car brake pads

A technology for brake pads and automobiles, applied in the field of brake pads, can solve the problems of easy entry into the lungs, poor thermal conductivity, braking failure, etc., and achieve the effects of reducing noise pollution, long service life, and slowing down energy transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An automobile brake pad, which comprises a steel back and a friction material bonded on the steel back, wherein the friction material comprises the following components by weight: 5 parts of butyl butylbenzene, peroxide Hydrogen cumene 1 part, epoxy resin 2 parts, boron phenolic resin 6 parts, polypropylene 6 parts, nylon powder 6 parts, boron nitride 6 parts, silane coupling agent A-1510.01 parts, cumene peroxide 2 parts 1 part of sulfur powder, 1 part of benzoic acid, 1 part of stearic acid, 1 part of boric acid, 55 parts of graphite, 5 parts of ceramic fiber, 1 part of potassium titanate, 1.95 parts of reduced iron powder, 1.5 parts of barium sulfate, aluminum alum 1 part of soil, 1 part of feldspar powder, 1 part of zinc oxide, 0.02 part of accelerator TT, 0.02 part of N-phenyl-2-naphthylamine, 1 part of fluorspar powder, 1 part of silicon carbide, and 1 part of coumarone.

[0024] The preparation method of the automobile brake pad is obtained according to a convent...

Embodiment 2

[0032] An automobile brake pad, which comprises a steel back and a friction material bonded on the steel back, wherein the friction material comprises the following components by weight: 5 parts of butyl butylbenzene, peroxide Hydrogen cumene 1 part, epoxy resin 2 parts, boron phenolic resin 6 parts, polypropylene 6 parts, nylon powder 6 parts, boron nitride 6 parts, silane coupling agent A-1510.01 parts, cumene peroxide 2 parts 1 part of sulfur powder, 1 part of benzoic acid, 1 part of stearic acid, 1 part of boric acid, 60 parts of graphite, 5 parts of ceramic fiber, 0.5 part of potassium titanate, 1.95 parts of reduced iron powder, 1.5 parts of barium sulfate, aluminum alum 1 part of soil, 1 part of feldspar powder, 1 part of zinc oxide, 0.02 part of accelerator H, 0.02 part of N-phenyl-2-naphthylamine, 1 part of fluorspar powder, 1 part of silicon carbide, and 1 part of coumarone.

[0033] The preparation method of this automobile brake pad is with embodiment 1.

Embodiment 3

[0035] An automobile brake pad, which comprises a steel back and a friction material bonded on the steel back, wherein the friction material comprises the following components by weight: 5 parts of butyl butylbenzene, peroxide Hydrogen cumene 1 part, epoxy resin 2 parts, boron phenolic resin 6 parts, polypropylene 6 parts, nylon powder 6 parts, boron nitride 6 parts, silane coupling agent A-1510.01 parts, cumene peroxide 2 parts 1 part of sulfur powder, 1 part of benzoic acid, 1 part of stearic acid, 1 part of boric acid, 50 parts of graphite, 8 parts of ceramic fiber, 1 part of potassium titanate, 1.95 parts of reduced iron powder, 1.5 parts of barium sulfate, aluminum alum 1 part of soil, 1 part of feldspar powder, 1 part of zinc oxide, 0.02 part of accelerator M, 0.02 part of N-phenyl-2-naphthylamine, 1 part of fluorspar powder, 1 part of silicon carbide, and 1 part of coumarone.

[0036] The preparation method of this automobile brake pad is with embodiment 1.

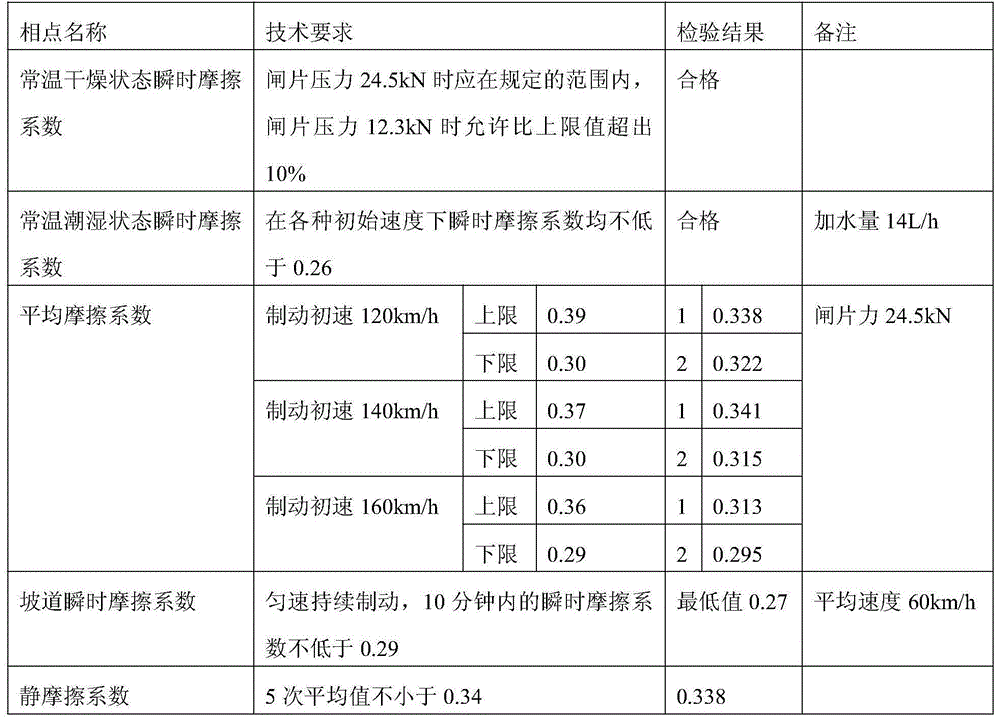

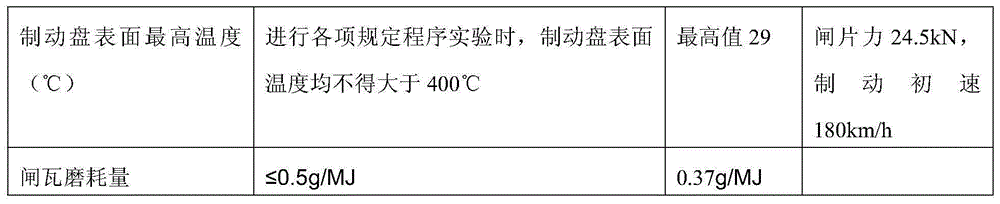

[0037] To...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com