Lithium ion battery system with high specific energy and ultra-low-temperature rate discharge

A lithium-ion battery, rate discharge technology, applied in battery electrodes, secondary batteries, battery pack components, etc., can solve problems affecting battery specific energy, low design capacity of lithium cobalt oxide, etc., achieve low temperature advantage prevention, good rate and low temperature performance, the effect of high air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a lithium-ion battery system with high specific energy and ultra-low temperature rate discharge. The positive electrode uses high-voltage lithium cobalt oxide with a particle size D50 of 6 μm, and the charging cut-off voltage is 4.4V. The negative electrode is artificial graphite coated with soft carbon, and the D50 is 8 μm. The electrolyte formula is 1.2M LiPF 6 The weight ratio of EC / DEC / DMC / EMC components is 15:25:25:35, the content of fluorinated ethylene carbonate additive is 5%, and the content of vinyl sulfate is 3%. The ceramic separator is a 12-micron dry-process polypropylene substrate coated with a 4-micron nano-ceramic layer on one side.

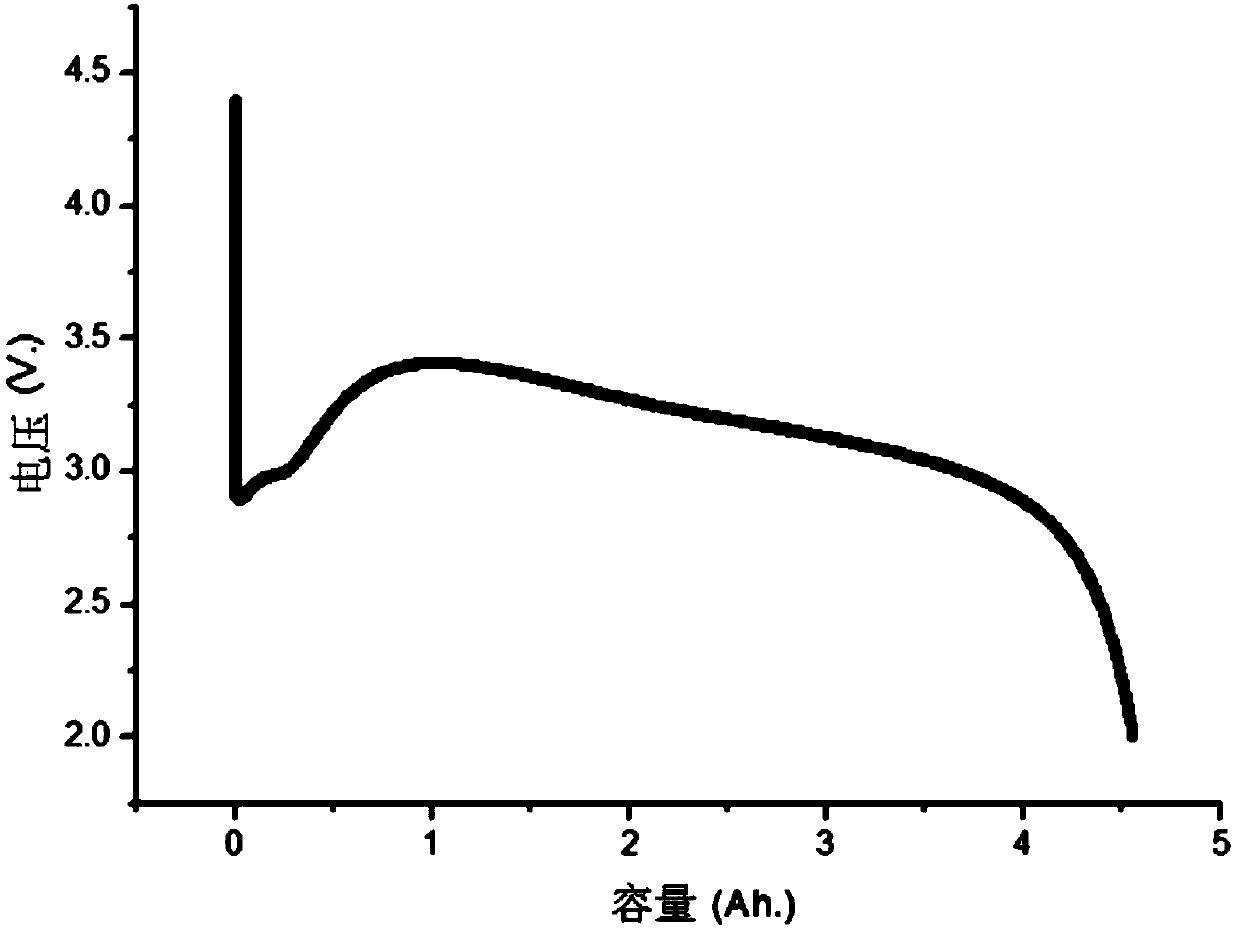

[0032] Such as figure 1 As shown, a 5.6 ampere-hour lithium-ion battery was fabricated according to the above-mentioned system, and its specific energy was calculated to be 238Wh / kg. The 5C continuous discharge capacity efficiency of the battery at -40°C is 80% of the normal temperature capacit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com