Cylinder gasket die and machining process method thereof

A processing technology and cylinder gasket technology, applied in the field of cylinder gasket mold and its processing technology, can solve the problems of poor sealing performance, short start and development time, lack of fastening mechanism, etc., so as to improve strength and tightness and reduce production. The effect of cost and process improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0030] The specific operation steps of the described a kind of cylinder gasket processing technology are as follows:

[0031] Raw material procurement: the procurement department purchases the required cylinder head gasket production and processing raw materials, iron-based powder 15%-30%, copper-based powder 10%-25%, engine oil 1%-4%, tackifier 0.6%-0.9%, 0.1%-0.4% preservative, 0.3%-0.6% oxidant, 20%-35% graphite, 7%-10% resin, 1%-2.5% friction modifier.

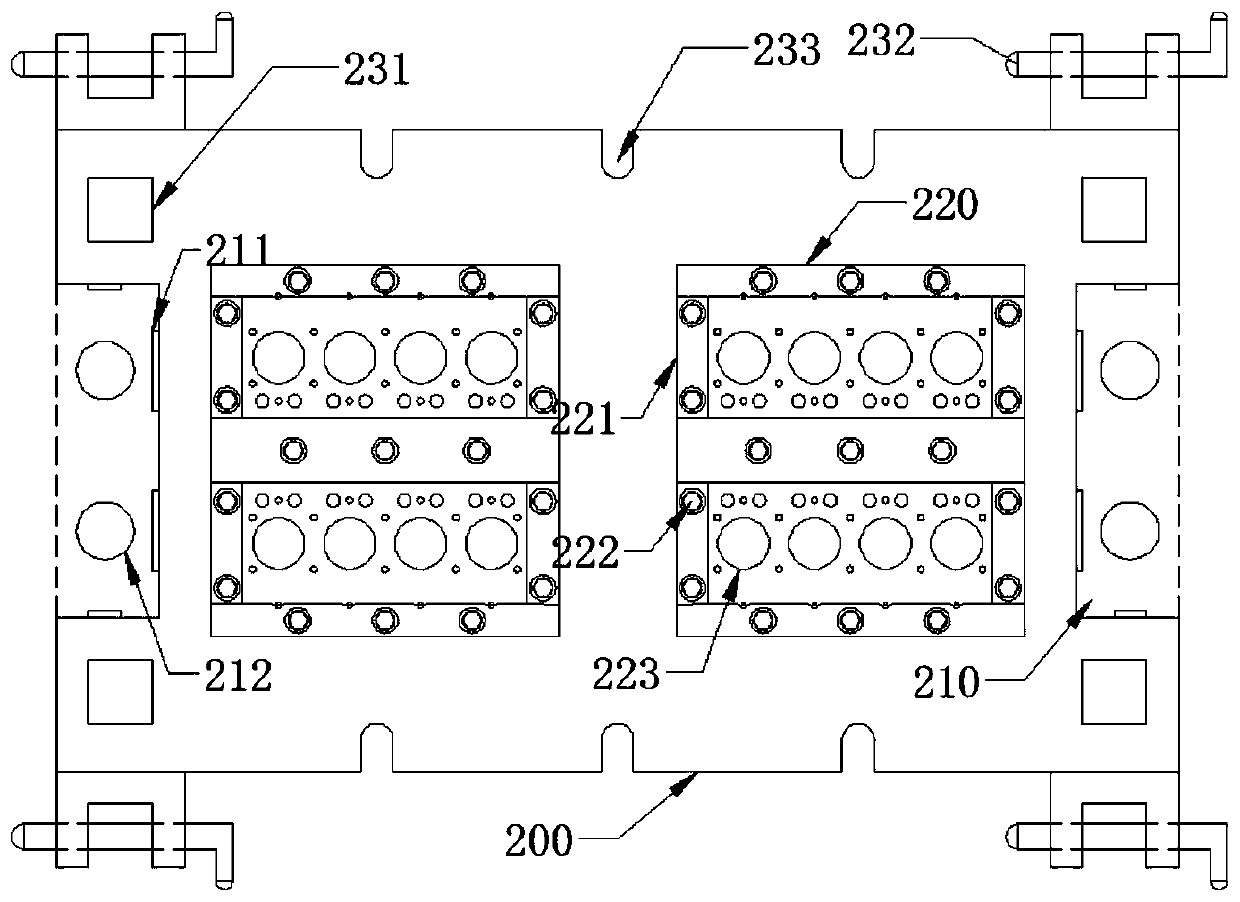

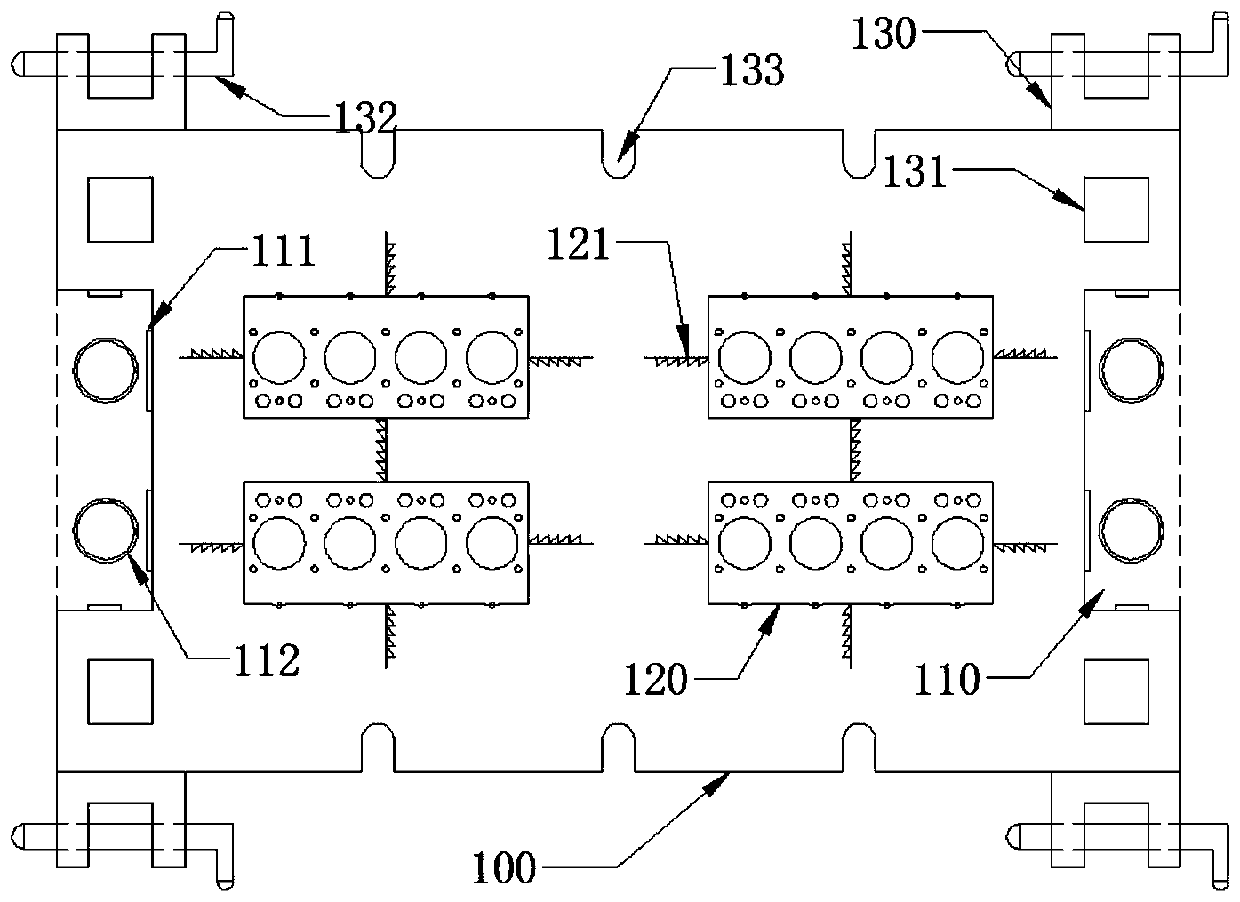

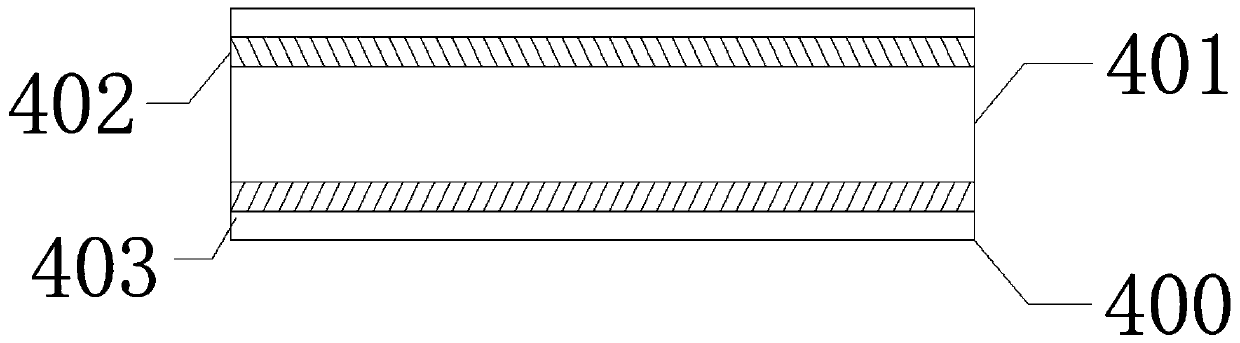

[0032] Thermoforming stage: Pour the mixed and processed raw materials into the mold for raw material production, and use a double-piece thermoforming machine tool to obtain the blank raw material of the cylinder gasket by means of pressure. There are many thermoforming processing methods that are not limited to the double-sheet thermoforming mentioned in the present invention, and there are also counter-molding and differential pressure. The hot pressing condition is to last 25-40 minutes in a high-necked induction heati...

Embodiment example 2

[0041] The specific operation steps of the described a kind of cylinder gasket processing technology are as follows:

[0042] Raw material procurement: the procurement department purchases the required cylinder head gasket production and processing raw materials, iron-based powder 15%-30%, copper-based powder 10%-25%, engine oil 1%-4%, tackifier 0.6%-0.9%, 0.1%-0.4% preservative, 0.3%-0.6% oxidant, 20%-35% graphite, 7%-10% resin, 1%-2.5% friction modifier.

[0043] Thermoforming stage: Pour the mixed and processed raw materials into the mold for raw material production, and use a double-piece thermoforming machine tool to obtain the blank raw material of the cylinder gasket by means of pressure. There are many thermoforming processing methods that are not limited to the double-sheet thermoforming mentioned in the present invention, and there are also counter-molding and differential pressure. The hot pressing condition is to last 25-40 minutes in a high-necked induction heati...

Embodiment example 3

[0051] The specific operation steps of the described a kind of cylinder gasket processing technology are as follows:

[0052] Raw material procurement: the procurement department purchases the required cylinder head gasket production and processing raw materials, iron-based powder 15%-30%, copper-based powder 10%-25%, engine oil 1%-4%, tackifier 0.6%-0.9%, 0.1%-0.4% preservative, 0.3%-0.6% oxidant, 20%-35% graphite, 7%-10% resin, 1%-2.5% friction modifier.

[0053] Thermoforming stage: Pour the mixed and processed raw materials into the mold for raw material production, and use a double-piece thermoforming machine tool to obtain the blank raw material of the cylinder gasket by means of pressure. There are many thermoforming processing methods that are not limited to the double-sheet thermoforming mentioned in the present invention, and there are also counter-molding and differential pressure. The hot pressing condition is to last 25-40 minutes in a high-necked induction heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com