A kind of nickel cobalt lithium manganate modified material and its preparation method and application

A technology of nickel-cobalt lithium manganese oxide and modified materials, which is applied in the field of nickel-cobalt lithium manganese oxide modified materials and its preparation, can solve the problems of limited level and lower energy density of nickel-cobalt lithium manganese oxide, and improve the stable phase, Good cycle performance and the effect of improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

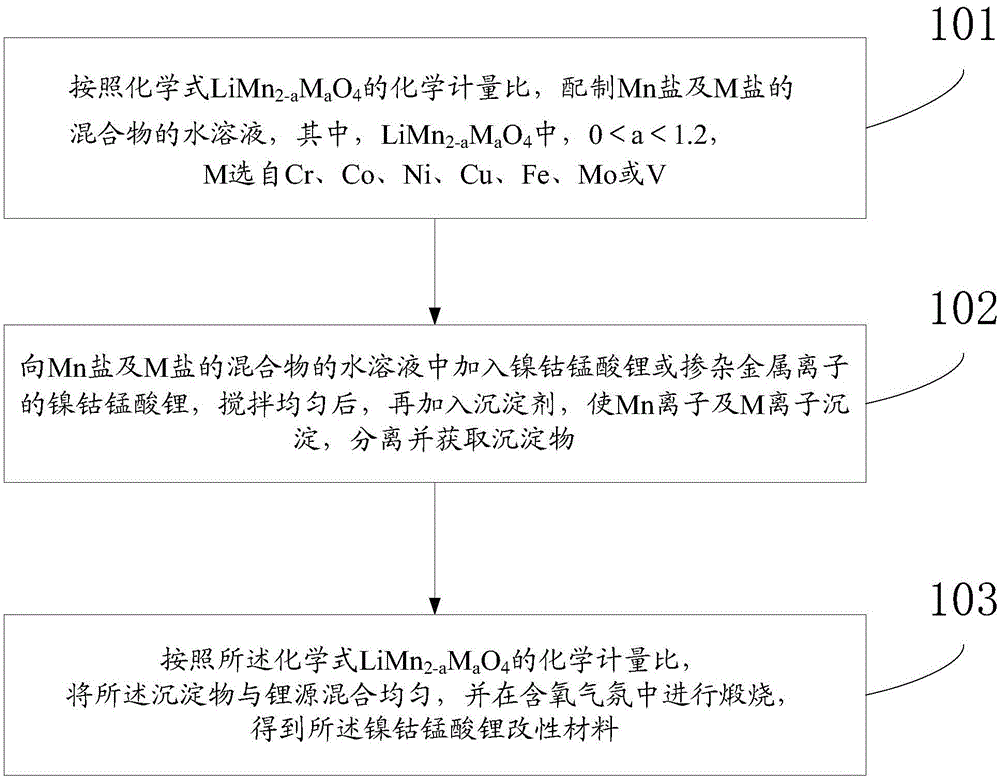

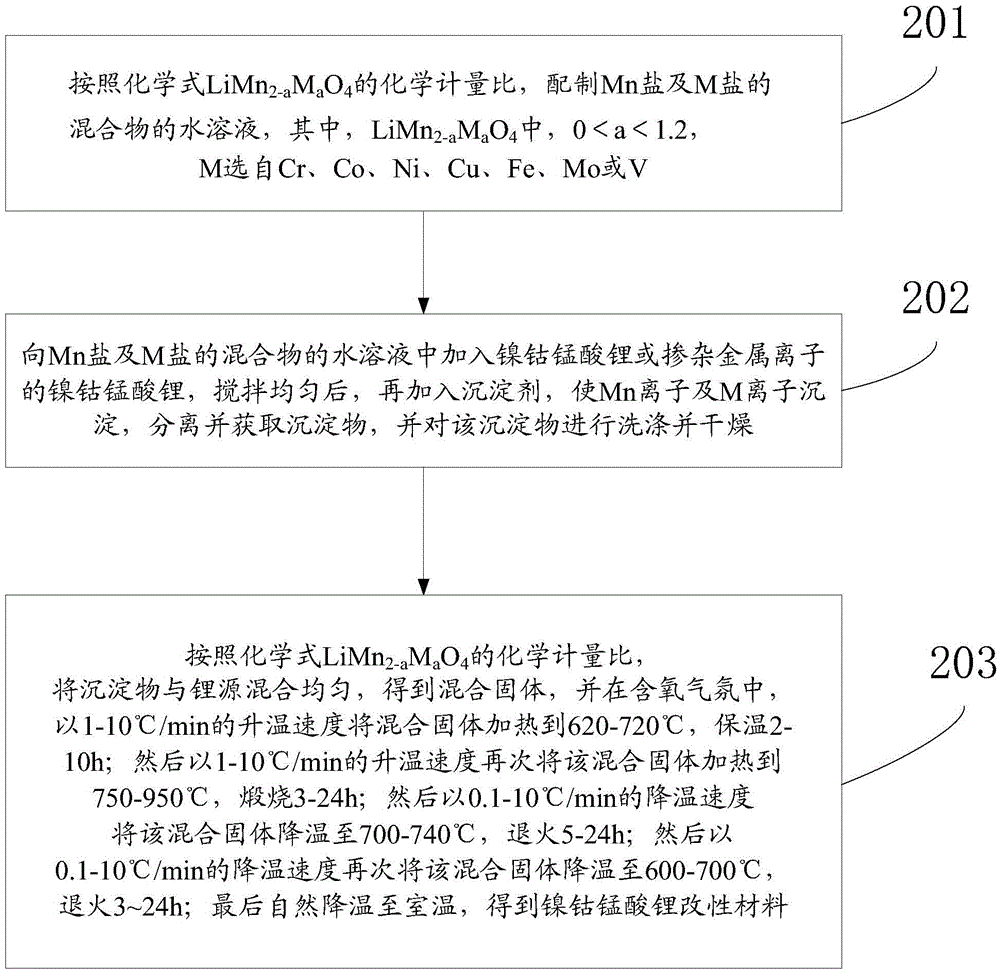

[0049] In the third aspect, the embodiment of the present invention also provides a preparation method of nickel cobalt lithium manganese oxide modified material, with figure 1 For the preparation flow chart of this method, as attached figure 1 As shown, the method includes:

[0050] Step 101, according to the chemical formula LiMn 2-a m a o 4 The stoichiometric ratio, the aqueous solution of the mixture of preparation Mn salt and M salt,

[0051] The LiMn 2-a m a o 4 where 0

[0052] Step 102: Add nickel-cobalt lithium manganate or nickel-cobalt lithium manganate doped with metal ions to the aqueous solution of the mixture of Mn salt and M salt, stir evenly, and then add a precipitant to precipitate Mn ions and M ions , separated and obtained the precipitate.

[0053] Step 103, according to the chemical formula LiMn 2-a m a o 4 The stoichiometric ratio is uniformly mixed with the precipitate and the lithium so...

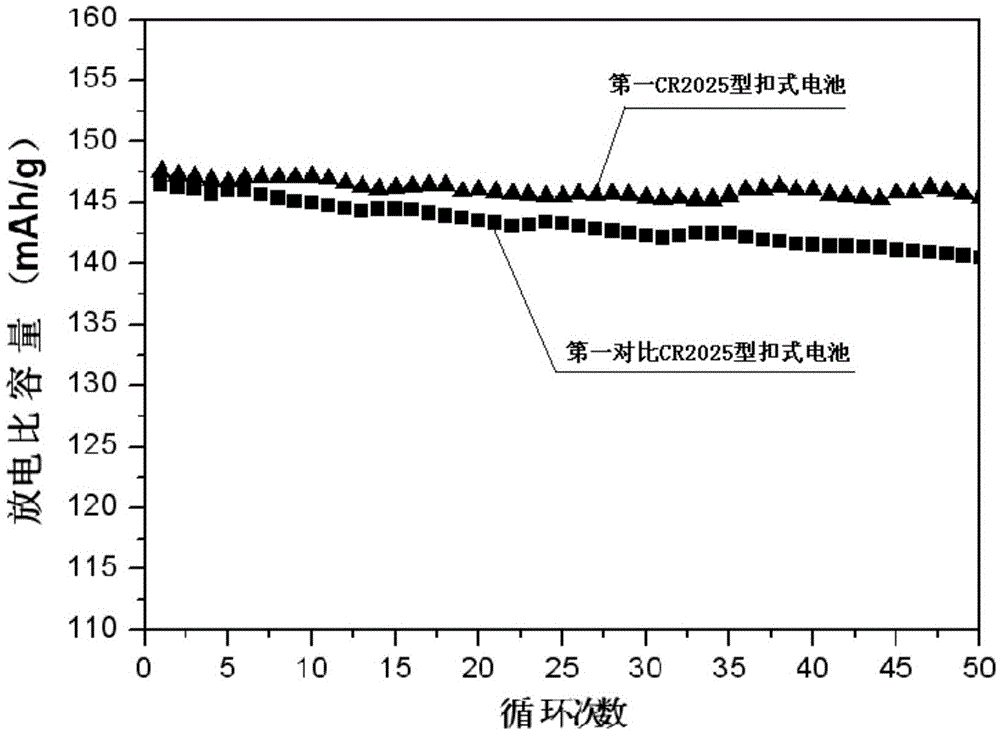

Embodiment 1

[0071] This embodiment provides a LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Modified materials, including: LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , and coated in LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Surface LiNi 0.5 mn 1.5 o 4 , where LiNi 0.5 mn 1.5 o 4 The mass of the LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 2% of the mass of the modified material. The LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The preparation steps of the modified material are as follows:

[0072] Prepare an aqueous solution of a mixture of soluble nickel chloride and manganese sulfate according to the molar ratio Ni:Mn=1:3, and add LiNi to the aqueous solution of the mixture under stirring 1 / 3 co 1 / 3 mn 1 / 3 o 2 , disperse evenly, and then add sodium carbonate dropwise to the mixed solution to completely precipitate the nickel ions and manganese ions, obtain the precipitate by suction filtration, wash the precipitate 3 times, and dry it.

[0073] The above-mentioned dry precipitate and lithium carbonate (Li excess 2%) are mixed uniformly, then ...

Embodiment 2

[0075] This embodiment provides a LiCoO 2 Modified materials, including: LiCoO 2 , and coated in LiCoO 2 Surface LiFe 0.5 mn 1.5 o 4 , where LiFe 0.5 mn 1.5 o 4 The mass of the LiCoO 2 0.2% of the mass of the modified material. The LiCoO 2 The preparation steps of the modified material are as follows:

[0076] Prepare an aqueous solution of a mixture of soluble ferric chloride and manganese sulfate according to the molar ratio Ni:Mn=1:3, and add LiCoO to the aqueous solution of the mixture under stirring 2 , disperse evenly, and then add dropwise oxalic acid to the mixed solution to completely precipitate the iron ions and manganese ions, obtain the precipitate by suction filtration, wash the precipitate 3 times, and dry it.

[0077] Mix the above-mentioned dried precipitate with lithium acetate (5% excess Li), then program temperature control, and calcinate the mixture of the precipitate and lithium acetate in air. The specific calcination process is as follows: he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com