Patents

Literature

41results about How to "Stability plays" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

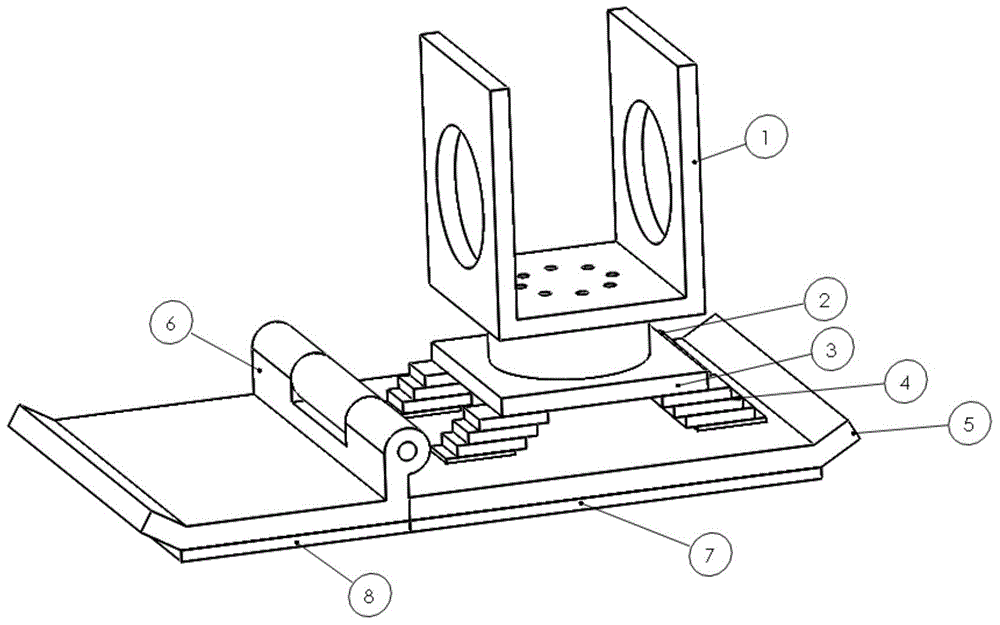

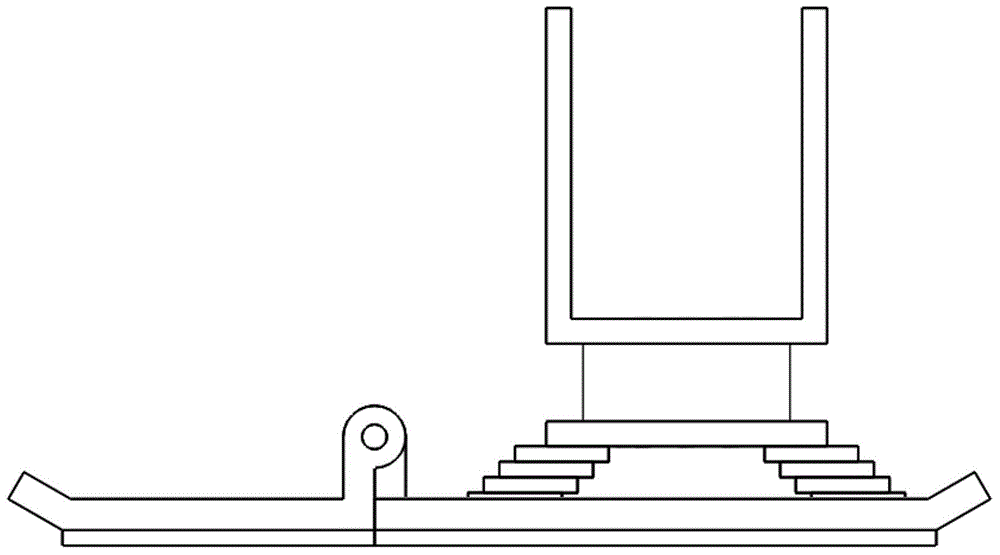

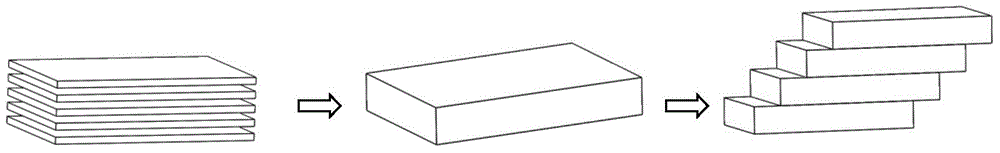

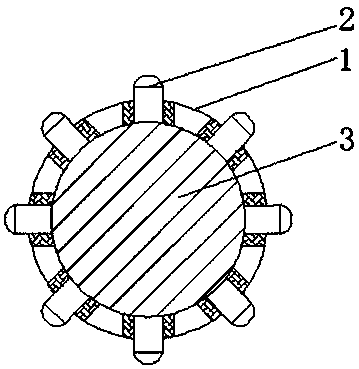

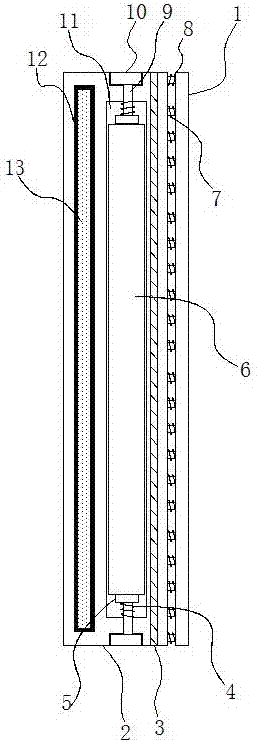

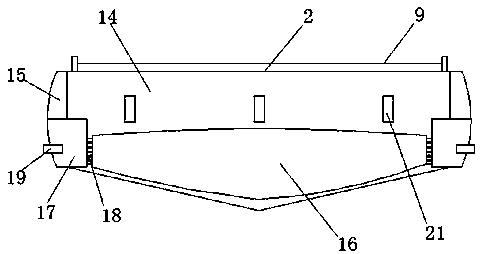

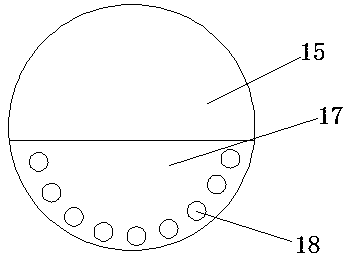

Bionic foot for bionic robot

The invention provides a bionic foot for a bionic robot. The bionic foot comprises a sole base, a bionic arch, an anti-sliding foot pad and a moveable sole, wherein the bionic arch has an arch-shaped structure, simulates a human arch and comprises four bionic arch plate spring stacking modules which are formed by successively staggering and stacking a plurality of plate spring blocks; the bionic arch has a buffering function when the robot walks and climbs stairs and can greatly reduce the ground impact force; the moveable sole is in pivoted connection with the sole base through a rotating shaft; the moveable sole and the sole base has a same degree of freedom; a spring is used for applying a pre-tightening force in the rotating shaft, so that a passive joint is formed; when the robot walks, the moveable sole is clung to the ground, so that the flexibility of the foot is increased and the moving posture of the foot while walking is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

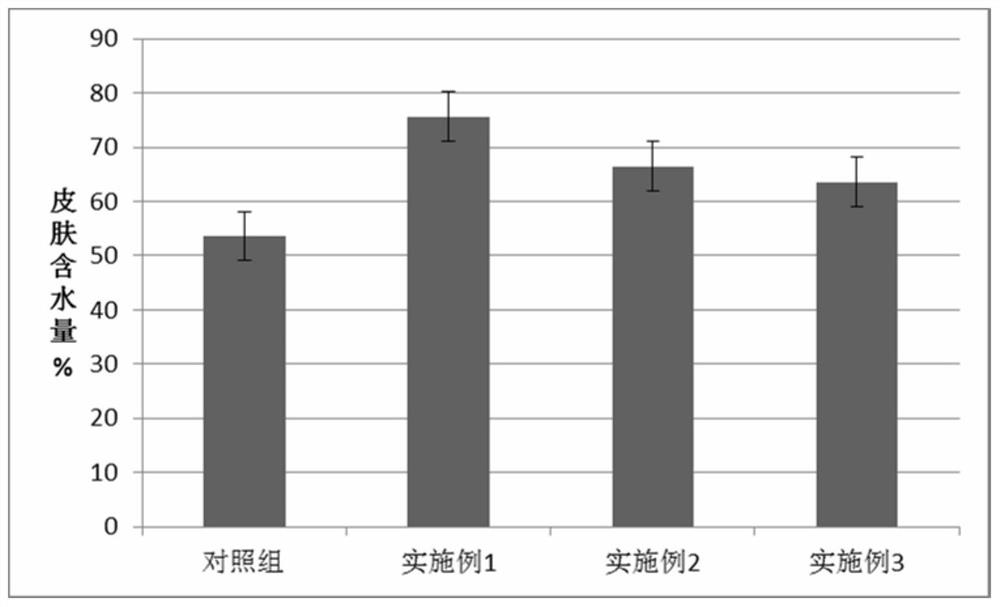

Hyaluronic acid composite polypeptide beverage and preparation method thereof

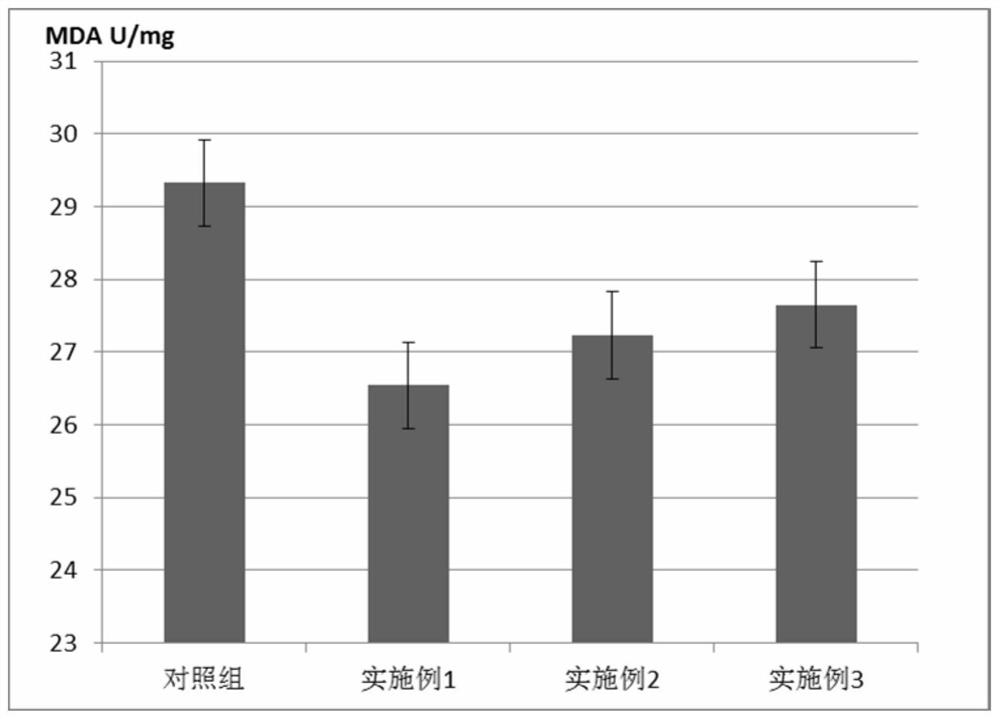

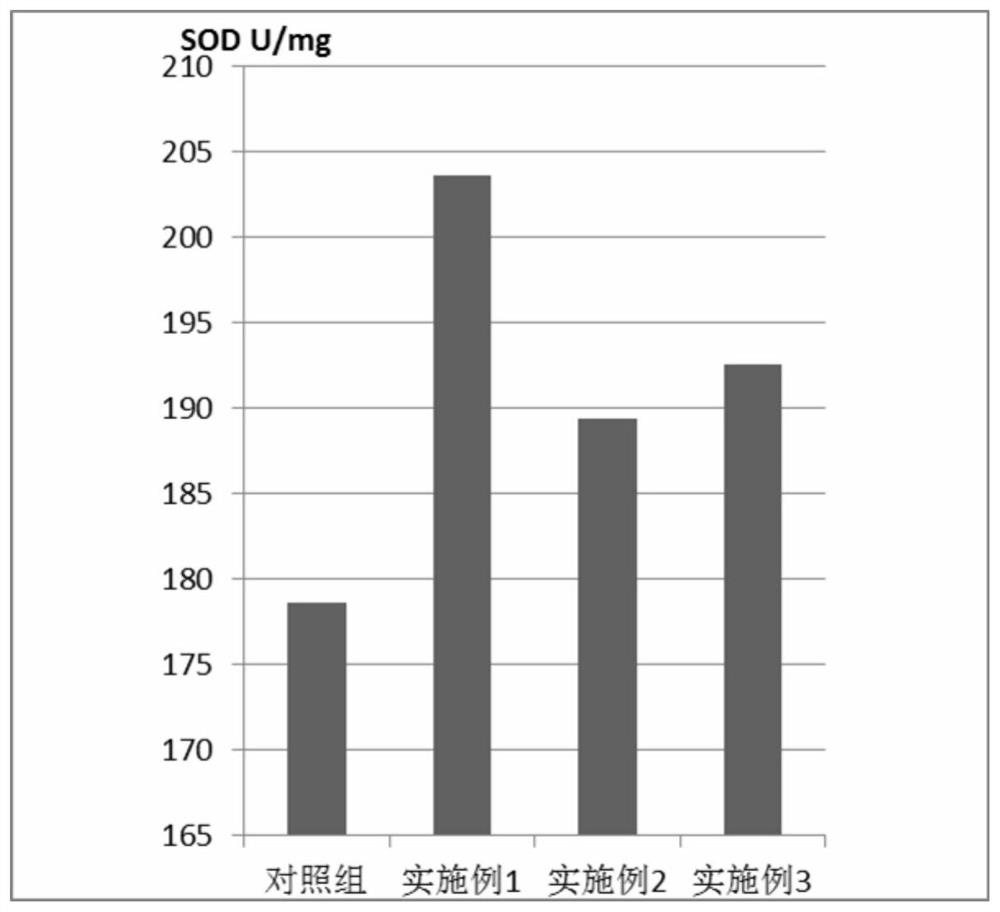

ActiveCN112998168AIncrease SOD activityGood flexibilityNatural extract food ingredientsFood ingredient functionsBiotechnologyFruit juice

The invention relates to the field of preparation of health-care drinks, and discloses a hyaluronic acid composite polypeptide drink and a preparation method thereof. The hyaluronic acid composite polypeptide beverage comprises the following components in percentage by weight: 0.01%-0.05% of fish collagen peptide, 5%-10% of litchi concentrated juice, 5%-15% of high fructose corn syrup, 0.1%-0.2% of a plant extract, 0.1%-0.3% of fruit juice powder, 0.01%-0.05% of olive powder, 0.01%-0.05% of inulin and the balance of a liquid solvent. The liquid solvent is a mixed solution of sodium hyaluronate and chitosan. The liquid solvent contains the following components in percentage by weight: 0.2%-0.5% of sodium hyaluronate and 0.1%-1.0% of chitosan. The beverage disclosed by the invention can achieve the effects of supplementing individual nutrition, improving skin moisture and delaying skin aging.

Owner:绿优品(福建)健康科技研发中心有限公司

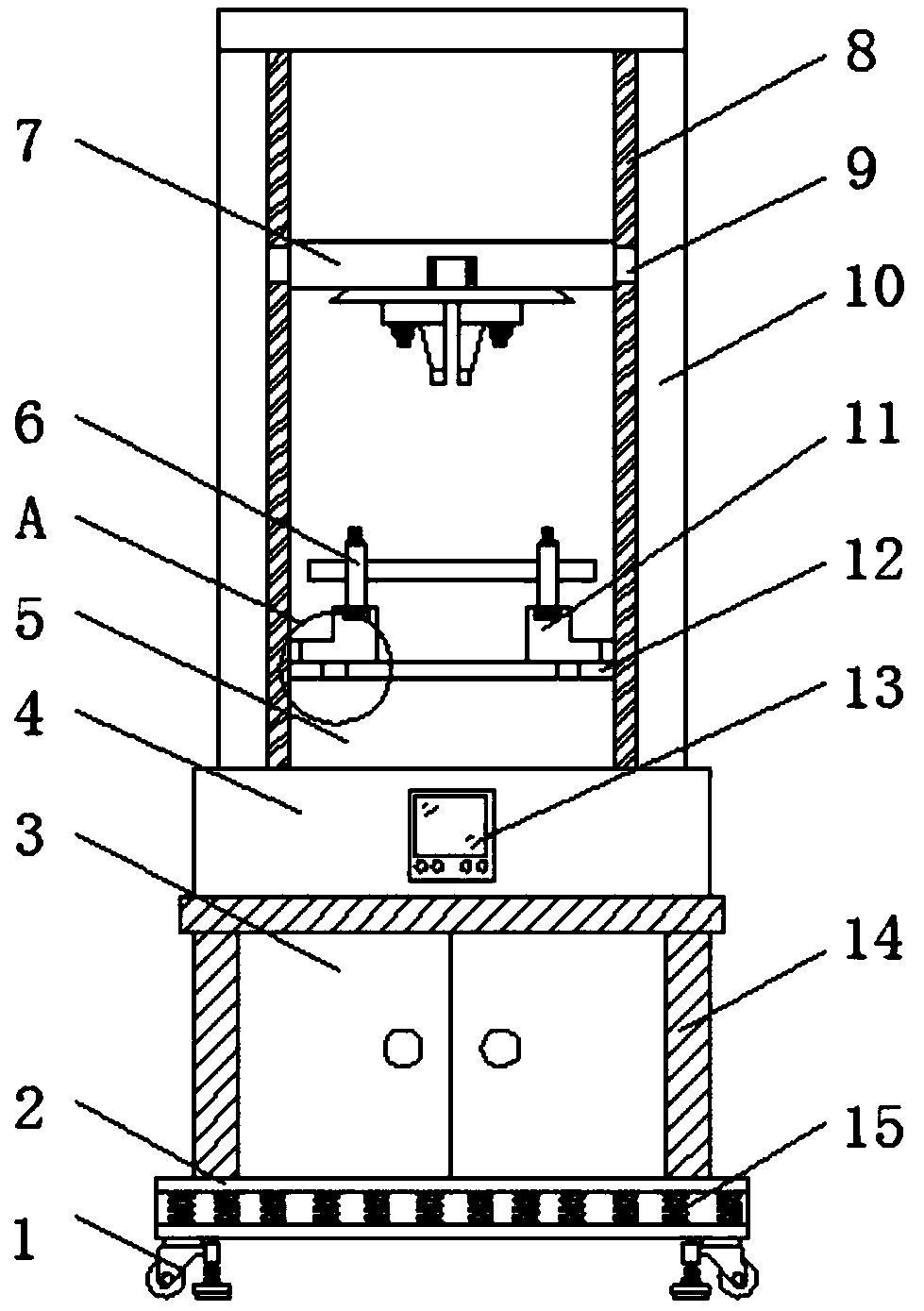

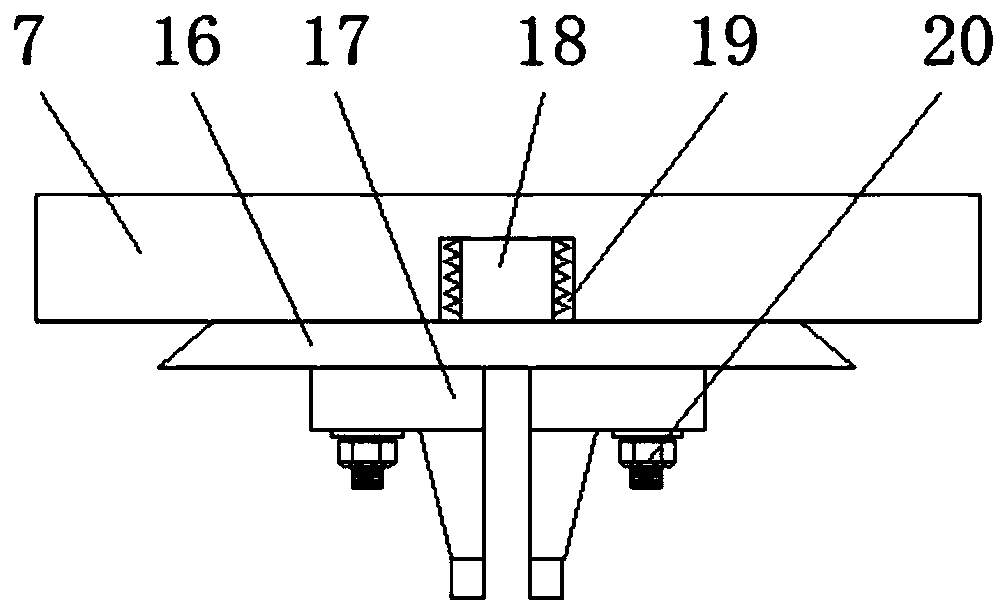

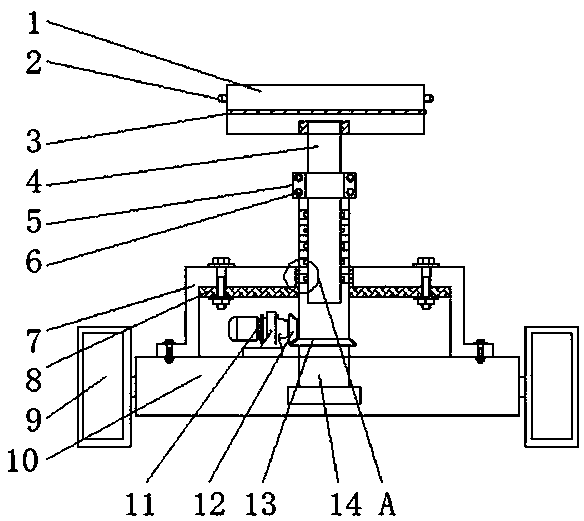

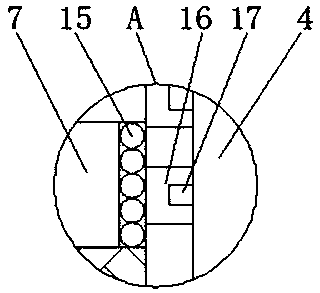

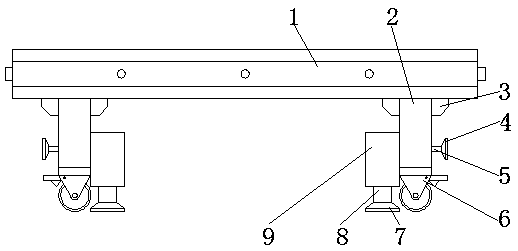

Housing construction steel beam flexural strength testing machine

PendingCN109100240AEasy to fixImprove structural strengthMaterial strength using steady bending forcesFlexural strengthEngineering

The invention discloses a housing construction steel beam flexural strength testing machine which comprises a buffer base, a testing platform, test heads and reinforcing ribs. Universal wheels are arranged on all of four corners at the bottom of the buffer base, an operation station is fixed at the central position at the top of the buffer base by a supporting frame, and a storage cabinet is fixedat the central position of the supporting frame; a control panel is arranged at one side of the operation station, and supporting pillars are arranged at both ends of the top of the operation station; the testing platform is arranged at the central position at the top of the operation station; a testing device is fixed at the bottom end of a lifting seat, and the test heads are fixed at both endsof the bottom of the testing device by first fixed bolts; and carbon steel reinforcing layers are arranged inside the side walls of the test heads. By mounting the buffer base, the universal wheels and damping springs, the housing construction steel beam flexural strength testing machine is convenient to move, meanwhile, stability is ensured in the moving and using process, damping and shockproofeffects are taken, and shaking is avoided.

Owner:GUIZHOU UNIV

Chinese torreya essential oil soap

InactiveCN106883959AMild ingredientsRich and fine foamSurface-active detergent compositionsSurface-active non-soap compounds and soap mixture detergentsChemistryWool

The invention discloses Chinese torreya essential oil soap. The soap contains the following components in percentage by weight: 7 to 10% of water, 13 to 18% of sorbitol, 8 to 10% of propylene glycol, 15 to 18% of stearic acid, 8 to 12% of lauric acid, 3 to 6% of glycerinum, 6 to 8% of AES, 20 to 25% of saccharose, 0.6 to 1.5% of wool fat, 0.2 to 0.5% of sodium hydroxide, 1 to 3% of alkyl glycoside, 1 to 2% of potassium cocoyl glycinate, 1 to 2% of Chinese torreya essential oil, 0.4 to 0.7% of daily chemical fragrance compound and 0.3 to 0.6% of a Curasao Aloe extract. The Chinese torreya essential oil soap can solve the detects in the prior art, and is a good skin care product capable of moistening skin, delaying senescence and promoting cell metabolism when used at home or during travel.

Owner:浙江如美日化有限公司

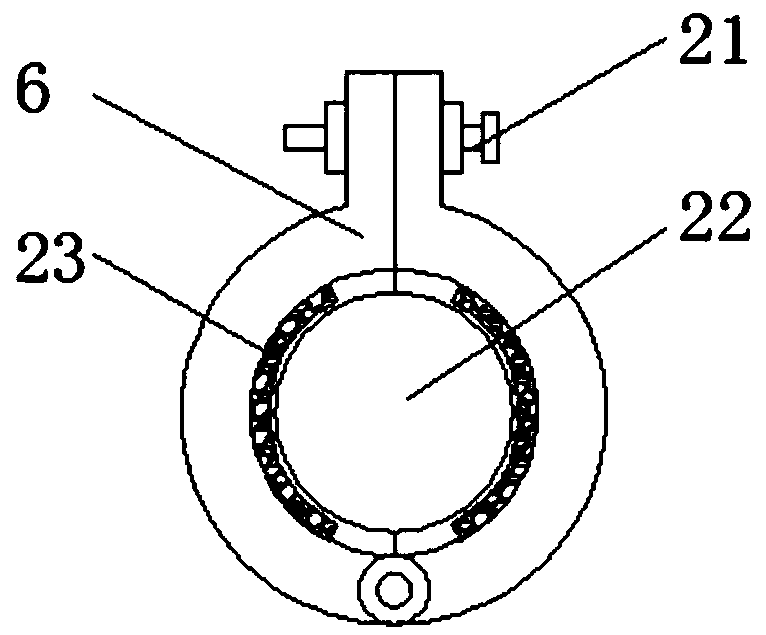

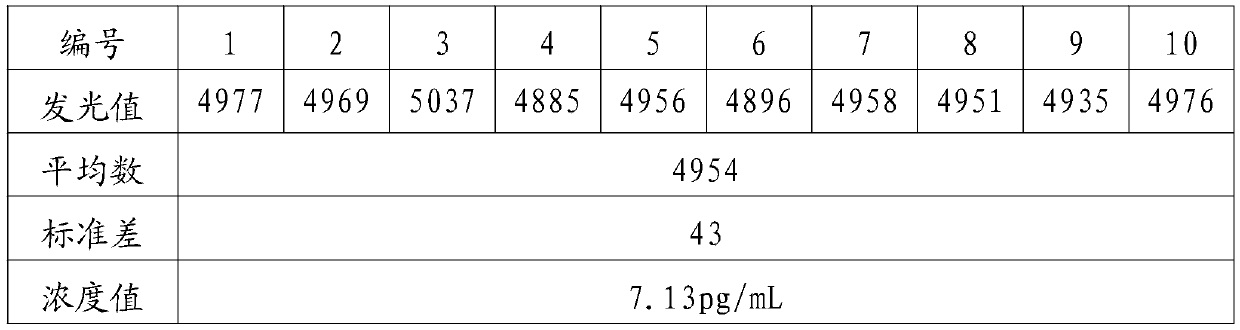

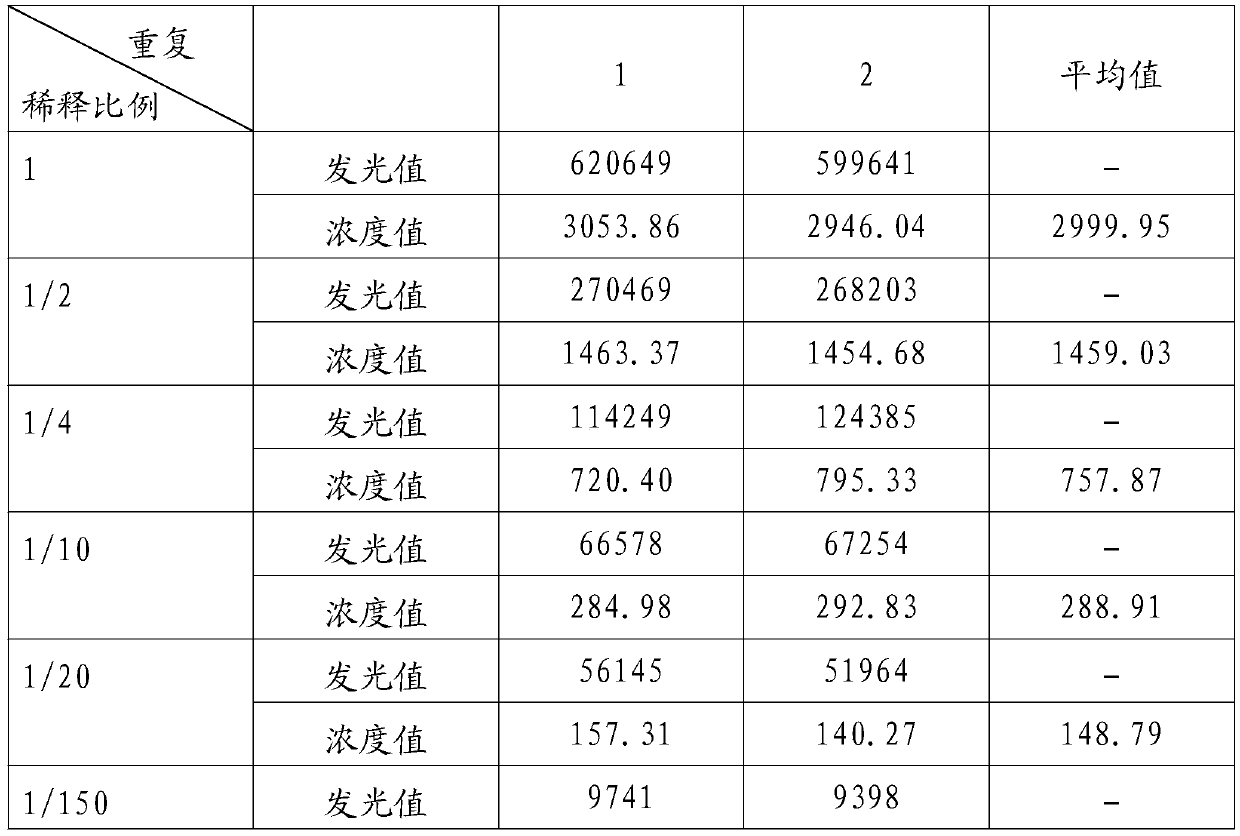

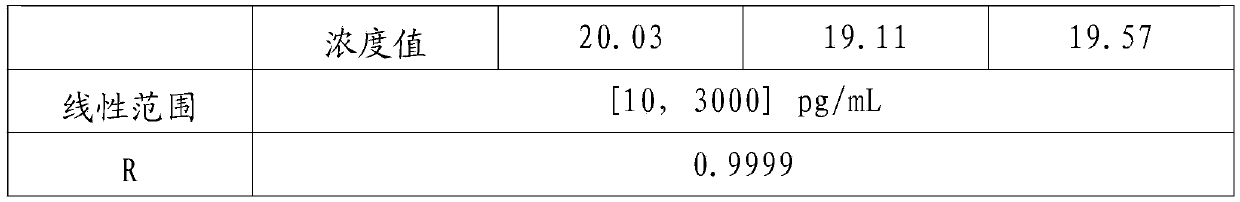

N-terminal B-type brain natriuretic peptide precursor magnetic particle chemiluminiscence detection kit

PendingCN110568198AIncrease the coating rateHigh sensitivityChemiluminescene/bioluminescenceBiological testingMicrosphereEnzyme

The invention belongs to the field of biotechnology detection and relates to an N-terminal B-type brain natriuretic peptide precursor magnetic particle chemiluminiscence detection kit. The kit comprises an NT-proBNP antibody-coated magnetic microsphere suspension, an NT-proBNP enzyme conjugate, an NT-proBNP reference substance, an NT-proBNP quality control substance, an NT-proBNP concentrated washing solution, a substrate solution A and a substrate solution B. In practical application, the kit has the advantages of high sensitivity, high accuracy, low intra-batch and inter-batch difference, wide linear range, and greatly improved e detection performance.

Owner:山东康华生物医疗科技股份有限公司

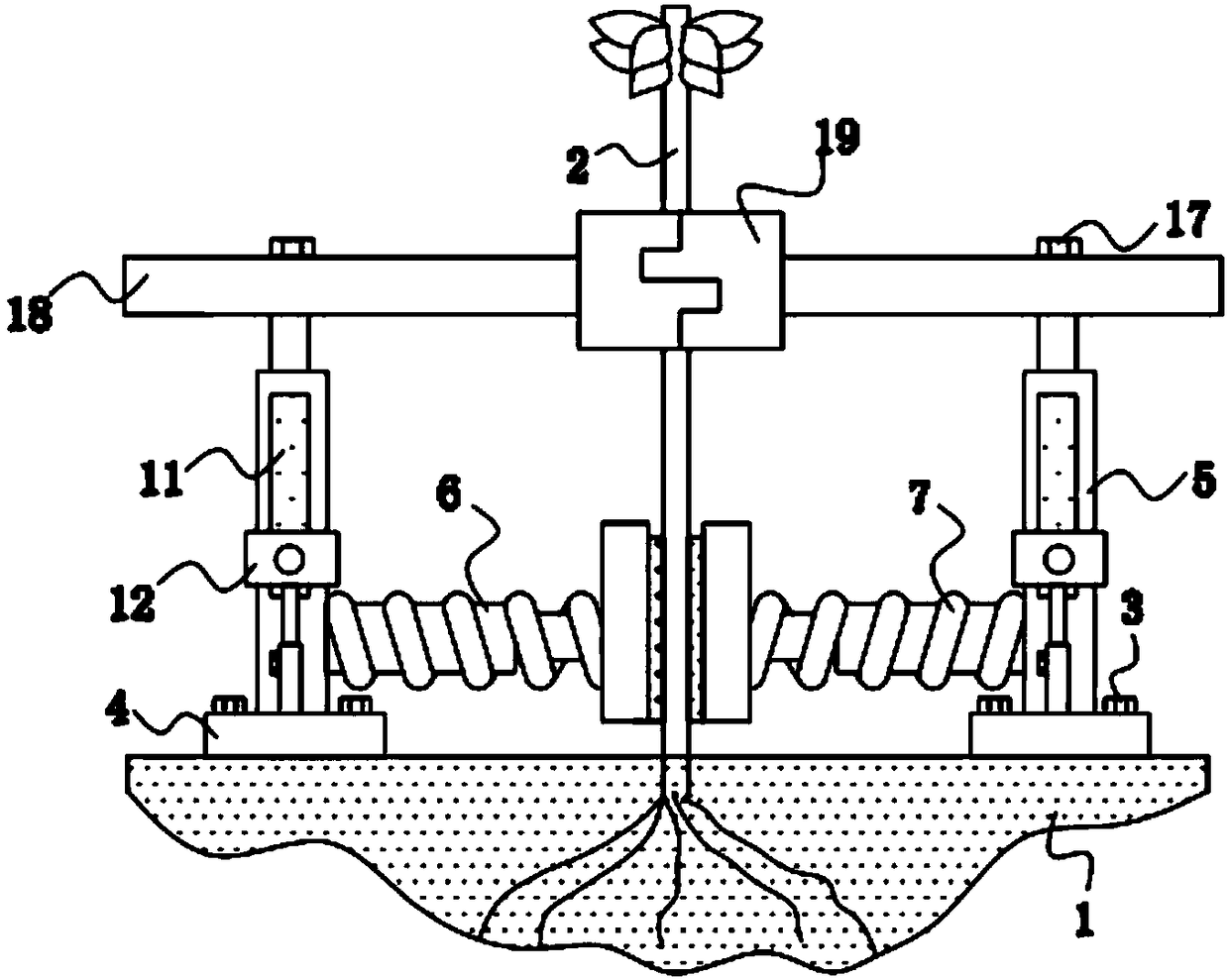

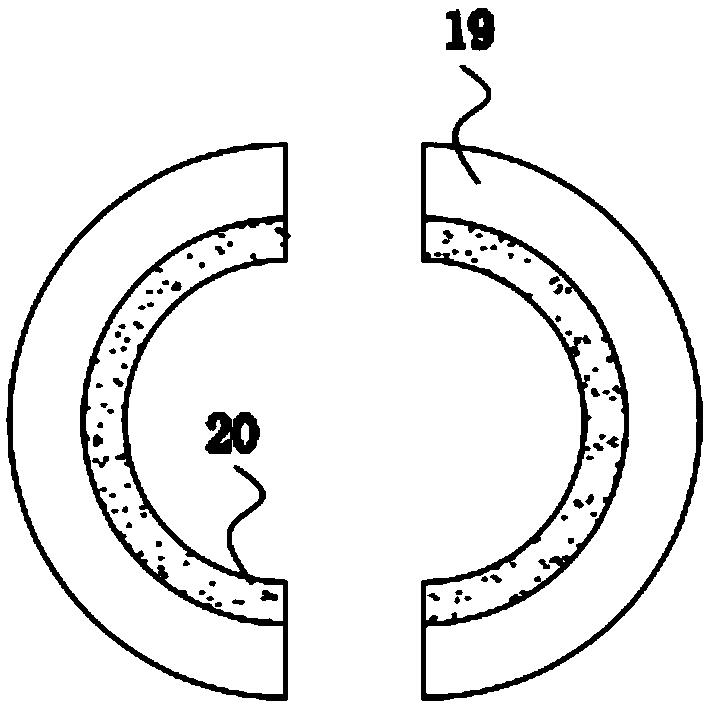

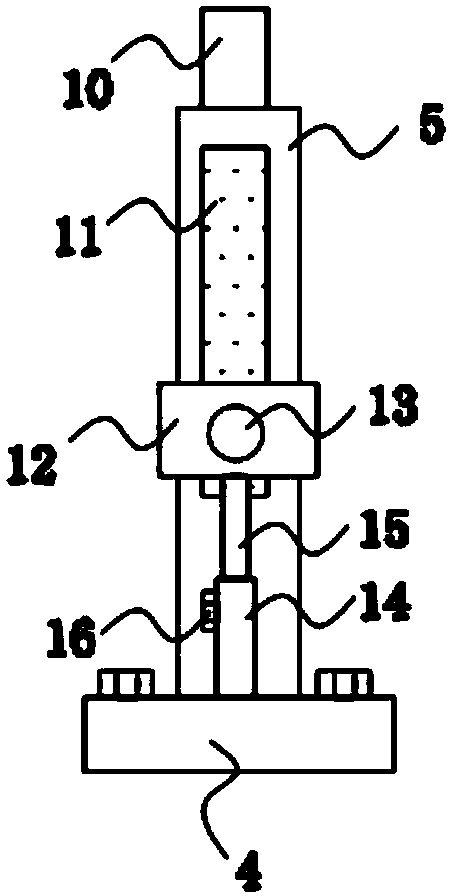

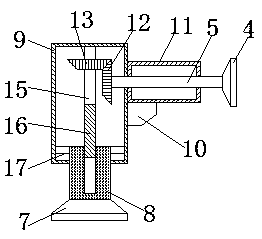

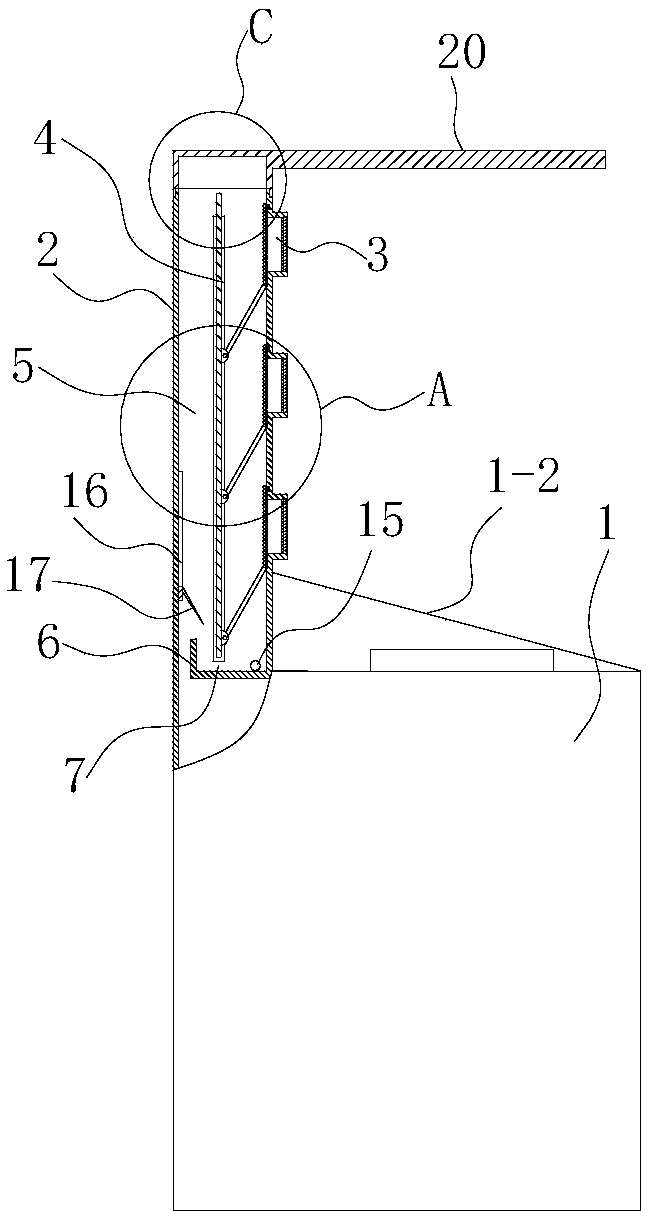

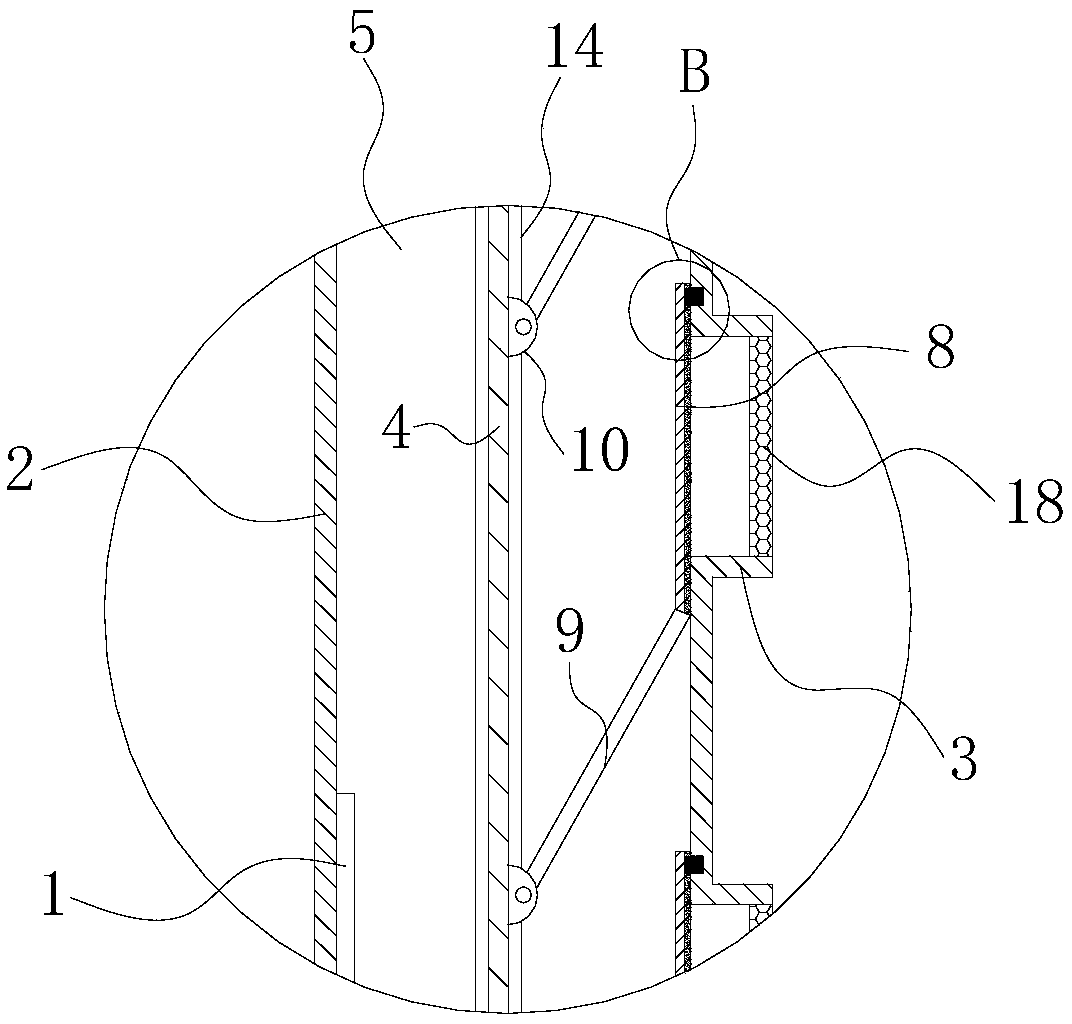

Convenient-to-adjust righting device for nursery stock planting

The invention discloses a convenient-to-adjust righting device for nursery stock planting. A soil layer and a nursery stock trunk planted on the soil layer are involved; fixed bases are connected to the left and right sides of the upper portions of the soil layer through anchor rods, guide sleeves are connected to the upper ends of the fixed bases, retractable rods are connected to the sides, close to each other, of the two guide sleeves, the outer walls of the retractable rods are sleeved with rubber springs, and abutting plates are connected to the end portions of the retractable rods. According to the convenient-to-adjust righting device for nursery stock planting, the anchor rods and the fixed bases are connected with the soil layer by means of external force (a hammer can be preferably selected for use), the stability of the fixed bases can be improved accordingly, and it is ensured that the subsequent work is smoothly carried out; the retractable rods are connected to the sides,close to each other, of the two guide sleeves, the outer walls of the retractable rods are sleeved with the rubber springs, the abutting plates are connected to the end portions of the retractable rods, a polyurethane cushion closely attached to the bottom of the outer wall of the nursery stock trunk adheres to the inner walls of the abutting plates through an adhesive, and therefore the nursery stock trunk can be abutted against from the bottom of the outer wall of the nursery stock trunk.

Owner:淮北达驰电气科技有限公司

Tin coating passivator

InactiveCN104451646AAvoid corrosionImprove stabilityMetallic material coating processesPhytic acidTert butyl

The invention discloses a tin coating passivator which comprises the following raw materials in parts by weight: 50-70 parts of trisodium phosphate, 2-5 parts of sodium tartrate, 2-5 parts of sodium molybdate, 2-5 parts of sodium citrate, 5-10 parts of cobaltous sulfate, 15-25 parts of phytic acid, 5-10 parts of oxalic acid, 10-20 parts of octadecylamine, 2-5 parts of nonylphenol polyoxyethylene ether, 4-7 parts of Tween-20, 5-10 parts of triethanolamine, 2-6 parts of 2,6-di-tert-butyl-4-methylphenol and 1-3 parts of N,N'-bis(1-methylpropyl)-1,4-phenylenediamine. The tin coating passivator provided by the invention does not contain high-valence chromium, does not cause environmental pollution or generate harm to a human body and has the advantages of corrosion resistance and oxidation resistance.

Owner:TIANCHANG FEILONG BRAND STEEL GRID

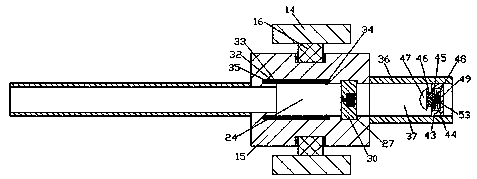

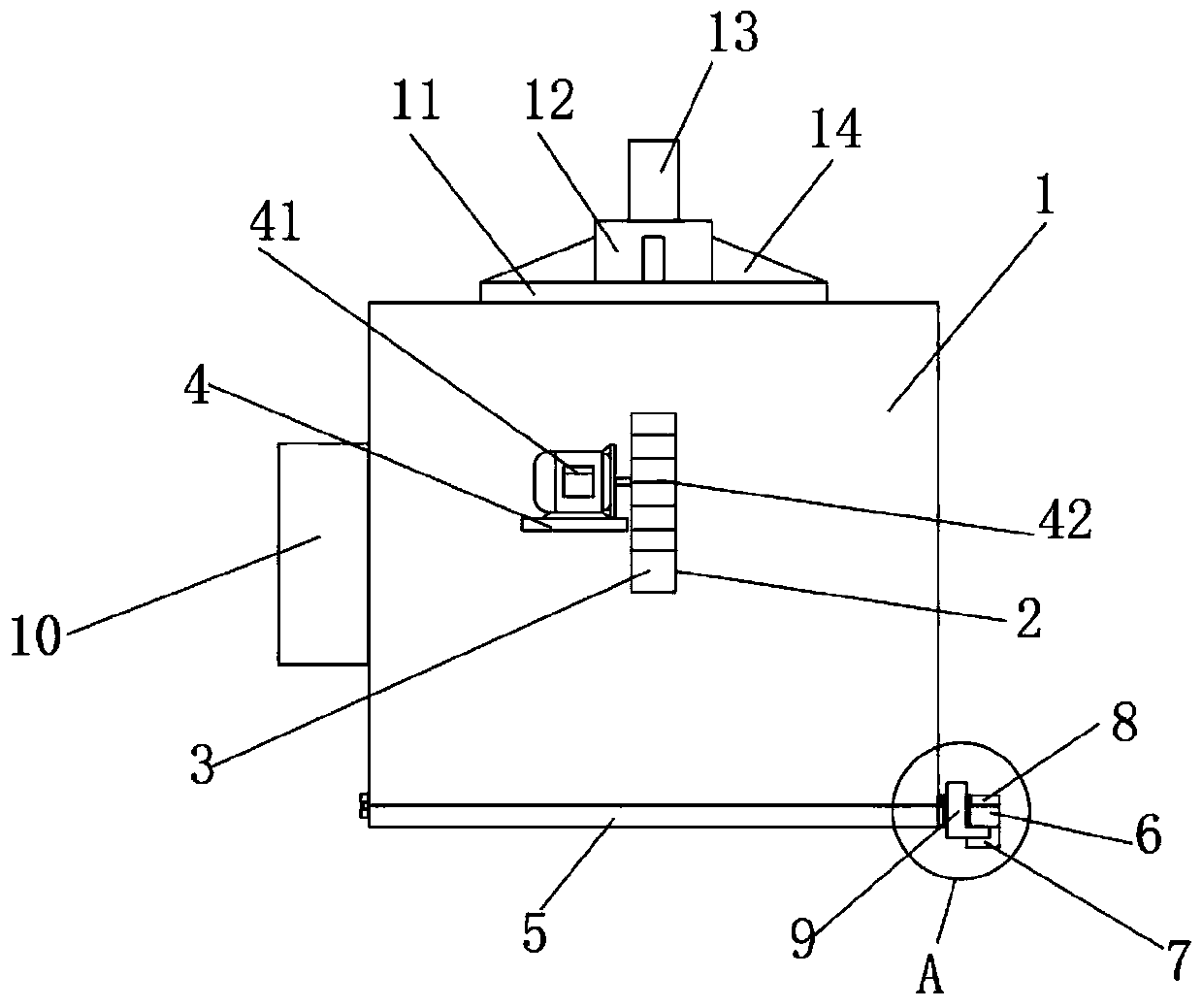

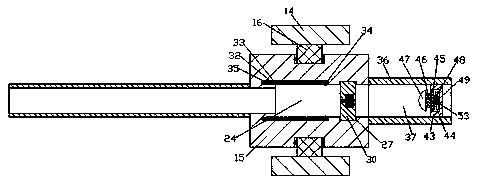

Method of using projectile launching device

The invention discloses a method of using a projectile launching device, the method includes a fixed base, the front and rear sides of a connecting block are symmetrically provided with a track movingwheel, the left side inside the fixed base is provided with a driving space, the right side in a transmission space is provided with an upwardly extending rotating shaft, the upper end of the rotating shaft passes through the upper end wall of the transmission space and is fixedly connected with a support block. Between two support rods on the support block, a fixed shell is arranged, a gun borewith an opening to the right is arranged inside the fixed shell, a gun barrel is arranged at the left end wall of the gun bore, and an ignition device extending to the left is arranged in a seal plate. In work, the manpower can be reduced through an automatic loading device, the hand clamping phenomenon caused by manual loading can be avoided, the safety of the personnel can be ensured, and the used projectile case can be quickly discharged through a shell withdrawal block, thereby saving time and increasing efficiency.

Owner:宁波市鄞州区丰余工业产品设计有限公司

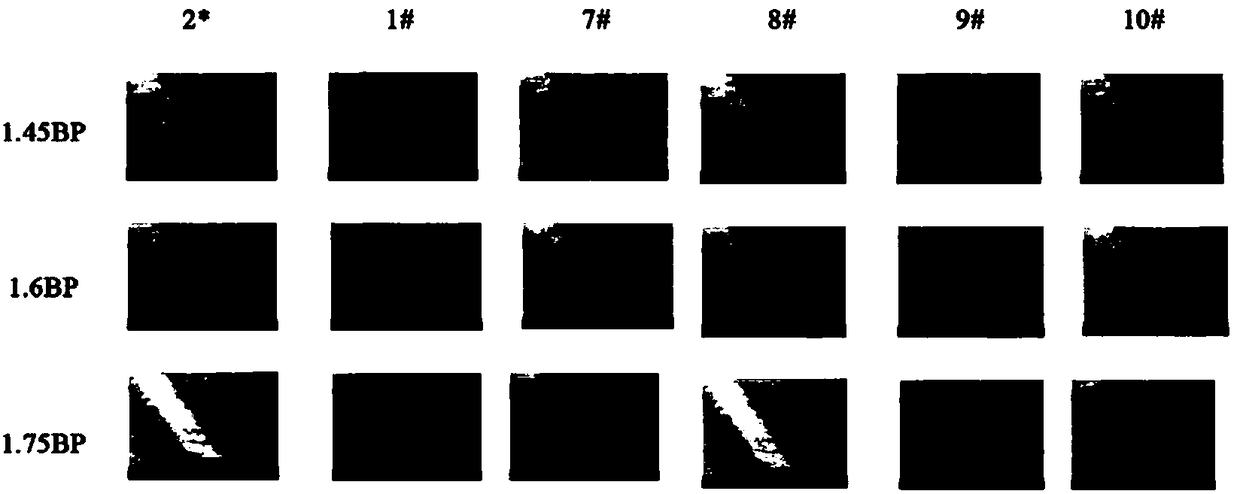

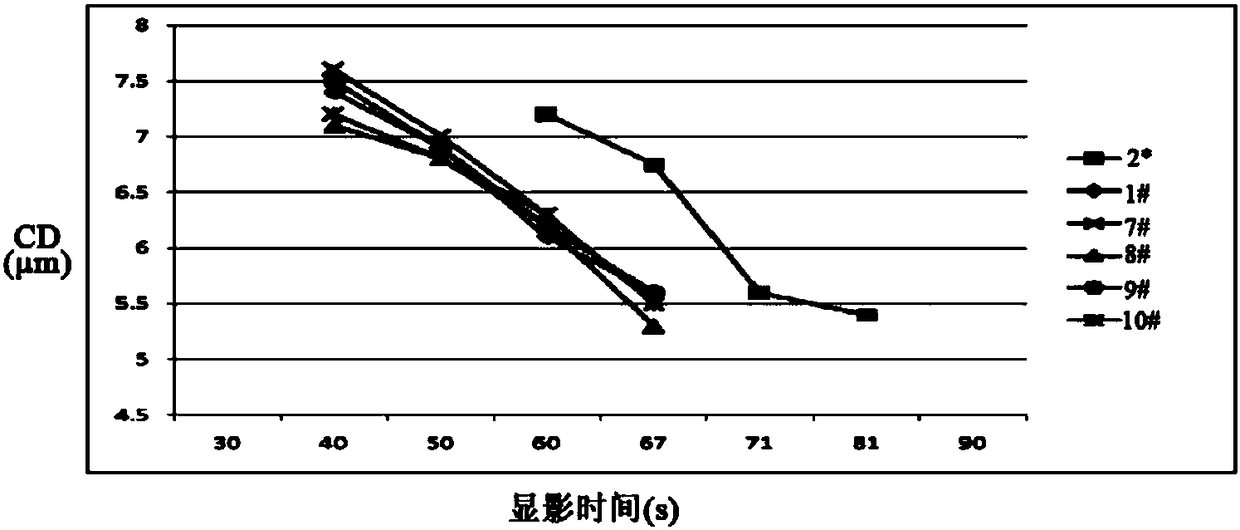

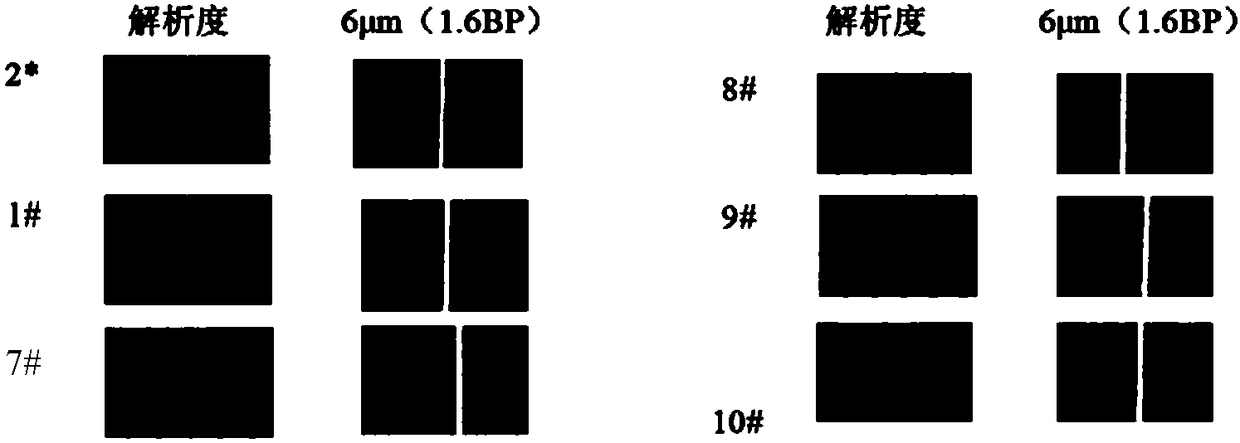

Photoresist resin solution, preparation method and preservation method thereof

InactiveCN109407465AStability playsGood storage stabilityPhotosensitive materials for photomechanical apparatusAntioxidantSolvent

The invention provides a photoresist resin solution, a preparation method and a preservation method thereof. The photoresist resin solution comprises a solvent and photoresist resin, and the photoresist resin solution further comprises a stabilizer, wherein the stabilizer is an antioxidant or a polymerization inhibitor. A stabilizing effect is achieved by applying the antioxidant or the polymerization inhibitor as the stabilizer to the photoresist resin solution, so that the preservation stability of the photoresist solution is improved. At the same time, the presence of the stabilizer does not adversely affect the etching accuracy of the subsequent photoresist resin used as a photoresist, and therefore, the stabilizer does not need to be separated during the application of the photoresistresin, namely, no unnecessary trouble is caused to the application of the photoresist resin.

Owner:CHANGZHOU TRONLY NEW ELECTRONICS MATERIALS +1

Spray irrigation device for sugar orange planting

PendingCN108990771AAffect normal growthAvoid shakingClimate change adaptationWatering devicesGear wheelSurface mounting

The invention discloses a spray irrigation device for sugar orange planting. The device includes a rotating disk, a main gear and a fixed pipe, wherein a nozzle is mounted on a surface of the rotatingdisk, the rotating disk is internally provided with a sieve, a moving pipe is connected below the rotating disk, a fixing plate is mounted at a front end of the moving pipe, bolts are fixed on both sides of the fixing plate, both sides of the moving pipe are provided with convex blocks, a groove is fixed at the inner side of the fixed pipe, the fixed pipe is located below the fixing plate, fixingbrackets are disposed on both sides of the fixed pipe, the insides of the fixing brackets are equipped with balls, a heat sink is fixed below the balls, a motor is arranged below the heat sink, and aslave gear is connected with the right side of the main gear. Compared with a common irrigation device in the prior art, the device is advantaged in that the position and the height can be adjusted at any time, uniform irrigation is performed, moreover, the inside of the device is less prone to blockage, and the device is easy to disassemble and clean.

Owner:榕江县富榕生态农业有限责任公司

High-stability solvent type plastic paint

InactiveCN106928816AGood liquidityHigh film strengthFireproof paintsAnti-corrosive paintsSolventChemistry

The invention discloses high-stability solvent type plastic paint. The high-stability solvent type plastic paint is prepared from, by mass, 10-20% of acrylic resin, 55-60% of phenolic epoxy acrylic resin, 20-30% of organic solvent, 2-5% of polyurethane thickener, 2-5% of organobentonite, 5-10% of dispersant, 10-15% of stabilizer and 10-15% of vinisol cooh; the stabilizer comprises diglycidyl ether, calcium ricinoleate, barium oleate, phenyl triethyl phosphate, 2-hydroxy-4-methoxy-diphenyl ketone and a color retaining agent. A series of other additives high in stability are added and combined with the stabilizer mainly having the stabilizing effect to comprehensively improve the stability of the paint from the respects of light resistance, high temperature resistance, chemical corrosion resistance, sedimentary stability and anti-volatilization performance, it is ensured that the paint is high in flowability and adhesion property, and a film formed by the paint is high in strength, uniform in color and long in service life.

Owner:德阳森华新材料科技有限公司

Building indoor decoration plate with photosensitive layer

Owner:XINXIANG UNIV

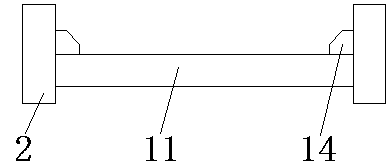

Conveyor for agricultural product

InactiveCN109204403AImprove stabilityStability playsHand carts with multiple axesHand cart accessoriesAgricultural engineeringThreaded rod

A conveyor for agricultural products includes a conveyor; both sides of the bottom of the conveyor are provided with reinforcing pipes, the front sides and the rear sides of the reinforcing pipes arefixedly connected with supporting legs, the top of each supporting leg is fixedly connected with the conveyor, the bottoms of the supporting legs are fixedly connected with universal wheels, the opposite sides of the two reinforcing pipes are fixedly connected with a shell, and the top of the shell inner cavity is movably connected with a first rotating rod. Through the cooperation of the conveyor, the support legs, the first reinforcement plate, a turntable, the second rotating lever, the universal wheels, the supporting plate, a threaded sleeve, a shell, a second reinforcing plate, a reinforcing pipe, a second bevel gear, a first bevel gear, a third reinforcing plate, a first rotating rod, a threaded rod and a positioning plate, the device solves the problem of poor stability of some existing conveying equipment for agricultural products. The conveyor for agricultural products has the advantages of good stability and is worth popularizing.

Owner:甘肃尚珍农产品科技发展有限公司

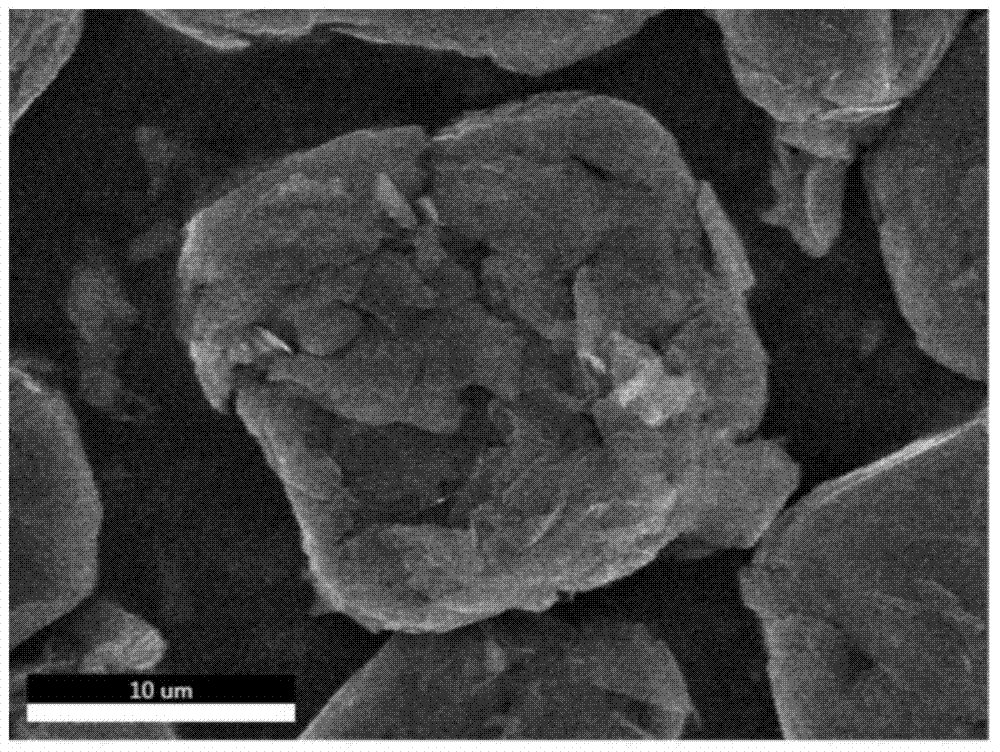

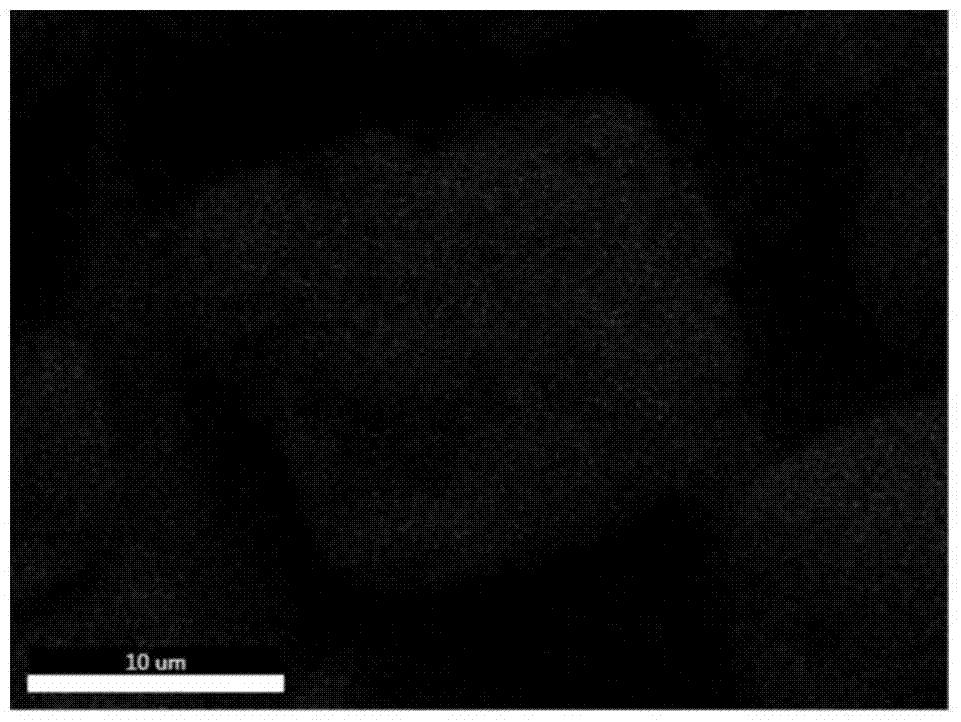

A kind of modification method of lithium ion battery graphite negative electrode material

ActiveCN105514394BImprove the first Coulombic efficiencyReduce irreversible capacityCell electrodesSecondary cellsCyclic processGraphite

The invention relates to a modification method for a lithium-ion battery graphite cathode material. The method comprises the following steps that a, graphite and a maleate water solution are mixed to obtain a mixed solution; b, the mixed solution is heated to be dry on the constant-stirring condition. Due to the existence of a wrapping layer, the effect of an artificial SEI membrane is achieved, the reversible capacity of the material is effectively lowered, and the first-time coulombic efficiency of a lithium-ion battery is improved. In addition, the wrapping layer can be better attached to the surface of the graphite, cointercalation of solvation lithium ions can be resisted to a certain extent, the effect of the SEI membrane is achieved, and the stability of a graphite structure is protected; in addition, lithium consumption can be resisted in the electrode cyclic process, and therefore long-term cyclic stability of the graphite material is better protected.

Owner:JIANGSU DAOYING TECH CO LTD

Improved integrated stove

InactiveCN109442509AGuaranteed stabilityEasy to cleanDomestic stoves or rangesLighting and heating apparatusEngineeringSmoke

The invention relates to the technical field of integrated stoves, and aims to provide an improved integrated stove which is convenient to use. According to the adopted technical scheme, the improvedintegrated stove comprises a cabinet body and a hollow smoke exhaust baffle arranged on the rear side of the top of the cabinet body, two combustors are symmetrically arranged on the left side and theright side of the top surface of the cabinet body, a partition block extending in the front-and-back direction of the cabinet body is arranged in the center of the top surface of the cabinet body, and a plurality of placing holes are formed in the top of the partition block. According to the improved integrated stove, the placing holes in the partition block can be used for allowing various seasonings such as an oil can, a sauce bottle, a cooking wine bottle and a seasoning pot to be placed, so that taking and using by an operator is very convenient, meanwhile, by placing the various bottlesand pots in the placing holes, the placement stability can be ensured; and meanwhile, the partition block plays a certain protection role so that the bottles and the pots can be effectively protected.

Owner:王忠灿

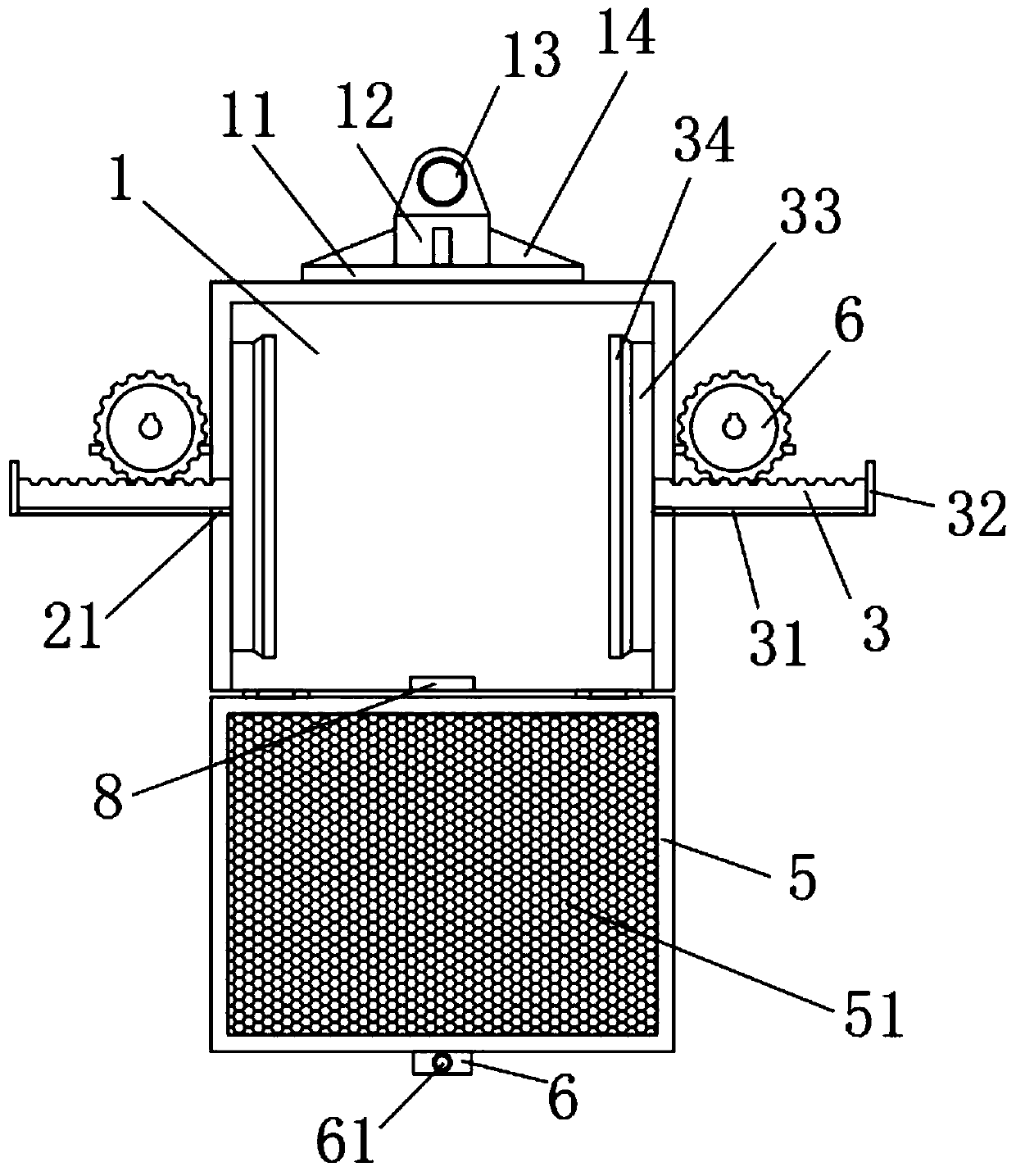

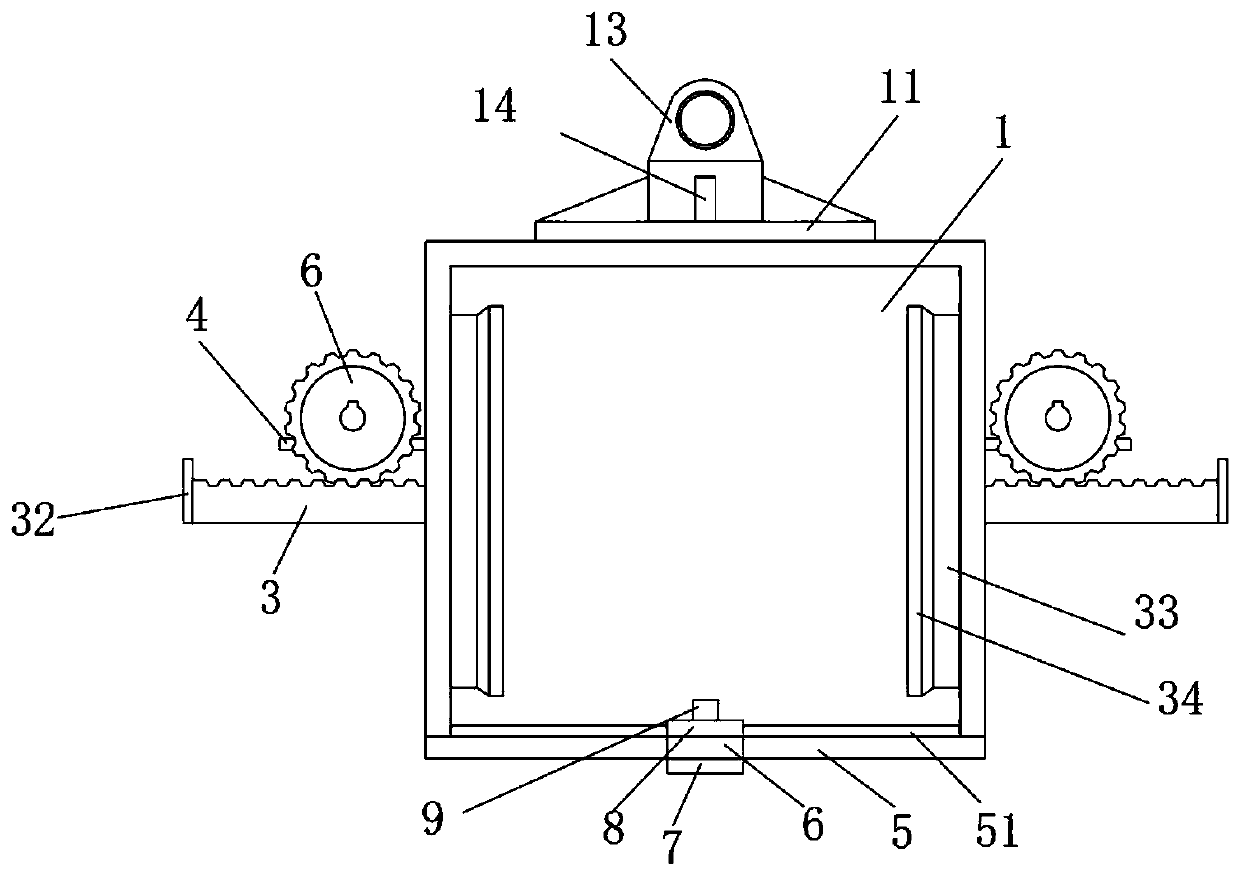

Concrete aerated block finished product kettle-out lifting tool

The invention relates to the technical field of concrete machining, and particularly discloses a concrete aerated block finished product kettle-out lifting tool. The concrete aerated block finished product kettle-out lifting tool comprises a transport box. The transport box is of a bottom opening structure, the front face of the transport box is of a transparent structure, sliding grooves are formed in the centers of the left side and the right side of the transport box, racks are slidingly connected into the sliding grooves, the positions of the left side, the right side and the top of the back face of the center of the transport box are fixedly connected with supporting plates, the centers of the tops of the mounting plates are fixedly connected with drive motors, gears are fixedly connected to the output ends of the front faces of the drive motors, and the sides, close to the inner wall of the transport box, of the racks are fixedly connected with clamping plates. An overturning cover is hinged to the back face of the bottom of the transport box, the front face of the overturning cover is fixedly connected with a first lock block, and the center of the bottom of the front face of the transport box is fixedly connected with a second lock block. The lifting tool replaces a traditional bolt twisting working manner to clamp concrete aerated blocks, and meanwhile the problem thatthe concrete aerated blocks fall in the transporting process is effectively avoided.

Owner:山东海靓节能科技股份有限公司

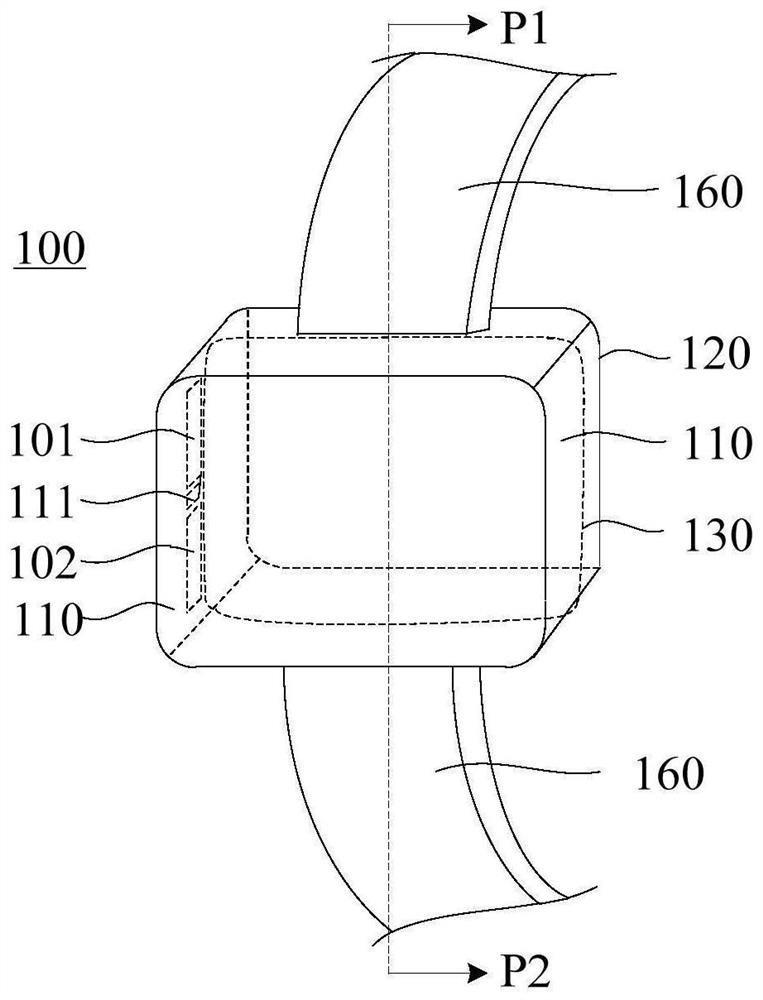

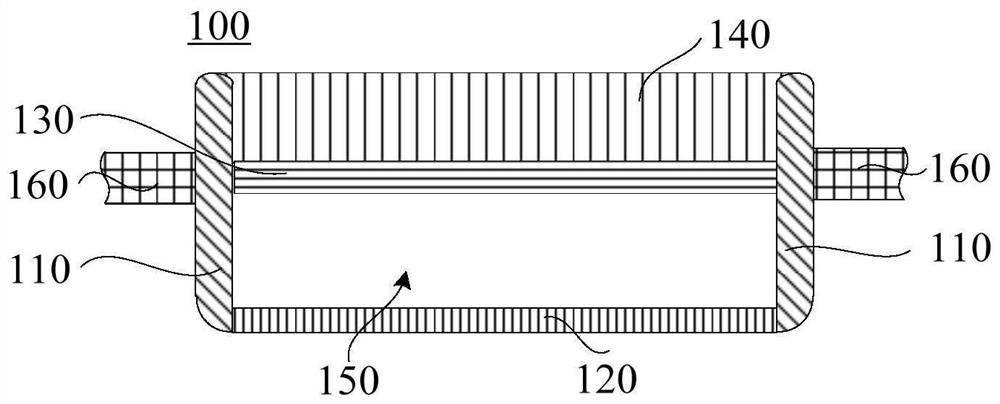

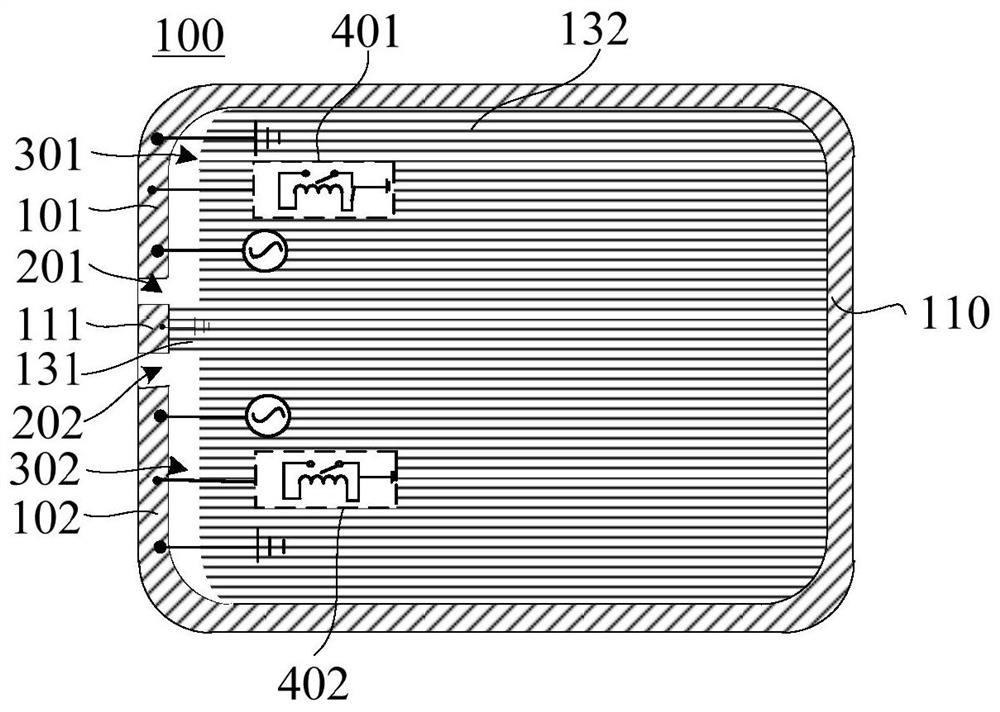

Wearable electronic equipment

ActiveCN112886210AImprove isolationImprove performanceAntenna adaptation in movable bodiesRadiating elements structural formsEngineeringElectrical and Electronics engineering

Owner:REALME CHONGQING MOBILE TELECOMM CORP LTD

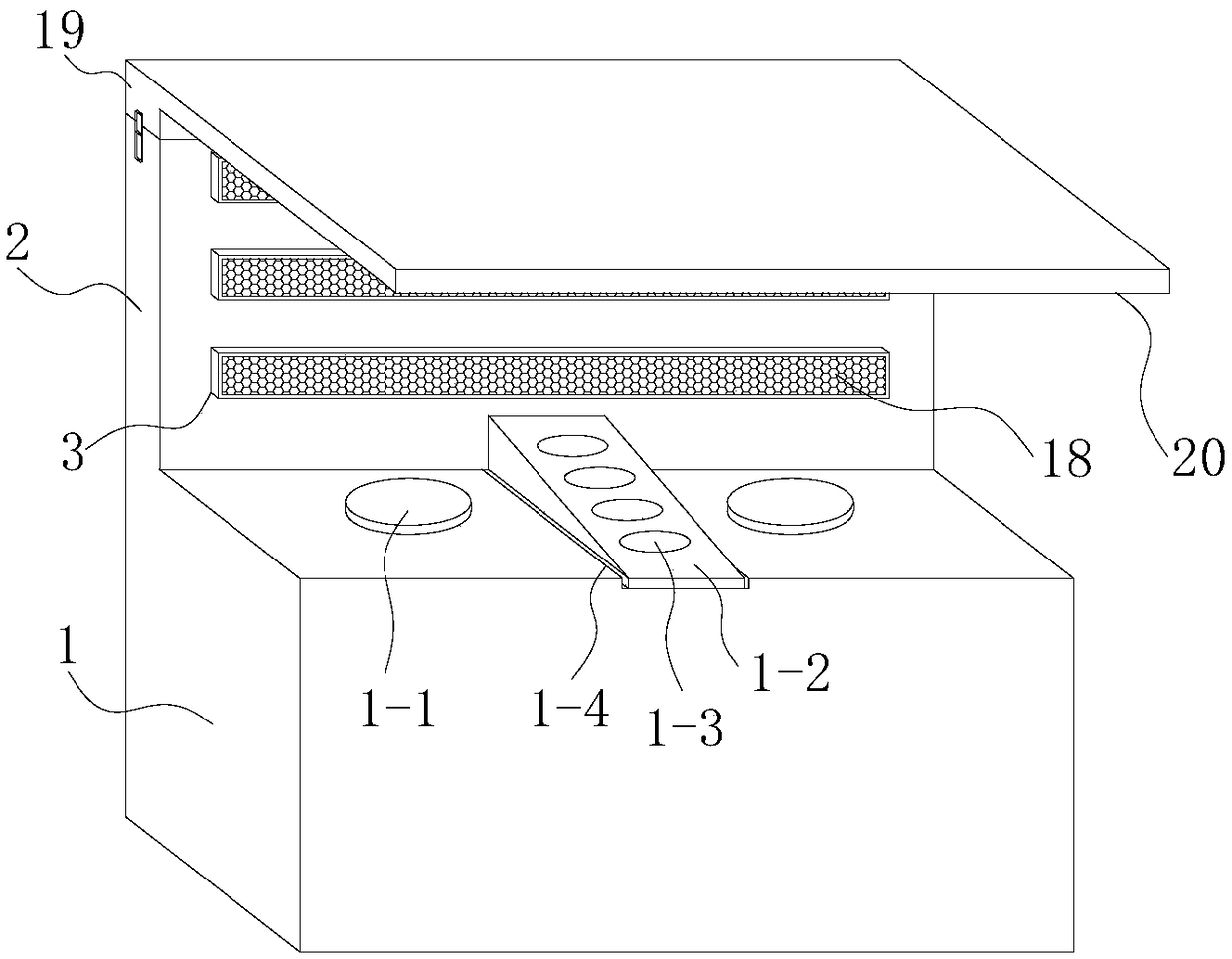

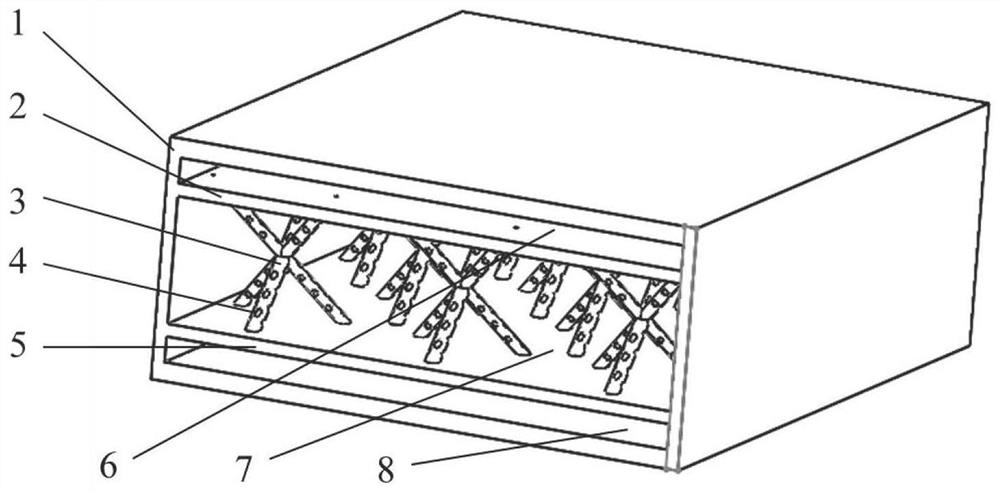

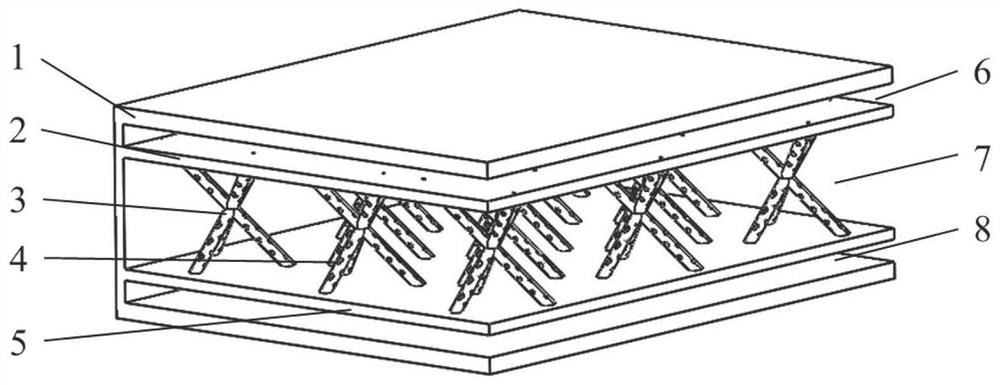

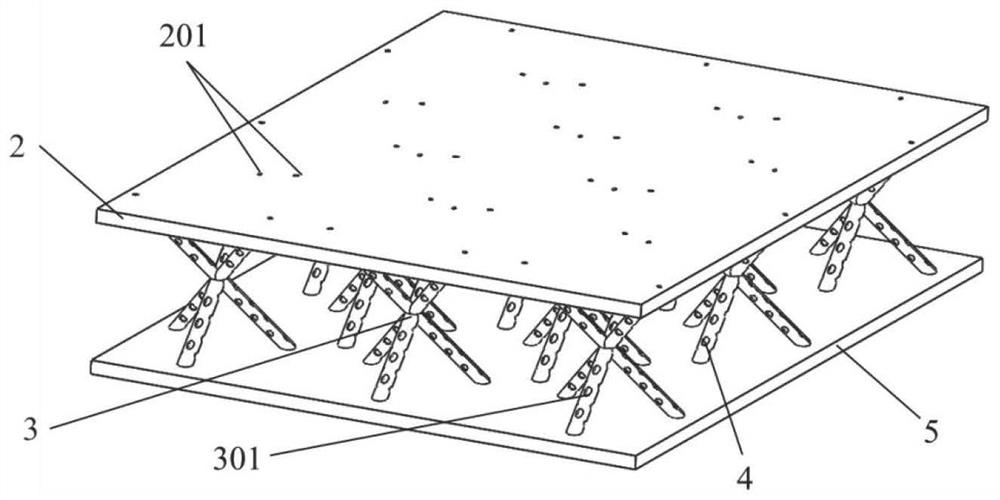

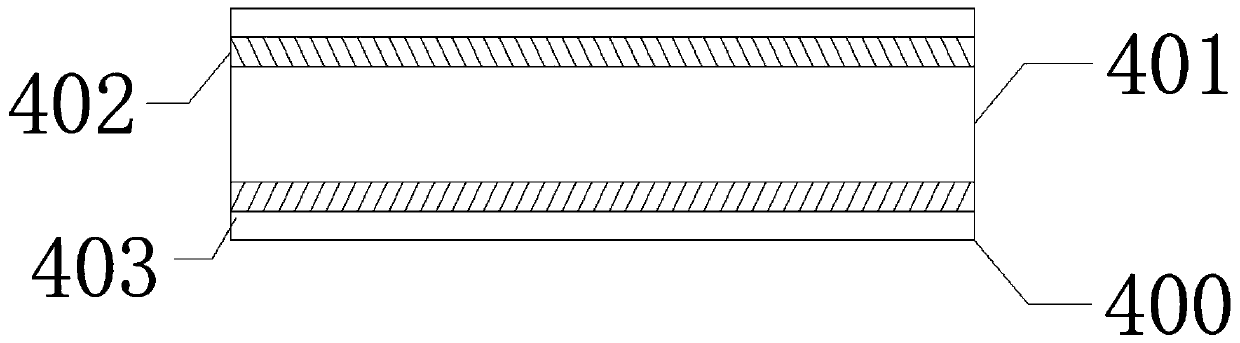

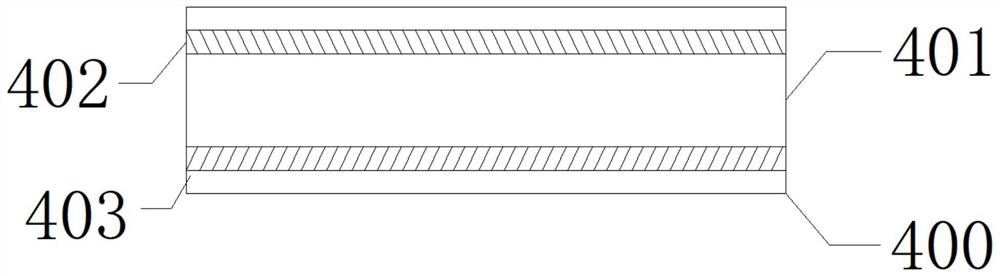

Miniature rapid cooling device based on porous water-drop-shaped Kagome structures

ActiveCN113701540AChange flow stateImprove mechanical propertiesIndirect heat exchangersHeat exchange apparatusHeat flowEngineering

A miniature rapid cooling device based on porous water-drop-shaped Kagome structures comprises a heat exchange box body structure; an upper baffle and a lower baffle are arranged in the heat exchange box body structure; an upper cooling cavity is formed between the heat exchange box body structure and the upper baffle; a lower cooling cavity is formed between the heat exchange box body structure and the lower baffle; a heat flow channel is formed between the upper baffle and the lower baffle; the porous hollow water-drop-shaped Kagome structures which are arranged in a staggered array mode are arranged in the heat flow channel; hollow cooling pipes of the same structure are arranged in the porous hollow water-drop-shaped Kagome structures; and the upper cooling cavity communicates with the lower cooling cavity through the hollow cooling pipes. The miniature rapid cooling device has good mechanical properties, is small in size, is convenient to prepare, and is detachable; and meanwhile, the arrangement mode of the water-drop-shaped Kagome structures can be adjusted or the quantity of lattice truss structures can be increased or decreased according to actual needs, and then uniform, rapid and efficient cooling is achieved.

Owner:XI AN JIAOTONG UNIV

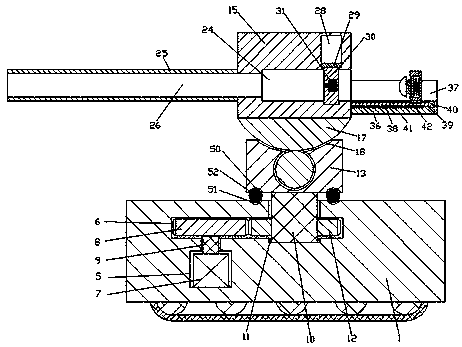

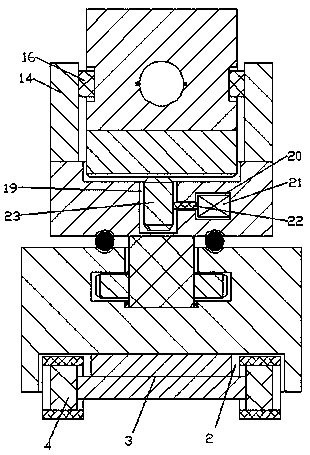

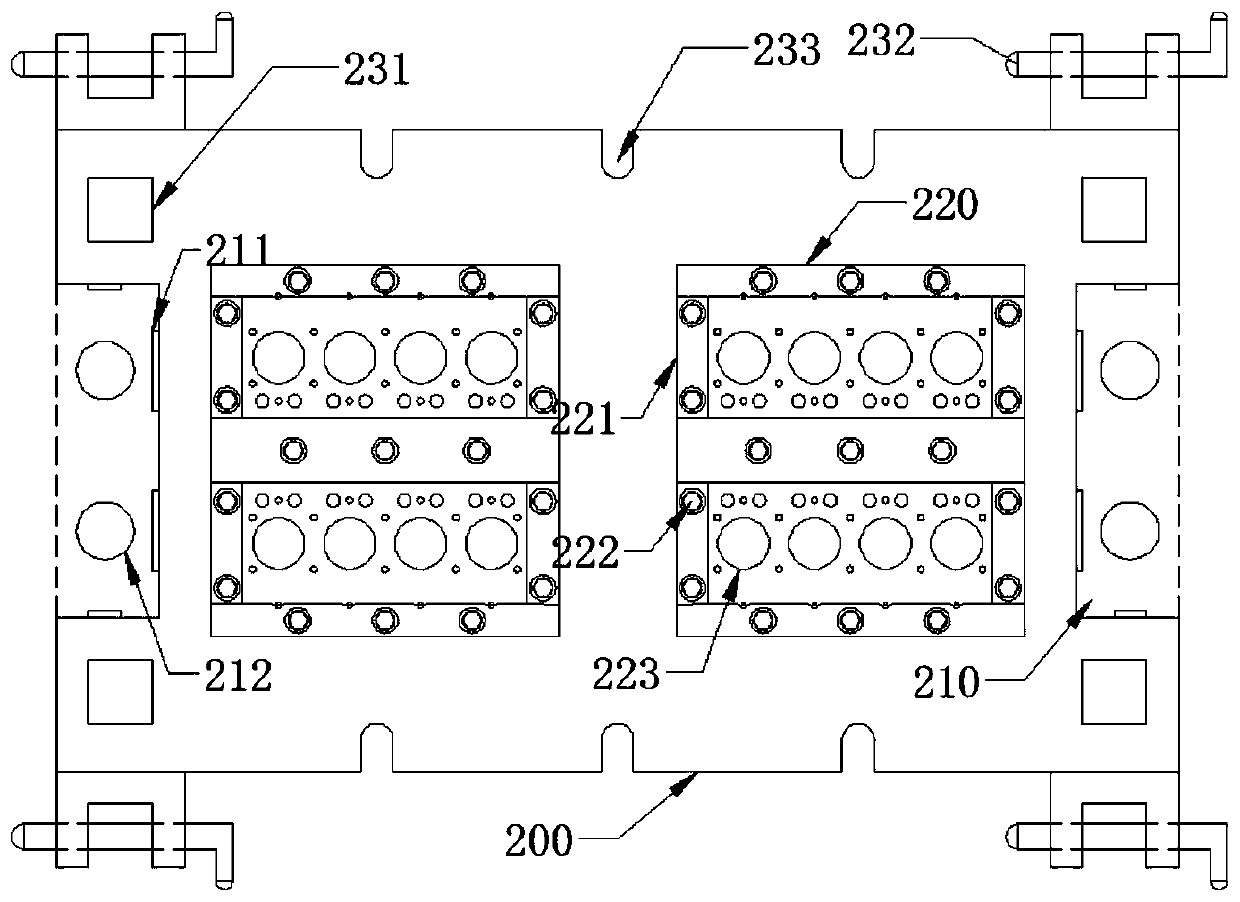

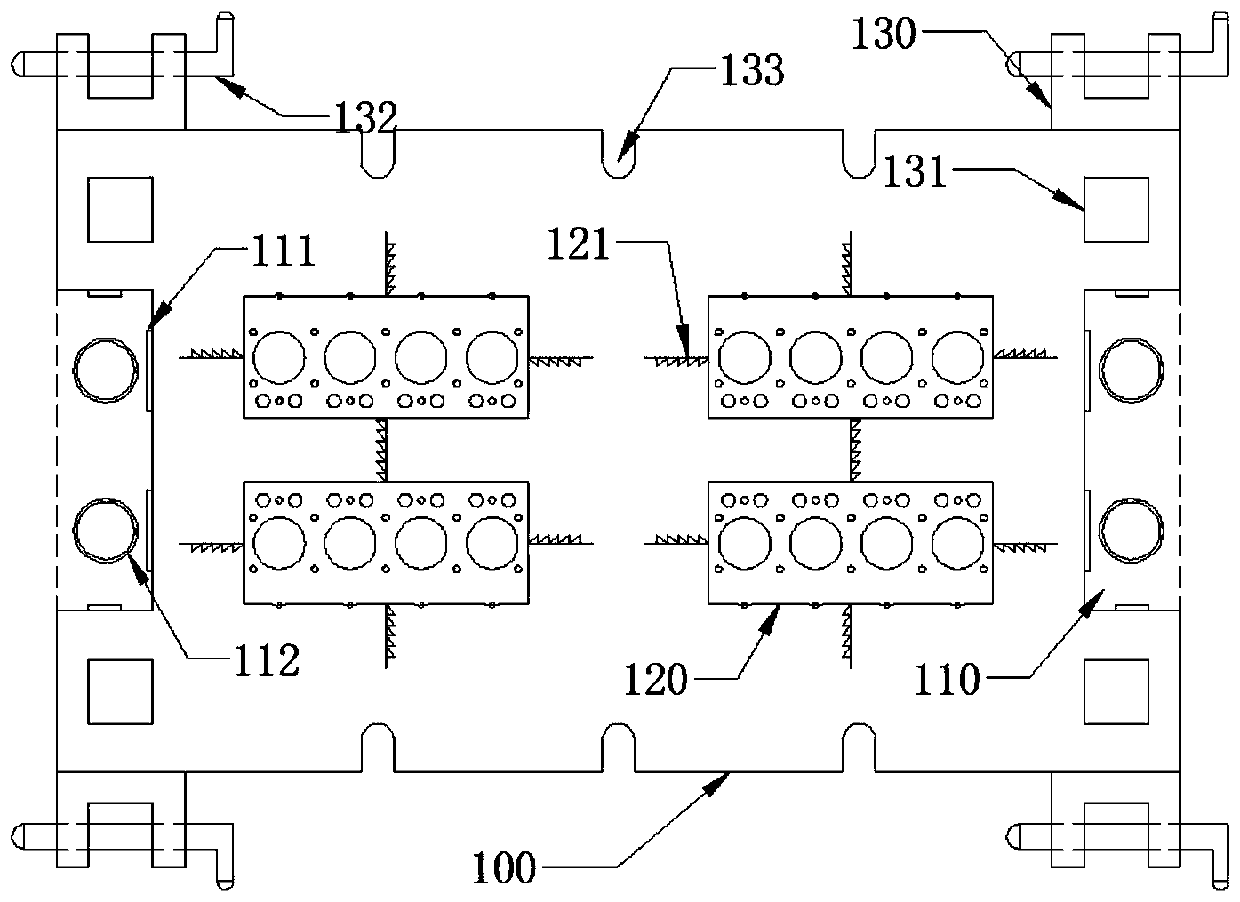

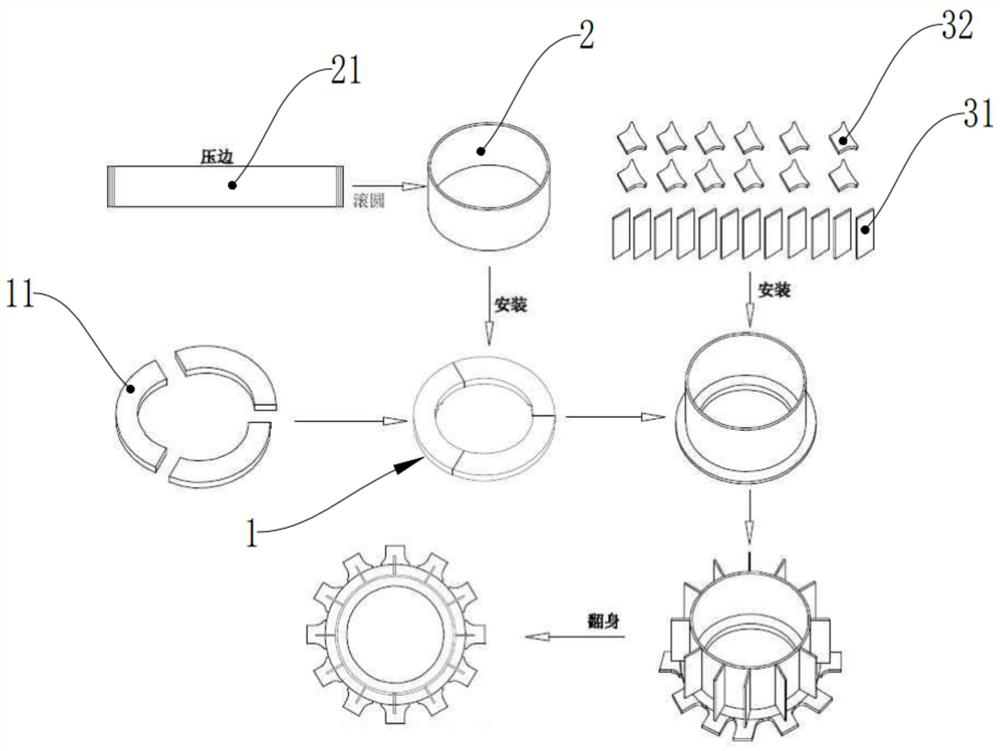

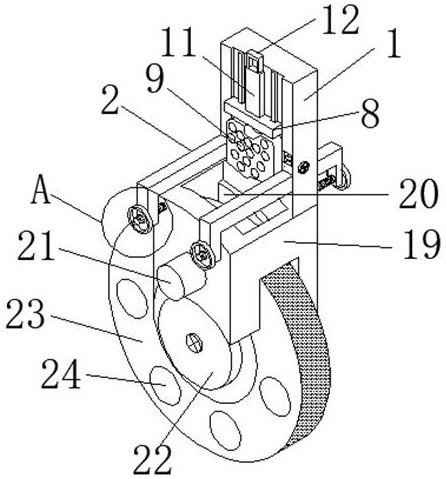

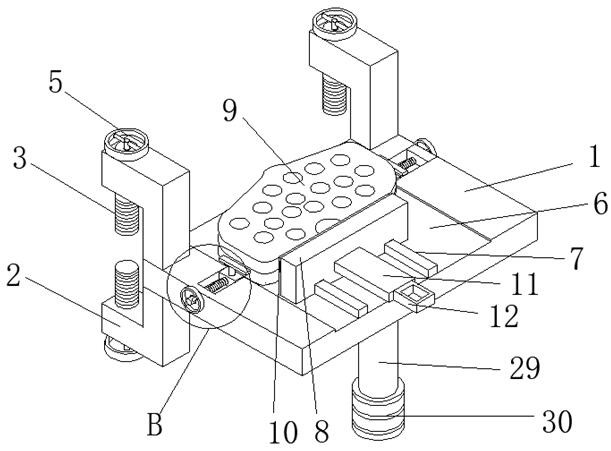

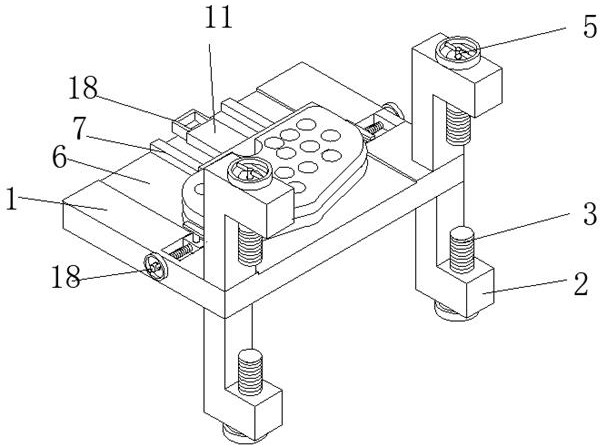

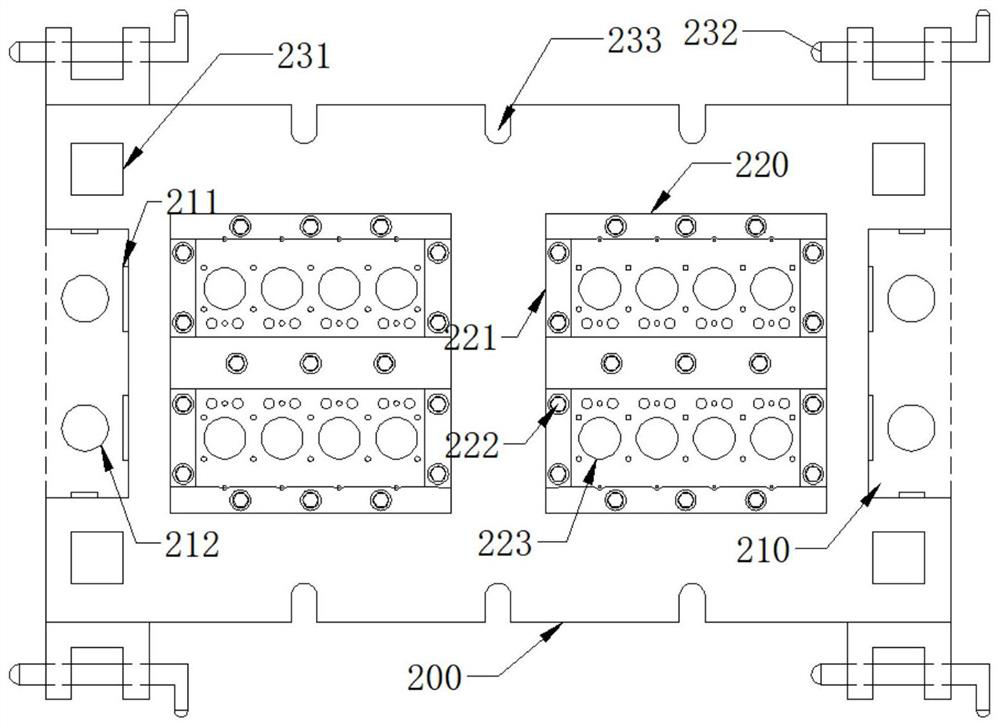

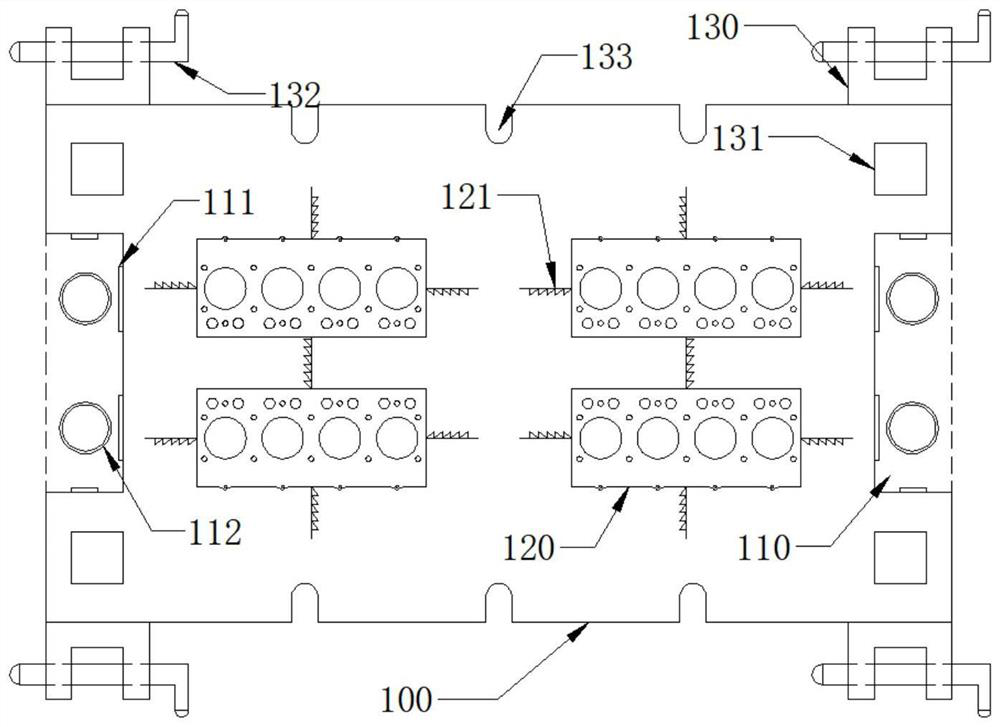

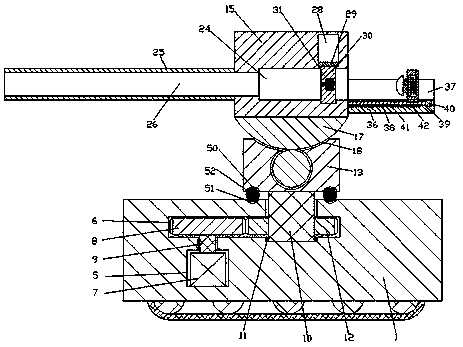

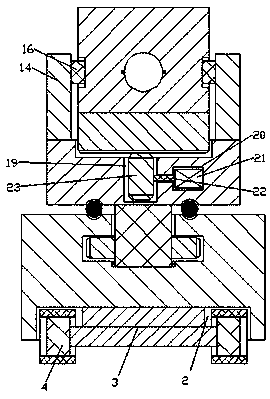

Cylinder gasket die and machining process method thereof

ActiveCN110899687ASimple processHigh strengthTransportation and packagingMetal-working apparatusMachining processWaste material

The invention discloses a cylinder gasket die and a machining process method thereof. The cylinder gasket die is composed of a lower die and an upper die. The lower die comprises lower die guide plates, guide columns, lower die bases and other parts of the lower die, wherein the lower die guide plates and the guide columns are arranged in lower die connecting parts correspondingly; and the upper die comprises upper die guide plates, guide sleeves, upper die bases and other parts of the upper die, wherein the upper die guide plates and the guide sleeves are arranged in upper die connecting parts correspondingly. Scrap cutters are arranged on the periphery of each lower die base. Each upper die base is surrounded by trimming knifes. The trimming knifes are fixed to a base of the upper die through bolts; various punched holes are formed in the trimming knifes; and the punched holes are also formed in the base of the upper die. The machining process of the cylinder gasket comprises the steps of raw material purchasing, hot forming stage, mold forming stage, hot pressing forming stage, heat treatment stage, surface treatment stage, grinding and polishing stage and part testing. On the basis that the production efficiency of the die is improved, the steps of the machining process of the cylinder gasket are regulated and perfected, and therefore, the quality of the cylinder gasket isfurther improved.

Owner:HUOSHAN HUINENG AUTO PARTS MFG

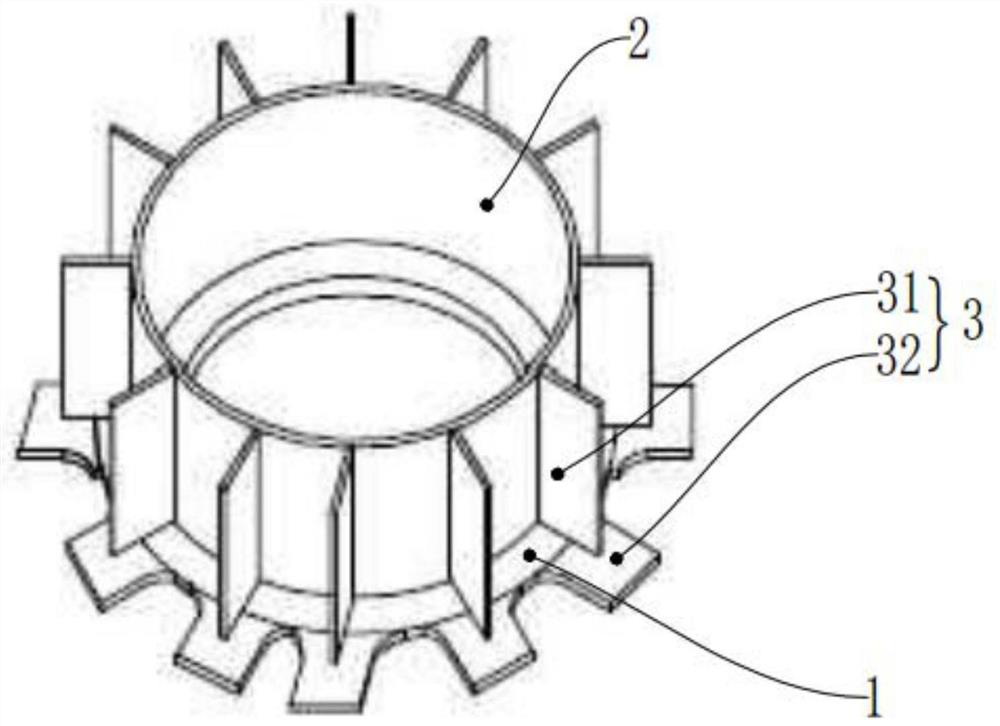

Propeller base of deepwater dynamic positioning crude oil conveying device and manufacturing method of propeller base

PendingCN112706909AStable structureGuaranteed installation accuracyPropulsion power plantsOutboard propulsion unitsShaped beamDynamic positioning

The invention discloses a propeller base of a deepwater dynamic positioning crude oil conveying device and a manufacturing method of the propeller base, and belongs to the field of ocean engineering. The propeller base comprises a flange plate, a cylinder and a plurality of T-shaped beams, the cylinder is arranged at the upper end of the flange plate, the T-shaped beams are evenly distributed on the outer side of the cylinder,each T-shaped beam comprises a web and a panel, one side of the web is connected with the outer side of the cylinder, the bottom of the web is connected with the upper side of the flange plate and the panel, and one side of the panel is connected with the outer side of the flange plate. According to the propeller base, the cylinder and the T-shaped beams are arranged on the flange plate, so that the assembled propeller base can provide a connecting structure for a main propeller and a stern of the ship body of the power positioning crude oil conveying device, and the mounting precision of the main propeller is guaranteed.

Owner:COSCO SHIPPING SHIPYARD (NANGTONG) CO LTD +1

Heat insulation plate assembly for automobile brake device

The invention relates to the technical field of automobile accessories, and discloses a heat insulation plate assembly for an automobile brake device. The heat insulation plate assembly comprises a machine body, one side of the machine body is fixedly provided with a fixing frame, the inner wall of the fixing frame is rotatably connected with a fixing rod, the top of the fixing rod is rotatably connected with a rotating shaft, the top of the rotating shaft is rotatably connected with a fixing wheel, the upper surface of the machine body is provided with a lead-in groove, and the outer surfaceof the lead-in groove is fixedly provided with a sliding rail. A pushing block is slidably connected to the outer surface of the sliding rail, a heat insulation plate is arranged at one end of the pushing block, and a rubber pad is arranged on the front surface of the pushing block. The heat insulation plate assembly has the advantages and effects that a worker screws a hand wheel to fix the heatinsulation plate, the machine body is fixed by using the fixing rod, after the device is fixed, the heat insulation plate can be pushed by loosening the hand wheel, then a handle is pushed, and the heat insulation plate slides into a brake system through the lead-in groove, so that assembly of the heat insulation plate is completed.

Owner:宁波米锐汽车配件技术有限公司

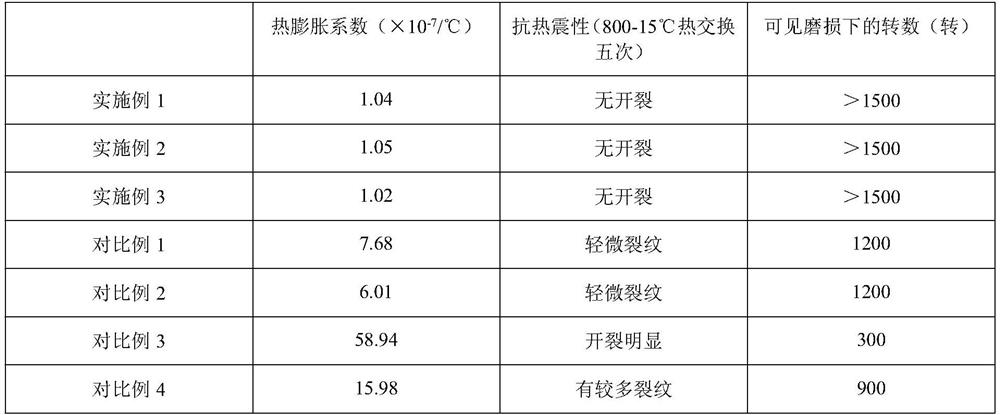

Wear-resistant and heat-resistant porcelain and processing technology

PendingCN114538909AImprove wear resistanceImprove heat resistanceCeramic materials productionGlazeEthylic acid

The invention provides wear-resistant heat-resistant porcelain and a processing technology thereof.The processing technology comprises the steps that firstly, zirconium nitrate, tantalum acetate and molybdenum nitrate serve as raw materials to be prepared into premixed powder, then petalite, micalex, ball clay, sepiolite and the premixed powder serve as raw materials to be prepared into a blank, and then spodumene, micalex, wollastonite, knar clay, red shale, diopside and the premixed powder serve as raw materials to be prepared into glaze; and finally, preparing the blank into a green body, biscuiting to obtain a biscuit, uniformly glazing the surface of the biscuit by using glaze, drying, performing ozone treatment, and sintering to obtain the product. And the obtained porcelain has good wear resistance and good heat resistance.

Owner:胡晓荣

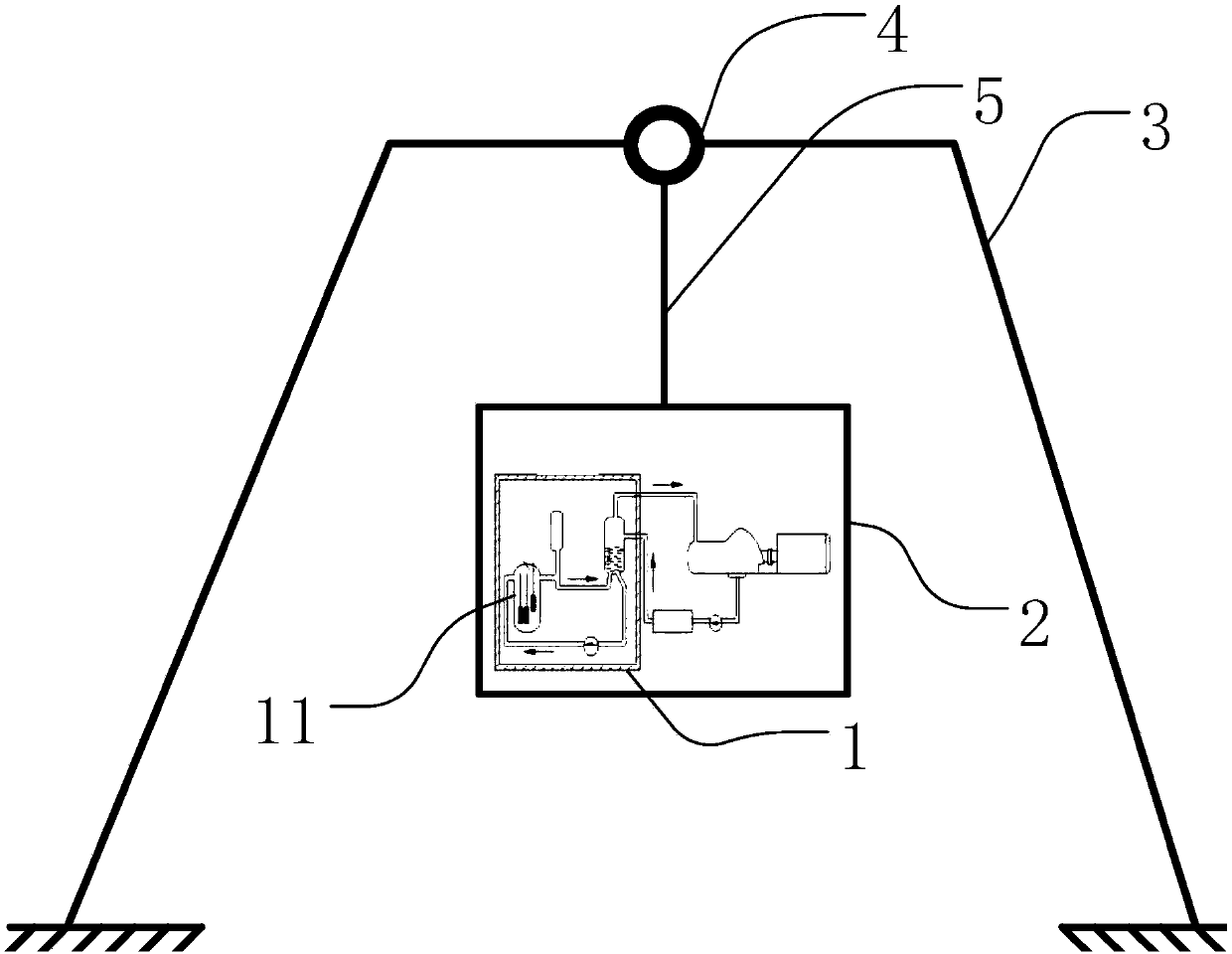

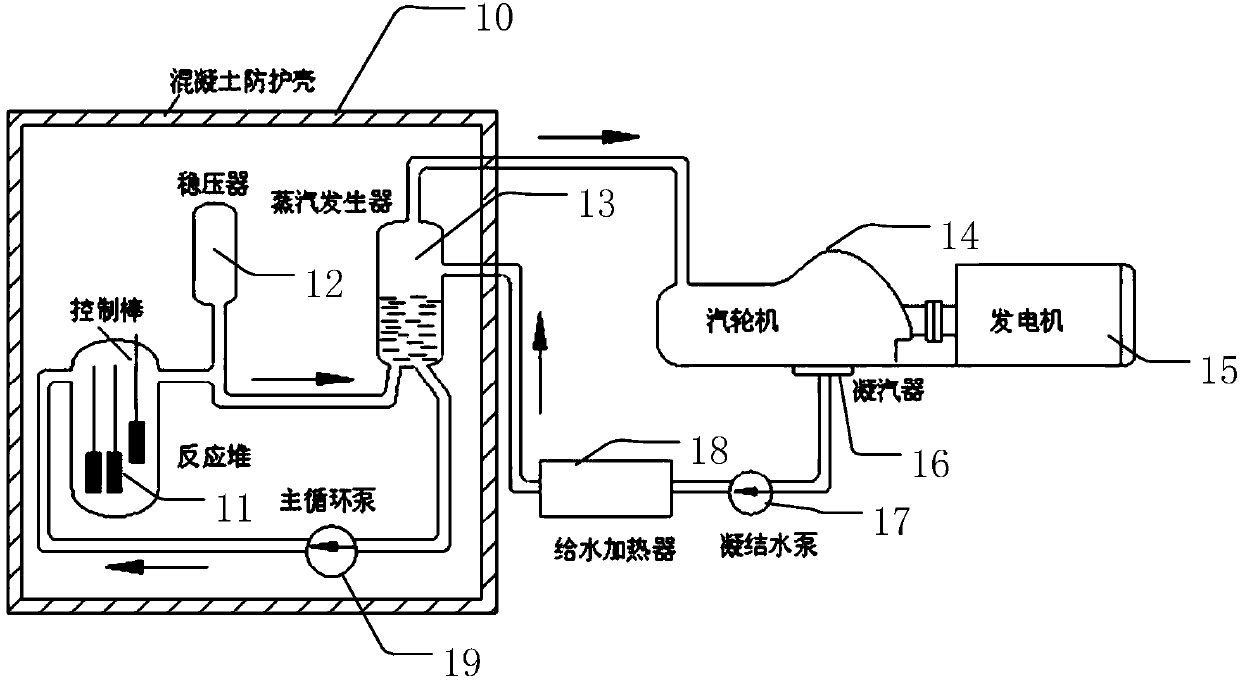

Nuclear reactor passive balance system and nuclear reactor passive balance method

PendingCN107910076AMeet the requirements of passive designReduce swingWaterborne vesselsNuclear energy generationNuclear reactor coreNuclear reactor

The invention relates to a nuclear reactor passive balance system. The nuclear reactor passive balance system comprises a nuclear power apparatus, a balance structure, a supporting mechanism and a movable hinge, wherein the nuclear power apparatus has a nuclear reactor; the nuclear power apparatus is fixed in the balance structure; the supporting mechanism is connected and supports the balance structure by virtue of the movable hinge; and the movable hinge can be hinged with the supporting mechanism in a manner of automatically rotating relative to the supporting mechanism, and the bottom of the movable hinge is connected with the top of the balance structure. By adopting the nuclear reactor passive balance system, the balance state of the nuclear reactor can be realized without external force, so that the inclination and tumbling of the nuclear reactor apparatus caused by an ocean environment can be prevented.

Owner:XIAMEN UNIV

A cylinder gasket mold and its processing method

ActiveCN110899687BSimple processHigh strengthTransportation and packagingMetal-working apparatusPunchingCylinder head

The invention discloses a cylinder head gasket processing method. The cylinder head gasket mold is composed of a lower mold and an upper mold, and the lower mold includes a lower mold guide plate and a guide column inside the connection part of the lower mold, a lower mold base and other parts of the lower mold; The upper mold includes an upper mold guide plate and a guide sleeve inside the upper mold connection part, an upper mold base and other parts of the upper mold; the lower mold base is surrounded by waste knives; the upper mold base is surrounded by trimming knives, The edge trimming knife is fixed on the base of the upper mold by bolts. There are various punching holes inside the edge trimming knife, and the punching holes are also installed on the base of the upper mold. The cylinder gasket processing process includes: raw material procurement, thermoforming stage, mold forming stage, hot pressing forming stage, heat treatment stage, surface treatment stage, grinding and polishing stage and parts testing, the present invention specifies and perfects the processing flow steps of the cylinder head gasket on the basis of improving the mold production efficiency, thereby further improving the cylinder head gasket. quality.

Owner:HUOSHAN HUINENG AUTO PARTS MFG

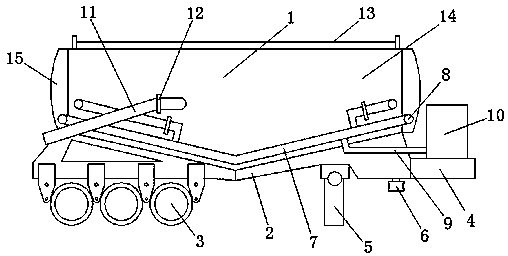

Semitrailer for transporting power tank

InactiveCN109334547AEasy to placeAchieve placementTank vehiclesVehicle fittings for liftingEngineeringRoad surface

The invention relates to a semitrailer for transporting a power tank. A tank body and a mounting rack are connected to be an entity, the strength of the tank body is improved, the tank body is in transition connection with wheels through the mounting rack, the wheels are installed on the mounting rack, and the strength of a rear axle under the walking state of the wheels is guaranteed; in addition, a bearing rack on the mounting rack is connected with a driving headstock, and the structural stability is also improved. Supporting legs at the bottom of the mounting rack can achieve the supporting function before the semitrailer and the driving headstock are installed and connected, and the semitrailer is conveniently placed. In addition, the tank body is provided with an air bag, a powder material in the tank body can be suspended through air chambers in end covers, and convenience is provided for material drawing; in addition, supporting rods and a reinforcement plate are arranged in the tank body, the strength of the tank body can be guaranteed, and deformation, even cracking in the process of transporting the tank body on the jolt road is avoided.

Owner:神州永达汽车制造有限公司

car brake pads

ActiveCN103511512BFast heat conductionImprove thermal stabilityOther chemical processesBraking membersEpoxyBenzoic acid

The invention provides an automobile brake pad which comprises a steel back and a friction material, wherein the friction material comprises the following materials in parts by weight: 1 to 10 parts of butylbenzene, 0.5 to 2 parts of cumyl hydroperoxide, 0.5 to 2 parts of epoxy resin, 1 to 15 parts of boric phenolic resin, 1 to 15 parts of polypropylene, 6 to 10 parts of nylon powder, 5 to 10 parts of boron nitride, 1 to 5 parts of dicumyl peroxide, 1 to 2 parts of sulphur powder, 1 to 2 parts of benzoic acid, 1 to 2 parts of stearic acid, 1 to 2 parts of boric acid, 50 to 60 parts of graphite, 5 to 8 parts of ceramic fibers, 0.5 to 1 part of potassium titanate, 1 to 2 parts of reduced iron powder, 1 to 2 parts of barium sulfate, 0.5 to 2 parts of bauxite, 0.5 to 2 parts of feldspar powder, 0.5 to 2 parts of zinc oxide, 0.5 to 2 parts of fluorite powder, 0.5 to 2 parts of silicon carbide and 0.5 to 2 parts of coumarone. The automobile brake pad is nuisanceless, pollution-free, noise-free, spark-free, wear-resistant and long in service life.

Owner:NINGBO JIA XUAN NEW MATERIALS

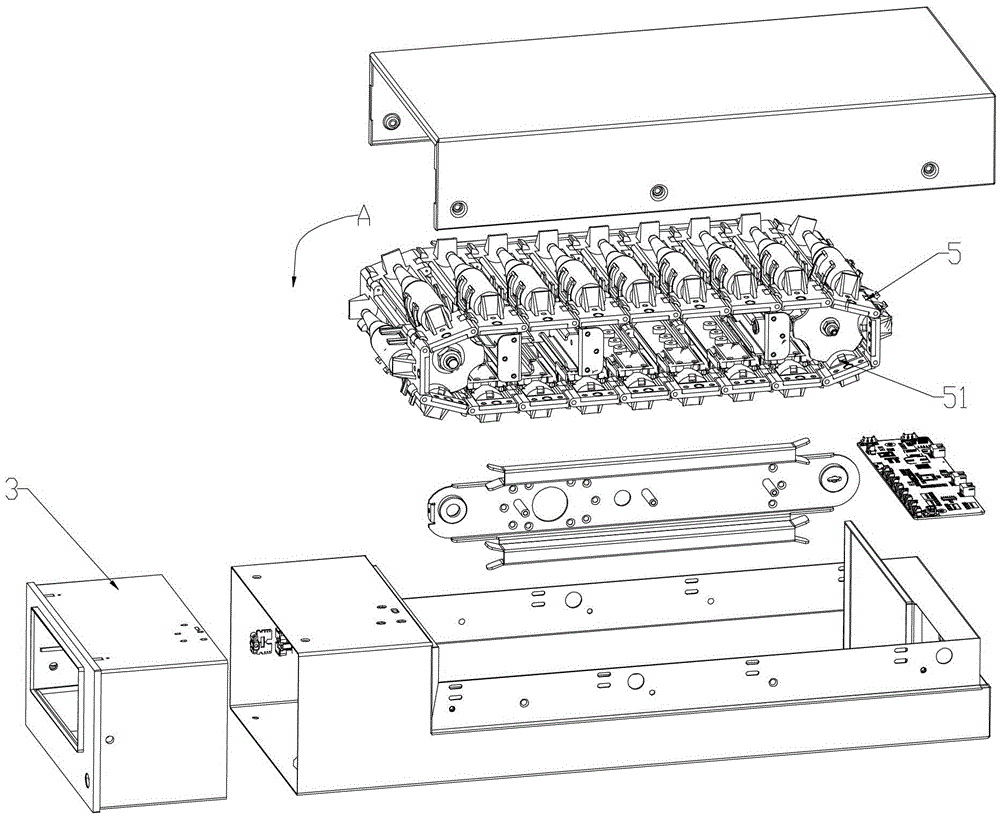

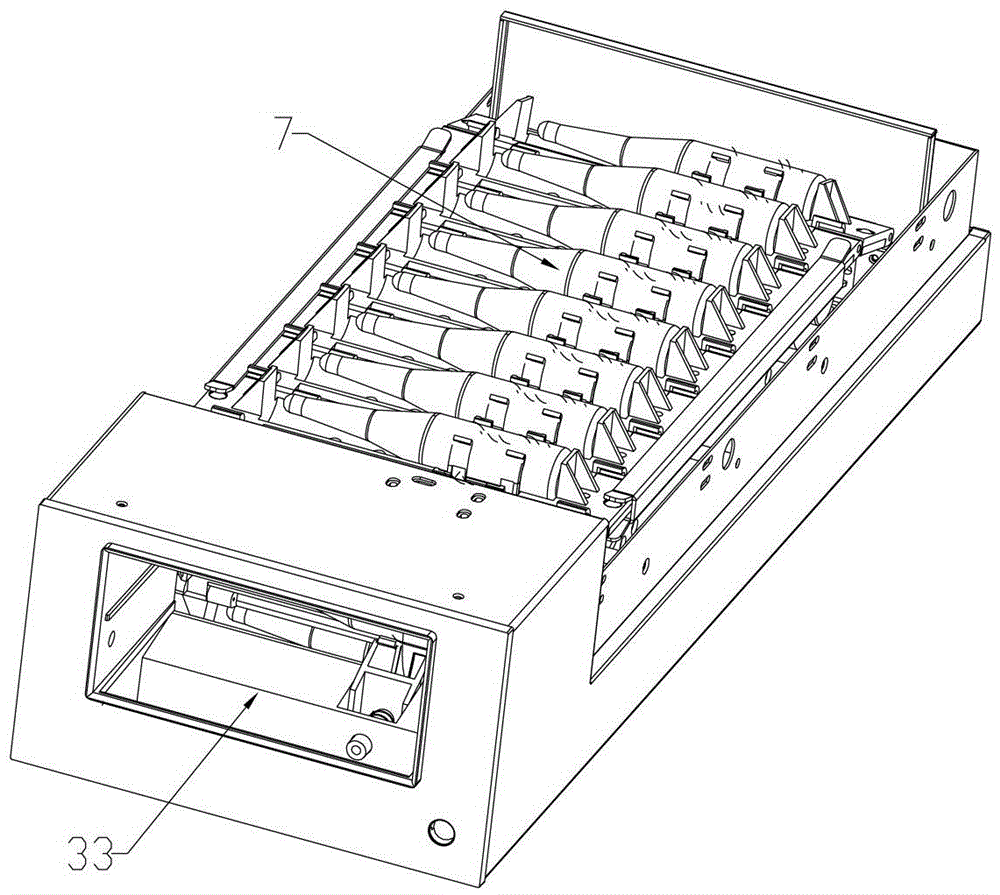

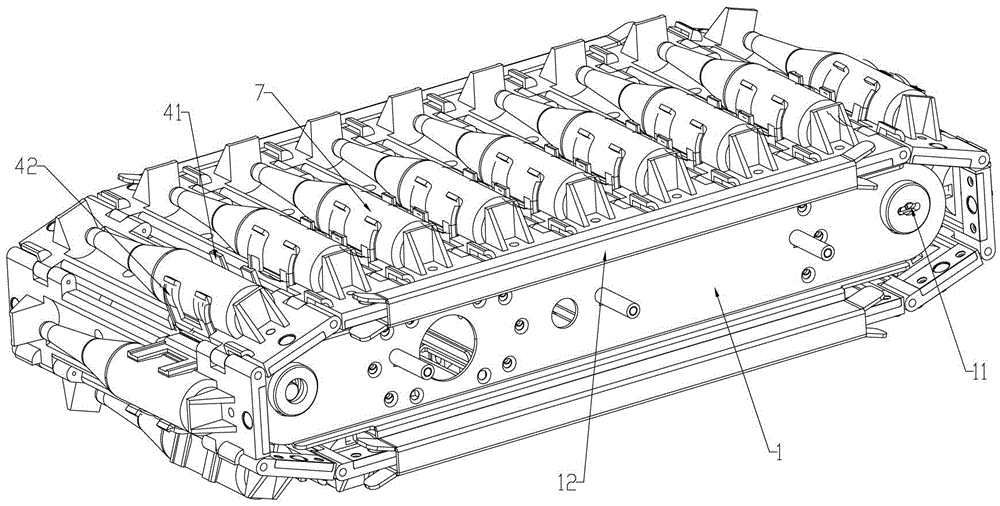

Intelligent injection drug storage device

An intelligent injection storage device comprises a supporting frame, an injection storage mechanism used for storing drug bottles, and an injection moving-out mechanism used for moving the drug bottles out of the injection storage mechanism. The injection storage mechanism comprises a driving shaft rotatably mounted on the supporting frame and fixedly provided with a driving wheel, a stepping motor with a motor body portion fixed on the supporting frame, a driven shaft, an annular crawler belt and a shock absorbing mechanism, the stepping motor is used for driving the driving shaft to rotate, a driven wheel is mounted on the driven shaft, injection clamping mechanisms are arranged on the annular crawler belt, chutes extending in the length direction of the supporting frame are arranged on two opposite sides of the supporting frame, the end portion of the driven shaft is slidably mounted in the chutes in an inserted manner, and the shock absorbing mechanism comprises a compression spring. By designing the chutes and the compression spring, the position of the driven shaft can be automatically adjusted to guarantee the annular crawler belt to be maintained in a tensioned state in the process of transmission to enable the annular crawler belt to smoothly run, so that safety and stability of drug conveying are improved.

Owner:深圳市安瑞科科技有限公司

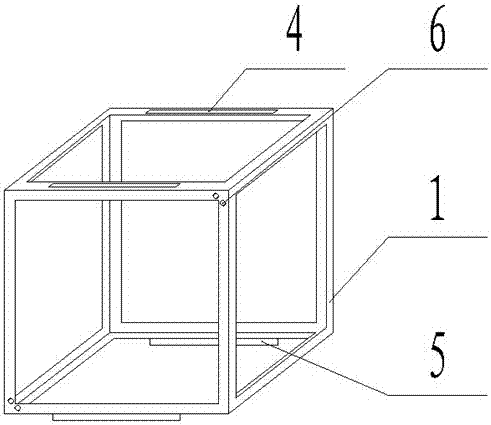

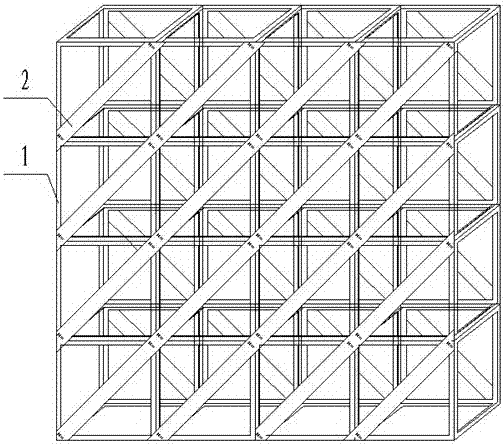

A steel shear wall structure

Owner:河南恒路钢结构有限公司

Projectile launching device

The invention discloses a projectile launching device. The projectile launching device comprises a fixed base, wherein crawler belt moving wheels are symmetrically arranged on the front side and the back side of a connection block; a driving space is arranged in the left side of the inside of the fixed base; a rotating shaft extending upwards is arranged on the right side of the inside of a transmission space; the upper end of the rotating shaft passes through the upper end wall of the transmission space and is fixedly connected with a support block; a fixed shell is arranged between two support rods above the support block; a gun bore with a rightward opening is arranged in the fixed shell; a gun barrel is arranged on the left end wall of the gun bore; an ignition device extending leftwards is arranged in a sealed plate. In operation, an automatic projectile loading device is capable of reducing the manpower, avoiding the occurrence of the phenomenon that the hands are pinched duringmanually loading projectile and ensuring the safety of the staff; a projectile shell withdrawing block is capable of rapidly discharging used projectile shells; the time is reduced; the efficiency isimproved.

Owner:宁波市鄞州区丰余工业产品设计有限公司

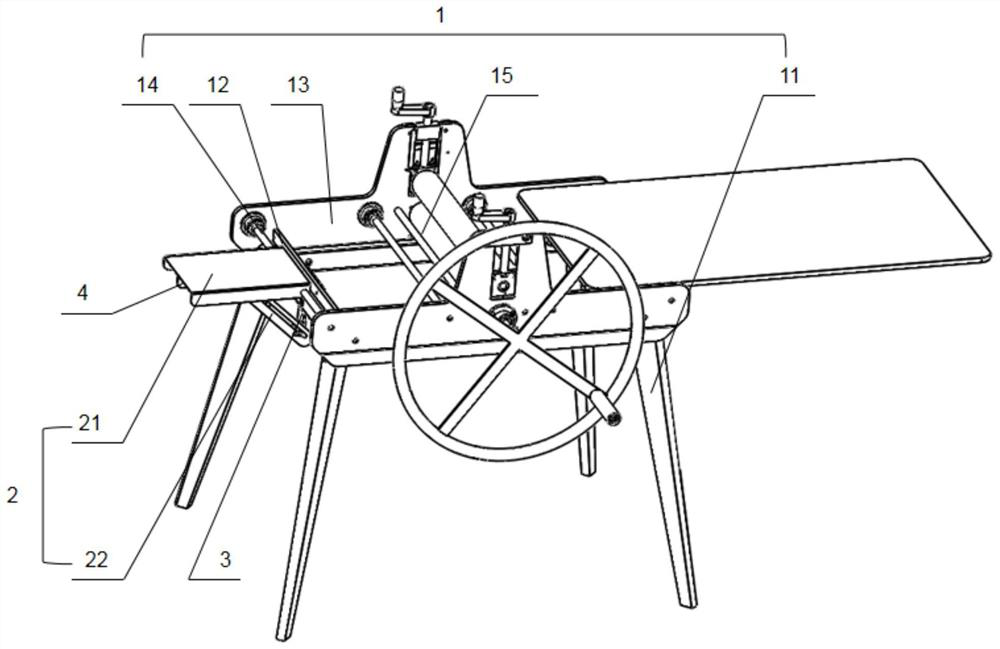

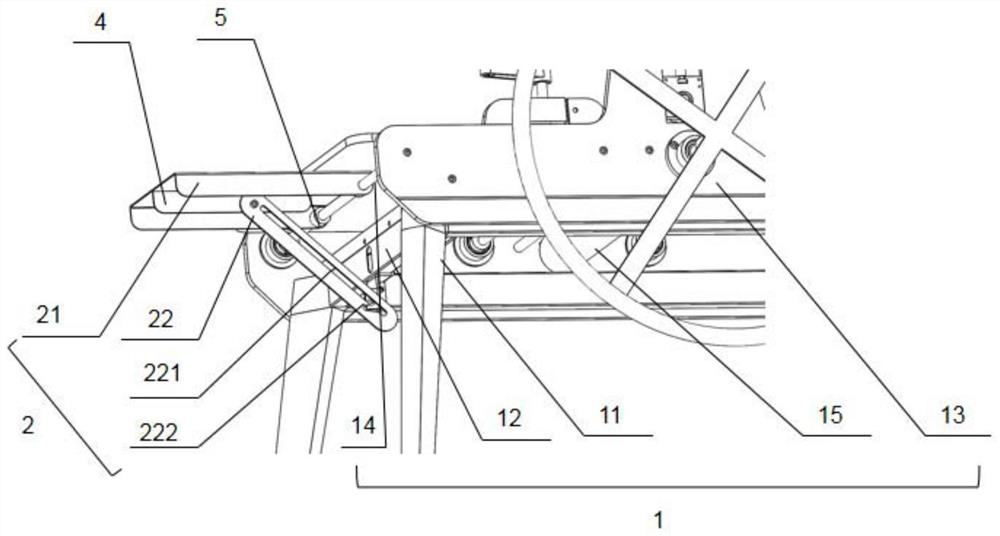

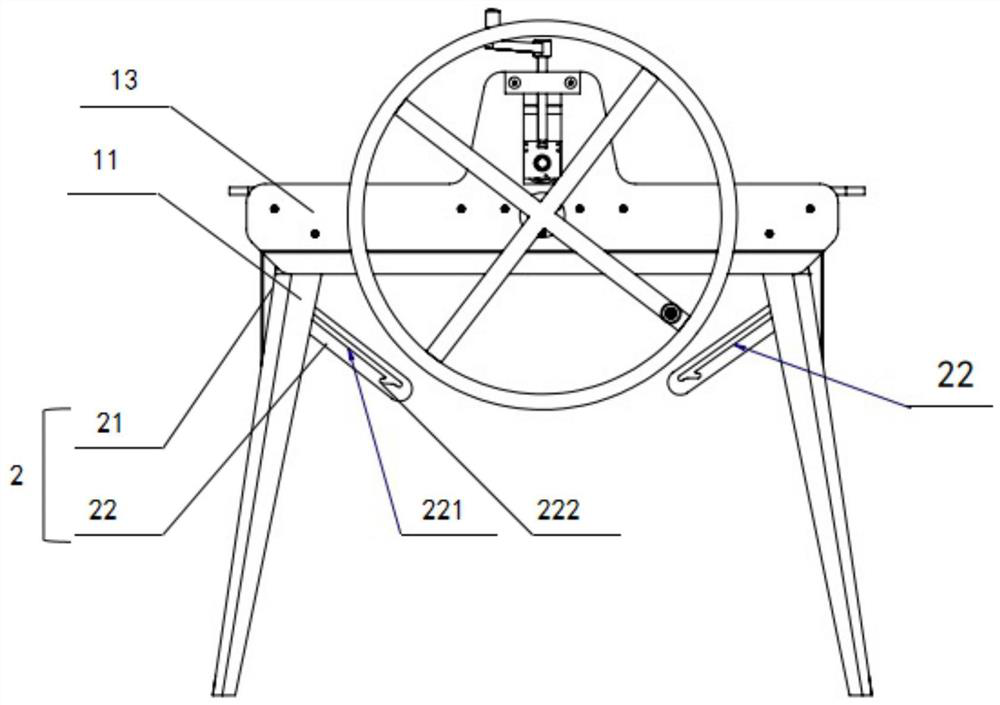

A method of using a safety mud machine with a telescopic folding bracket

ActiveCN110948648BRecovery lengthImprove the safety of usePress rollersAuxillary shaping apparatusEngineeringMechanical engineering

The present invention relates to a method for using a safety clay board machine with telescopic folding brackets, which belongs to the field of mud board machines, and has a mud board machine body for adjusting the height of mud pressing rollers, and the mud board machine body includes four supporting legs and two longitudinal reinforcement plates , two vertical plates, cylindrical reinforcing rods, and guide rollers; also includes two bracket components and restraint components; the bracket components are arranged at the feed end and discharge end of the mud block body; Parallel; its upper horizontal plane is tangent to the circular highest point of the guide roller. When the bracket assembly is unfolded, it supports the wooden board and the clay board, so that the mud board does not shake during the dragging process of the wooden board, and avoids that when the mud board is formed and discharged, the speed of dragging the wooden board is too fast, which may cause the wooden board to slip. Injure the user, further improve the safety and stability of the masonry machine; after the work is over, the bracket assembly can be shrunk and recovered as a whole, and the original length of the masonry machine can be restored; no additional floor space is occupied, and the structural design is reasonable .

Owner:景德镇百陶会陶艺装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com