Preparation method of modified ternary anode material

A positive electrode material and modification technology, which is applied in the field of preparation of modified ternary positive electrode materials, can solve the problems of poor cycle stability of ternary positive electrode materials, achieve the effect of improving poor cycle stability and prolonging cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

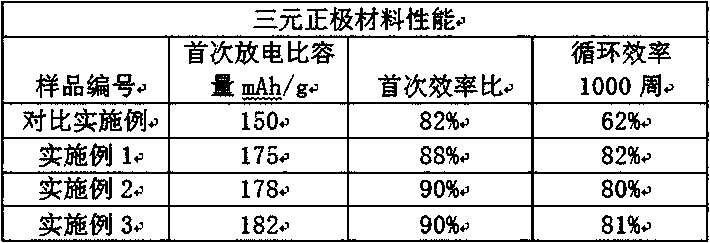

Examples

Embodiment 1

[0021] The preparation method of the modified ternary positive electrode material in this embodiment, the positive electrode material is coated with polyvinylpyrrolidone resin on the ternary positive electrode material, and an amorphous carbon coating layer is formed on the surface of the ternary positive electrode material. Polyvinylpyrrolidone is organic Silicon modified polyvinylpyrrolidone, the ternary cathode material is LiNixCoyMnzO 2 , where 0.3 ≤ x ≤ 1, 0 ≤ y≤ 0.5, 0 ≤ z ≤ 0.5, and x+y+z=1; the specific preparation method includes the following steps:

[0022] (1) Mix 5g modified polyvinylpyrrolidone with 100g LiNi 0.5 co 0.2 mn 0.3 o 2 Ternary cathode material is mixed in the ethanol of 420g to obtain mixture A;

[0023] (2) After stirring for 1 hour at 20°C, filter to obtain mixture B;

[0024] (3) The mixture B was heated and carbonized under the protection of air, the carbonization temperature was 300°C, and the carbonization time was 5 hours. The carbonizatio...

Embodiment 2

[0027] The preparation method of the modified ternary positive electrode material in this embodiment, the positive electrode material is coated with polyvinylpyrrolidone resin on the ternary positive electrode material, and an amorphous carbon coating layer is formed on the surface of the ternary positive electrode material. Polyvinylpyrrolidone is organic Silicon modified polyvinylpyrrolidone, the ternary cathode material is LiNixCoyMnzO 2 , where 0.3 ≤ x ≤ 1, 0 ≤y ≤0.5, 0 ≤ z ≤ 0.5, and x+y+z=1; the specific preparation method includes the following steps:

[0028] (1) Mix 20g modified polyvinylpyrrolidone with 100g LiNi 0.5 co 0.2 mn 0.3 o 2 Ternary cathode material is mixed in the ethanol of 1200g to obtain mixture A;

[0029] (2) Stir at 90°C for 2 hours and then filter to obtain mixture B;

[0030] (3) The mixture B was heated and carbonized in the air atmosphere, the carbonization temperature was 700°C, and the carbonization time was 1h to obtain the mixture C;

...

Embodiment 3

[0033] The preparation method of the modified ternary positive electrode material in this embodiment, the positive electrode material is coated with polyvinylpyrrolidone resin on the ternary positive electrode material, and an amorphous carbon coating layer is formed on the surface of the ternary positive electrode material. Polyvinylpyrrolidone is organic Silicon modified polyvinylpyrrolidone, the ternary cathode material is LiNixCoyMnzO 2 , where 0.3 ≤ x ≤ 1, 0 ≤ y≤ 0.5, 0 ≤ z ≤ 0.5, and x+y+z=1; the specific preparation method includes the following steps:

[0034] (1) Mix 15g modified polyvinylpyrrolidone with 100g LiNi 0.5 co 0.2 mn 0.3 o 2 Ternary cathode material is mixed in the ethanol of 700g to obtain mixture A;

[0035] (2) Stir at 50°C for 1.5h and then filter to obtain mixture B;

[0036] (3) The mixture B was heated and carbonized in the air atmosphere, the carbonization temperature was 500°C, and the carbonization time was 3 hours to obtain the mixture C; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com