A method of using a safety mud machine with a telescopic folding bracket

A telescopic folding and mudboard technology, applied in ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of the wooden board smashing the user, the mudboard shaking, the limited length of the whole machine, etc., to improve the stability and structure. Reasonable design, the effect of improving the safety and stability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

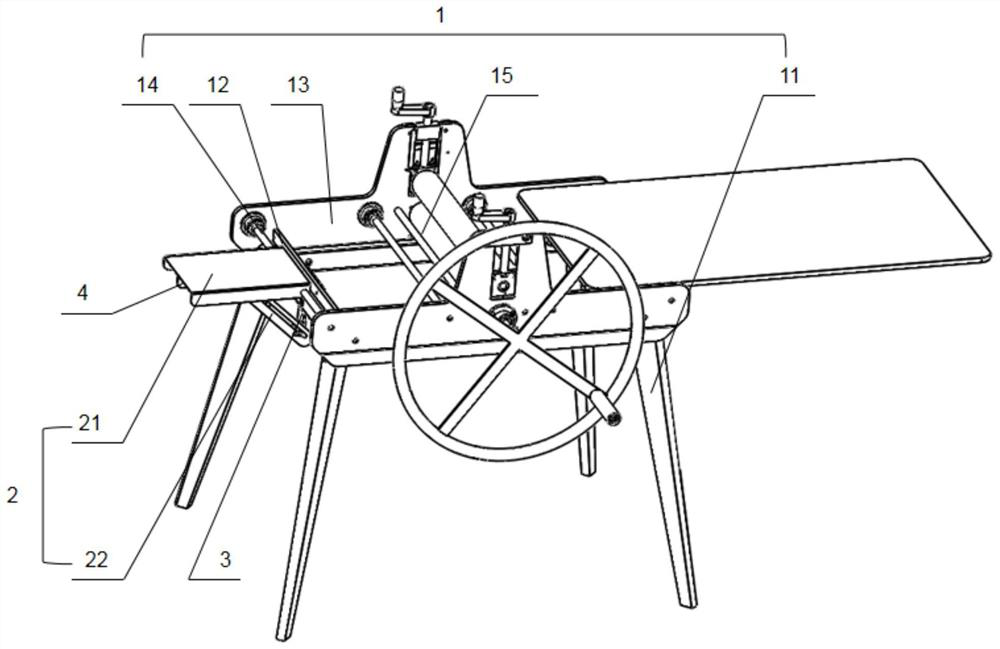

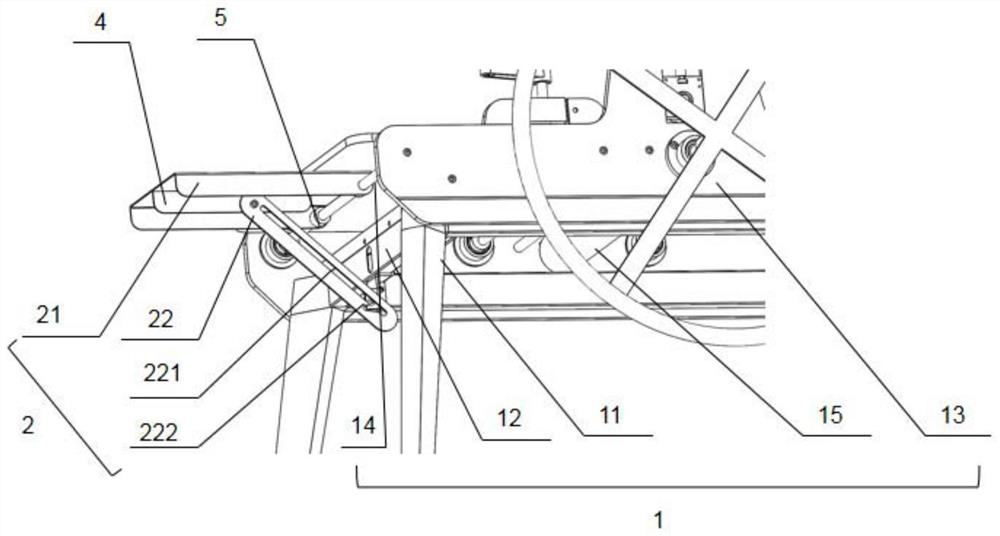

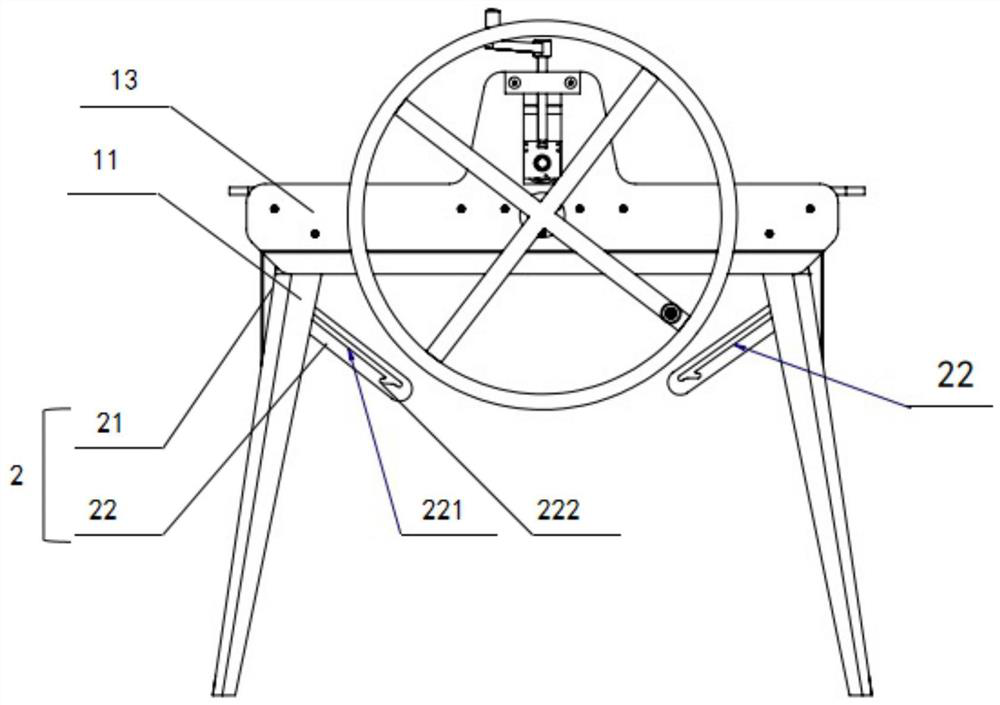

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0034] Such as Figure 1-6 shown. The present invention proposes a method of using a safety clay board machine with a telescopic folding bracket, which has a mud board body 1 for adjusting the height of the mud pressing roller, and the mud board body 1 includes four parts that are arranged outward along the diagonal direction to form a support function. The supporting legs 11, two longitudinal reinforcing plates 12 arranged longitudinally on the tops of the four supporting legs 11 and relatively inwardly, two vertical plates 13 arranged transversely on the top ends of the four supporting legs 11 and relatively externally, and arranged on the two vertical plates 13 Cylindrical reinforcing rods 14 arranged at intervals on the opposite inner side of the planks, and guide rollers 15 for driving planks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com