Method for preparing carbon cathode material and lithium iron battery using the material

A lithium-ion battery and negative electrode material technology, applied in the direction of electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as unfavorable to clean production, pollute the production environment, and increase the cost of preparation, so as to improve the first Coulombic efficiency and cycle stability Good compatibility, avoiding the peeling effect of graphite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

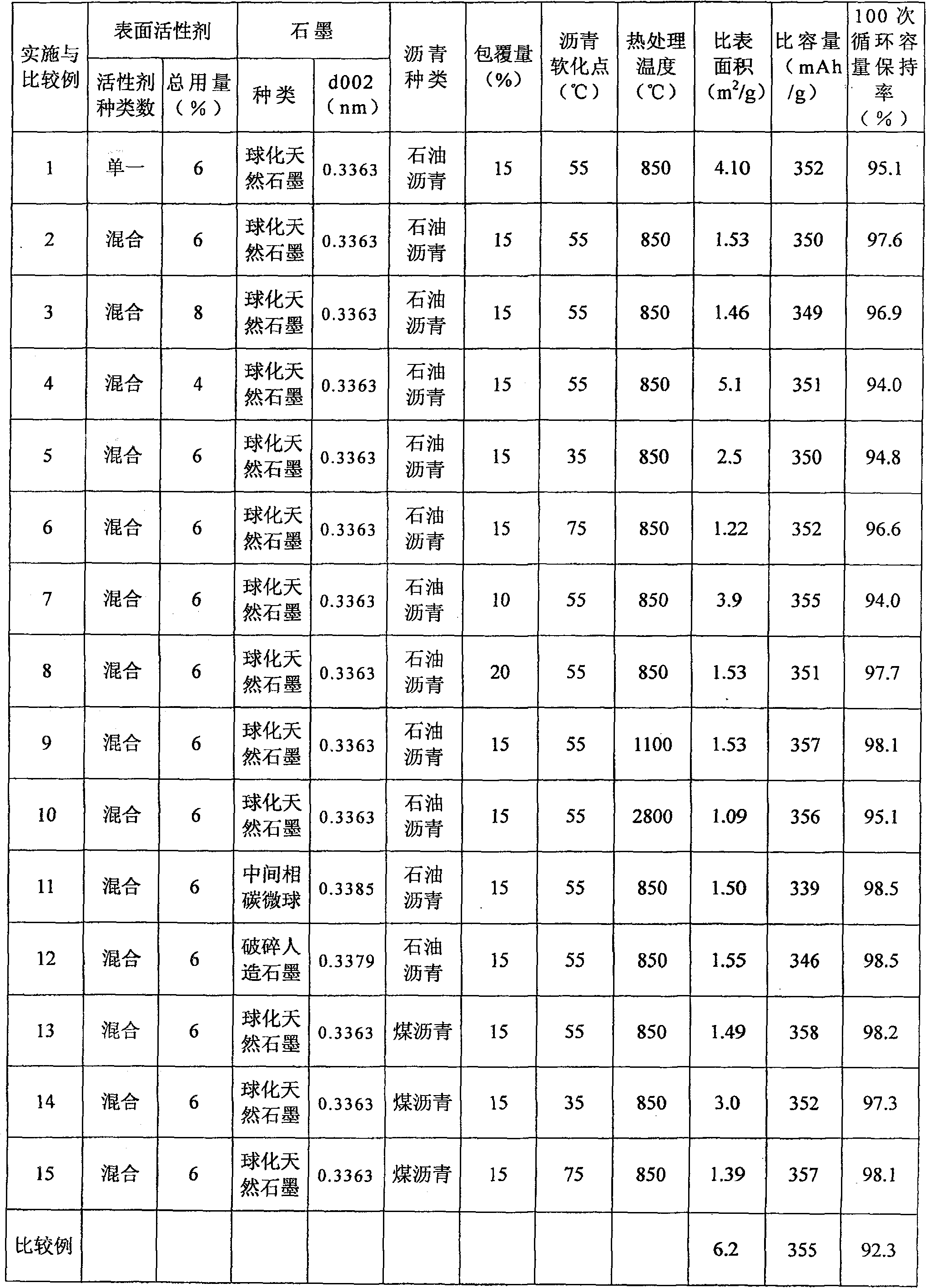

Examples

Embodiment 1

[0020] (1) Take 6 grams of petroleum asphalt with a softening point of 55°C and heat it to 85°C to make it have good fluidity.

[0021] (2) Dissolve 0.36g of cetyltrimethylammonium chloride aqueous solution in 40ml of water according to 6% of the pitch weight, and adjust the pH to 4-5, and keep the temperature at 85°C to prepare the surfactant aqueous solution. (3) Take 4ml of surfactant aqueous solution, add 85°C asphalt to it, stir vigorously at high speed, keep the temperature at 85°C after mixing, and prepare emulsified asphalt. (4) Add 40 grams of spherical natural graphite (referred to as spheroidized graphite) to the remaining 36ml of surfactant solution, and stir it into a paste, wherein the specific surface area of spheroidized graphite is 6.2m 2 / g, particle size 5-50μm and d002 0.3363nm; (5) Add emulsified pitch to graphite paste and stir at high speed for 1h to evaporate the water. (6) Heat-treat the emulsified pitch-coated graphite in an inert atmosphere of arg...

Embodiment 2

[0023] (1) Take 6 grams of petroleum asphalt with a softening point of 55°C and heat it to 85°C to make it have good fluidity.

[0024] (2) Dissolve 0.36 g of cetyltrimethylammonium chloride aqueous solution in 40 ml of water according to 6% of the pitch weight, add 0.06 g of nonylphenol polyoxyethylene ether, and adjust the pH=4 to 5, and make it The temperature was kept at 85°C to prepare an aqueous surfactant solution. (3) Take 4ml of surfactant aqueous solution, add 85°C asphalt to it, stir vigorously at high speed, keep the temperature at 85°C after mixing, and prepare emulsified asphalt. (4) Add 40 grams of spherical natural graphite (referred to as spheroidized graphite) to the remaining 36ml of surfactant solution, and stir it into a paste, wherein the specific surface area of spheroidized graphite is 6.2m 2 / g, particle size 5-50μm and d002 0.3363nm; (5) Add emulsified pitch to graphite paste and stir at high speed for 1h to evaporate the water. (6) Heat-treat the...

Embodiment 3

[0026] (1) Take 6 grams of petroleum asphalt with a softening point of 55°C and heat it to 85°C to make it have good fluidity.

[0027] (2) Dissolve 0.48 g of cetyltrimethylammonium chloride aqueous solution in 40 ml of water according to 8% of the pitch weight, add 0.08 g of nonylphenol polyoxyethylene ether, and adjust the pH=4 to 5, and make it The temperature was kept at 85°C to prepare an aqueous surfactant solution. (3) Take 4ml of surfactant aqueous solution, add 85°C asphalt to it, stir vigorously at high speed, keep the temperature at 85°C after mixing, and prepare emulsified asphalt. (4) Add 40 grams of spherical natural graphite (referred to as spheroidized graphite) to the remaining 36ml of surfactant solution, and stir it into a paste, wherein the specific surface area of spheroidized graphite is 6.2m 2 / g, particle size 5-50μm and d002 0.3363nm; (5) Add emulsified pitch to graphite paste and stir at high speed for 1h to evaporate the water. (6) Heat-treat the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com