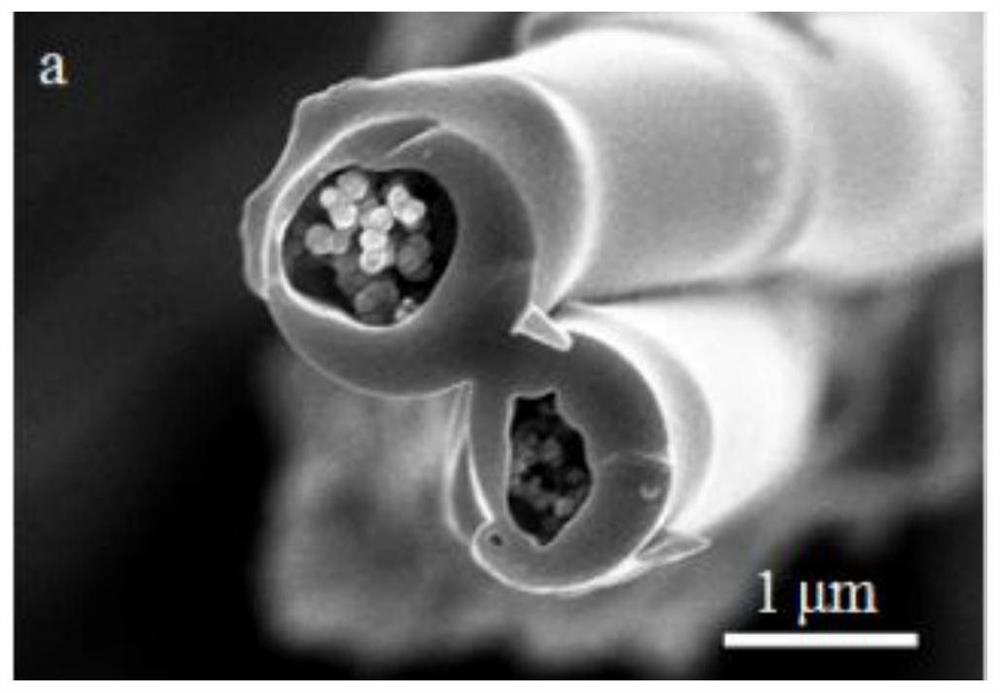

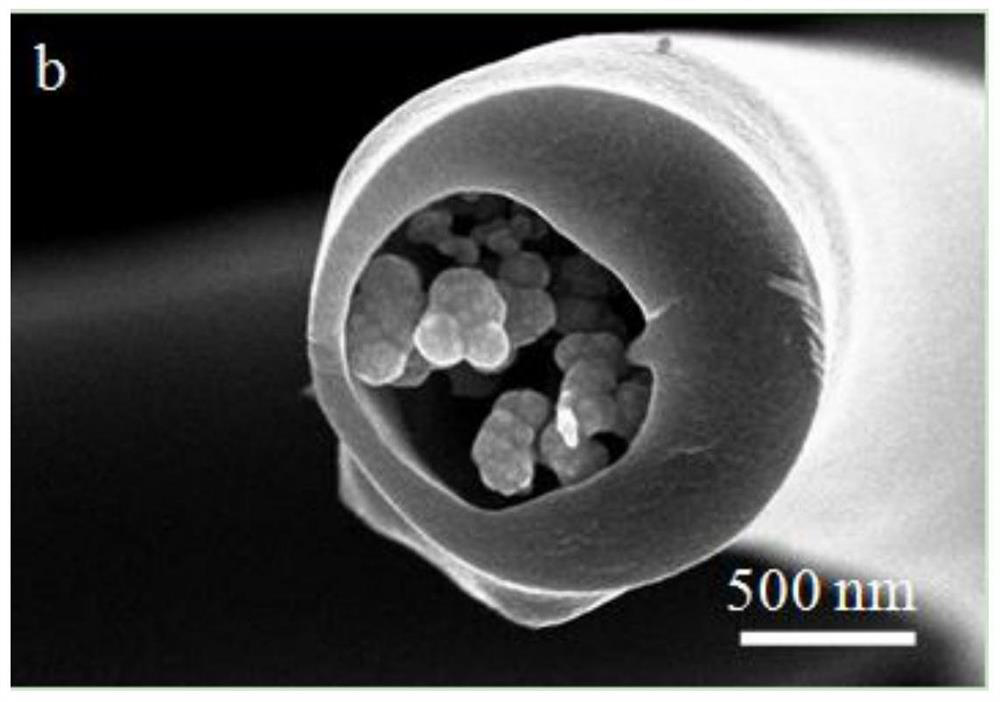

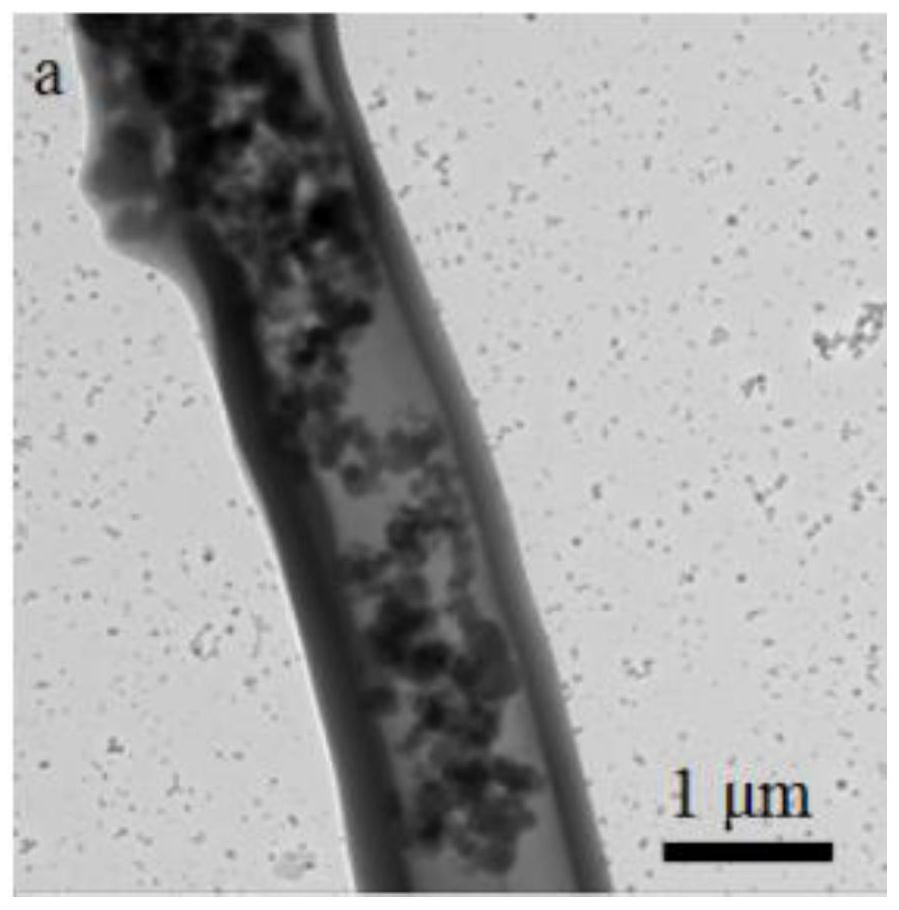

A core-shell structure silicon/carbon fiber flexible composite electrode material and its preparation method and application

ActiveCN110112405BAdapt to volume expansionAvoid destructionCell electrodesSecondary cellsFiberNano silicon

The invention relates to a core-shell structure silicon / carbon fiber flexible composite electrode material and a preparation method and application thereof, belonging to the technical field of flexible electrode materials. In order to solve the problem that the volume change of the existing silicon electrode causes the electrode structure to break and the electrochemical performance and flexibility of the flexible electrode to decrease after the binder is added, the present invention provides a core-shell structure silicon / carbon fiber flexible composite electrode material, which consists of core-shell Structural silicon / carbon fiber is made by electrospinning. The core nano-silicon particles of the core-shell structure silicon / carbon fiber are evenly encapsulated in the carbon fiber shell. The core part can effectively adapt to the volume expansion of silicon, and the carbon shell can prevent the electrolyte from penetrating into the core. , which improves the cycle performance and service life of the electrode; it has good flexibility and mechanical stability without adding binders, conductive agents and electrode pastes, and can withstand a large degree of bending. It is applied to lithium In the field of ion battery technology, the electrochemical performance and flexibility of lithium ion batteries can be further improved.

Owner:HARBIN UNIV OF SCI & TECH

A lithium-ion battery electrolyte and battery with both high and low temperature performance

ActiveCN110931870BInhibition of continuous reductive decompositionReduce consumptionSecondary cellsOrganic electrolytesElectrolytic agentLithium-ion battery

The invention belongs to the technical field of lithium-ion batteries, and in particular relates to a lithium-ion battery electrolyte and a battery with both high and low temperature performance. By adding bis-pentafluorophenylphosphino-based compounds in the electrolyte, the reduction reaction occurs on the negative electrode material in preference to the solvent to form an SEI film with excellent performance, prevent the co-intercalation of solvent molecules, improve the interface stability of the negative electrode, and improve lithium Low-temperature performance of ion batteries; complexation with HF in the electrolyte at high temperatures, avoiding the erosion of positive electrode materials by HF in the electrolyte under high temperature and high pressure conditions, and improving the high-temperature performance of lithium-ion batteries.

Owner:GUANGZHOU TINCI MATERIALS TECH

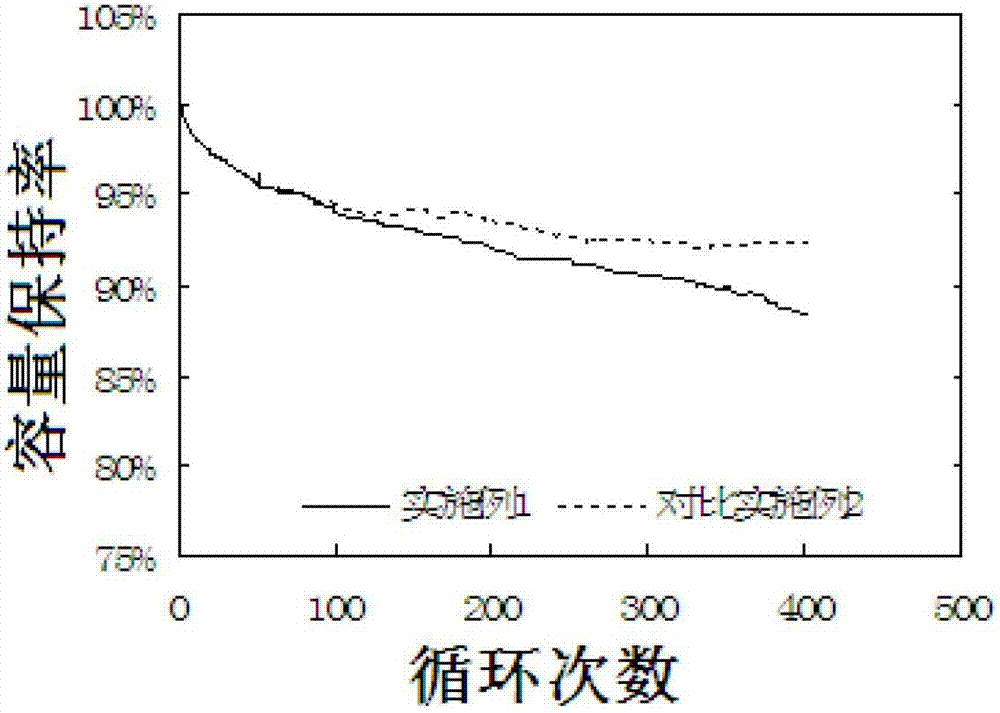

A kind of modified natural graphite and preparation method thereof

ActiveCN104037417BImprove bindingImprove cycle performanceCell electrodesSecondary cellsLithium-ion batteryLithium electrode

The invention discloses modified natural graphite and a preparation method thereof. The preparation method comprises the following steps: (1) adding a wetting dispersant and a bonding agent in a weight ratio of 1: 10 to 3: 10 into water and carrying out full mixing so as to prepare a mixed solution with a mass concentration of 30 to 60%; (2) adding natural graphite into the mixed solution prepared in the step (1) and successively carrying out mixing and drying; (3) fully mixing a substance obtained in the step (2) with an amorphous carbon precursor and a graphitization catalyst in a cladding kettle, carrying out heating to 300 to 400 DEG C and then carrying out thermal condensation polymerization at a constant temperature; (4) subjecting a substance obtained in the step (3) to compression molding and then carrying out hot isostatic pressing; and (5) subjecting a substance obtained in the step (4) to carbonizing treatment at first and graphitization treatment next under the protection of inert gas. A lithium ion battery negative electrode material prepared from the modified natural graphite has high initial charge and discharge efficiency, long cycle performance and good application prospects.

Owner:SHANGHAI SHANSHAN TECH CO LTD

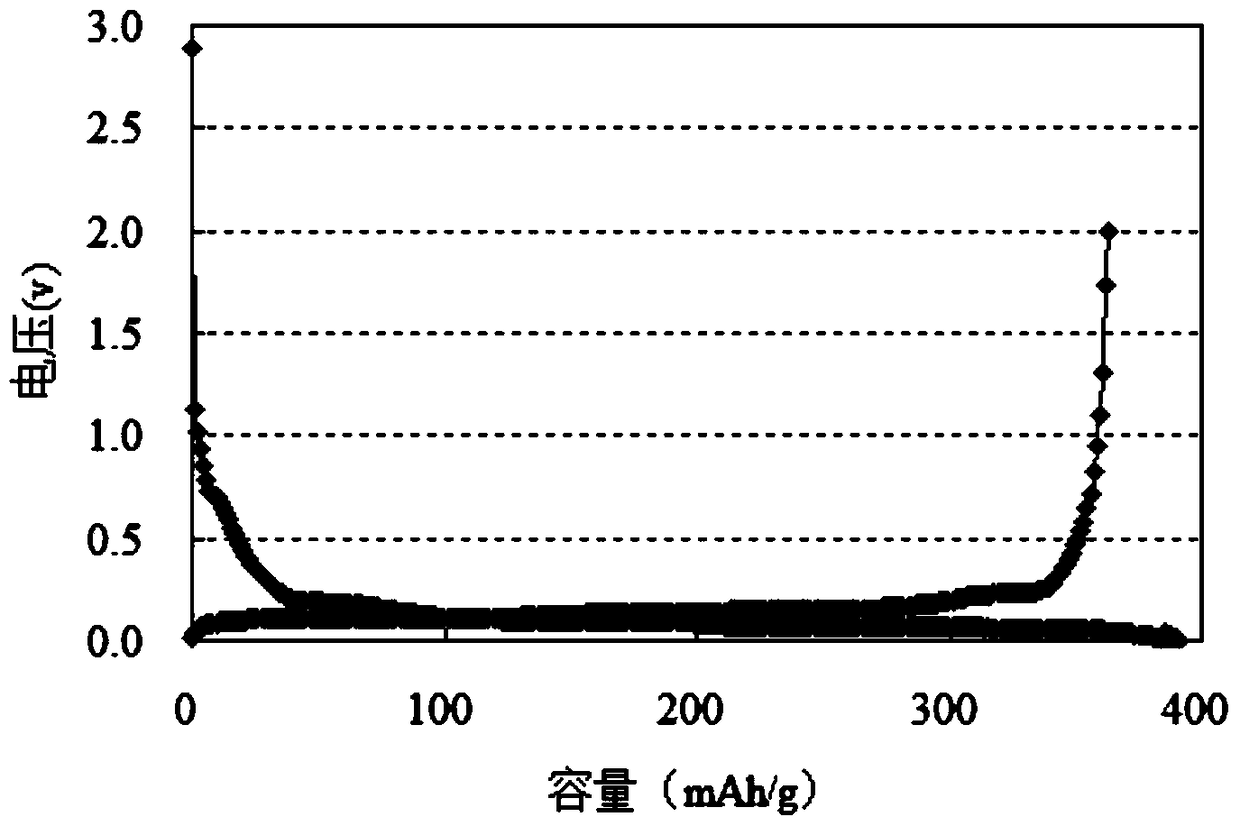

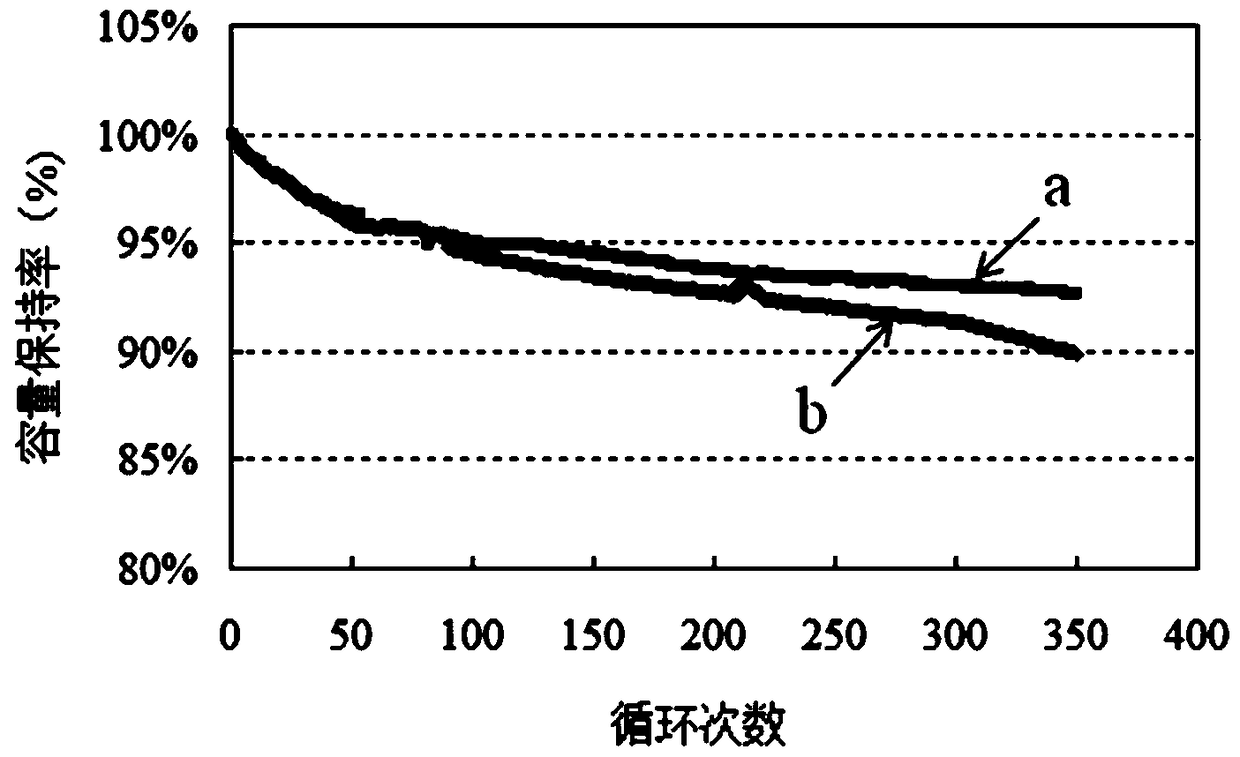

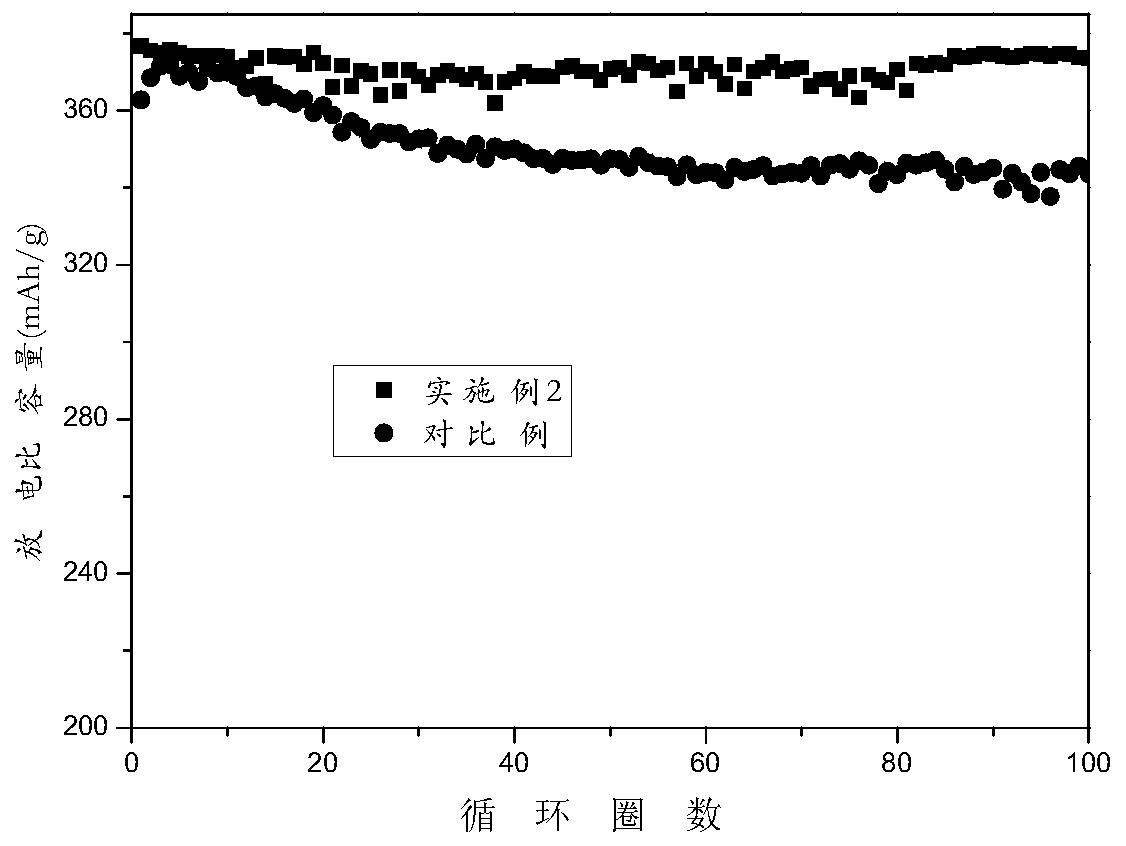

A kind of lithium ion battery graphite negative electrode material and preparation method thereof

ActiveCN104425822BPromote circulationImprove charge and discharge efficiencyGraphiteNegative electrodesElectrical batteryPhysical chemistry

The invention discloses a graphite negative electrode material of a lithium ion battery and a preparation method for the graphite negative electrode material. The preparation method comprises the following steps of (1) heating a mixture of a macromolecular material and natural graphite according to a rate of 0.5-1.5 DEG C per minute to the temperature of 200-350 DEG C in inert gas atmosphere, and preserving the temperature for 80-200 minutes to obtain a wrapping body; (2) mixing the wrapping body and an asphalt carbon precursor to obtain a mixture, heating the mixture to the temperature of 380-450 DEG C according to the heating rate of 2.5-3.5 DEG C per minute, performing retrogressive reaction for 60-200 minutes under a condition of constant temperature, heating to the temperature of 580-620 DEG C, and keeping the temperature for 30-60 minutes to obtain a composite body; and (3) performing carbonization treatment on the composite body under the temperature of 600-1,500 DEG C. The lithium ion battery prepared from the graphite material prepared by the preparation method disclosed by the invention is excellent in circulating performance, high in low-temperature property and high in charging and discharging efficiency.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

A kind of lithium-ion battery negative electrode sheet and manufacturing method thereof

ActiveCN105470460BIncreased durabilityImprove cycle stabilityCell electrodesCarbon layerSide reaction

The invention relates to a negative electrode piece of a lithium ion battery and a fabrication method of the negative electrode piece. The negative electrode piece of the lithium ion battery comprises a negative electrode current collector, a negative electrode material layer and a soft carbon layer, wherein the negative electrode material layer is applied onto the current collector, and the soft carbon layer is applied onto the negative electrode material layer. The fabrication method of the negative electrode piece of the lithium ion battery comprises the following steps of preparing a negative electrode paste; coating the negative electrode paste; preparing a soft carbon paste; coating the soft carbon paste; and grinding the negative electrode piece. By uniformly applying the soft carbon paste onto the negative electrode material layer, the compatibility of the negative electrode piece and an electrolyte can be improved, the side reaction of a negative electrode and the electrolyte is reduced, the expansion of the negative electrode also can be reduced to a certain extent, thus, the cycle performance of the battery is improved, and meanwhile, the low-temperature performance of the battery is further improved.

Owner:WANXIANG 123 CO LTD

A kind of fluorinated alkylsulfonimide additive for promoting the film formation of graphite carbon negative electrode and electrolyte solution containing the additive

ActiveCN107706454BInhibition of continuous reductive decompositionContinuous reductive decomposition reductionSecondary cells servicing/maintenanceElectrolytic agentFuran

The invention discloses a fluoroalkylsulfonylimide lithium-ion battery electrolyte additive whose structural formula is shown in formula I to promote the film formation of graphite carbon negative electrode: wherein, R 1 is hydrogen, benzene ring, five-membered or six-membered heterocyclic group selected from furan, thiophene, pyrrole, thiazole, imidazole, pyridine, pyrazine, pyrimidine, pyridazine , R 2 and R 3 It is a F atom or a fluoroalkyl group in which 1 to 3 hydrogen atoms in a methyl group, an ethyl group, or a propyl group are replaced by F. The SEI film formed by the fluoroalkylsulfonimide additive is better than the SEI film formed by VC, which can better improve the cycle stability of the graphite carbon negative electrode, improve the safety performance of the lithium-ion battery, and show good performance. Practicality and economic value.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

Lithium-ion battery germanium/carbon composite negative electrode material and its preparation method and application

ActiveCN110085847BImprove cycle stabilityAvoid reunionSecondary cellsNegative electrodesCarbon compositesElectrolytic agent

The invention discloses a lithium-ion battery germanium / carbon composite negative electrode material and a preparation method and an application thereof. The composite negative electrode material includes germanium nanoparticles, mesocarbon microbeads and amorphous carbon. The preparation method comprises the steps of (1) dissolving GeO2 in an alkaline solution, adding nanocrystalline cellulose, adjusting the pH-value of the obtained first suspension, adding the mesocarbon microbeads and stirring to form a second suspension, and transferring the second suspension to a water bath; (2) preparingan NaBH4 solution, adding the heated second suspension, stirring for reaction in the water bath, washing wafer vacuum filtration, then carrying out vacuum drying, roasting the dried solid in an inertgas or reducing atmosphere to obtain the product. The composite negative electrode material disclosed by the invention has high mass capacity and volume specific capacity, can effectively alleviate the volume change and pulverization of germanium, is high in cycle stability and good in compatibility with a propylene carbonate containing electrolyte, has the advantages of good low-temperature electrochemical performance and the like and can be applied to lithium-ion batteries.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing carbon cathode material and lithium iron battery using the material

InactiveCN101186292BReduce dosageLow costElectrode manufacturing processesSecondary cellsQuinolineSolvent

The invention provides a preparation method of carbon negative electrode material and lithium ion battery that uses the material. Emulsified asphalt is prepared by taking water as solvent, graphite is coated by the emulsified asphalt and the composite material is carbonized. The solvent applied by the carbon negative electrode material of the lithium ion battery prepared by the method has low cost, can eliminate solvent contamination and solves the difficulty that a great deal of poisonous organic solvent such as toluene, quinoline, etc. are applied when asphalt is dissolved in the past. By adopting the composite material prepared by the method as cathode of the lithium ion battery, the battery has the advantages of excellent performances, such as good electrolyte compatibility, high efficiency of coulomb during the first charging and discharging, low irreversible capacity and long cycle life, etc.

Owner:LIAONING TECHNICAL UNIVERSITY

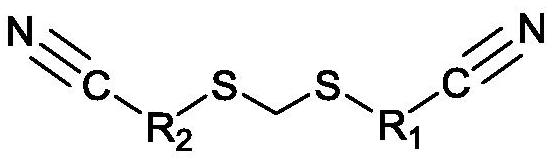

Electrolyte of lithium ion battery

InactiveCN111613835AInhibit gas productionSolve the gas situationSecondary cells servicing/maintenanceOrganic electrolytesElectrolytic agentAlkane

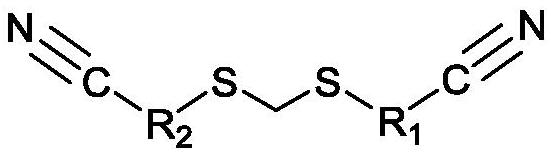

The invention discloses an electrolyte of a lithium ion battery for improving the safety performance of the battery. The electrolyte comprises an organic solvent, a lithium salt dissolved in the organic solvent and an additive, the additive is dithiocyano alkane, the corresponding molecular formula of the additive is CNR1SSR2CN, R1 and R2 are alkane with the carbon atom number ranging from 0 to 4,or hydrogen atoms on the alkane are replaced by fluorine atoms, and the number of the replaced fluorine atoms is within 1-5. In the actual experiment process, the added dithiocyano alkane additive can form surface protective films on the surfaces of the positive electrode and the negative electrode of the lithium ion battery as a sulfur-containing substance, so that the co-intercalation of solvents is prevented under the conditions of battery formation, circulation and the like, and the side reactions are reduced. Meanwhile, the nitrile substance can inhibit gas production of the battery under a high-voltage condition, and can effectively solve the problem of gas expansion of the battery under high voltage when being used as an additive of the electrolyte of the lithium ion battery.

Owner:贵州兴锂新能源科技有限公司

Additive of lithium ion battery electrolyte and electrolyte containing same

InactiveCN101685882AReduce reductive decompositionPrevent co-embeddingSecondary cellsPropylene carbonateLithium-ion battery

The invention discloses an additive of lithium ion battery electrolyte, containing allyl ethyl carbonate (AEC). The invention also discloses the lithium ion battery electrolyte containing the additive. The additive and electrolyte of the invention can improve the compatibility of propylene carbonate (PC) and the natural graphite cathode materials, thus effectively prolonging the cycle life of thelithium ion battery.

Owner:SHENZHEN BAK BATTERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com