Non-aqueous electrolyte for lithium ion battery with ternary positive electrode material and negative silicon-oxygen-carbon composite negative electrode material

A non-aqueous electrolyte and lithium-ion battery technology, applied in non-aqueous electrolytes, electrolytes, secondary batteries, etc., can solve problems such as high-temperature gas production/battery voltage drop, electrolyte interface damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

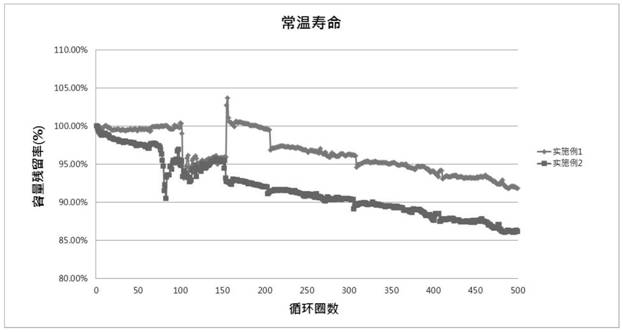

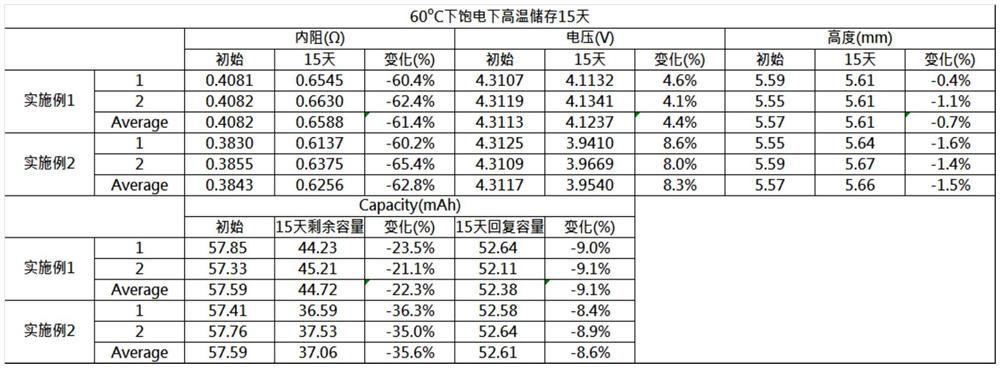

Examples

Embodiment 1

[0027] The model of the button-type lithium secondary battery used in the embodiment of the present invention is CL1154, the first / second digit of the size definition is the battery diameter of 11mm, the third / fourth digit of the size definition is the battery thickness of 5.4mm, and the shell of the button-type lithium secondary battery Tool parts, including small shell metal, insulating rubber ring and large shell metal.

[0028] The internal structure of the battery includes a positive electrode plate, a negative electrode plate, a separator, a non-aqueous electrolyte, and a conductive handle. The positive electrode material used for the positive electrode plate is a nickel-cobalt-aluminum ternary positive electrode material (the chemical formula is LiNi 0.6 mn 0.2 co 0.2 o 2 (referred to as NMC622)), the negative electrode material used in the negative electrode plate is a silicon-oxygen-carbon composite material, and the material of the separator can be a microporous ma...

Embodiment 2

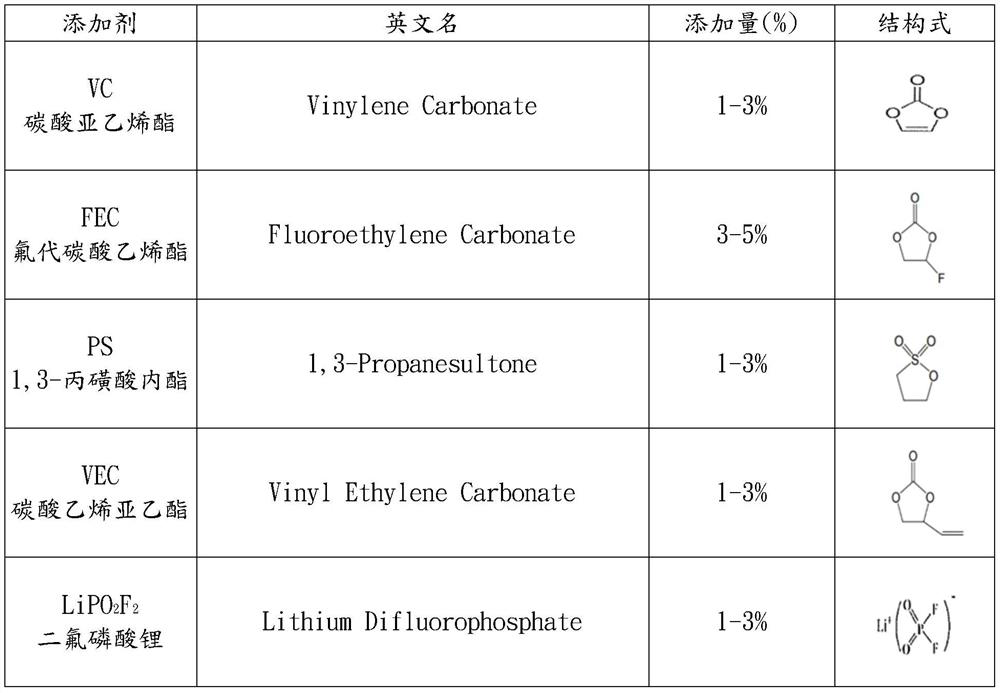

[0029] Embodiment 2 wherein the solvent part is composed of ethylene carbonate EC, ethyl methyl carbonate EMC wherein, by weight, the electrolyte solvent is 100 parts by weight, wherein ethylene carbonate is 10-30 parts by weight, methyl ethyl carbonate The ester is 70-90 parts by weight. The additives include 3-5% vinylene carbonate, 5-10% fluoroethylene carbonate, 3-5% 1,3-propane sultone, 3-5% ethylene carbonate and 3-5 % Composed of lithium difluorophosphate.

[0030] After the positive and negative plates and the separator are rolled into a dry battery cell, dry it in an oven at 80-85°C for 48 hours, then move it into a drying room for use, and inject the non-aqueous electrolyte solution of Example 1 into the baked dry cell. After being placed in the battery cell and standing for 24 hours, a button lithium secondary battery is obtained after activation.

[0031]In embodiment 1 and embodiment 2, the content of ethylene carbonate, ethyl methyl carbonate, lithium hexafluor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com