Metal hip joint combined handle

A hip, metal technology, applied in hip joints, joint implants, joint implants, etc., can solve problems such as affecting the fixation effect of the hip joint, and achieve the problem of poor femoral matching, high surface friction coefficient, and structural stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Describe the present invention in detail below in conjunction with accompanying drawing;

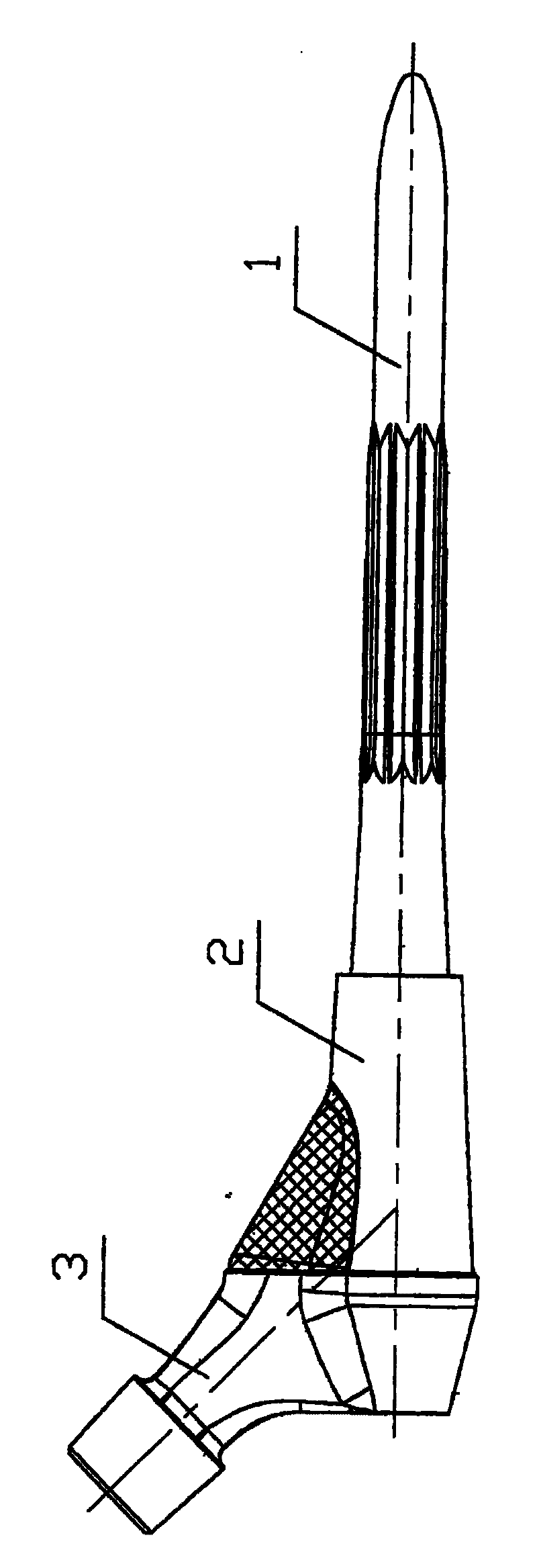

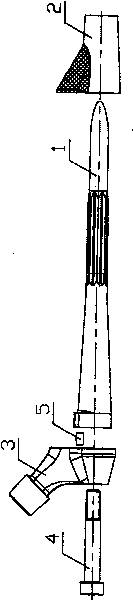

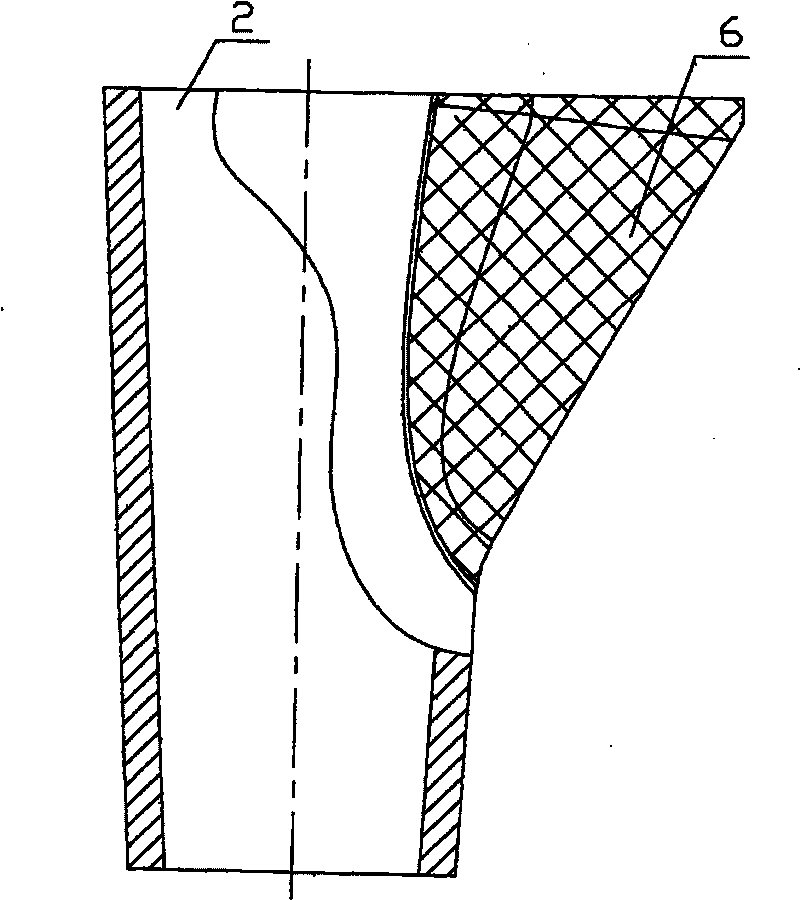

[0024] From Figure 1-Figure 6 It can be seen that the structure of the present invention is a titanium alloy hip joint stem, which includes a femoral stem body 1 , a femoral stem neck body 3 , a bushing 2 at the proximal end of the femoral stem, a positioning pin 5 and a fixing bolt 4 . The proximal bushing 2 is a conical cylindrical body formed by scanning and melting titanium alloy powder through an electron beam fusion molding equipment, including two parts: the main body is a solid structure, and the bushing nose part 6 has a loose mesh porous structure with an average pore diameter of 400 microns, porosity 70%, similar to cancellous structure, elastic modulus closer to cancellous bone; femoral stem body 1 is a slender cylinder formed by forging and machining of titanium material, the distal end of femoral stem body 1 It is pointed, with a tuning fork-like longitudinal decom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com