A kind of modification method of lithium ion battery graphite negative electrode material

A technology for lithium-ion batteries and graphite negative electrodes, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of insignificant effect, low output, high cost, etc., to ensure long-term cycle stability, improve the first Coulombic efficiency, reduce The effect of irreversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present embodiment provides a kind of modification method of lithium-ion battery graphite negative electrode material, and it comprises the following steps:

[0027] (a) Dissolve 0.0152g of maleic acid in 10ml of deionized water, drop into the prepared sodium hydroxide solution until the pH of the solution is 7, the mass of sodium maleate at this time is 0.02g, and then add 2g to the solution Natural graphite and the graphite is completely soaked in the solution by magnetic stirring, and the container used is a 25ml beaker;

[0028] (b) Place the beaker described in step (a) in a water bath under temperature control at 60°C, and continuously stir the mixture in the beaker until dry;

[0029] (c) Place the product in step (b) in a blast drying oven at 60°C for 24 hours to remove residual moisture in step (b).

Embodiment 2

[0031] This embodiment provides a modification method of graphite negative electrode material for lithium ion battery, the preparation process is basically the same as that in Example 1, the difference is that 0.0304g of maleic acid is used to prepare the solution, so that the quality of maleate is graphite 2% of the mass.

Embodiment 3

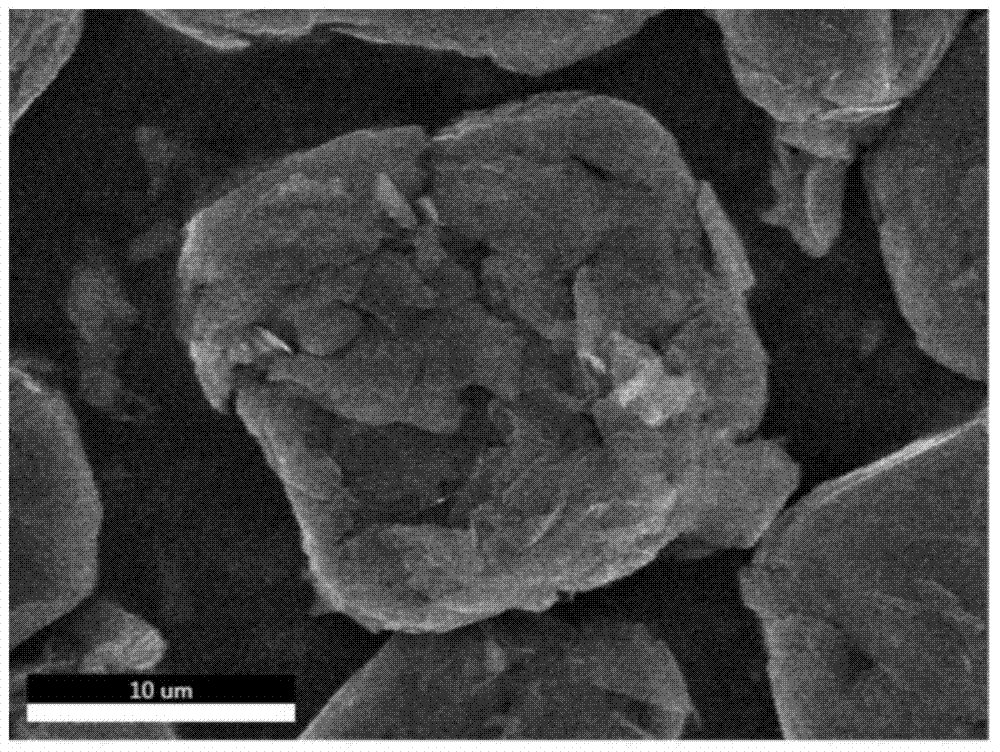

[0033] This embodiment provides a method for modifying graphite negative electrode materials for lithium ion batteries. The preparation process is basically the same as in Example 1. The difference is that 0.0456g of maleic acid is used to prepare a solution so that the quality of the maleate is graphite. 3% of the mass; the obtained lithium-ion battery graphite anode material EDAX figure is as follows Figure 2 to Figure 4 (in, figure 2 EDAX image for the C element, image 3 is the EDAX image of the O element, Figure 4 EDAX image of Na element), SEM (scanning electron microscope) picture as figure 1 As shown, the TEM (transmission electron microscope) image is shown in Figure 6 shown (in addition, Figure 5 TEM image of uncoated graphite).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com